Decoupled Control Design of Aerial Manipulation Systems for Vegetation Sampling Application

Abstract

1. Introduction

2. Modeling of an AMS

2.1. Kinematic Modeling

2.2. Dynamic Modeling

3. Controller Design

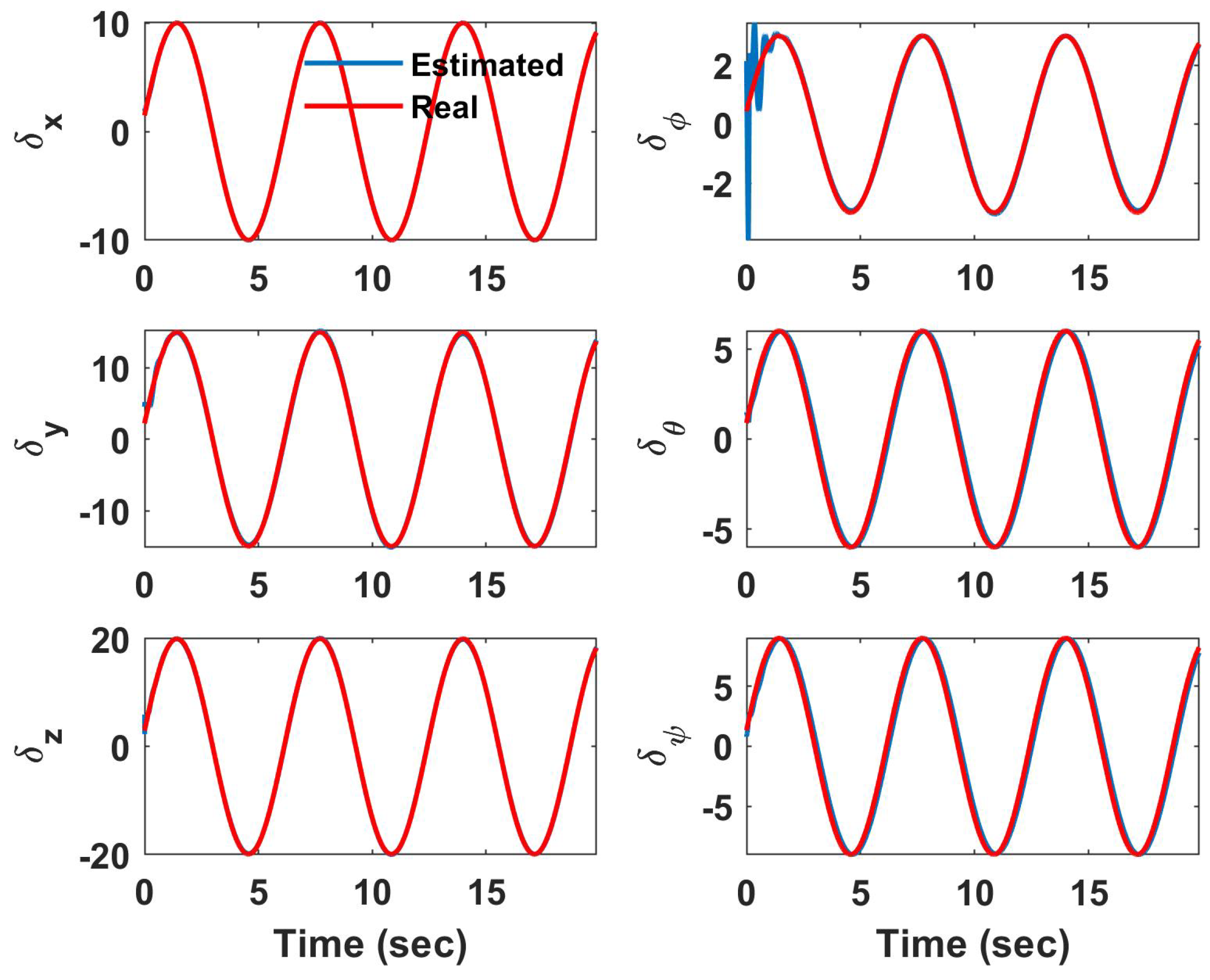

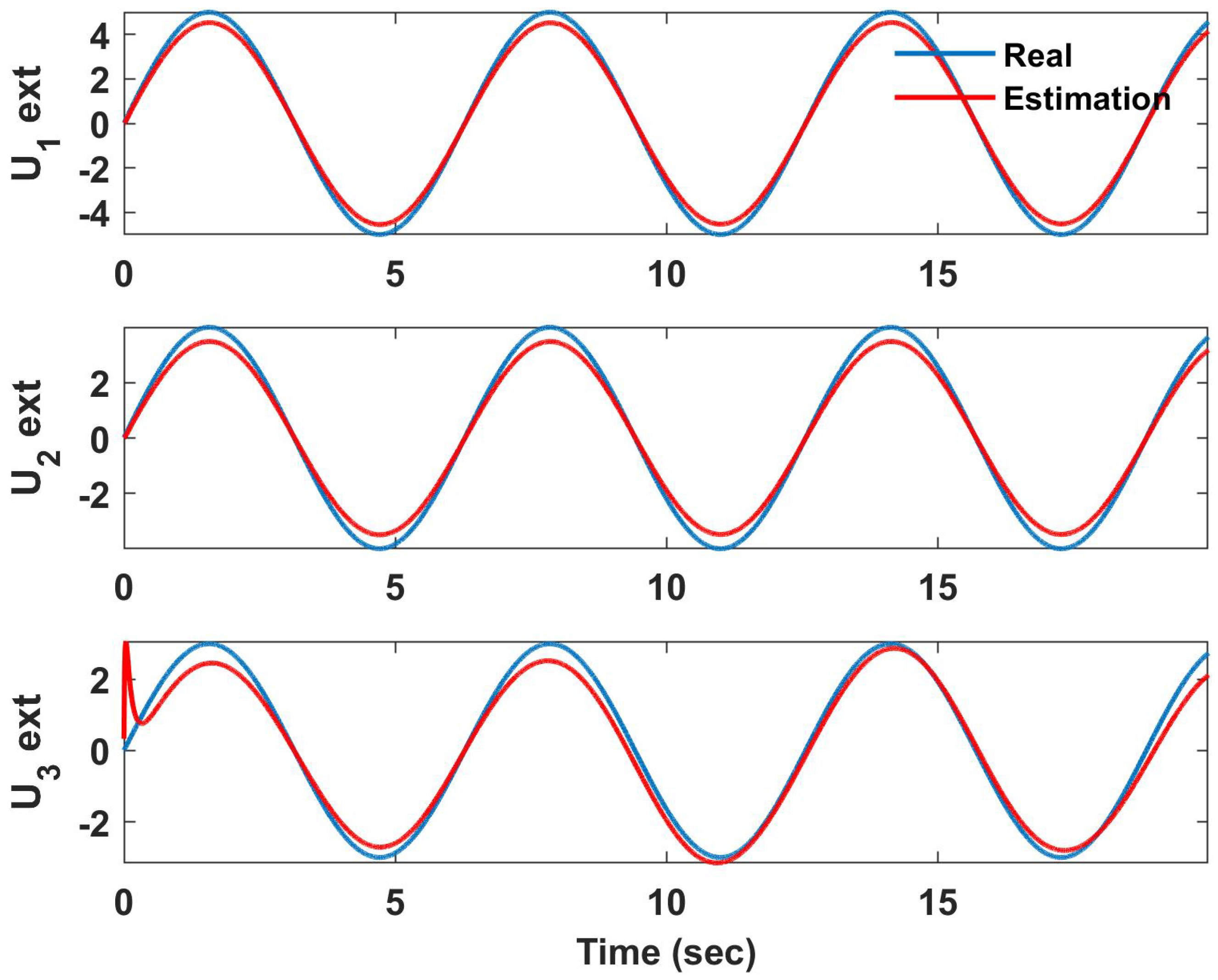

3.1. Disturbance Observer-Based Control

