Condition Monitoring of the Torque Imbalance in a Dual-Stator Permanent Magnet Synchronous Motor for the Propulsion of a Lightweight Fixed-Wing UAV

Abstract

:1. Introduction

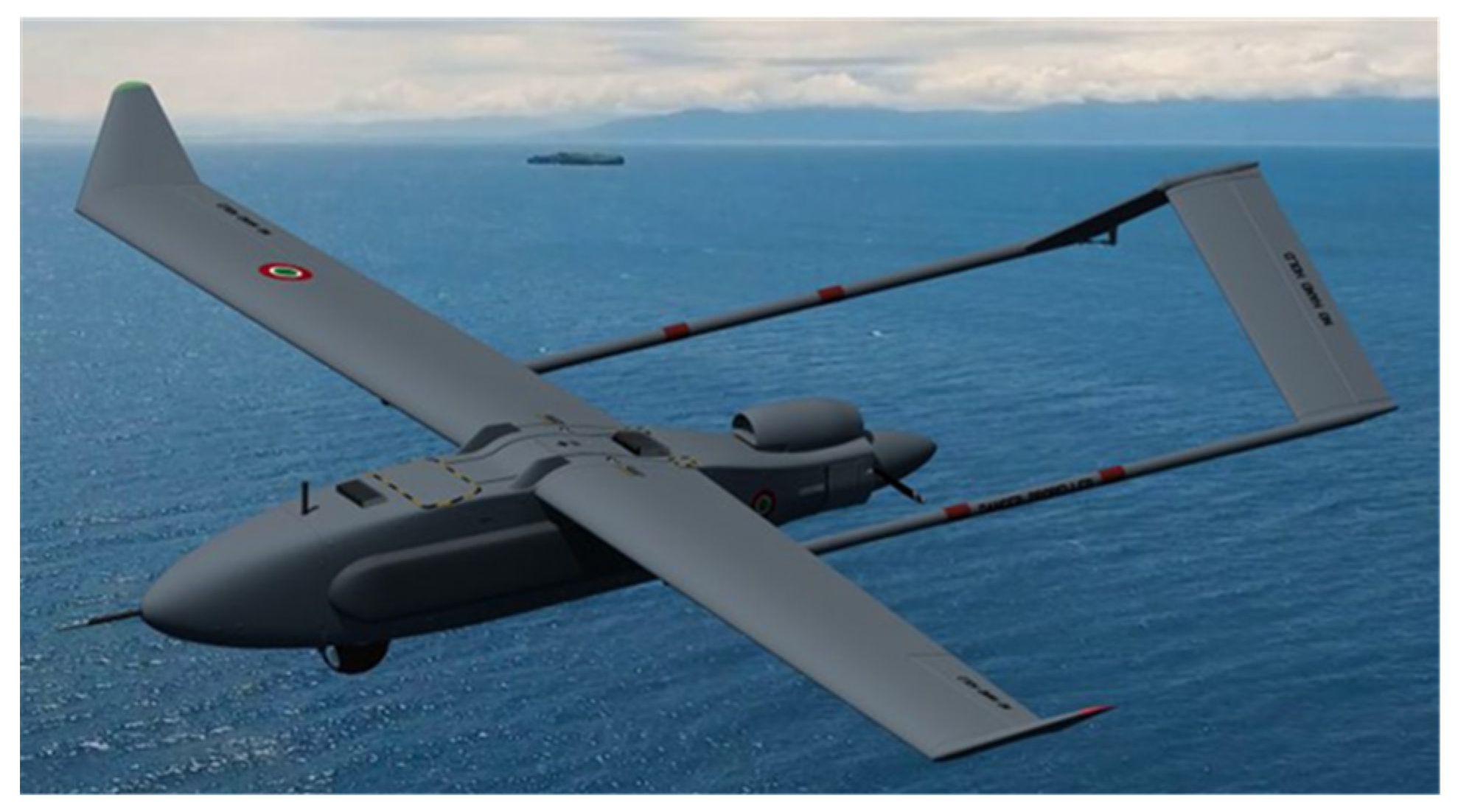

1.1. Research Context

- Mass (including payloads): 35 kg;

- Take-off/landing system: pneumatic launcher and parachute/airbags;

- Propulsion system: fixed-pitch twin-blade propeller driven by dual-redundant FEPS (3.5 kW maximum power);

- Relevant payloads: Synthetic Aperture Radar and Sense-And-Avoid System;

- Cruise speed: 26 m/s;

- Flight endurance: 6 h;

- Data-link operational range: 100 km;

- Radar ground swath range: 3 km (0.2 m image reconstruction accuracy).

1.2. Full-Electric Propulsion Requirements

1.3. Torque Imbalance between Stator Modules

- non-periodic, when related to

- ○

- uniform demagnetization of a module;

- ○

- misalignment of electrical angle due to sensor offset or imperfections of the stator–rotor coupling;

- periodic, when related to

- ○

- different air gap eccentricity;

- ○

- local demagnetization;

- ○

- cogging disturbances;

- ○

- variation of electrical parameters;

- ○

- local damages on mechanical parts and bearings.

2. Materials and Methods

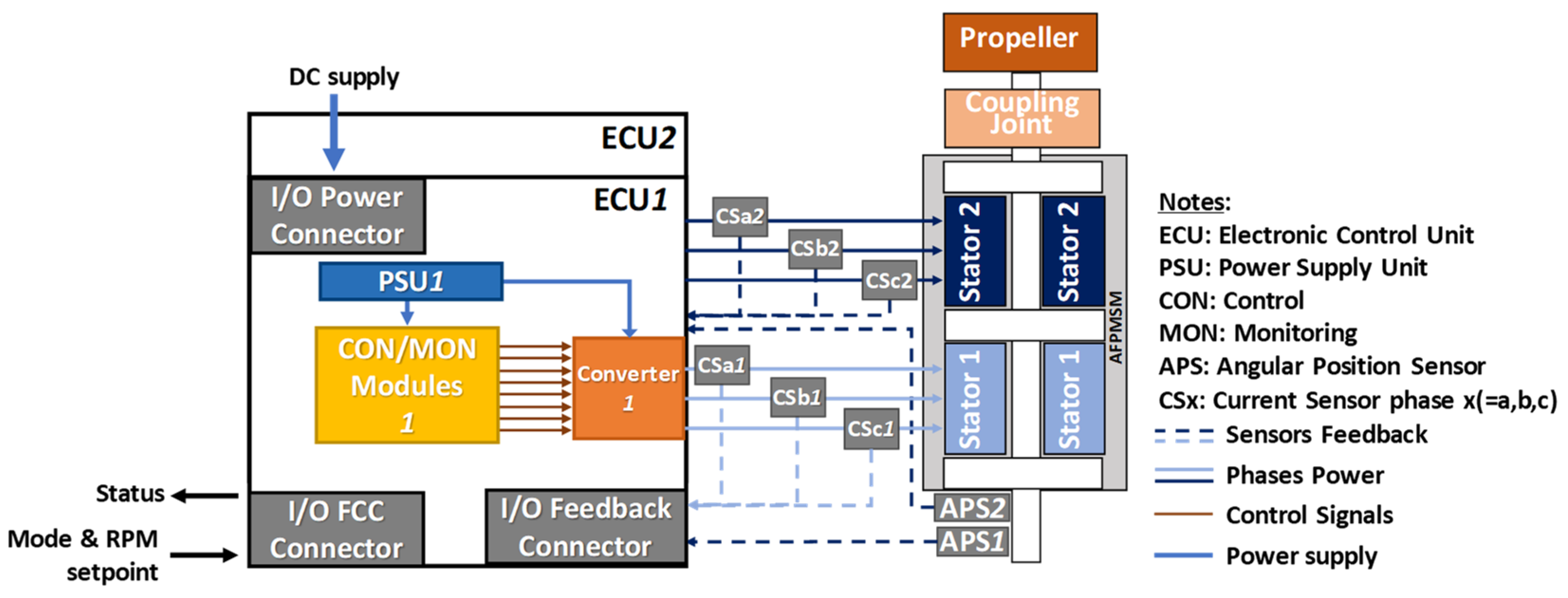

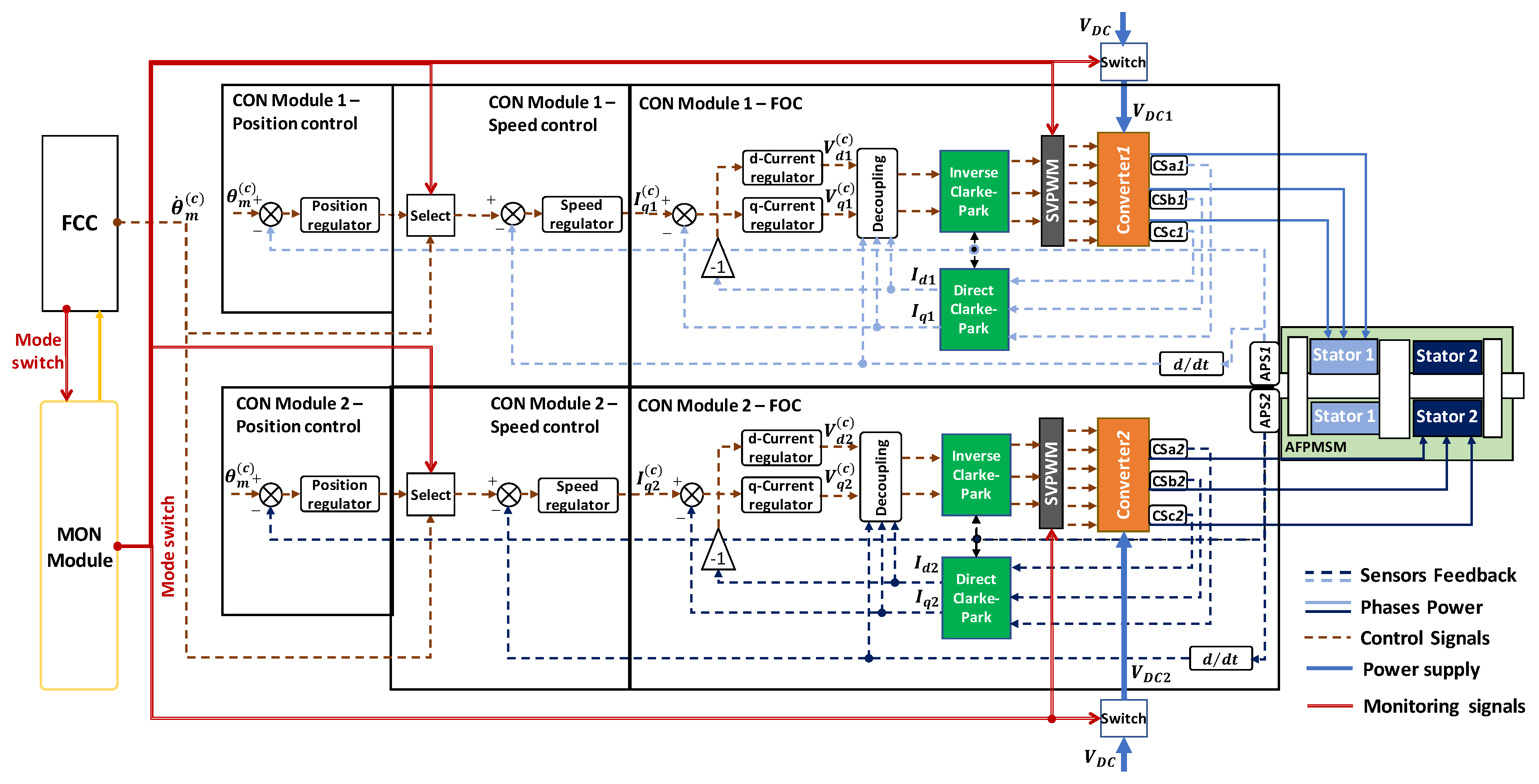

2.1. System Description

2.2. Modelling with Demagnetization and Angular Misalignment

2.2.1. Aero-Mechanical Modelling

2.2.2. Electrical Modelling of the Single Stator

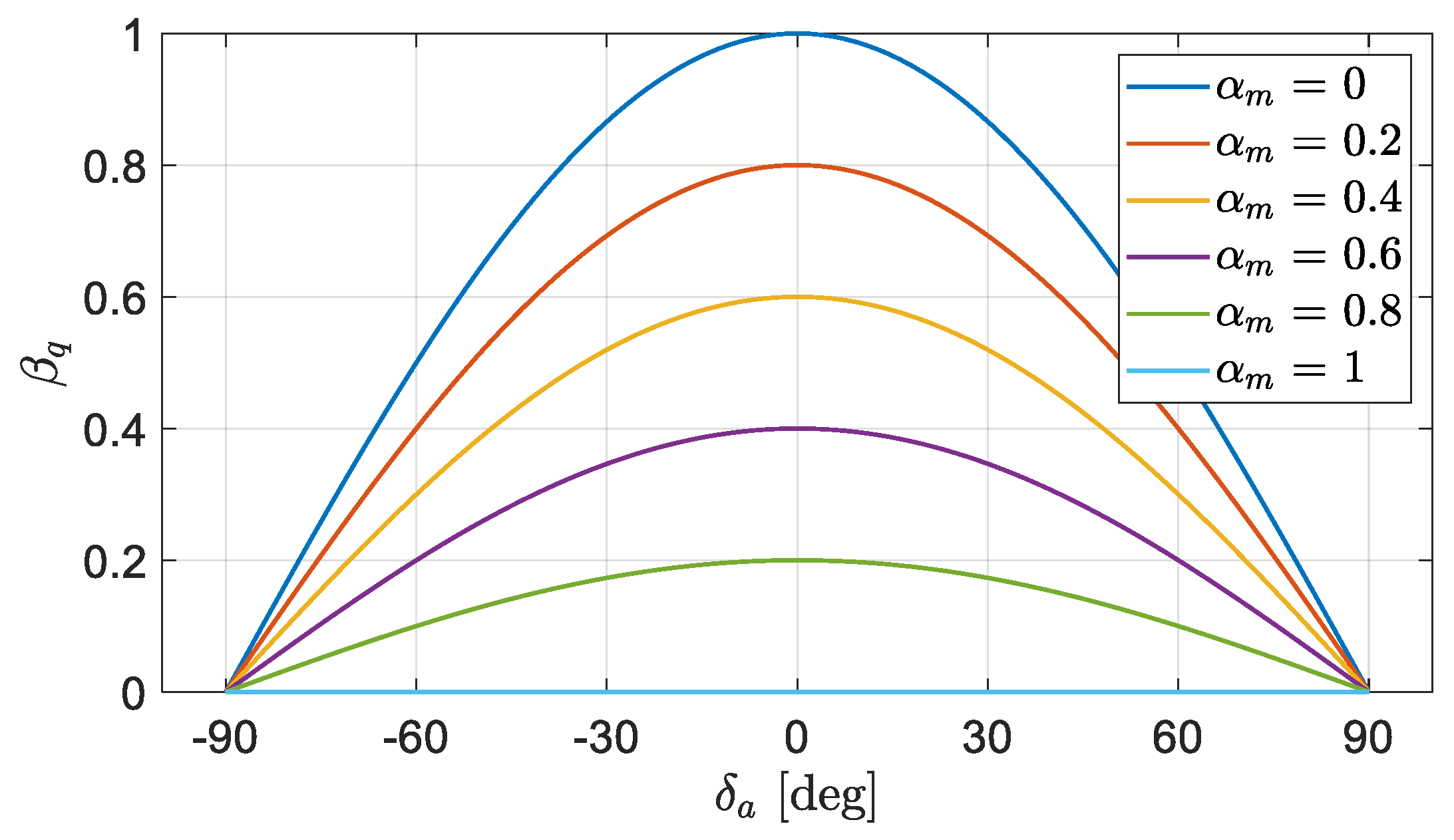

2.2.3. Torque Imbalance between Modules with Angular Misalignment and Demagnetization

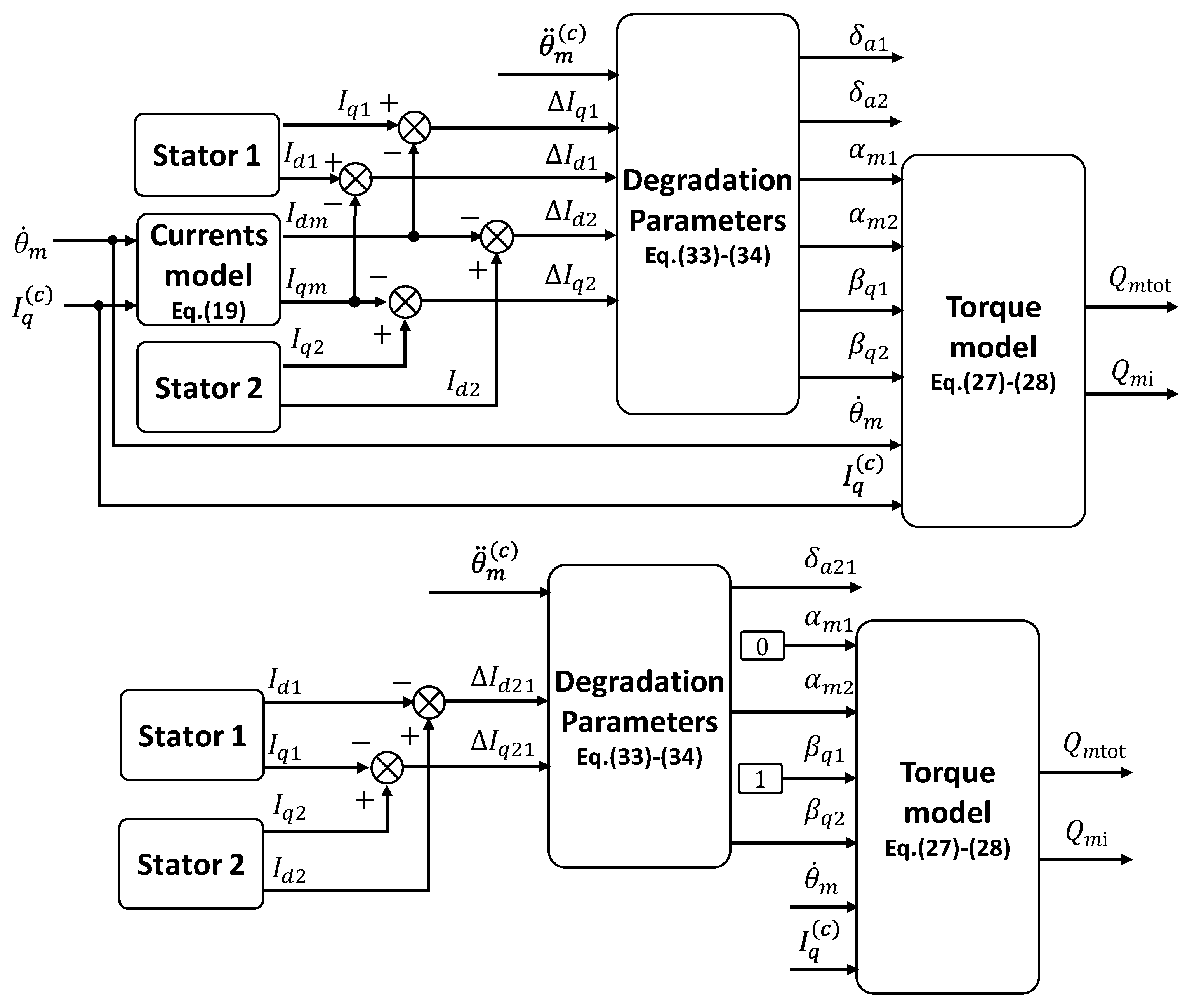

2.3. Monitoring of Demagnetization and Angular Misalignment

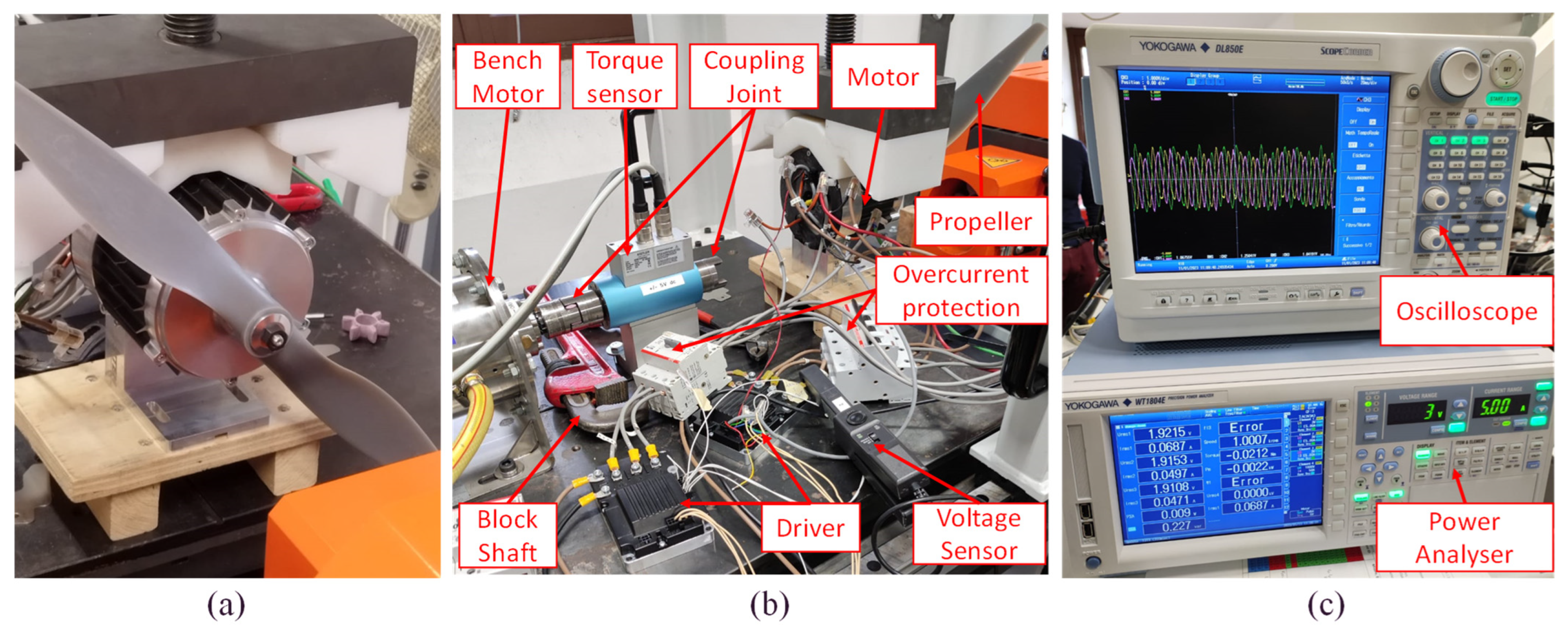

2.4. FEPS Prototype Test Plan

- T1.

- Single stator/dragged rotor/torque control: i.e., while the rotor is dragged at constant speed by an external motor, one of the two FEPS modules is controlled in torque, and the step inputs of the quadrature current are tracked. The test aimed to characterize the module efficiency as functions of speed and torque.

- T2.

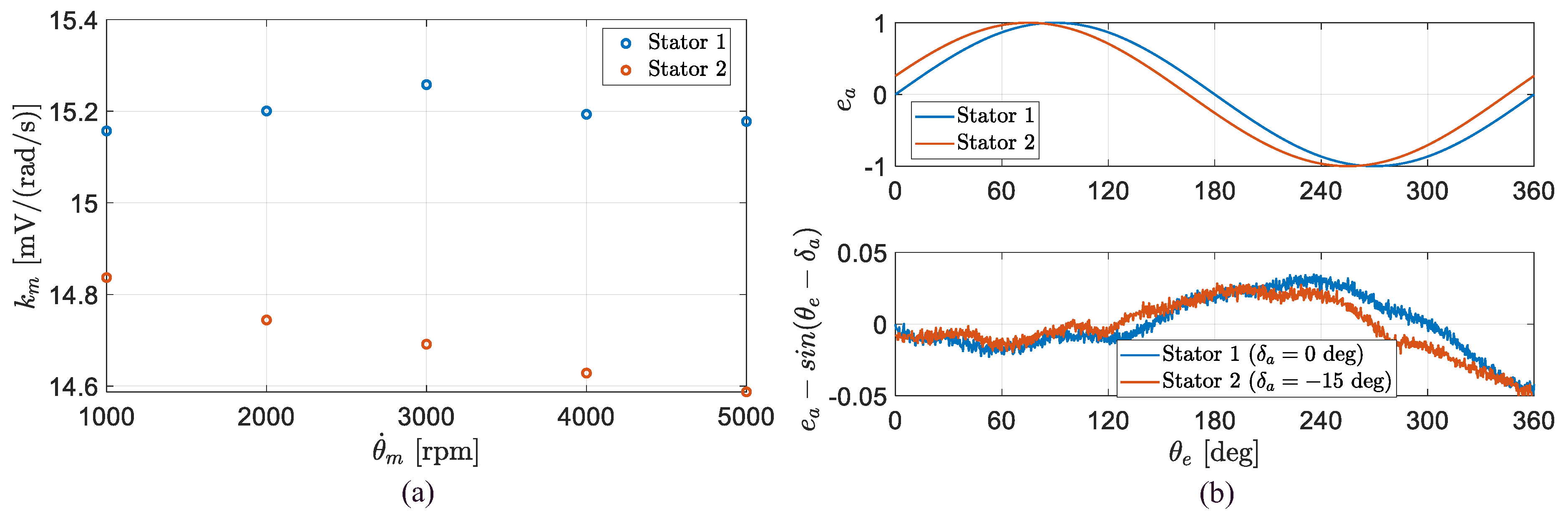

- Dual stator/dragged rotor/open-phases: i.e., the rotor is dragged at a constant speed by an external motor with disconnected phases on both modules. The test aimed to identify the speed constant of the modules and the BEMF waveforms ( and in Equation (3)).

- T3.

- Single stator/blocked rotor/torque control: i.e., while the rotor is blocked, one of the two modules is controlled in torque, and step inputs of the quadrature current are tracked. The test aimed to identify the stator resistance and inductance ( and in Equation (2)), as well as to validate the current regulators ( and in Equation (18)).

- T4.

- Dual stator/coupled propeller/speed control: i.e., once the propeller is coupled to the rotor, one of the two modules is controlled in speed tracking and ramped-step inputs are given. The test aimed to identify the rotor inertia ( in Equation (1)) and validate the speed regulators.

3. Results

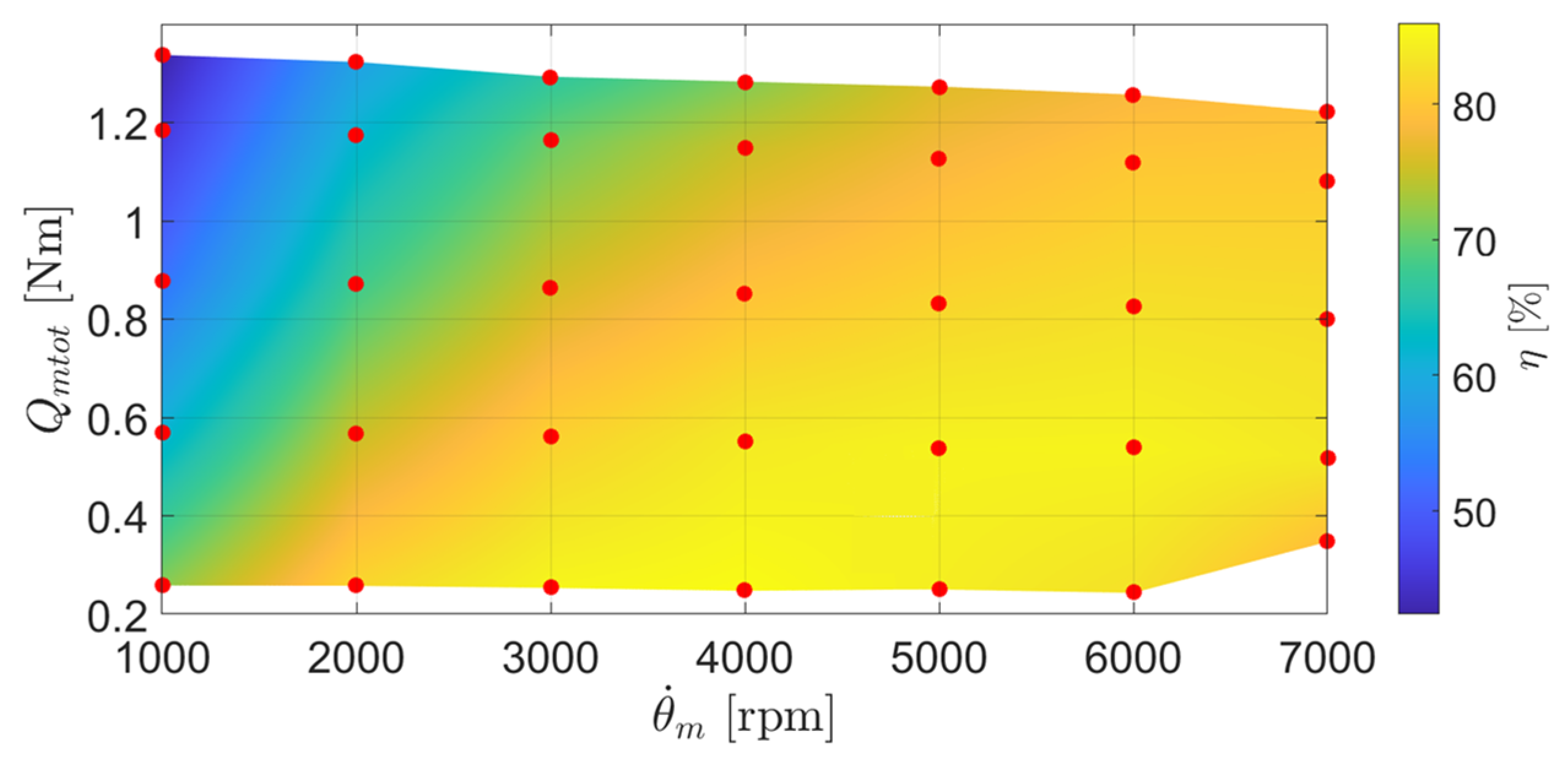

3.1. Open-Loop Performances

- imposing the rotor speed using the external speed-controlled motor;

- generating a resistant torque using the current-controlled FEPS module;

- measuring using the power signal analyser and the steady-state value of the ratio between the mechanical power output and electrical power input.

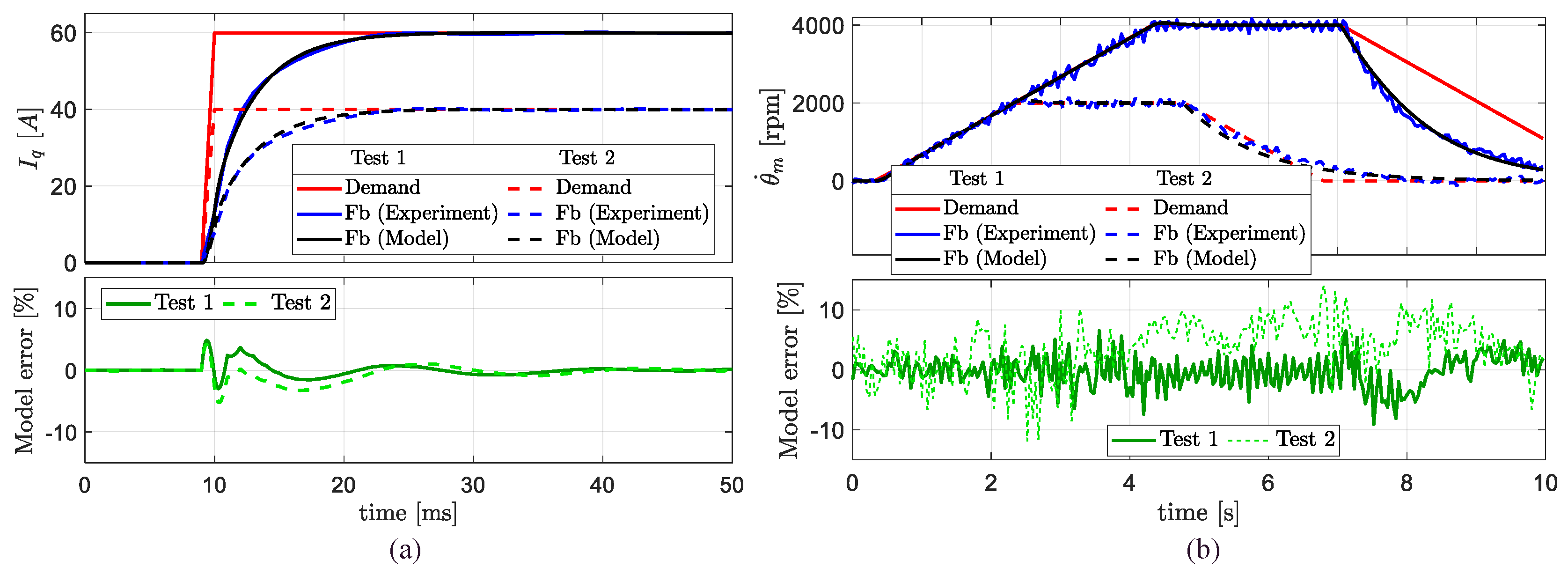

3.2. Closed-Loop Performances and Model Validation

3.3. Characterization of Monitoring Performances via Nonlinear Simulation

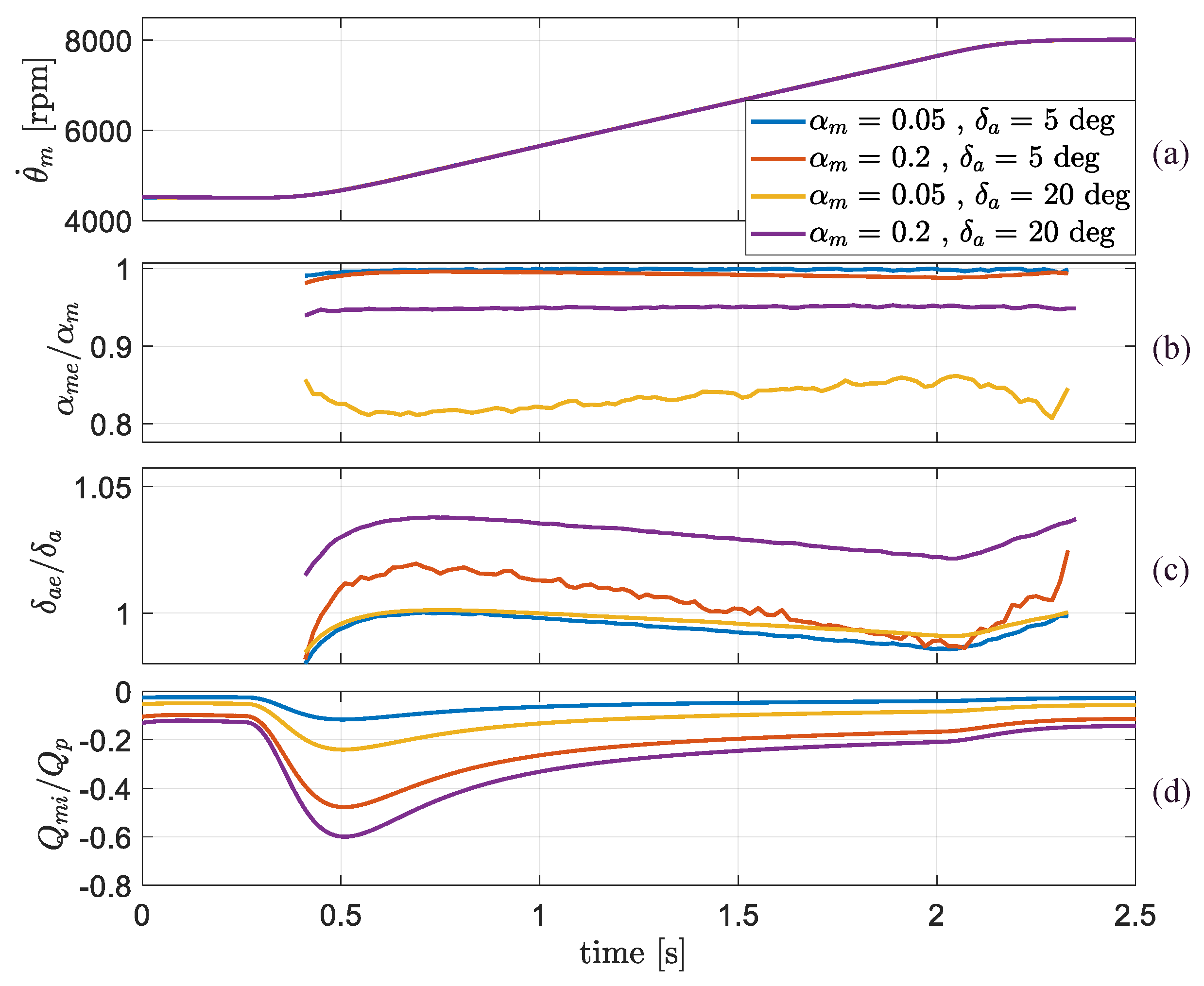

- firstly, by imposing speed requests characterized by constant acceleration;

- secondly, by using the time history of the speed request recorded during a flight manoeuvre of the Rapier X-25 UAV by Sky Eye Systems (Italy), which (having similar architecture, weight, propeller, aerodynamics, and control systems) was the baseline solution for the development of the TERSA UAV.

3.3.1. Constant-Acceleration Testing

3.3.2. Flight Manoeuvre Testing

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Definition | Symbol | Value | Unit |

|---|---|---|---|

| Stator phase resistance (single module) | 0.025 | Ω | |

| Stator phase inductance (single module) | 2 × 10−5 | H | |

| Pole pairs number | 5 | - | |

| Motor speed constant | 0.0152 | V/(rad/s) | |

| Voltage supply | 36 | V | |

| Rotor inertia | 2.2 × 10−2 | kg·m2 | |

| Propeller diameter | 0.5588 | m | |

| Propeller inertia | 1.186 × 10−3 | kg·m2 | |

| Coupling joint stiffness | 1.598 × 103 | Nm/rad | |

| Coupling joint damping | 0.2545 | Nm/(rad/s) | |

| Proportional gain of current regulator | 0.001 | V/A | |

| Integral gain of current regulator | 10 | V/(A s) | |

| Control sample time | 10−4 | s | |

| Monitoring acceleration threshold | 35 | rad/s2 |

References

- Chan, C.C. The State of the Art of Electric and Hybrid Vehicles. Proc. IEEE 2002, 90, 247–275. [Google Scholar] [CrossRef]

- Zhang, B.; Song, Z.; Zhao, F.; Liu, C. Overview of Propulsion Systems for Unmanned Aerial Vehicles. Energies 2022, 15, 455. [Google Scholar] [CrossRef]

- Suti, A.; Di Rito, G.; Galatolo, R. Climbing Performance Enhancement of Small Fixed-Wing UAVs via Hybrid Electric Propulsion. In Proceedings of the 2021 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Modena, Italy, 8–9 April 2021; pp. 305–310. [Google Scholar]

- Dici. Tersa. Available online: https://www.dici.unipi.it/progetti/tersa (accessed on 25 June 2023).

- Suti, A.; Di Rito, G.; Galatolo, R. Fault-Tolerant Control of a Dual-Stator PMSM for the Full-Electric Propulsion of a Lightweight Fixed-Wing UAV. Aerospace 2022, 9, 337. [Google Scholar] [CrossRef]

- Sky Eye Systems. Rapier X-Skysar. Available online: https://www.skyeyesystems.it/products/rapier-x-skysar/ (accessed on 15 July 2023).

- Sudha, B.; Vadde, A.; Sachin, S. A Review: High Power Density Motors for Electric Vehicles. J. Phys. Conf. Ser. 2020, 1706, 012057. [Google Scholar] [CrossRef]

- Bouaziz, O.; Jaafar, I.; Ammar, F.B. Performance Analysis of Radial and Axial Flux PMSM Based on 3D FEM Modeling. Turk. J. Electr. Eng. Comput. Sci. 2018, 26, 1587–1598. [Google Scholar] [CrossRef]

- Cao, W.; Mecrow, B.C.; Atkinson, G.J.; Bennett, J.W.; Atkinson, D.J. Overview of Electric Motor Technologies Used for More Electric Aircraft (MEA). IEEE Trans. Ind. Electron. 2012, 59, 3523–3531. [Google Scholar] [CrossRef]

- Suti, A.; Di Rito, G.; Galatolo, R. Fault-Tolerant Control of a Three-Phase Permanent Magnet Synchronous Motor for Lightweight UAV Propellers via Central Point Drive. Actuators 2021, 10, 253. [Google Scholar] [CrossRef]

- STANAG 4671; Standardization Agreement—Unmanned Aerial Vehicles Systems Airworthiness Requirements (USAR). NATO: Brussels, Belgium, 2009.

- Ryu, H.-M.; Kim, J.-W.; Sul, S.-K. Synchronous Frame Current Control of Multi-Phase Synchronous Motor Part II. Asymmetric Fault Condition Due to Open Phases. In Proceedings of the Conference Record of the 2004 IEEE Industry Applications Conference, 39th IAS Annual Meeting, Seattle, WA, USA, 3–7 October 2004; pp. 268–275. [Google Scholar]

- Zhang, C.; Chen, F.; Li, L.; Xu, Z.; Liu, L.; Yang, G.; Lian, H.; Tian, Y. A Free-Piston Linear Generator Control Strategy for Improving Output Power. Energies 2018, 11, 135. [Google Scholar] [CrossRef]

- Bennett, J.W.; Mecrow, B.C.; Atkinson, D.J.; Atkinson, G.J. Safety-Critical Design of Electromechanical Actuation Systems in Commercial Aircraft. IET Electr. Power Appl. 2011, 5, 37. [Google Scholar] [CrossRef]

- Mazzoleni, M.; Di Rito, G.; Previdi, F. Electro-Mechanical Actuators for the More Electric Aircraft; Springer International Publishing: Cham, Switzerland, 2021; ISBN 978-3-030-61798-1. [Google Scholar]

- Beltrao de Rossiter Correa, M.; Brandao Jacobina, C.; Cabral da Silva, E.R.; Nogueira Lima, A.M. An Induction Motor Drive System with Improved Fault Tolerance. IEEE Trans. Ind. Appl. 2001, 37, 873–879. [Google Scholar] [CrossRef]

- Ribeiro, R.L.A.; Jacobina, C.B.; Lima, A.M.N.; da Silva, E.R.C. A Strategy for Improving Reliability of Motor Drive Systems Using a Four-Leg Three-Phase Converter. In Proceedings of the APEC 2001, Sixteenth Annual IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 4–8 March 2021; pp. 385–391. [Google Scholar]

- Zhang, R.; Prasad, V.H.; Boroyevich, D.; Lee, F.C. Three-Dimensional Space Vector Modulation for Four-Leg Voltage-Source Converters. IEEE Trans. Power Electron. 2002, 17, 314–326. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Rahim, N.A.; Hew, W.P. Axial-Flux Permanent-Magnet Machine Modeling, Design, Simulation and Analysis. Sci. Res. Essays 2011, 6, 2525–2549. [Google Scholar]

- Wang, Z.; Chen, J.; Cheng, M. Fault Tolerant Control of Double-Stator-Winding PMSM for Open Phase Operation Based on Asymmetric Current Injection. In Proceedings of the 2014 IEEE 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 3424–3430. [Google Scholar]

- Baranski, M.; Szelag, W.; Jedryczka, C. Influence of Temperature on Partial Demagnetization of the Permanent Magnets during Starting Process of Line Start Permanent Magnet Synchronous Motor. In Proceedings of the 2017 IEEE International Symposium on Electrical Machines (SME), Naleczow, Poland, 18–21 June 2017; pp. 1–6. [Google Scholar]

- McFarland, J.D.; Jahns, T.M. Influence of D- and q-Axis Currents on Demagnetization in PM Synchronous Machines. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 4380–4387. [Google Scholar]

- Krichen, M.; Elbouchikhi, E.; Benhadj, N.; Chaieb, M.; Benbouzid, M.; Neji, R. Motor Current Signature Analysis-Based Permanent Magnet Synchronous Motor Demagnetization Characterization and Detection. Machines 2020, 8, 35. [Google Scholar] [CrossRef]

- Ullah, Z.; Hur, J. A Comprehensive Review of Winding Short Circuit Fault and Irreversible Demagnetization Fault Detection in PM Type Machines. Energies 2018, 11, 3309. [Google Scholar] [CrossRef]

- Sarikhani, A.; Mohammed, O. Demagnetization Control for Reliable Flux Weakening Control in PM Synchronous Machine. In Proceedings of the 2012 IEEE Industry Applications Society Annual Meeting, Las Vegas, NV, USA, 7–11 October 2012; pp. 1–8. [Google Scholar]

- Galea, M.; Papini, L.; Zhang, H.; Gerada, C.; Hamiti, T. Demagnetization Analysis for Halbach Array Configurations in Electrical Machines. IEEE Trans. Magn. 2015, 51, 8107309. [Google Scholar] [CrossRef]

- Cao, L.; Wu, Z. On-Line Detection of Demagnetization for Permanent Magnet Synchronous Motor via Flux Observer. Machines 2022, 10, 354. [Google Scholar] [CrossRef]

- Moosavi, S.S.; Djerdir, A.; Amirat, Y.A.; Khaburi, D.A. Demagnetization Fault Diagnosis in Permanent Magnet Synchronous Motors: A Review of the State-of-the-Art. J. Magn. Magn. Mater. 2015, 391, 203–212. [Google Scholar] [CrossRef]

- Xi, X.; Meng, Z.; Li, Y.; Li, M. On-Line Estimation of Permanent Magnet Flux Linkage Ripple for PMSM Based on a Kalman Filter. In Proceedings of the IECON 2006—32nd Annual Conference on IEEE Industrial Electronics, Paris, France, 7–10 November 2006; pp. 1171–1175. [Google Scholar]

- Min, Y.; Huang, W.; Yang, J.; Zhao, Y. On-Line Estimation of Permanent-Magnet Flux and Temperature Rise in Stator Winding for PMSM. In Proceedings of the 2019 IEEE 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–5. [Google Scholar]

- Xu, W.; Jiang, Y.; Mu, C.; Blaabjerg, F. Improved Nonlinear Flux Observer-Based Second-Order SOIFO for PMSM Sensorless Control. IEEE Trans. Power Electron. 2019, 34, 565–579. [Google Scholar] [CrossRef]

- Bobtsov, A.; Pyrkin, A.; Aranovskiy, S.; Nikolaev, N.; Slita, O.; Kozachek, O.; Quoc, D.V. Stator Flux and Load Torque Observers for PMSM. IFAC—Pap. OnLine 2020, 53, 5051–5056. [Google Scholar] [CrossRef]

- Uddin, M.N.; Zou, H.; Azevedo, F. Online Loss-Minimization-Based Adaptive Flux Observer for Direct Torque and Flux Control of PMSM Drive. IEEE Trans. Ind. Appl. 2016, 52, 425–431. [Google Scholar] [CrossRef]

- APC Propellers. Technical Info. Available online: https://www.apcprop.com/technical-information/performance-data/ (accessed on 20 May 2023).

- Bae, B.-H.; Sul, S.-K. A Compensation Method for Time Delay of Full-Digital Synchronous Frame Current Regulator of PWM AC Drives. IEEE Trans. Ind. Appl. 2003, 39, 802–810. [Google Scholar] [CrossRef]

- Siemens. Products & Services, Motors. Available online: https://www.siemens.com/global/en/products/drives/electric-motors/motion-control-motors/motor-spindles.html (accessed on 1 July 2023).

- Kistler. Measure, Analyze, Innovate. Available online: https://www.kistler.com/it/it/cp/shaft-torque-sensors-4503b/p0000238 (accessed on 1 July 2023).

- Yokogawa. Test & Measurement. Available online: https://tmi.yokogawa.com/solutions/products/power-analyzers/wt1800e-high-performance-power-analyzer/ (accessed on 1 July 2023).

- Yokogawa. Test & Measurement. Available online: https://tmi.yokogawa.com/solutions/products/data-acquisition-equipment/high-speed-data-acquisition/dl950/ (accessed on 1 July 2023).

- BySTORM & CO. Available online: https://bystorm.it/ftd50/ (accessed on 1 June 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suti, A.; Di Rito, G.; Mattei, G. Condition Monitoring of the Torque Imbalance in a Dual-Stator Permanent Magnet Synchronous Motor for the Propulsion of a Lightweight Fixed-Wing UAV. Drones 2023, 7, 618. https://doi.org/10.3390/drones7100618

Suti A, Di Rito G, Mattei G. Condition Monitoring of the Torque Imbalance in a Dual-Stator Permanent Magnet Synchronous Motor for the Propulsion of a Lightweight Fixed-Wing UAV. Drones. 2023; 7(10):618. https://doi.org/10.3390/drones7100618

Chicago/Turabian StyleSuti, Aleksander, Gianpietro Di Rito, and Giuseppe Mattei. 2023. "Condition Monitoring of the Torque Imbalance in a Dual-Stator Permanent Magnet Synchronous Motor for the Propulsion of a Lightweight Fixed-Wing UAV" Drones 7, no. 10: 618. https://doi.org/10.3390/drones7100618

APA StyleSuti, A., Di Rito, G., & Mattei, G. (2023). Condition Monitoring of the Torque Imbalance in a Dual-Stator Permanent Magnet Synchronous Motor for the Propulsion of a Lightweight Fixed-Wing UAV. Drones, 7(10), 618. https://doi.org/10.3390/drones7100618