A UAV-GPR Fusion Approach for the Characterization of a Quarry Excavation Area in Falconara Albanese, Southern Italy

Abstract

1. Introduction

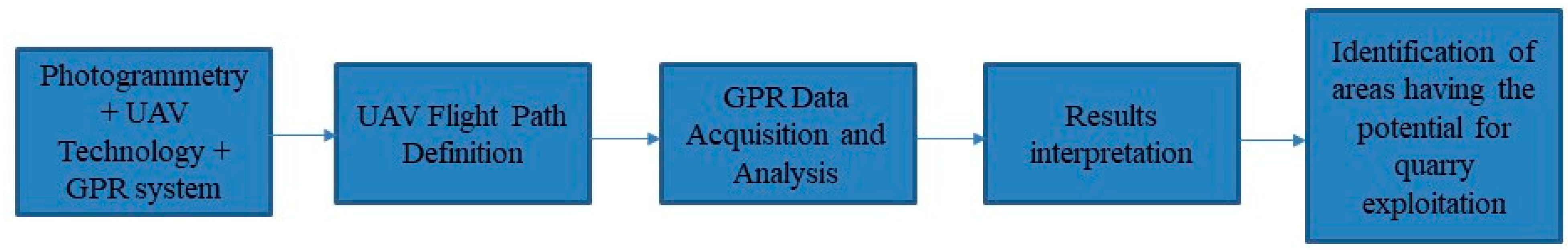

2. Materials and Methods

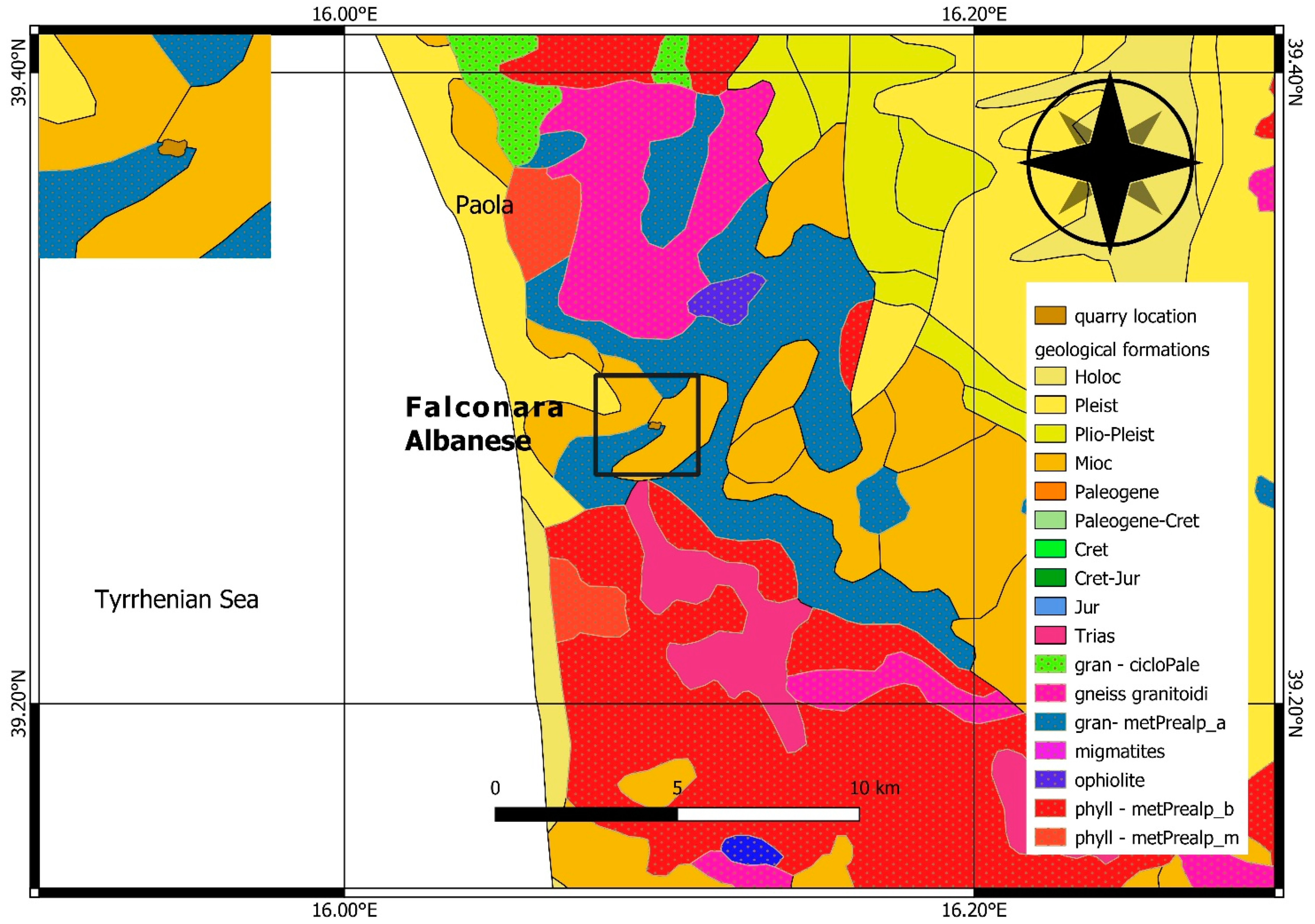

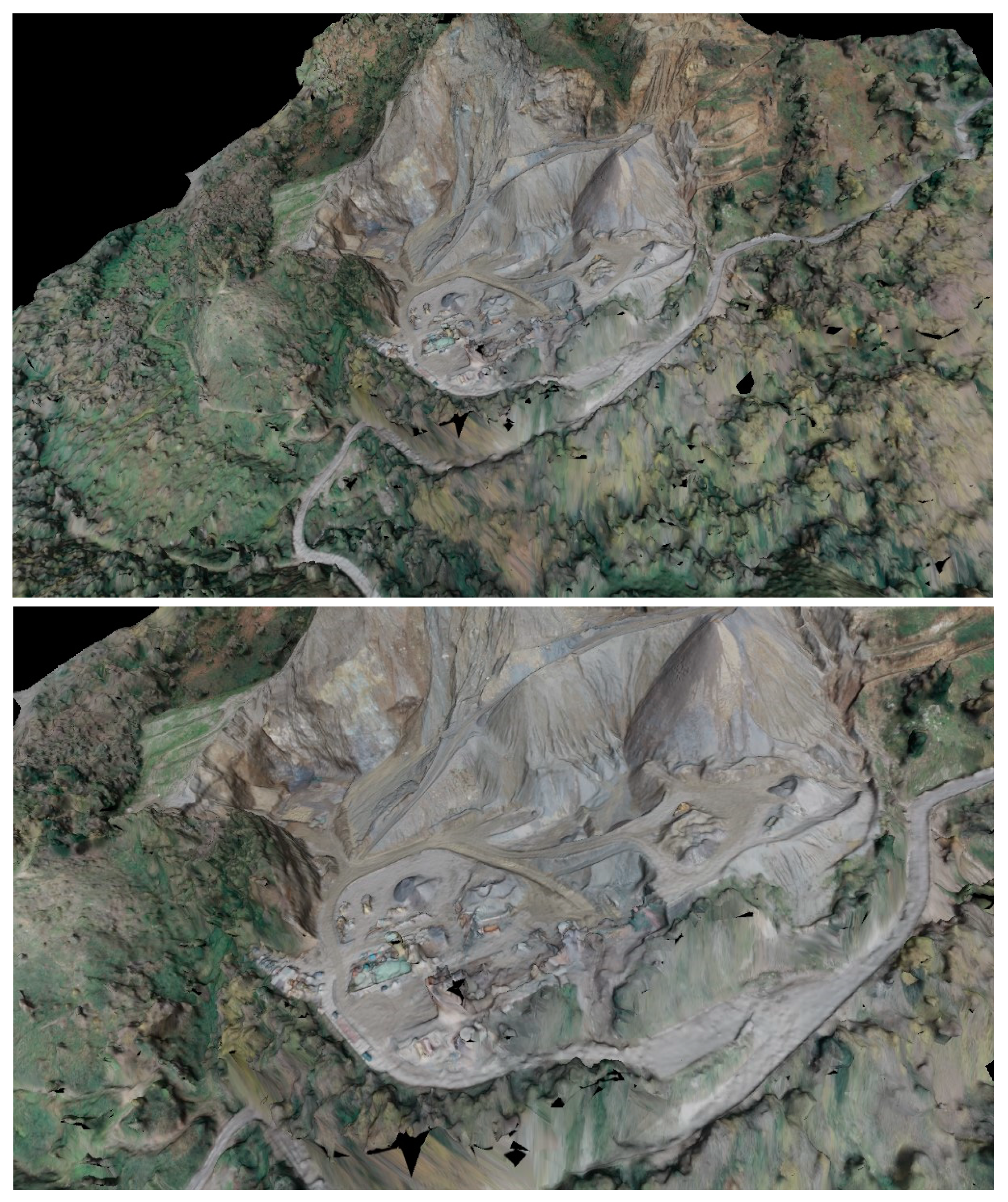

2.1. Study Area

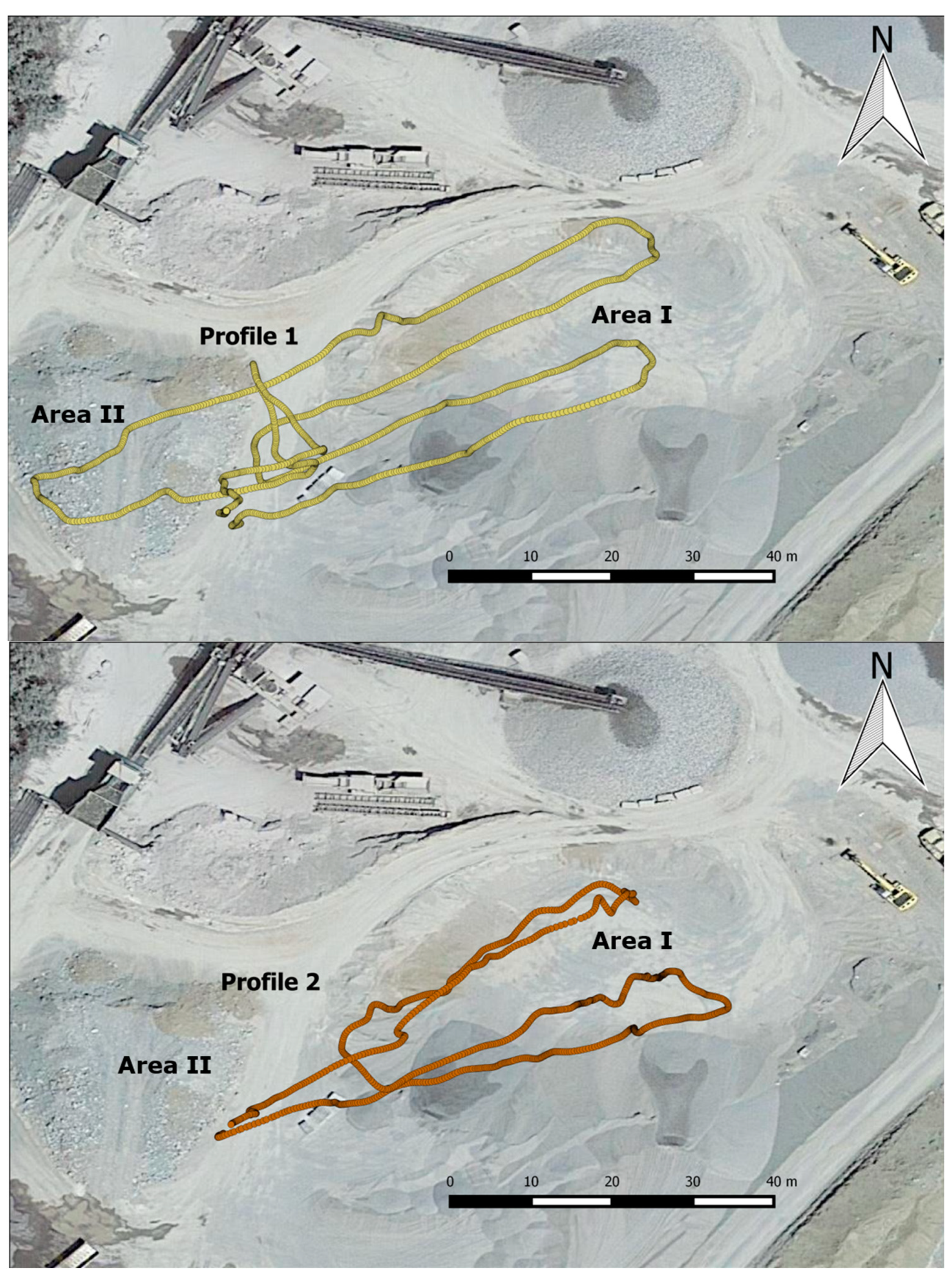

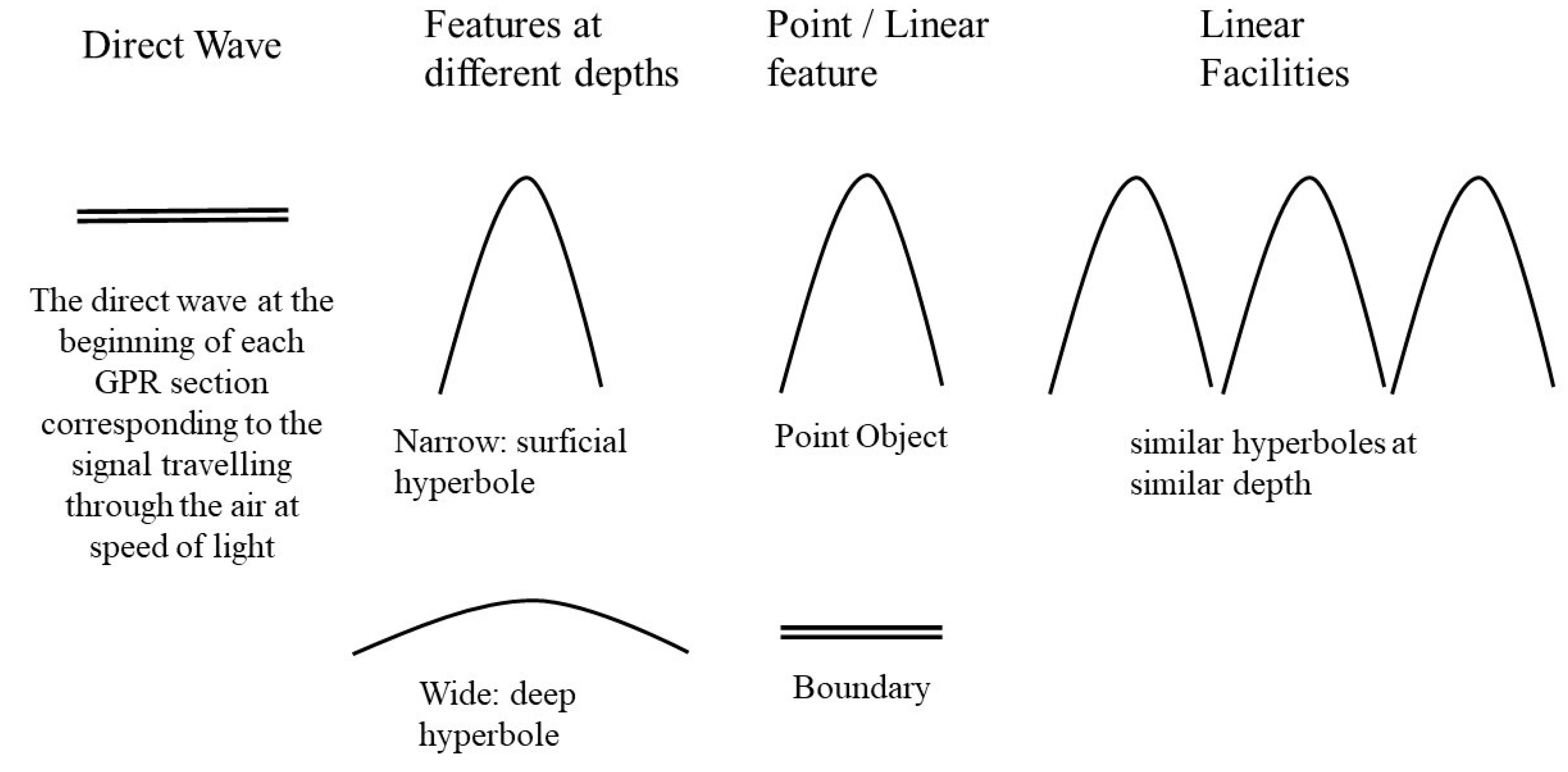

2.2. Data Acquisition and Processing

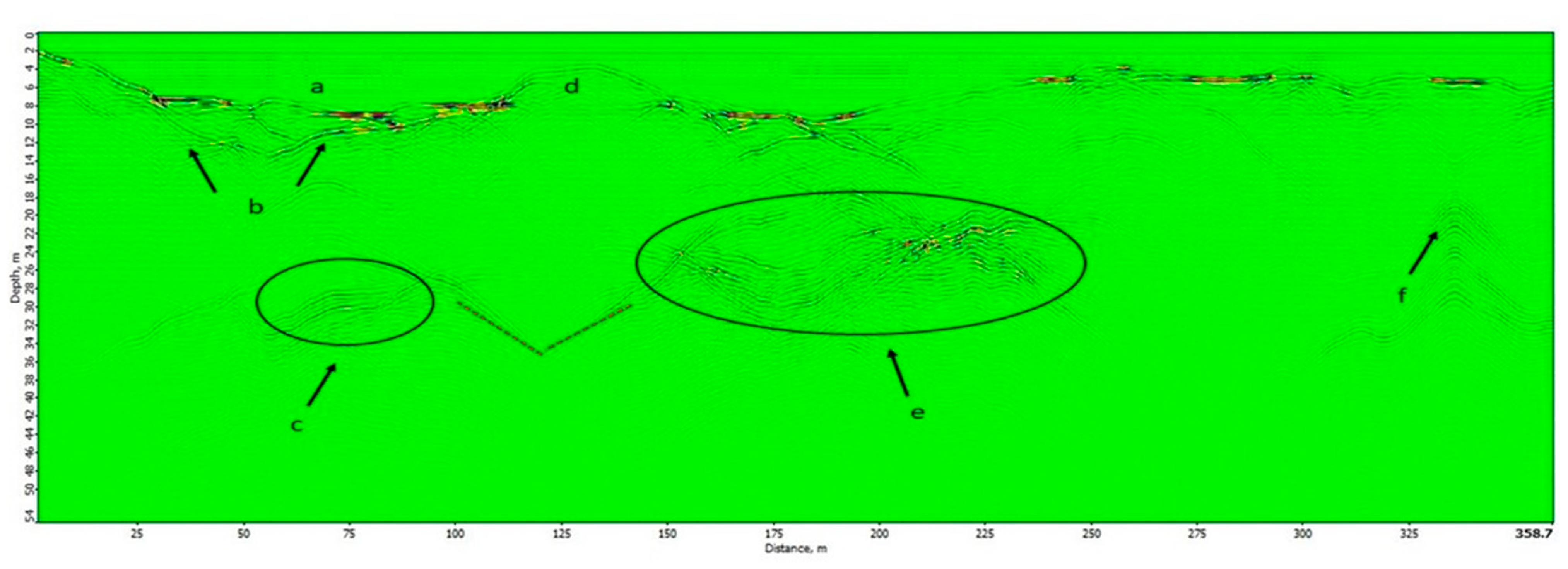

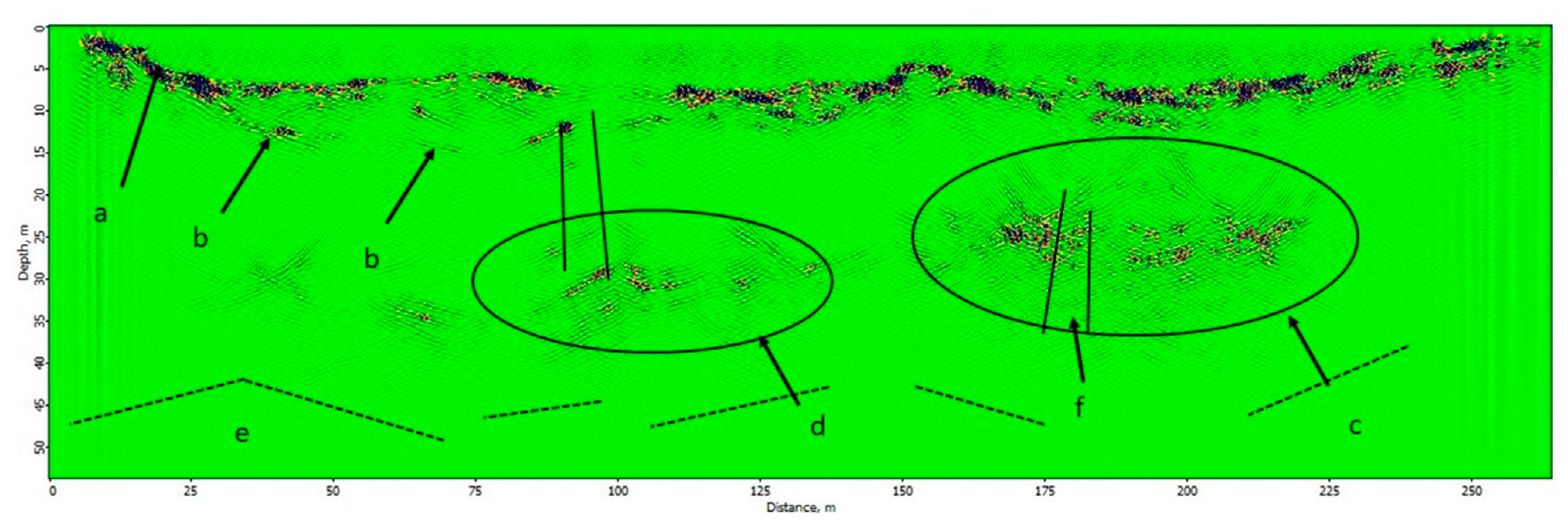

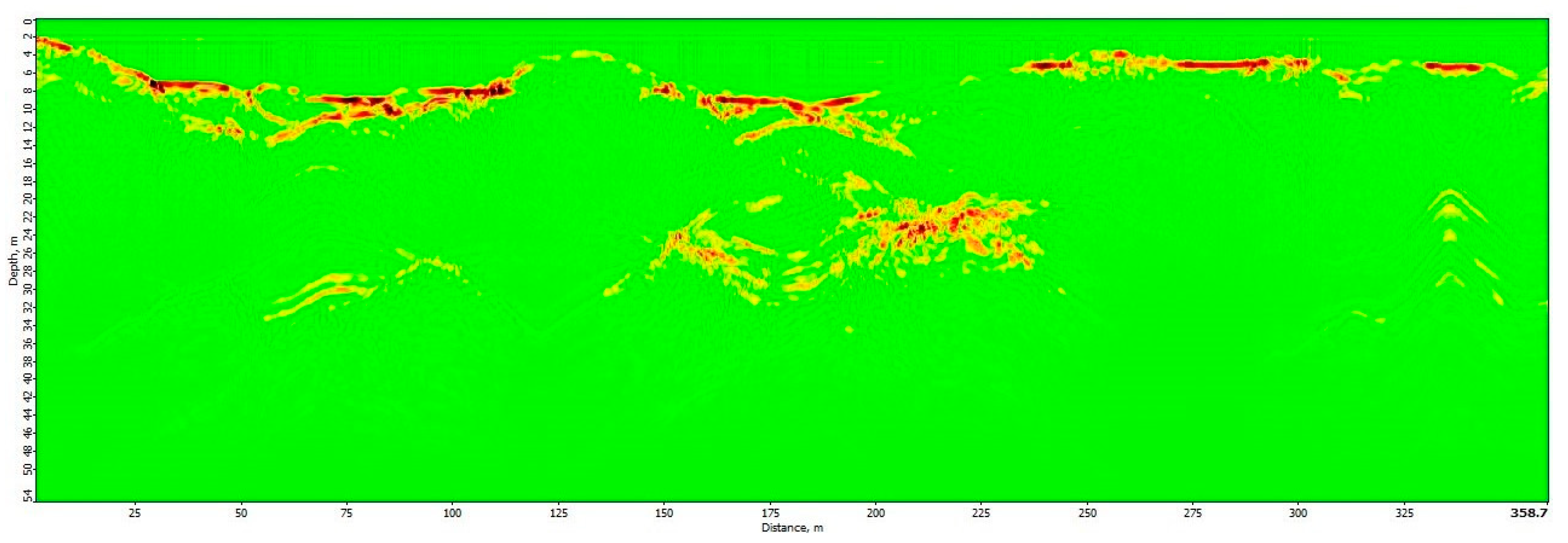

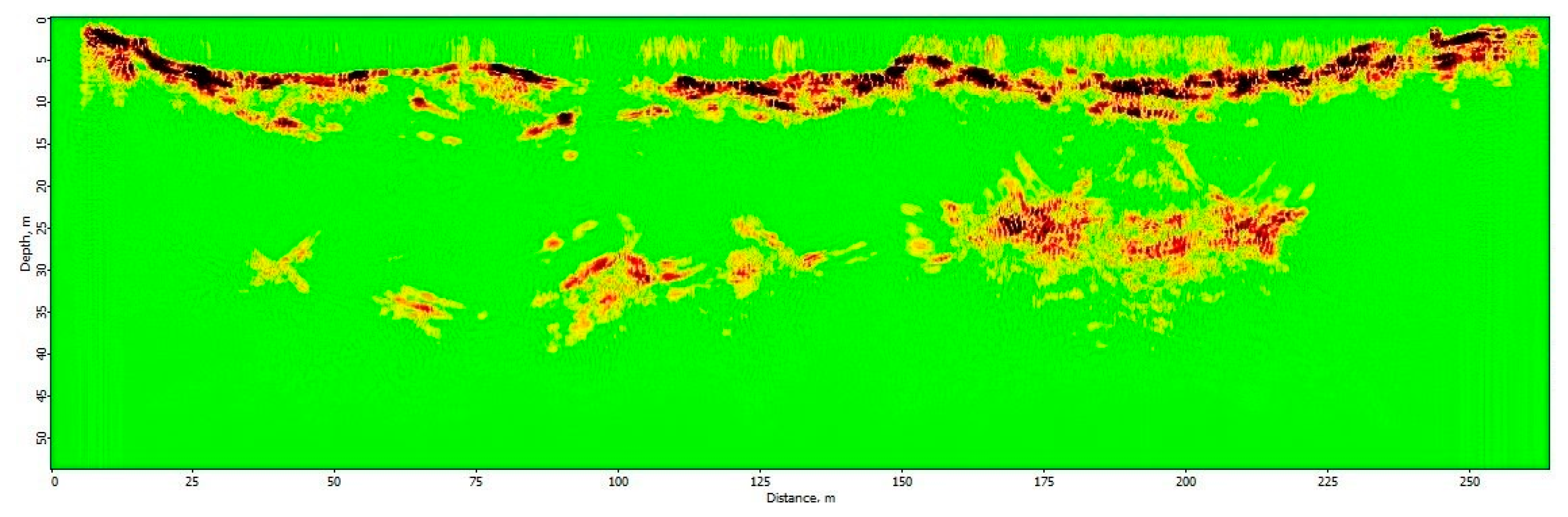

3. Results

4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raymond, G.P. Research on Railroad Ballast Specification and Evaluation. Transp. Res. Rec. 1985, 1006, 1–8. [Google Scholar]

- Hazrathosseini, A.; Mahdevari, S. Geometric Quality Assessment of in Situ Blocks in Dimension Stone Quarries. Bull. Eng. Geol. Environ. 2019, 78, 2377–2385. [Google Scholar] [CrossRef]

- Bayisa, R.; Kumar, R.T.; Seifu, K. Quarry Site Selection and Geotechnical Characterization of Ballast Aggregate for Ambo-Ijaji Railway Project in Central Ethiopia: An Integrated GIS and Geotechnical Approach. In Engineering Geology for Society and Territory—Volume 6; Lollino, G., Giordan, D., Thuro, K., Carranza-Torres, C., Wu, F., Marinos, P., Delgado, C., Eds.; Springer International Publishing: Cham, Germany, 2015; pp. 329–335. [Google Scholar] [CrossRef]

- Vignaroli, G.; Urru, G.; Rossetti, F.; Belardi, G.; Piaggi, L. Tectonic Structures and Commercial Compartments in Active Quarrying: A Case History from Northern Italy. Bull. Eng. Geol. Environ. 2017, 76, 477–496. [Google Scholar] [CrossRef]

- Sousa, L.M.O.; Oliveira, A.S.; Alves, I.M.C. Influence of Fracture System on the Exploitation of Building Stones: The Case of the Mondim de Basto Granite (North Portugal). Environ. Earth Sci. 2016, 75, 39. [Google Scholar] [CrossRef]

- Porsani, J.L.; Sauck, W.A.; Júnior, A.O.S. GPR for Mapping Fractures and as a Guide for the Extraction of Ornamental Granite from a Quarry: A Case Study from Southern Brazil. J. Appl. Geophys. 2006, 58, 177–187. [Google Scholar] [CrossRef]

- Davis, J.L.; Annan, A.P. Ground-penetrating radar for high-resolution mapping of soil and rock stratigraphy1. Geophys. Prospect 1989, 37, 531–551. [Google Scholar] [CrossRef]

- Caselle, C.; Bonetto, S.; Comina, C.; Stocco, S. GPR Surveys for the Prevention of Karst Risk in Underground Gypsum Quarries. Tunn. Undergr. Space Technol. 2020, 95, 103137. [Google Scholar] [CrossRef]

- Marchetti, M.; Cafarella, L.; Di Mauro, D.; Zirizzotti, A. Ground Magnetometric Surveys and Integrated Geophysical Methods for Solid Buried Waste Detection: A Case Study. Ann. Geophys. 2002, 45, 563–573. [Google Scholar]

- Orlando, L.; Marchesi, E. Georadar as a Tool to Identify and Characterise Solid Waste Dump Deposits. J. Appl. Geophys. 2001, 48, 163–174. [Google Scholar] [CrossRef]

- Tomecka-Suchoń, S.; Gołębiowski, T.; Dec, J.; Magiera, J. Application of GPR and Seismic Methods for Noninvasive Examination of Glacial and Postglacial Sediments in the Psia Trawka Glade: The Tatra Mts., Poland. Acta Geophys. 2019, 67, 1777–1789. [Google Scholar] [CrossRef]

- Shukla, S.B.; Chowksey, V.M.; Prizomwala, S.P.; Ukey, V.M.; Bhatt, N.P.; Maurya, D.M. Internal Sedimentary Architecture and Coastal Dynamics as Revealed by Ground Penetrating Radar, Kachchh Coast, Western India. Acta Geophys. 2013, 61, 1196–1210. [Google Scholar] [CrossRef]

- Grasmueck, M. 3-D Ground-penetrating Radar Applied to Fracture Imaging in Gneiss. Geophysics 1996, 61, 1050–1064. [Google Scholar] [CrossRef]

- Jeannin, M.; Garambois, S.; Grégoire, C.; Jongmans, D. Multiconfiguration GPR Measurements for Geometric Fracture Characterization in Limestone Cliffs (Alps). Geophysics 2006, 71, B85–B92. [Google Scholar] [CrossRef]

- Elkarmoty, M.; Colla, C.; Gabrielli, E.; Kasmaeeyazdi, S.; Tinti, F.; Bonduà, S.; Bruno, R. