1. Introduction

With the advancement of technology, robotic platforms such as the multirotor aerial craft, also known as an unmanned aerial vehicle (UAVs), are disrupting traditional industries in the high-rise maintenance (inspection and cleaning) sector. Due to a UAV’s vertical takeoff and landing capability, ability to navigate in severe environments, and payload augmentation, increasing numbers of UAVs are employed to assist in dangerous and difficult manual maintenance operations. These purpose-built UAVs modernise traditional methods of setting up mechanised elevated work platforms (MEWPs) or scaffolds in order to inspect or clean structures at a height. UAVs serve as a convenient medium to extend the reach of sensors or payload to the desired operating position.

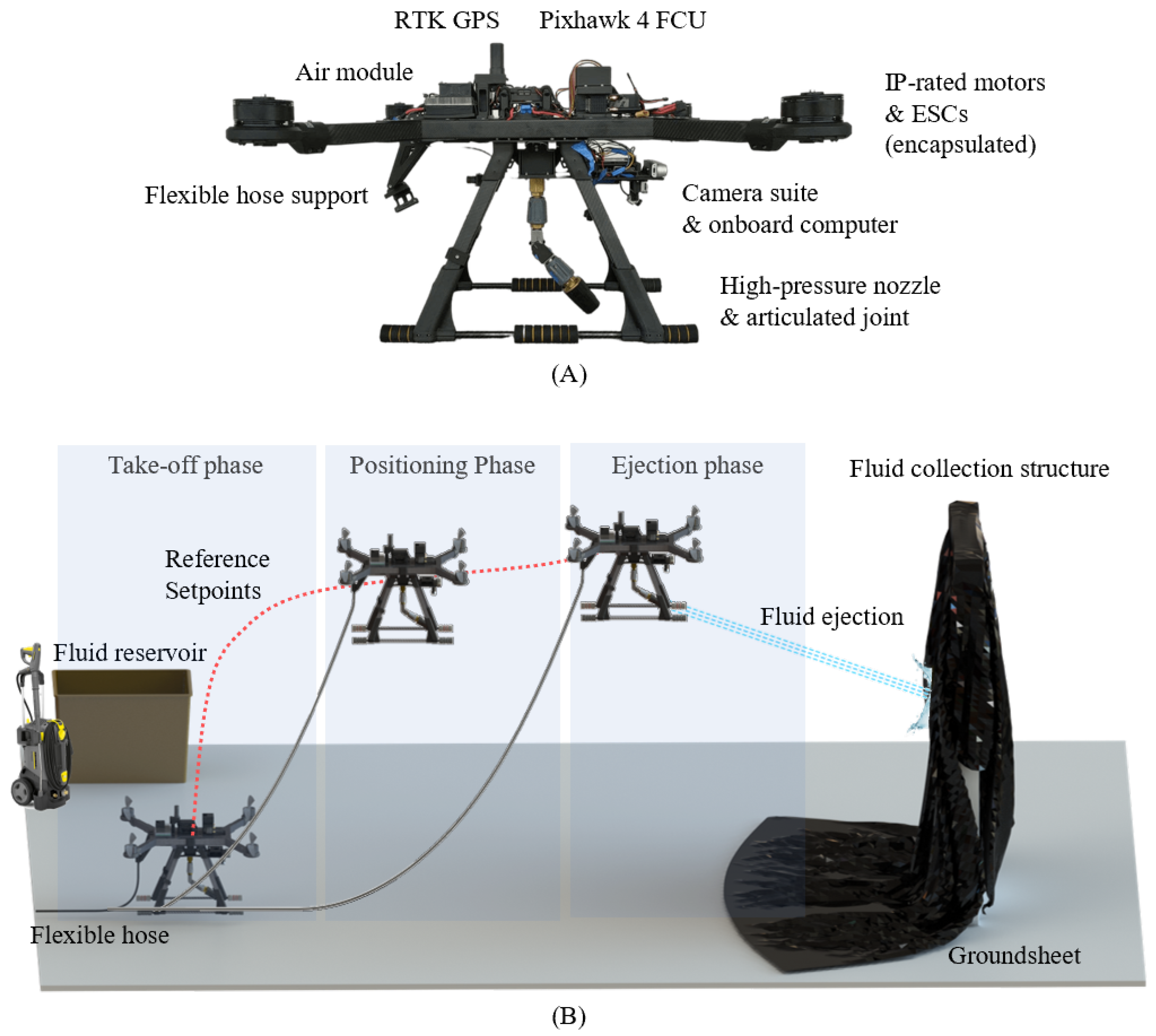

Many commercial-off-the-shelf (COTS) UAVs are able to carry an onboard camera-gimbal system, providing a stable level horizon, which makes high-rise inspection with UAVs a default solution for many users. On the other hand, fluid ejection UAVs are still uncommon, as there is no readily available gimbal for nozzles. There are past works that explored low-volume spraying [

1,

2], as well as high-rise maintenance works that employ the use of a UAV [

3,

4,

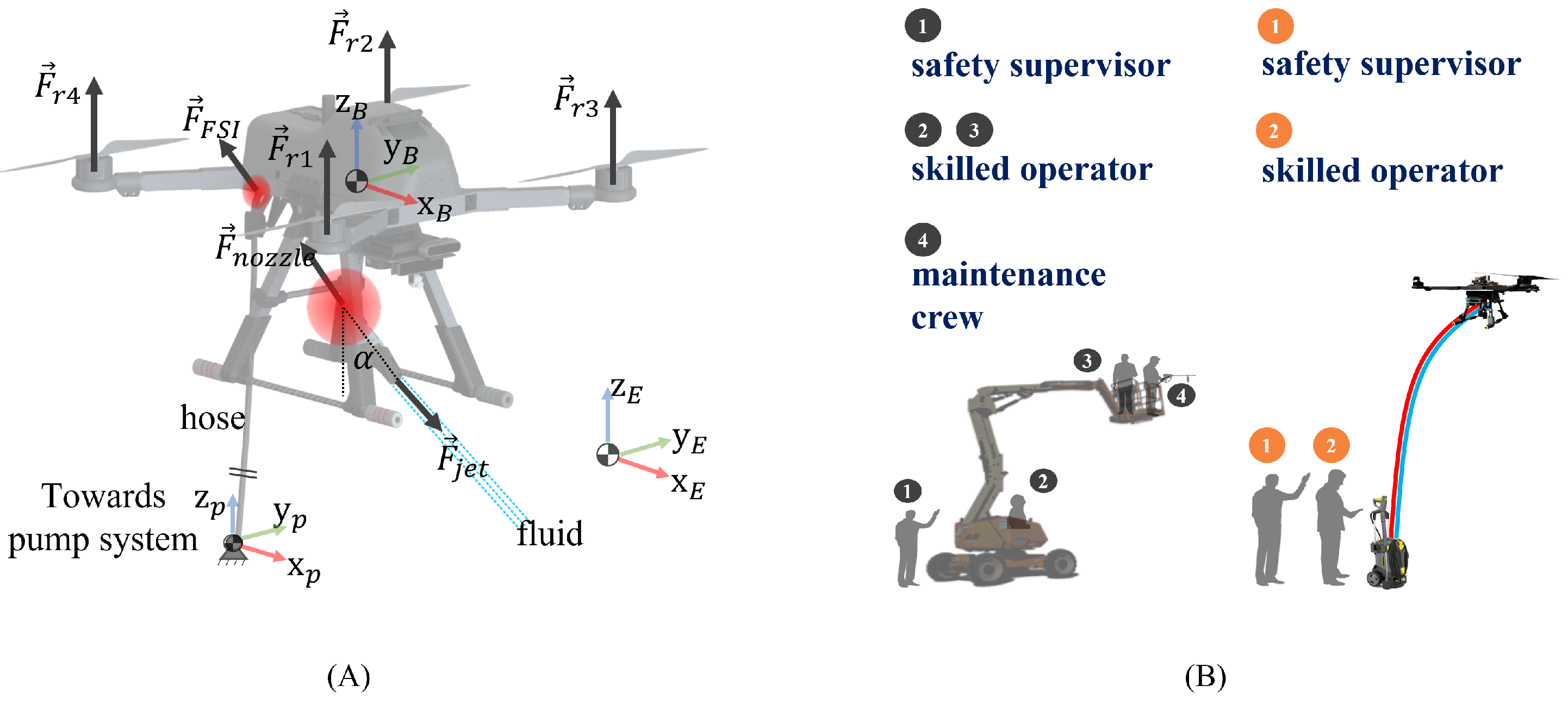

5]. In the applications of clustered built-environment spaces, such as structural cleaning and bulk carrier cargo hold maintenance, regular cleaning maintains the safety standards for public use and for switching from mineral cargo to food cargo, respectively. The current cleaning methods shown in

Figure 1 demonstrate the manual intensity and need for assisted equipment. Therefore, the use of cleaning robots is highly beneficial, as current solutions are extremely manual and rely heavily on the use of MEWPs to reduce the standoff distance of the fluid ejection for more effective cleaning. As illustrated in

Figure 2, UAV solutions also help to eliminate the need for any humans to work from heights and reduce the amount of manpower needed in a single cleaning operation.

Besides the reduction of manpower and risk, a UAV equipped with a high-pressure water jet provides flexibility in cleaning hard-to-reach areas without the need to be in close proximity to buildings with complex geometries or facades where employment of MEWPs may not be feasible. Furthermore, employment of UAVs in cleaning applications can increase operational efficiency; unlike typical MEWP operations, which require coordination between 2–3 operators, the UAV control and cleaning application can be done semi-autonomously and remotely by an operator. However, with high-pressure fluid ejection, the UAV will be subjected to flow-induced forces that push the UAV in the opposite direction of ejection. Without a stable ejection phase, the adoption of such solutions are still low due to the fear of collision. In situations such as localised cleaning, analysis of the external perturbations acting on the UAV during the ejection phase from the jet ejection is critical, as the resulting drift may lead to undesirable positioning of the point of contact of the fluid. Furthermore, excessive drift imposes a constraint on the available operating area, particularly in clustered environments.

An interesting aspect of fluid ejection was presented by [

6] by studying the hybrid kinematics modelling for accurate jetting onto targets. An aerial-hose-type robot was developed by [

7,

8] by exploiting fluid jet propulsion for elevation, coupled with control valve mechanisms to regulate the jet flow for lateral and frontal motion. However, none of these prior works studied the flow-induced forces acting upon the UAVs and how they might affect its stability.

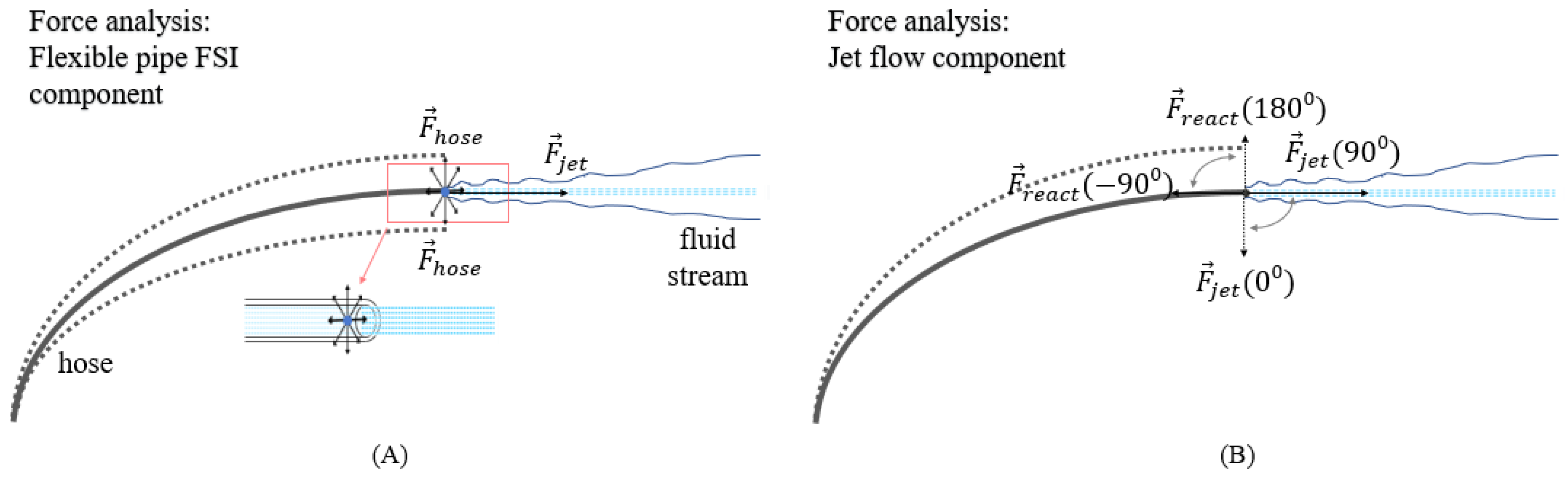

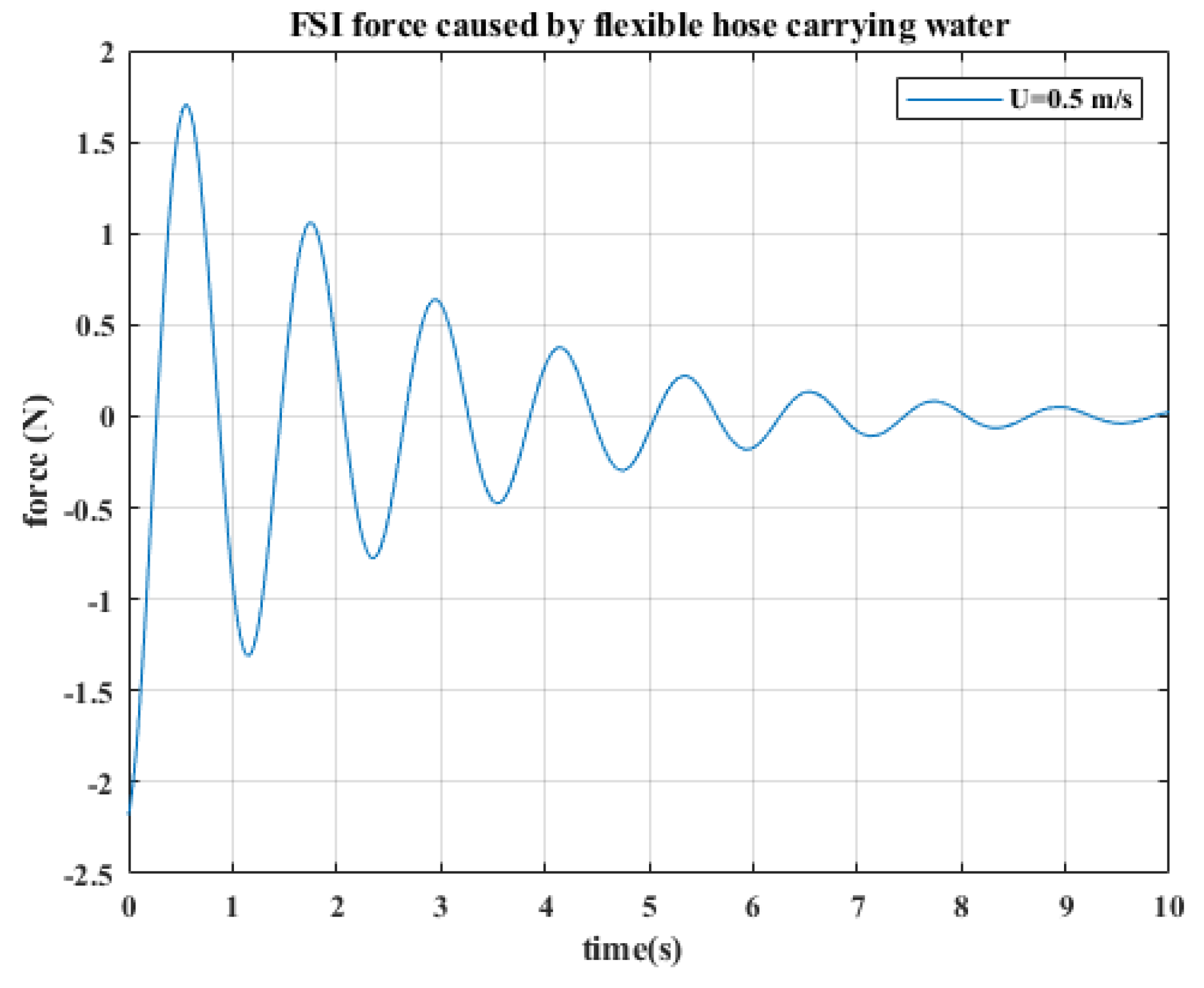

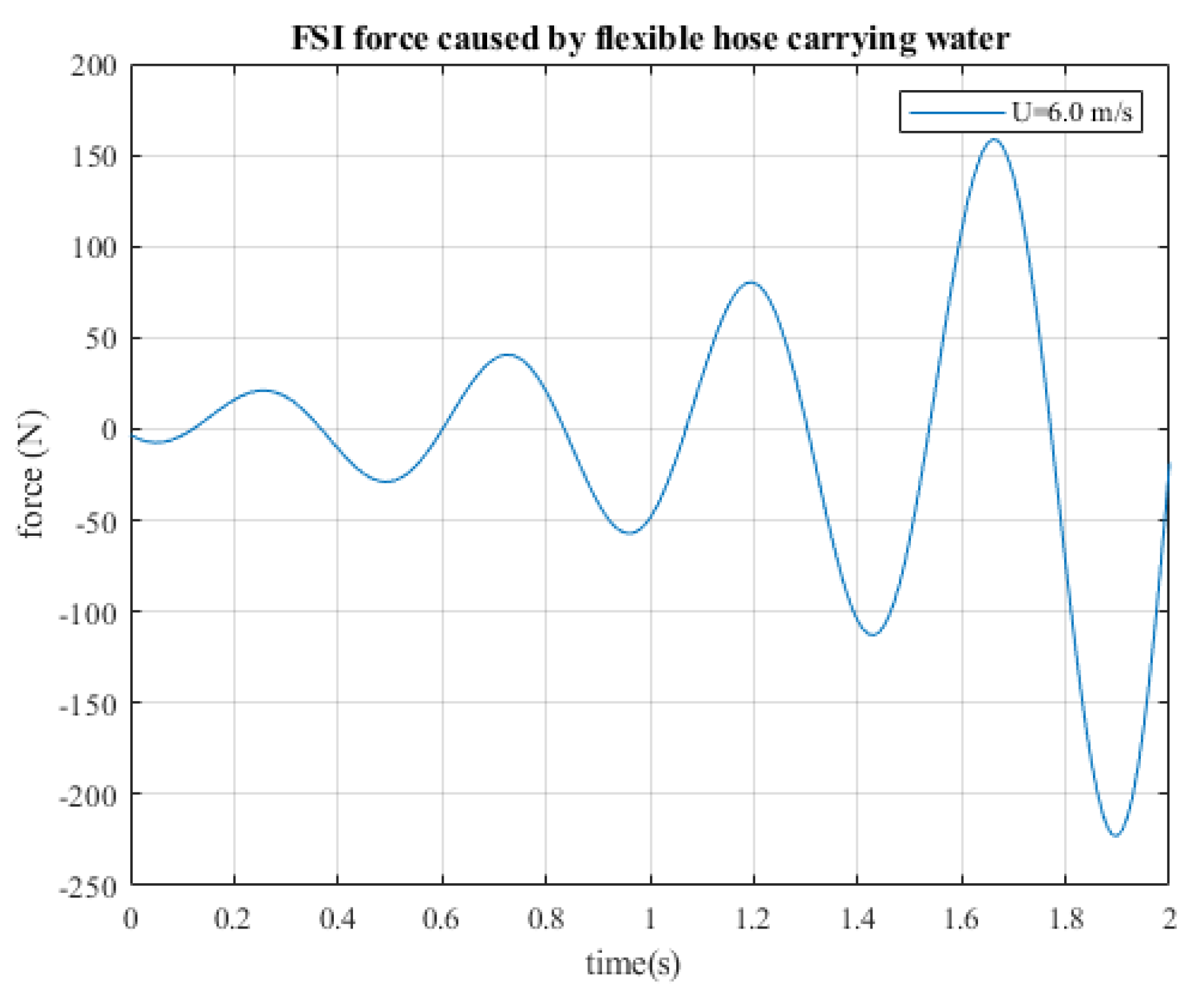

With the involvement of fluid ejection in a tethered setup, the free end of the hose that is connected to any pseudo-fixed platform will be subjected to a phenomenon known as fluid–structure interaction (FSI). There are past works that have studied the FSI effects of a pipe conveying fluid in a cantilevered arrangement, as described in [

9,

10,

11]. While all of them are in a cantilevered arrangement, [

9] has a converging cantilevered pipe towards the free end, [

10] has the pipe suspended by its fixed point, and [

11] investigates the scenario of constrained pipes. In addition, [

12] discussed the effects of varying flow velocity on the end-mass of a single straight or articulated pipe. The stability of the flow-induced perturbations is dependent on the critical pipe in-flow velocity

, which increases as larger end-masses are used [

13]. Considering constant and variable flow velocities, [

14] studied the fluttering observed in a cantilevered system, as well as additional buckling in simple supported systems.

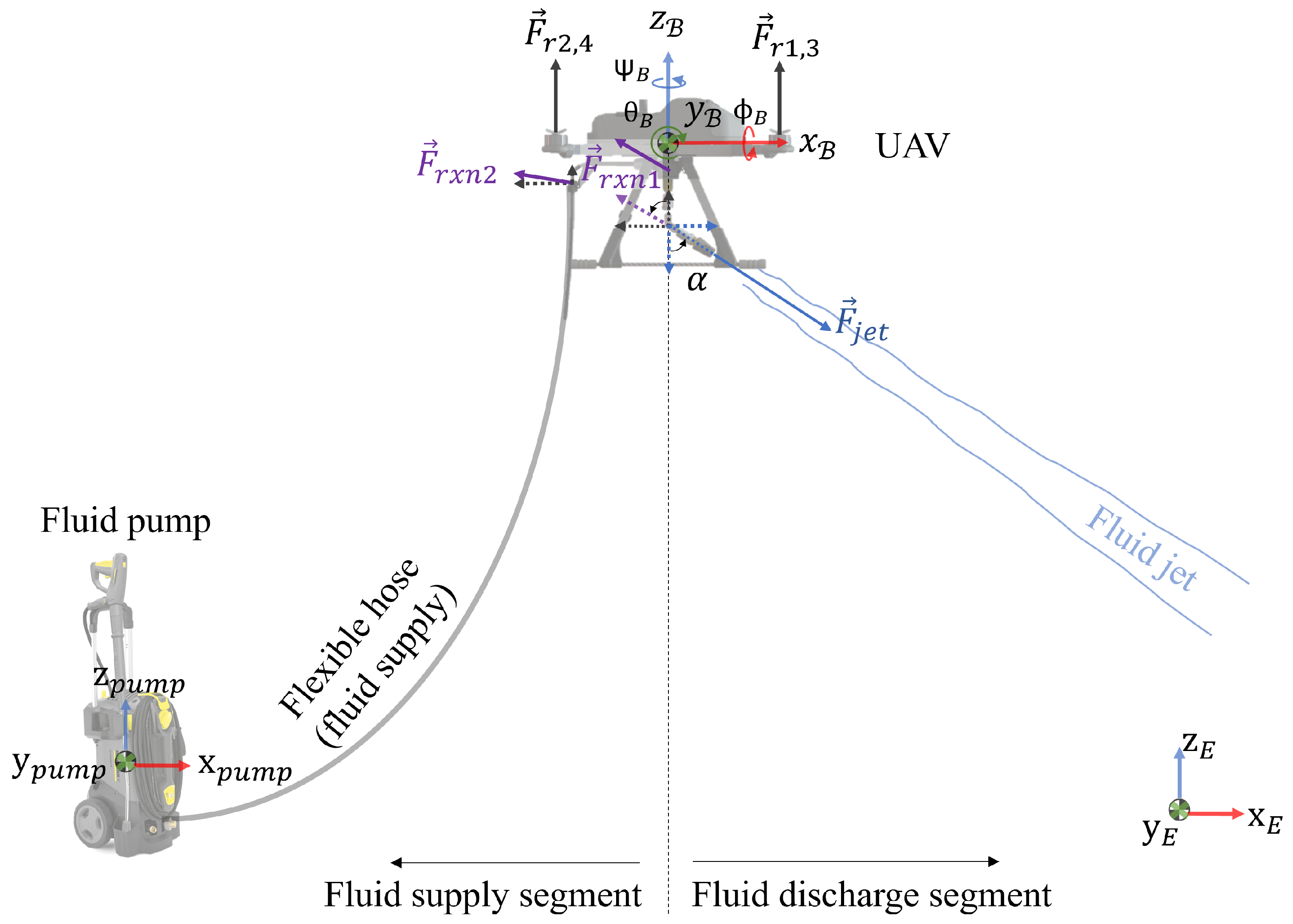

To visualise this effect, one end of the hose is connected to the pressure pump system, with the other end of the pipe extended and laying freely (free end). As the fluid flows through the hose, the free end is expected to ’whip’ around. For a fluid-ejecting UAV, as shown in

Figure 2, the free end of the hose is attached to the platform, and this translates to a ’whipping’ effect on the UAV. The translated effect, combined with the jet reaction, can be destructive to the UAV’s stability if it is not carefully studied and mitigated. An improved controller was introduced by [

15] by employing FF control to stabilise the UAV; however, the system is small and it uses fluid as a medium for propulsion. On the other hand, [

16,

17] explored mechanical means like thrusters and flow re-direction to aid the stability of the UAV in flight. Even though all of these works employ a tethered concept, the authors did not study the flow-induced effects on their UAV, which could affect the stability without external excitation. With knowledge of the flow-induced disturbance model acting on the UAV system, corrective methods can be better implemented.

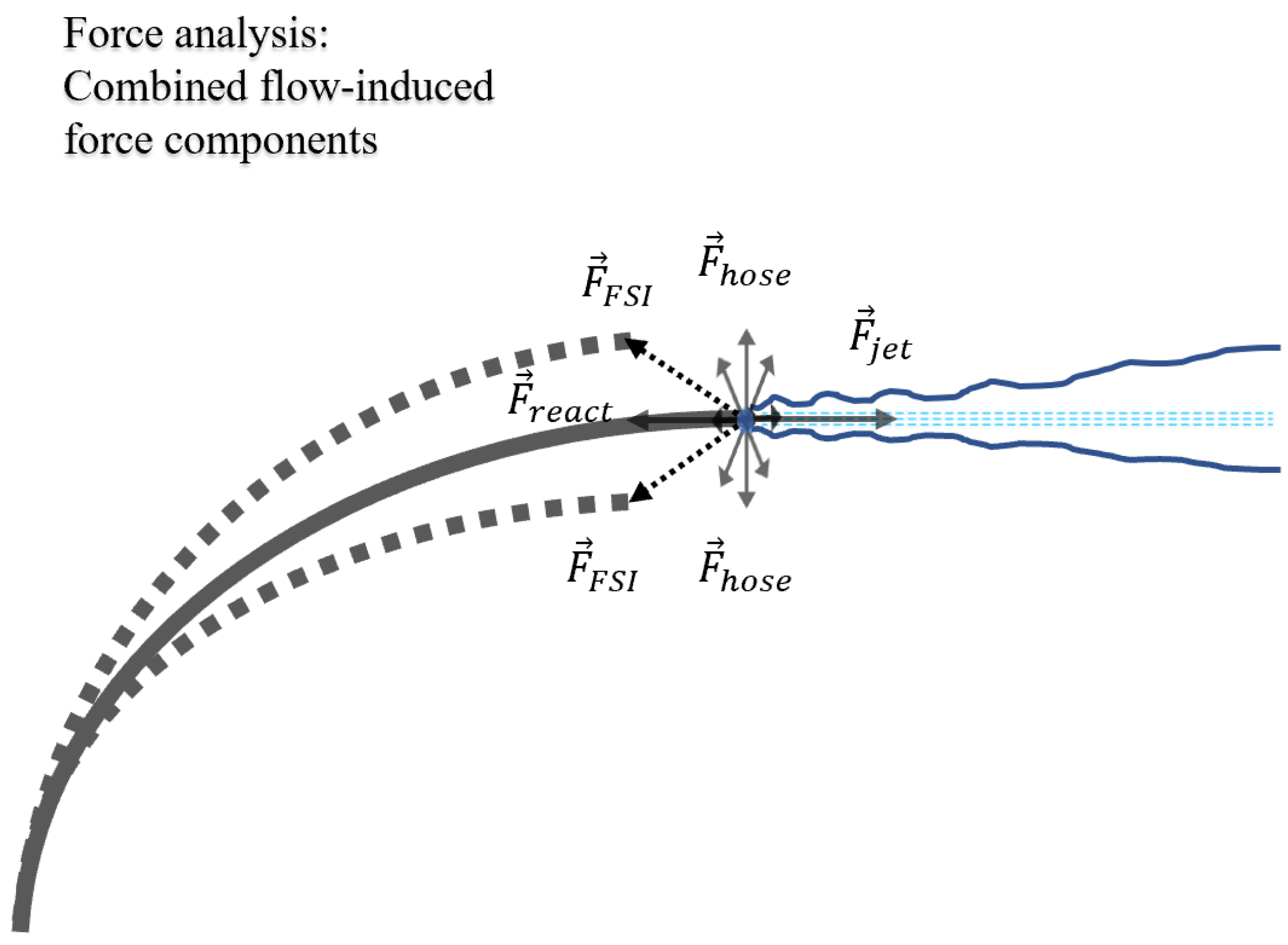

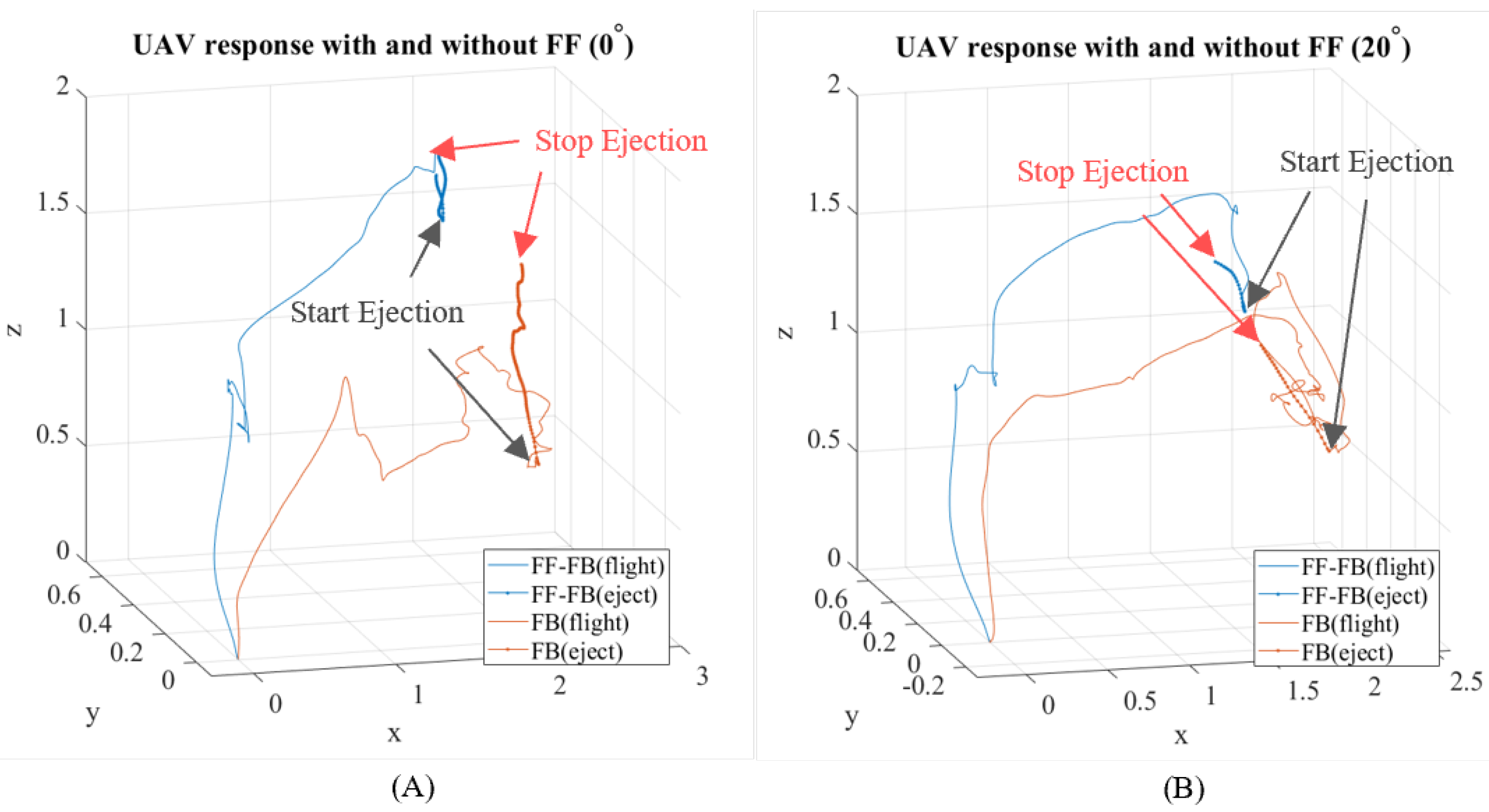

Therefore, this paper focuses on the study of the flow-induced forces acting on a pseudo-fixed end-mass, that is, a hovering UAV with the free end of the flexible hose tethered to it. In order to utilise the FSI effects and jet reaction for a constructive purpose, this paper investigates the effects of this interaction between the free end of the hose attached to the pseudo-fixed end-mass in terms of its time and spatial responses. Thereafter, this knowledge is applied to the control scheme of the UAV to ensure the stability of the platform during fluid ejection. Modifications to the UAV control scheme will be introduced, which include the employment of an FF-FB controller. The flow-induced forces will be assumed as disturbances for UAV position correction.

Section 2 addresses the flow-induced dynamic models and

Section 3 will cover the UAV control system and the FF-FB strategy.

Section 4 and

Section 5 will present the simulations and experimental validations, respectively.

Section 6 will present the conclusion and future works. In this paper, a variable with subscript

B indicates that the variable is represented in the body-fixed frame

. Otherwise, the variable is in the earth-fixed frame

. All variables for angles are described in degrees (°).

In summary, the niche of this paper is the approximation of the flow-induced effects from the fluid supply and discharge segments on the UAV platform. Subsequently, these flow-related forces are treated as disturbances to the UAV platform, and the proposed control strategy is applied to mitigate these flow-induced effects.

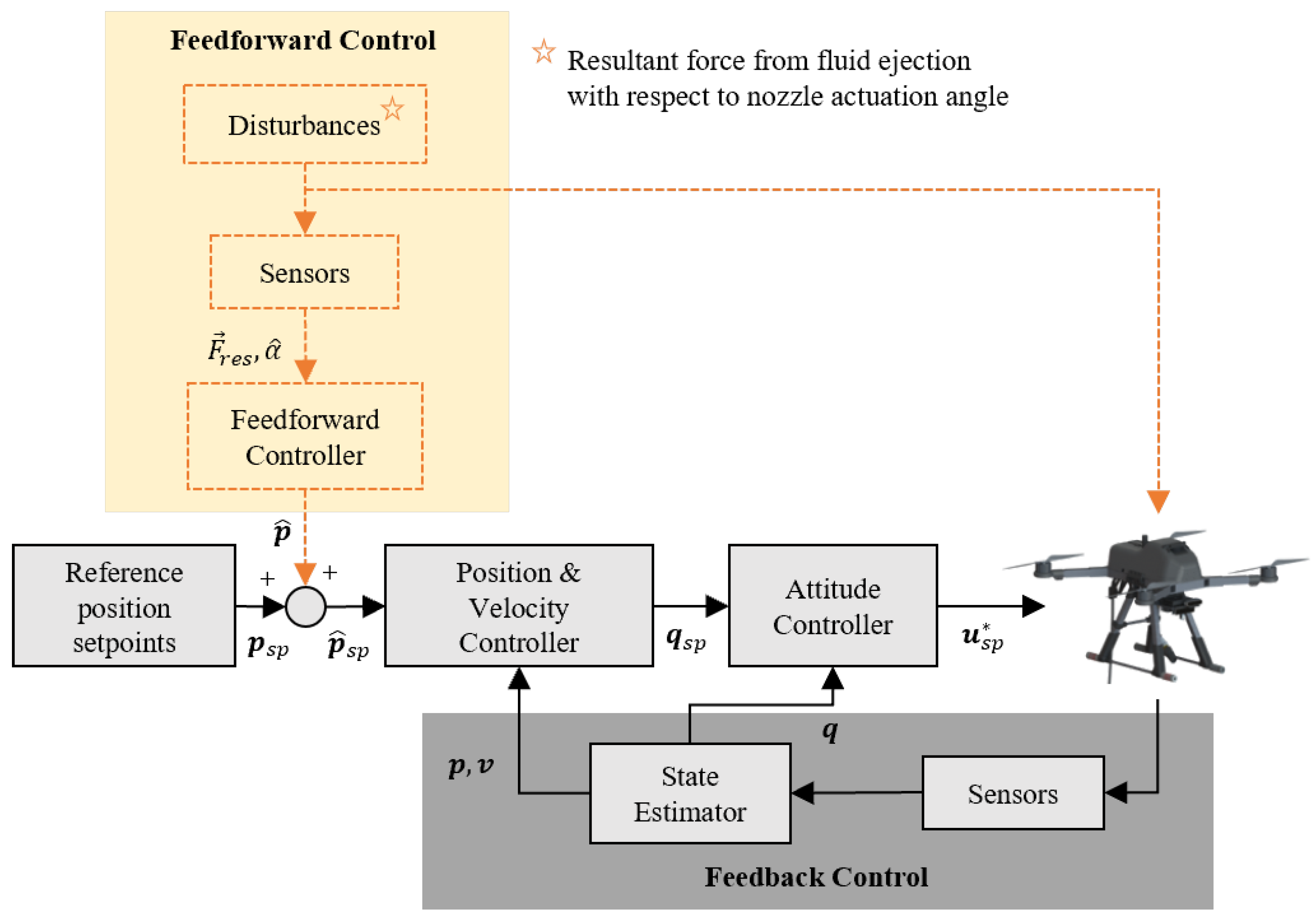

3. UAV Control System, Disturbance, and Feedforward (FF) Strategy

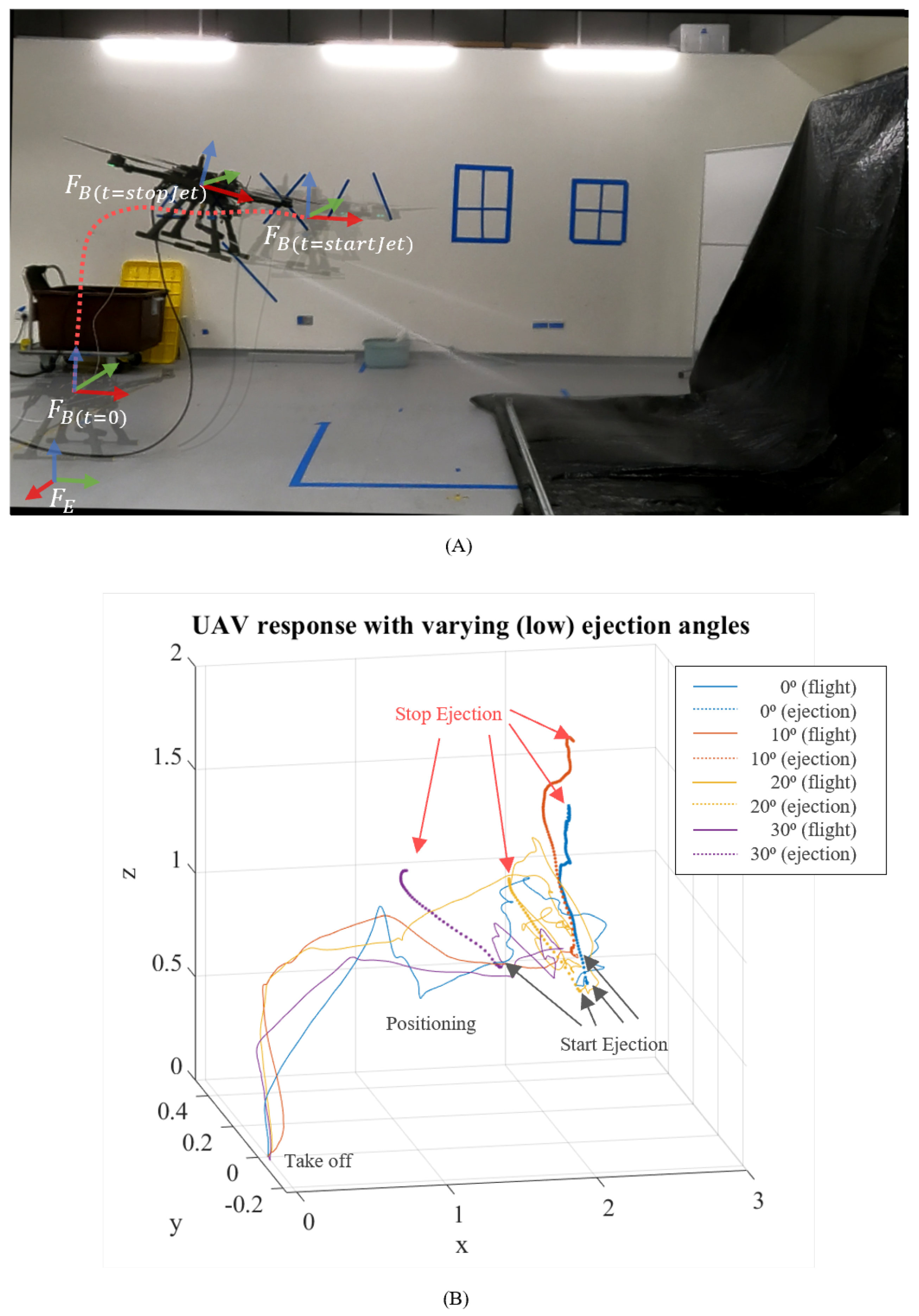

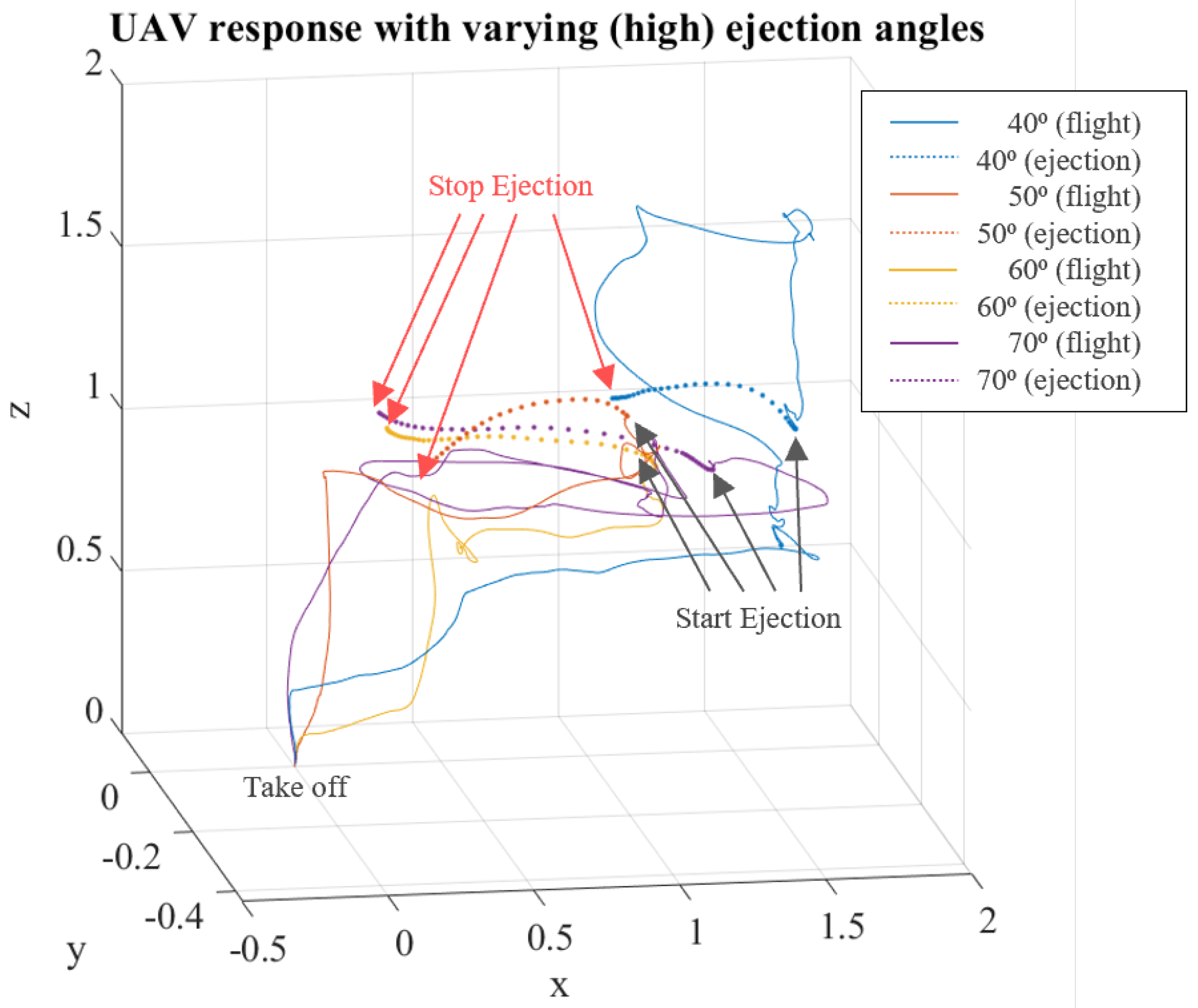

During the ejection process, the UAV will be subjected to unwanted physical disturbances that influence the UAV’s desired position, which may cause instability or potential collision with nearby structures. To reduce such disturbances due to the fluid ejection, an FF-FB strategy is proposed. With reference to

Figure 8, the control scheme is comprised of two main loops, namely feedforward (FF) and feedback (FB). Our strategy introduces an FF loop (as highlighted in

Figure 8) to a standard FB loop for active UAV position compensation. This section describes a combined FF-FB UAV control scheme with the

as a disturbance input that results in the displacement in UAV position. The FF loop detects the forces caused by the fluid ejection as disturbance input and outputs the estimated corrections for the reference position setpoints, where the FB loop corrects the error between the observed UAV position and the reference position setpoints. This ensures that the UAV is kept as close as possible to the desired setpoints, especially during fluid ejection. The FF loop is comprised of sensors to quantify the disturbance force caused by the fluid ejection and a controller that addresses the measured disturbance (

) with estimated position setpoint corrections. The FB loop is comprised of sensors to measure the pose and position of the UAV to update the state estimations in order to reduce the observed error via error dynamics methods.

3.1. UAV Control System

Table 2 list the various definitions of the variables introduced in the control scheme, as shown in

Figure 8. The following assumptions were made with regards to the UAV and its control scheme in this study:

Assumptions list 1 for UAV:

The origin of the body-fixed frame, , is set at the center of gravity (CoG) of the UAV;

The UAV is symmetrical and rigid;

The moment caused by attaching the flexible hose to the UAV is negligible;

The dynamics of the UAV motors and propellers are negligible;

The thrust and drag forces are proportional to the square of the rotor speed;

The flow-induced forces acting on the nozzle housing act in the region of the CoG, and hence any moments generated are negligible;

The nozzle is bounded by a single rotary mechanism that limits the fluid jet between the x-z axes only.

Assumptions list 2 for control scheme:

The position and velocity signals are available;

All velocities and the forces are bounded;

The Euler angles () satisfy and .

In this paper, the UAV dynamic model is assumed to be a standard x quadrotor configuration, with consideration of the above assumptions. Hence, the various controllers and the plant will correspond to the various position-attitude controllers and quadrotor dynamic model, respectively. Proportional-integral-derivative (PID) FB control is employed within the various control loops. Since the UAV will be subjected to a disturbance, resulting in the drift in UAV position due to the fluid ejection, an FF control strategy can be employed in anticipation of the occurrence of the disturbance to minimise the position drift during ejection.

The fluid-ejecting quadrotor dynamics configuration is formulated and structured in a state space representation similar to [

25]:

where

A is the system matrix,

x is the state vector,

B is the input matrix,

u is the vector,

D is the disturbance matrix, and

d is the disturbance vector.

Considering the platform’s moments of inertia and a simple PID FB control loop, the UAV response is stable for any given 3D target position. Noting that the typical UAV state space system does not facilitate onboard fluid ejection, in order to simulate the fluid ejection response on the UAV, the addition of the disturbance matrix is introduced. Refer to

Appendix A for the breakdown of the respective matrices.

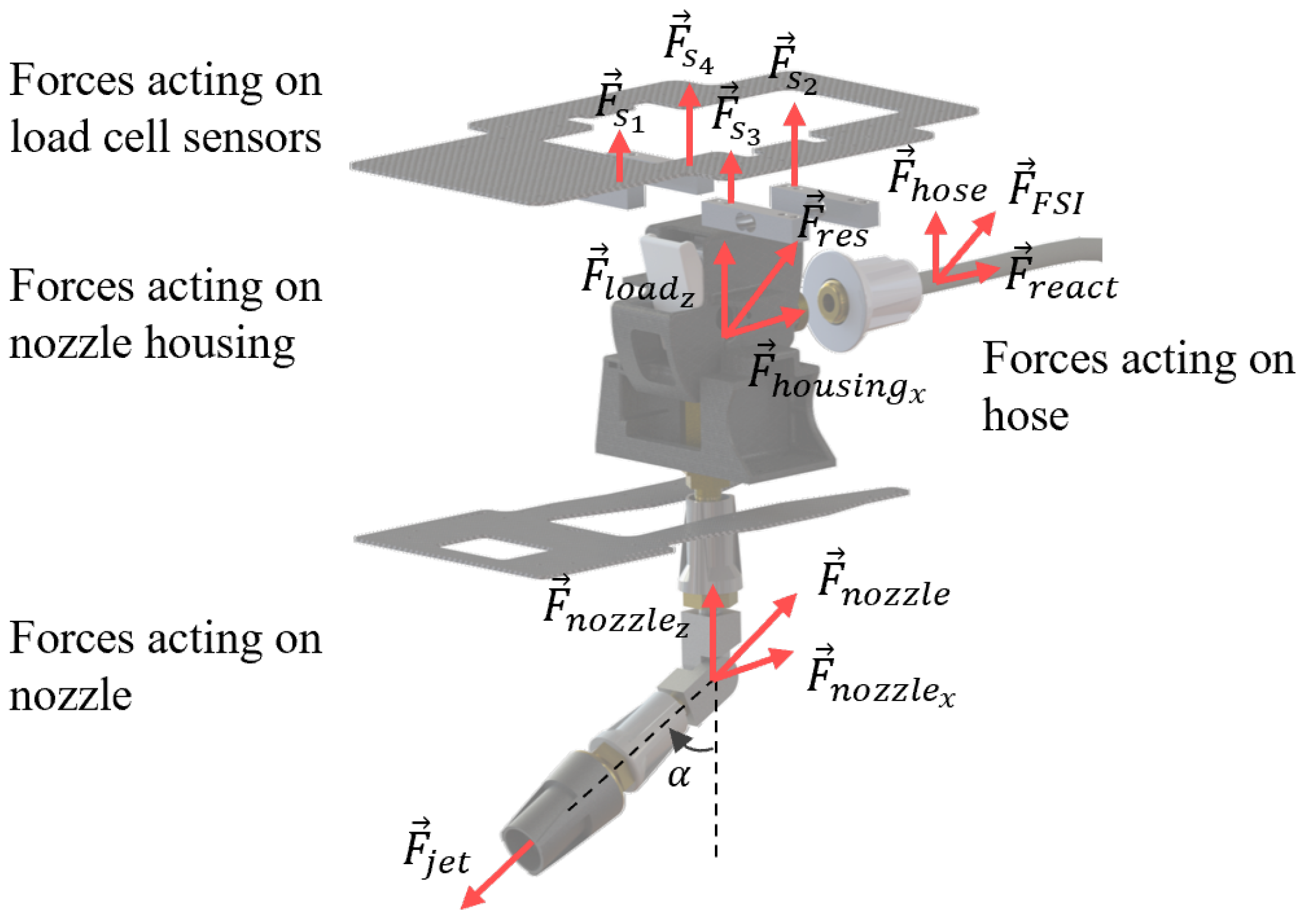

3.2. Disturbance: Flow-Induced Forces

In this section, the disturbance matrix that describes the relationship between

and

, which acts on the nozzle housing, is investigated and modelled. At the discharge segment, the disturbance model also determines the physical shift in UAV position during ejection for the respective

values. Noting that the change in

value affects the resultant vector direction between

and

, with reference to Equation (

13) and

Figure 7, the following assumptions are made for

:

where c represents cos, and

and

represent the weights for

and

, respectively, due to some damping effect or material compressibility (which are not studied). Equation (

15) presents a large number of possible permutations for the gains

and

; however, one solution is to obtain the

values empirically through a series of UAV flights with ejection for

. With reference to Assumption 1.6 and

Appendix A, the disturbance vector becomes:

d = [

0

≈ 0 0 ≈ 0]

.

3.3. Feedforward (FF) Control Strategy

The presence of the disturbance input caused by the fluid ejection can be minimised with the employment of an FF control loop that can correct the UAV’s position error in anticipation. The FF loop helps to reduce the work needed to be done by the the PID FB loop too. The disturbance input will be measured by the onboard load sensors, which measure the translated resultant force caused by the fluid ejection

on the UAV body. The sensors are made up of an array of single-direction load cells, which detects and measures the presence of the translated force (in +z) experienced by the housing that couples the hose to the UAV. As shown in

Figure 7, the load sensors are arranged such that the change in nozzle actuation angle

affects the individual cell measurement, which is critical in determining

.

Since the hose is connected to the nozzle housing and the point of ejection happens at the nozzle, which is offset by the articulated joint, the nozzle experiences an instantaneous jet reaction force. This is translated onto the nozzle housing as the flow-induced force , which gives each load cells the reading that corresponds to the with respect to . This information will be fed into the disturbance vector .