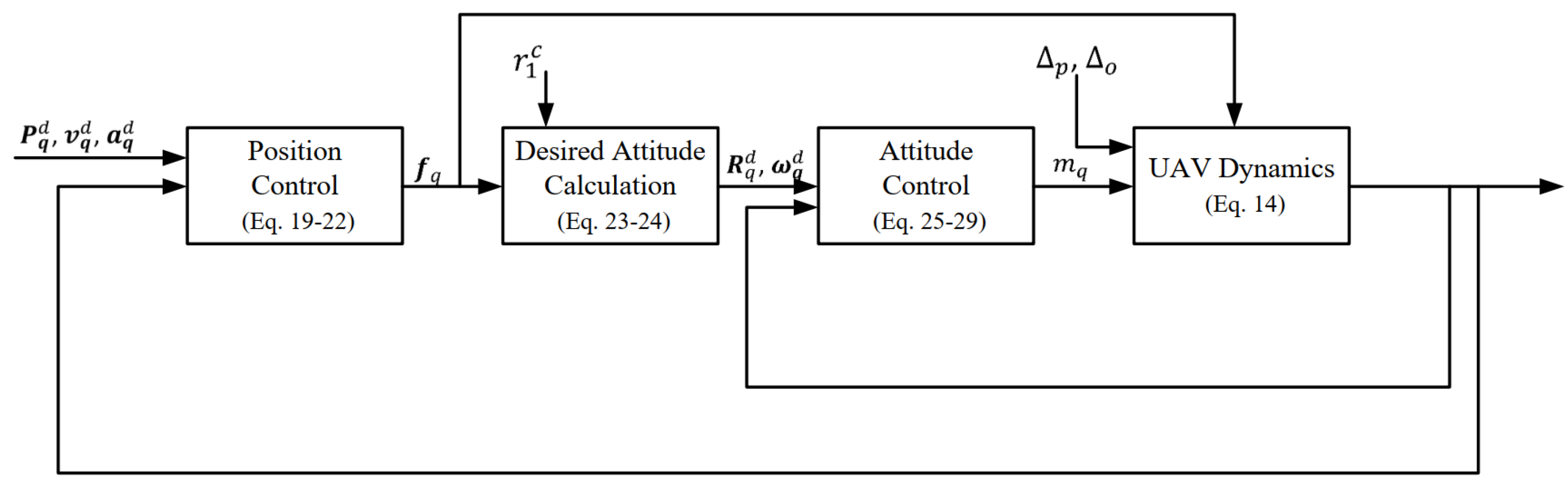

3.1.1. UAV Control

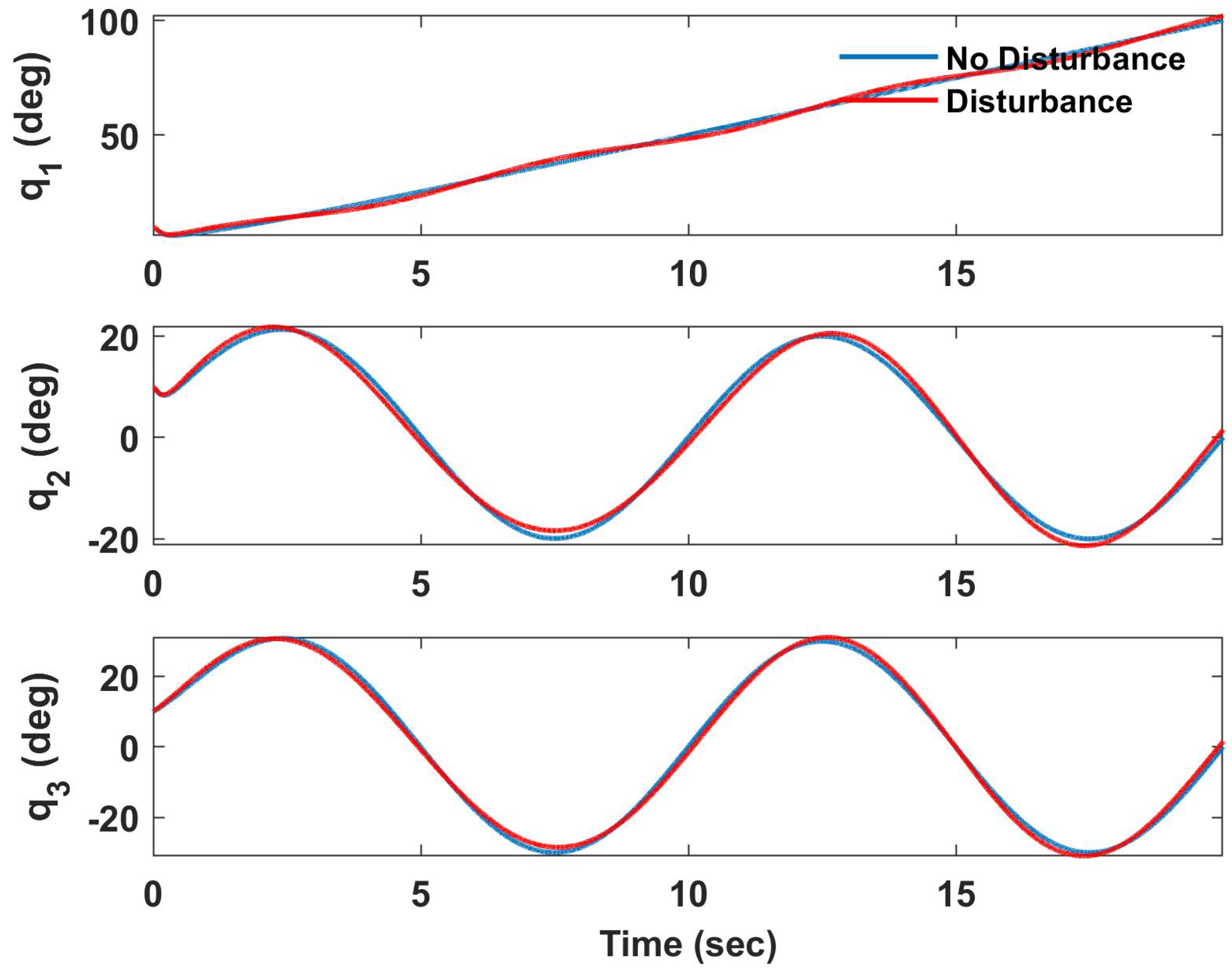

3.1.2. Arm Control

3.2. Adaptive Sliding Mode Control

3.2.1. UAV Control

3.2.2. Arm Control

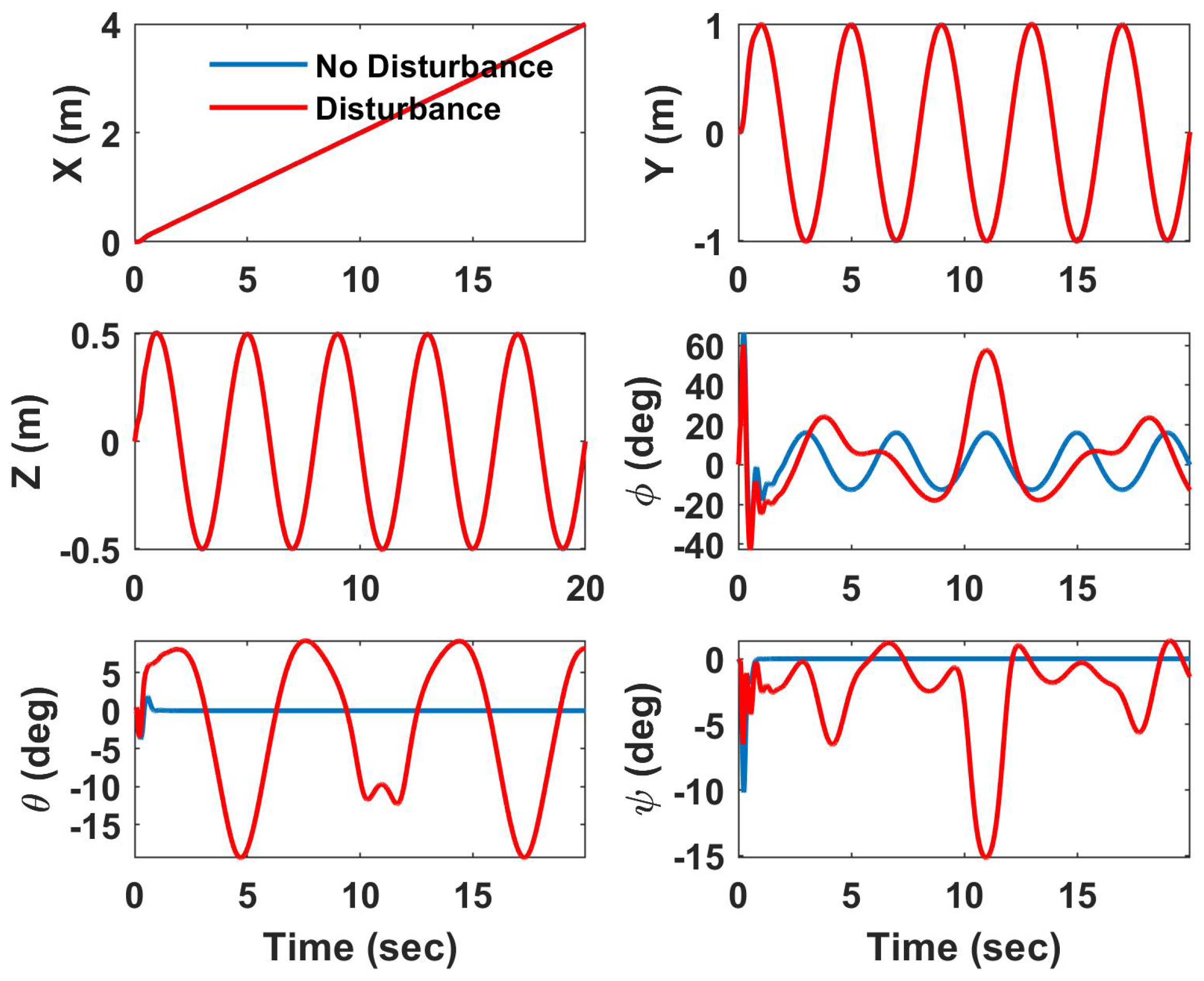

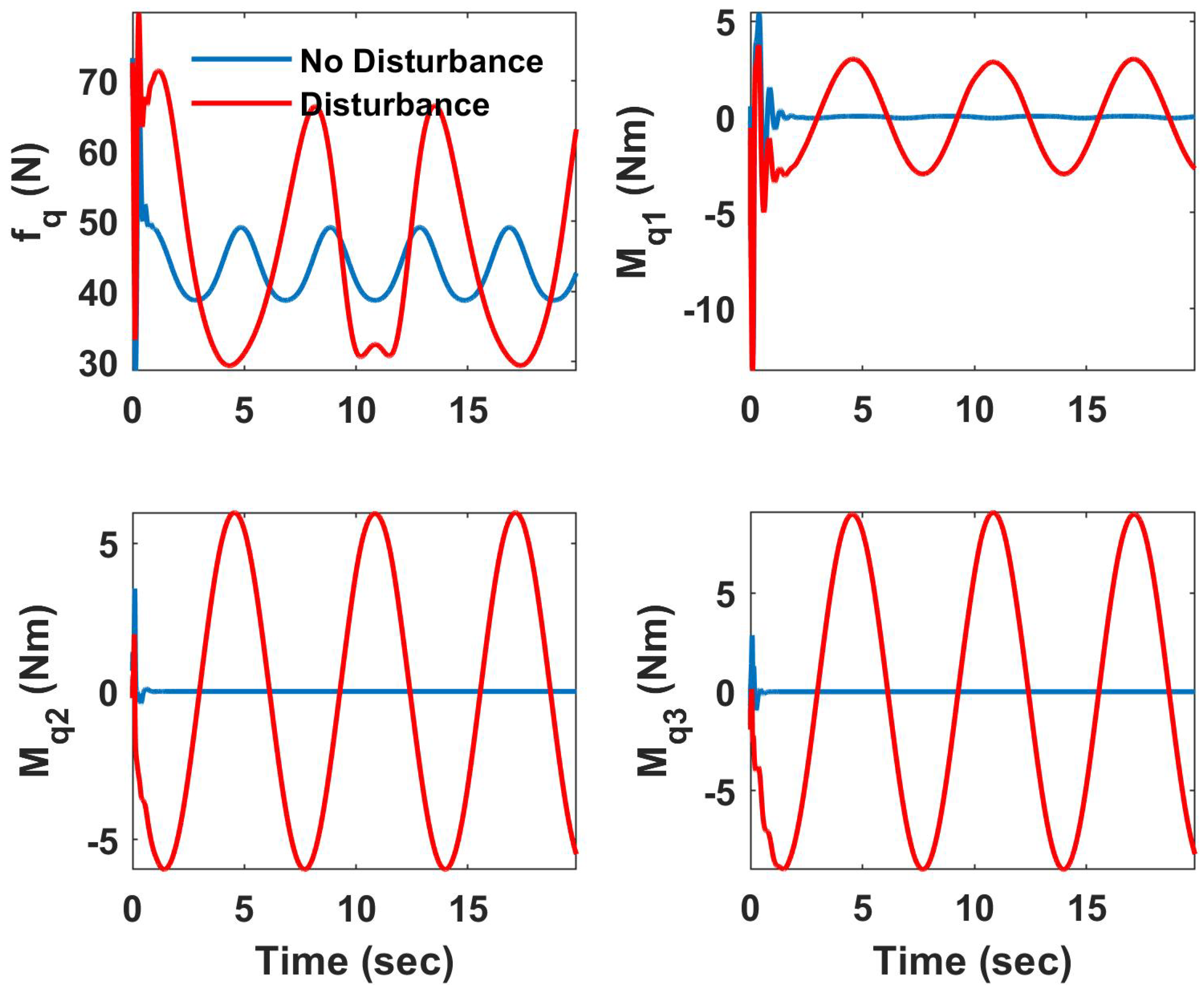

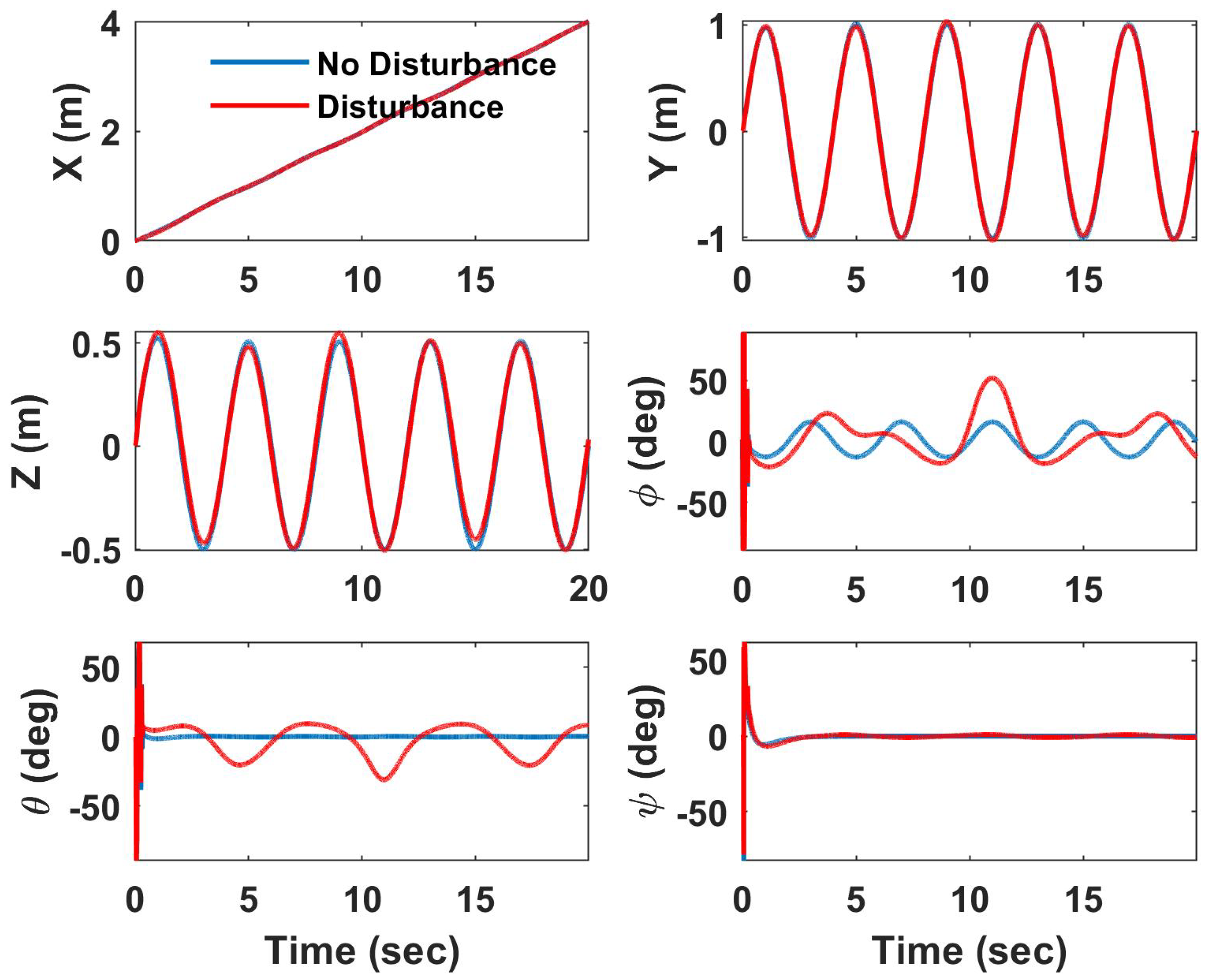

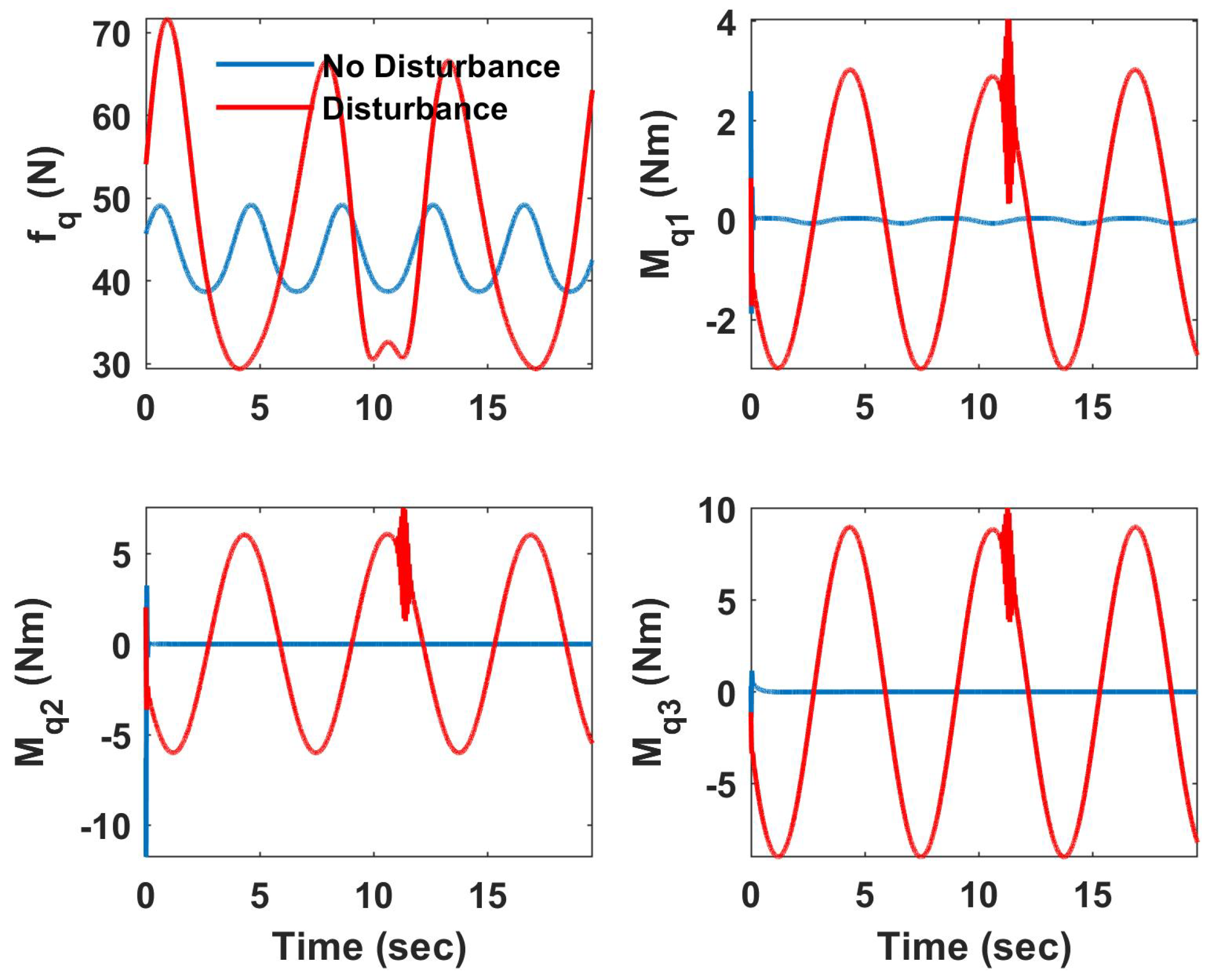

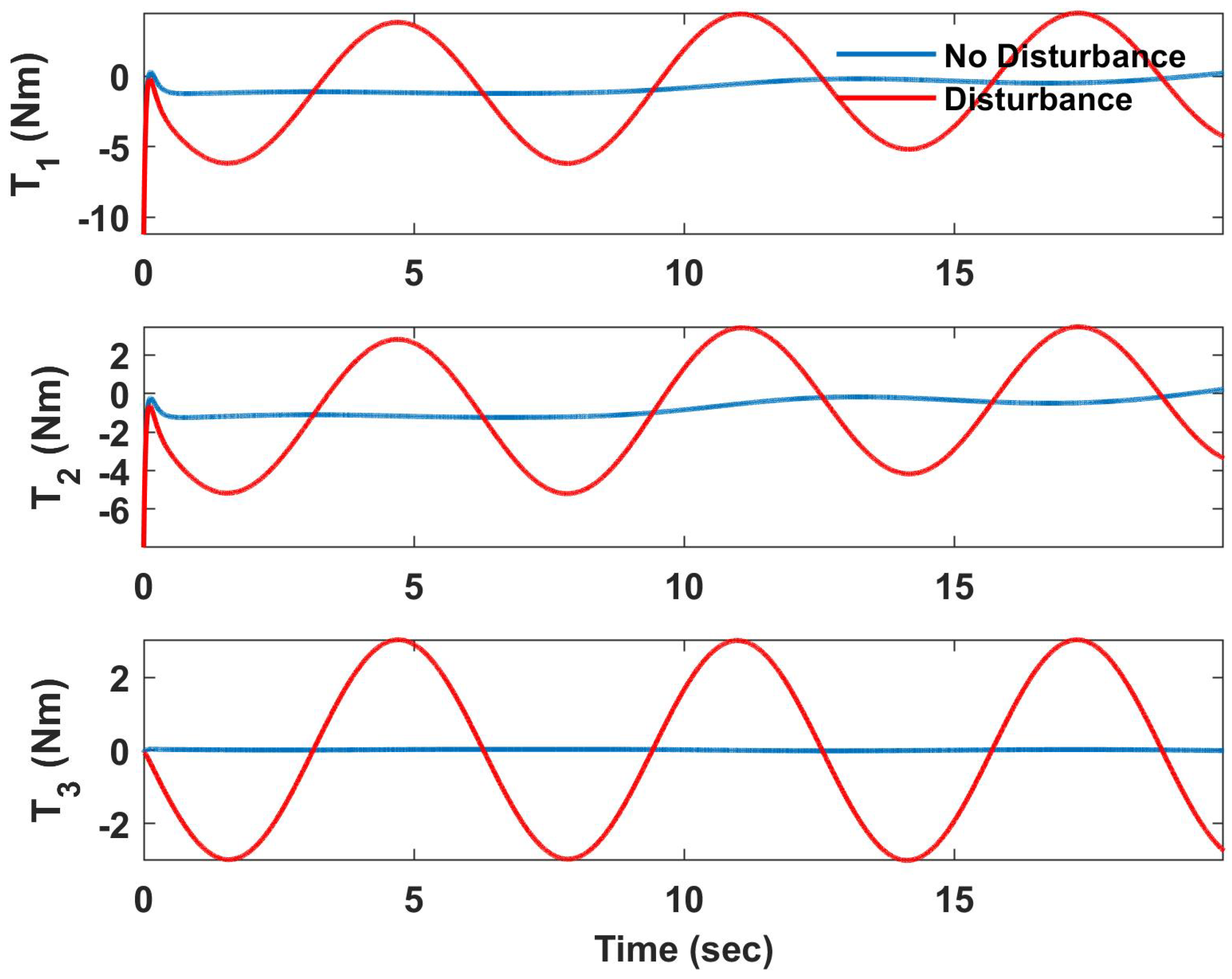

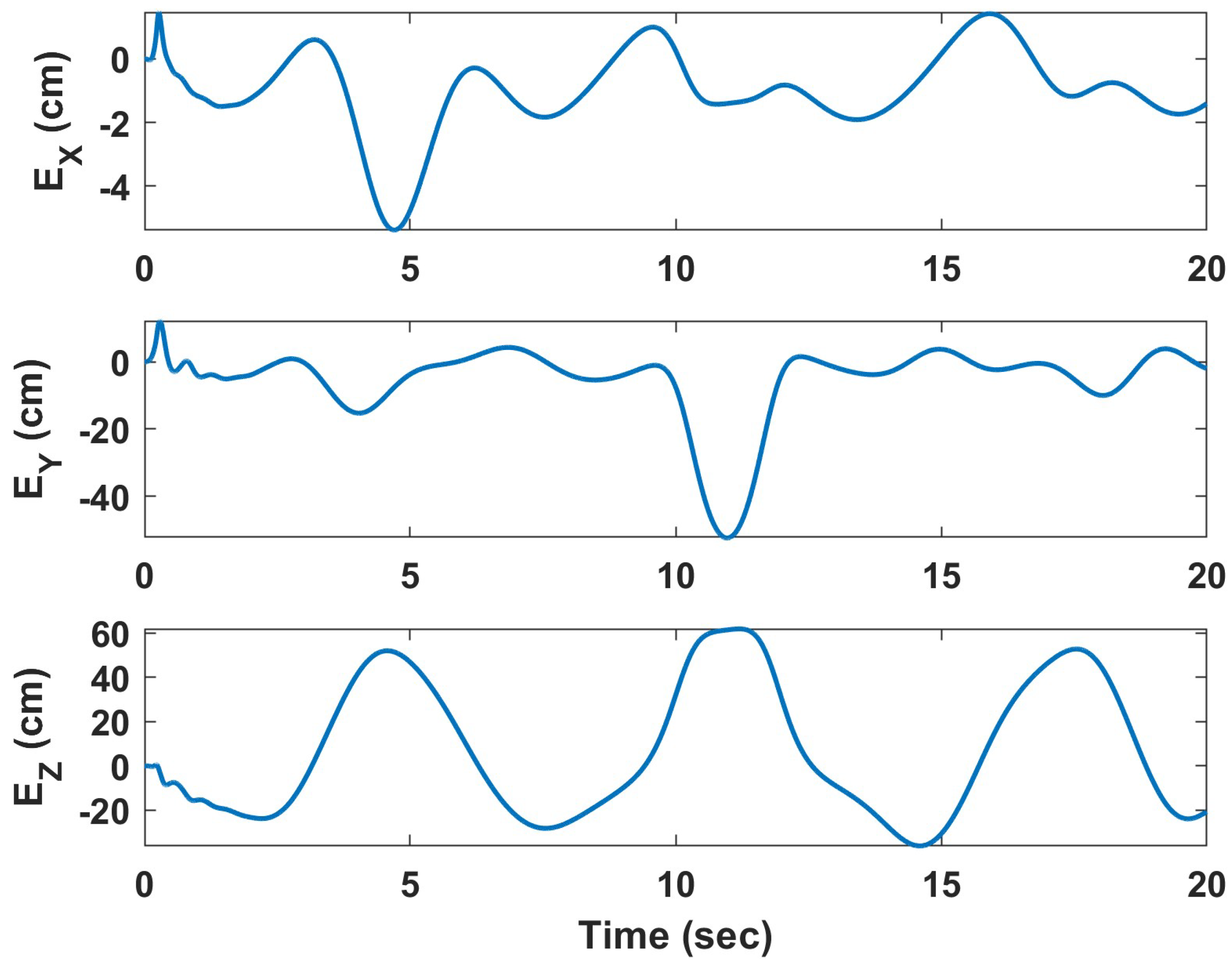

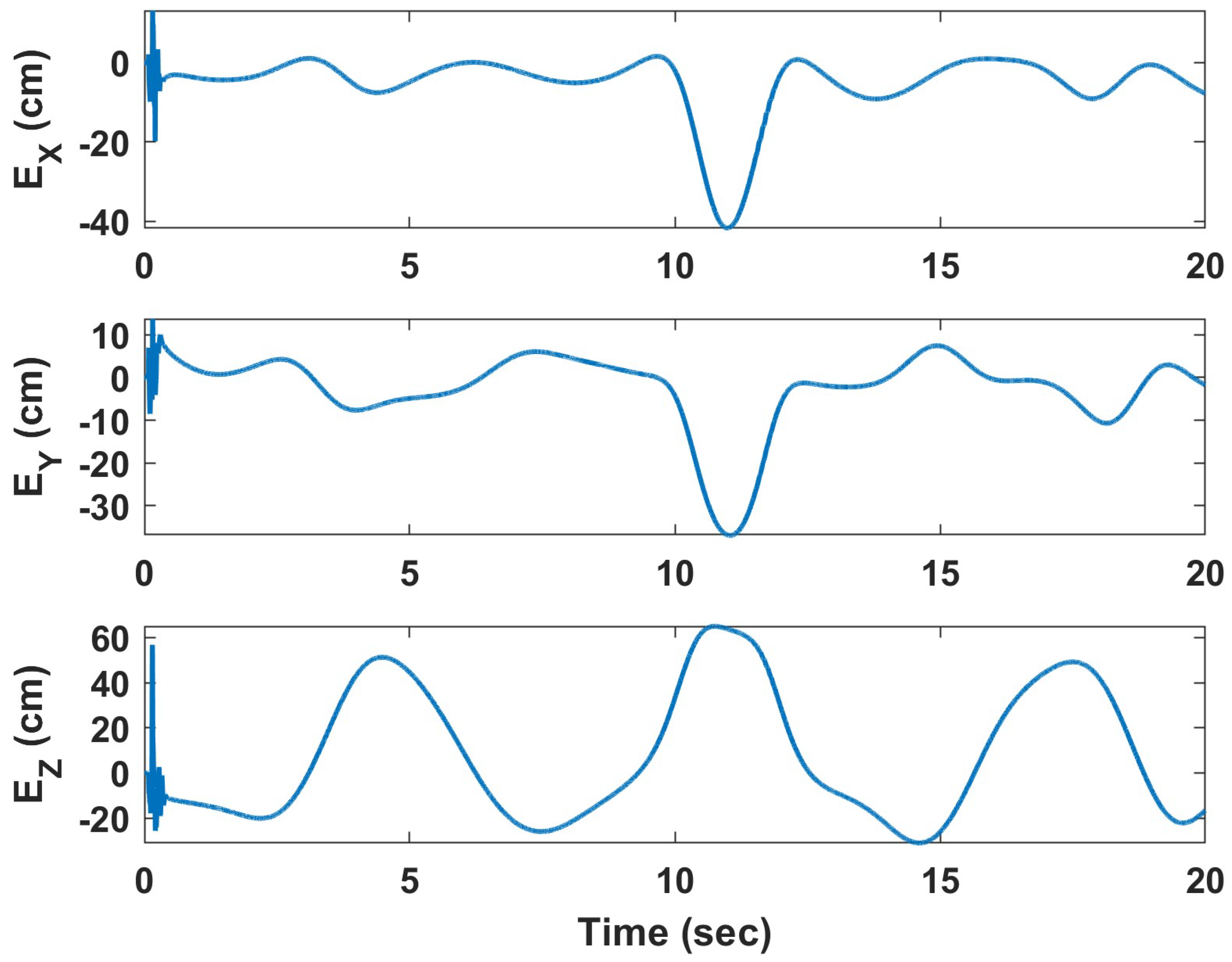

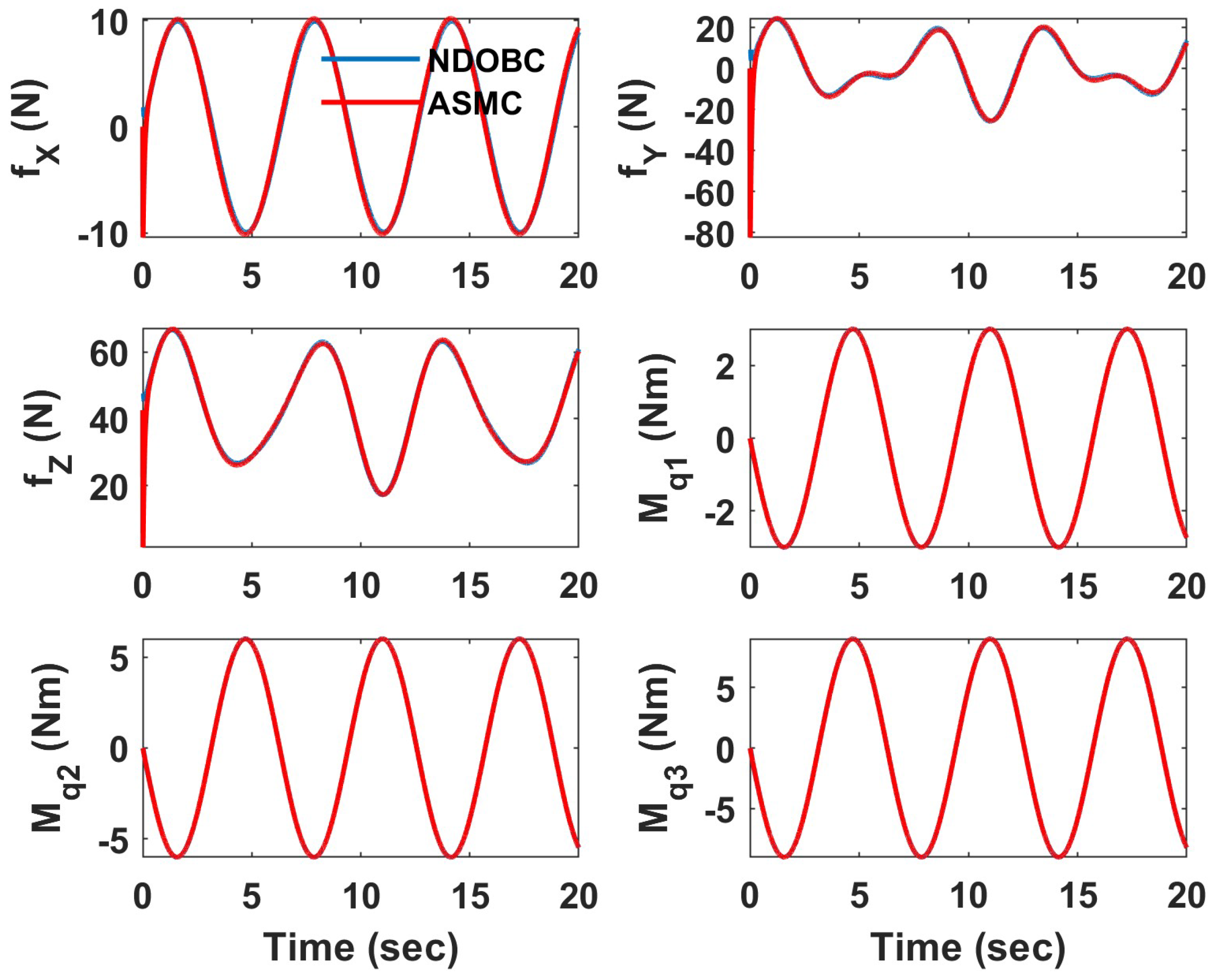

4. Simulation Results

4.1. Helical Trajectory

4.1.1. Underactuated UAV

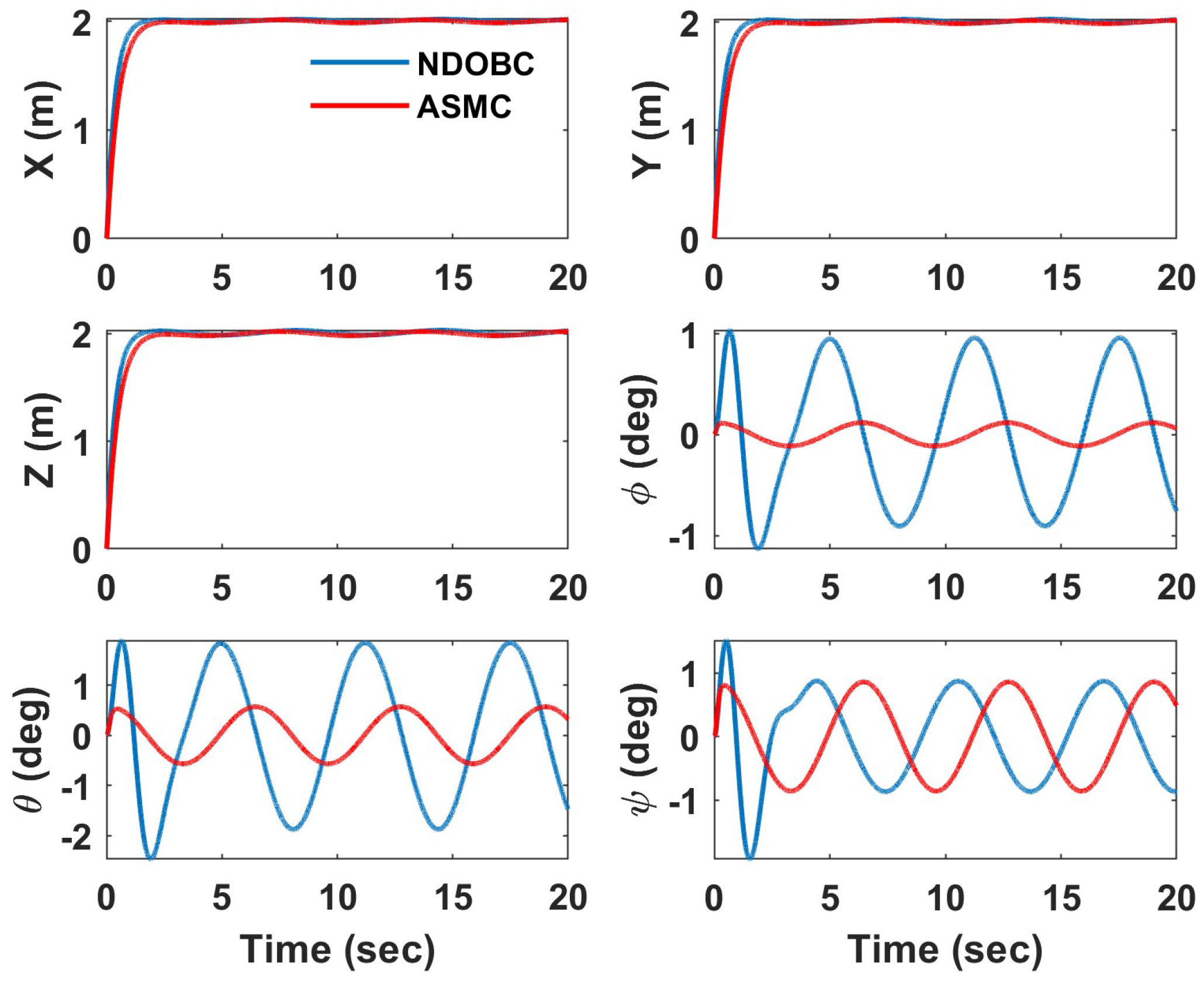

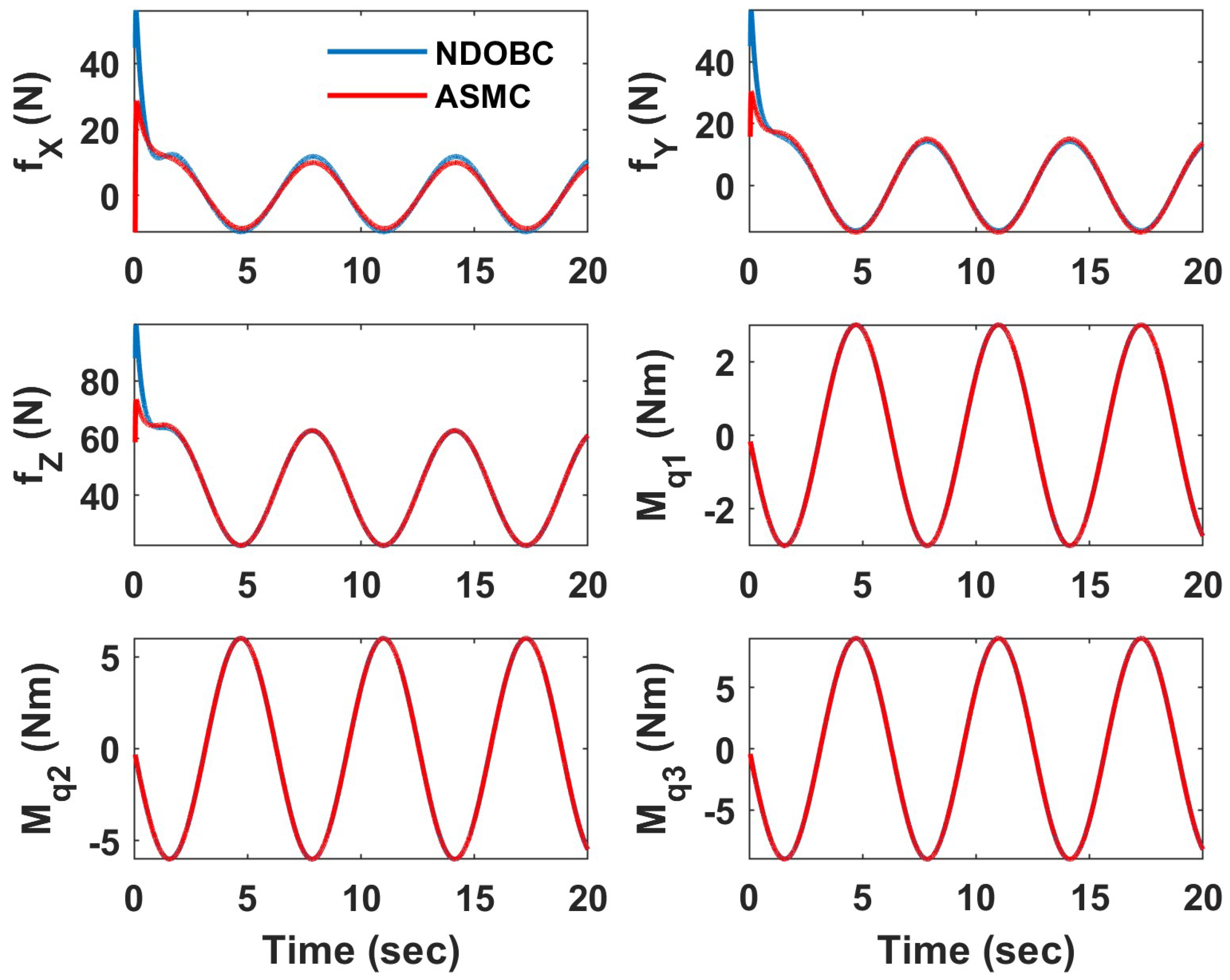

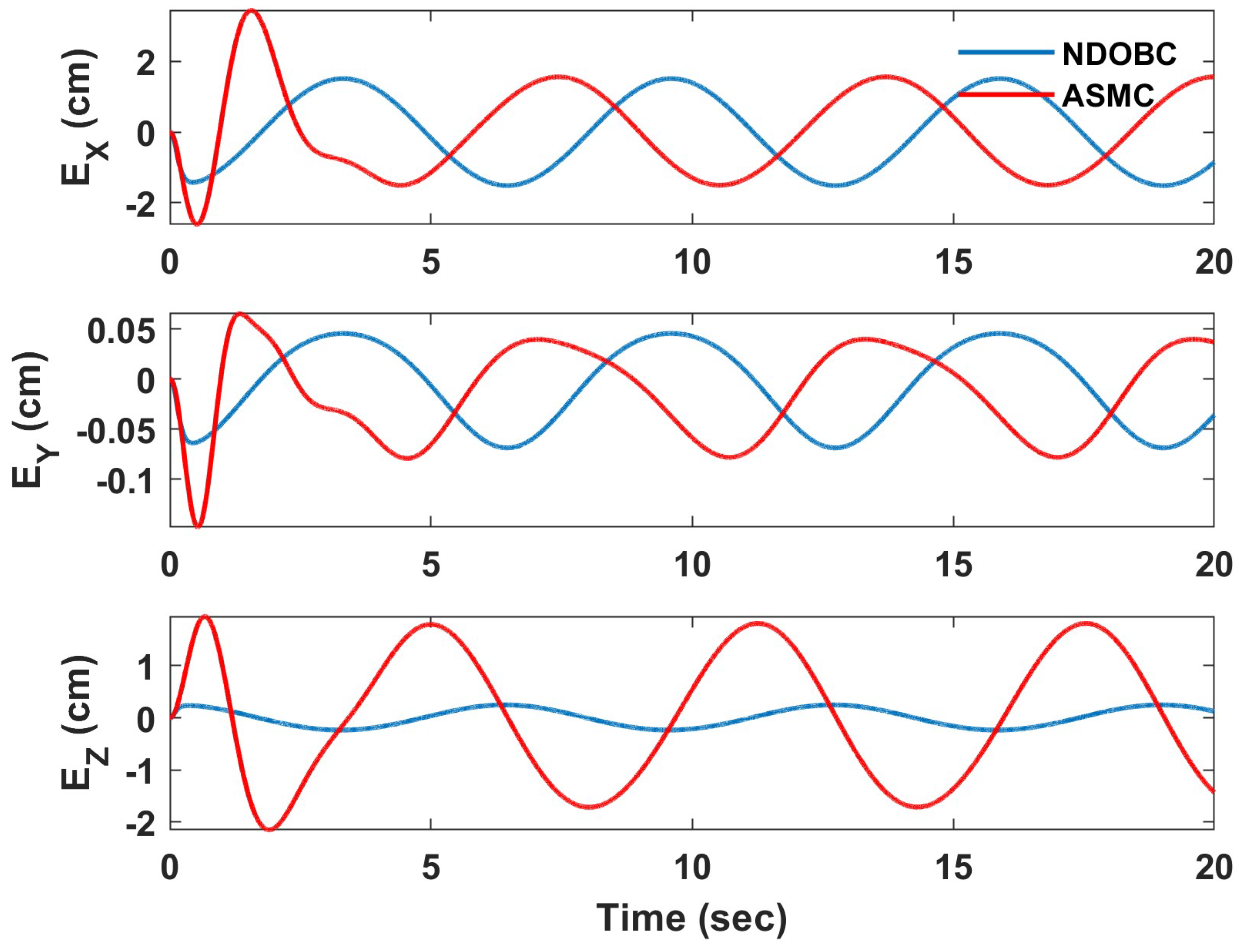

4.1.2. Fully Actuated UAV

4.2. Hover Vegetation Sampling Scenario—Fully Actuated UAV

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AMS | Aerial Manipulation System |

| ASMC | Adaptive Sliding Mode Control |

| NN | Neural Network |

| DO | Disturbance Observer |

| DOB | Disturbance Observer Based |

| EE | End Effector |

| NDOB | Nonlinear Disturbance Observer |

| NDOBC | Nonlinear Disturbance Observer-Based Control |

| SD | Standard Deviation |

| UAV | Unmanned Aerial Vehicle |

References

- Stolaroff, J.K.; Samaras, C.; O’Neill, E.R.; Lubers, A.; Mitchell, A.S.; Ceperley, D. Energy use and life cycle greenhouse gas emissions of drones for commercial package delivery. Nat. Commun. 2018, 9, 409. [Google Scholar] [CrossRef] [PubMed]

- Trujillo, M.Á.; Martínez-de Dios, J.R.; Martín, C.; Viguria, A.; Ollero, A. Novel aerial manipulator for accurate and robust industrial NDT contact inspection: A new tool for the oil and gas inspection industry. Sensors 2019, 19, 1305. [Google Scholar] [CrossRef] [PubMed]

- Brescianini, D.; D’Andrea, R. Computationally efficient trajectory generation for fully actuated multirotor vehicles. IEEE Trans. Robot. 2018, 34, 555–571. [Google Scholar] [CrossRef]

- Shimahara, S.; Leewiwatwong, S.; Ladig, R.; Shimonomura, K. Aerial torsional manipulation employing multi-rotor flying robot. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; pp. 1595–1600. [Google Scholar]

- Lee, D.; Jang, D.; Seo, H.; Kim, H.J. Model predictive control for an aerial manipulator opening a hinged door. In Proceedings of the 19th International Conference on Control, Automation and Systems (ICCAS), Jeju, Republic of Korea, 15–18 October 2019; pp. 986–991. [Google Scholar]

- Thomas, J.; Loianno, G.; Sreenath, K.; Kumar, V. Toward image based visual servoing for aerial grasping and perching. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–5 June 2014; pp. 2113–2118. [Google Scholar]

- Mellinger, D.; Lindsey, Q.; Shomin, M.; Kumar, V. Design, modeling, estimation and control for aerial grasping and manipulation. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; pp. 2668–2673. [Google Scholar]

- Kutia, J.R.; Stol, K.A.; Xu, W. Aerial manipulator interactions with trees for canopy sampling. IEEE ASME Trans. Mechatron. 2018, 23, 1740–1749. [Google Scholar] [CrossRef]

- Kutia, J.R.; Stol, K.A.; Xu, W. Initial flight experiments of a canopy sampling aerial manipulato. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Arlington, VA, USA, 7–10 June 2016; pp. 1359–1365. [Google Scholar]

- Xu, H.; Yang, Z.; Zhou, G.; Liao, L.; Xu, C.; Wu, J.; Zhang, Q.; Zhang, C. A Novel Aerial Manipulator with Front Cutting Effector: Modeling, Control, and Evaluation. Complexity 2021, 2021, 5695681. [Google Scholar] [CrossRef]

- Kutia, J.R.; Stol, K.A.; Xu, W. Canopy sampling using an aerial manipulator: A preliminary study. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Denver, CO, USA, 9–12 June 2015; pp. 477–484. [Google Scholar]

- Busch, C.A.M.; Stol, K.A.; Van der Mark, W. Dynamic tree branch tracking for aerial canopy sampling using stereo vision. Comput. Electron. Agric. 2021, 182, 106007. [Google Scholar] [CrossRef]

- Chen, W.; Yang, J.; Guo, L.; Li, S. Disturbance-observer-based control and related methods—An overview. IEEE Trans. Ind. Electron. 2015, 63, 1083–1095. [Google Scholar] [CrossRef]

- Samadikhoshkho, Z.; Ghorbani, S.; Janabi-Sharifi, F.; Zareinia, K. Nonlinear control of aerial manipulation systems. Aerosp. Sci. Technol. 2020, 104, 105945. [Google Scholar] [CrossRef]

- Caccavale, F.; Giglio, G.; Muscio, G.; Pierri, F. Adaptive control for UAVs equipped with a robotic arm. IFAC Proc. Vol. 2014, 47, 11049–11054. [Google Scholar] [CrossRef]

- Yilmaz, E.; Zaki, H.; Unel, M. Nonlinear adaptive control of an aerial manipulation system. In Proceedings of the 18th IEEE European Control Conference (ECC), Naples, Italy, 25–28 June 2019; pp. 3916–3921. [Google Scholar]

- Song, X.; Hu, S. Hierarchy-Based Adaptive Generalized Predictive Control for Aerial Grasping of a Quadrotor Manipulator. Science 2019, 24, 451–458. [Google Scholar] [CrossRef]

- Pierri, F.; Muscio, G.; Caccavale, F. An adaptive hierarchical control for aerial manipulators. Robotica 2018, 36, 1527–1550. [Google Scholar] [CrossRef]

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Robotics: Modeling, Planning, and Control, 1st ed.; Springer: London, UK, 2009. [Google Scholar]

- Lee, T.; Leok, M.; McClamroch, N.H. Nonlinear robust tracking control of a quadrotor UAV on SE (3). Asian J. Control 2013, 15, 391–408. [Google Scholar] [CrossRef]

| x (cm) | y (cm) | z (cm) | (deg) | (deg) | (deg) | |

|---|---|---|---|---|---|---|

| Mean | 0.133 | 0.418 | 0.132 | 13.624 | 8.001 | 2.683 |

| SD | 0.169 | 0.505 | 0.202 | 16.156 | 9.186 | 3.528 |

| x (cm) | y (cm) | z (cm) | (deg) | (deg) | (deg) | |

|---|---|---|---|---|---|---|

| Mean | 0.471 | 1.716 | 2.226 | 13.071 | 9.557 | 0.693 |

| SD | 0.558 | 1.913 | 2.405 | 15.206 | 11.395 | 0.895 |

| (deg) | (deg) | (deg) | |

|---|---|---|---|

| Mean | 0.1584 | 0.1750 | 0.0574 |

| SD | 0.1766 | 0.1950 | 0.0650 |

| (deg) | (deg) | (deg) | |

|---|---|---|---|

| Mean | 0.1918 | 0.9528 | 1.0383 |

| SD | 1.3336 | 1.0661 | 1.1556 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samadikhoshkho, Z.; Lipsett, M. Decoupled Control Design of Aerial Manipulation Systems for Vegetation Sampling Application. Drones 2023, 7, 110. https://doi.org/10.3390/drones7020110

Samadikhoshkho Z, Lipsett M. Decoupled Control Design of Aerial Manipulation Systems for Vegetation Sampling Application. Drones. 2023; 7(2):110. https://doi.org/10.3390/drones7020110

Chicago/Turabian StyleSamadikhoshkho, Zahra, and Michael Lipsett. 2023. "Decoupled Control Design of Aerial Manipulation Systems for Vegetation Sampling Application" Drones 7, no. 2: 110. https://doi.org/10.3390/drones7020110

APA StyleSamadikhoshkho, Z., & Lipsett, M. (2023). Decoupled Control Design of Aerial Manipulation Systems for Vegetation Sampling Application. Drones, 7(2), 110. https://doi.org/10.3390/drones7020110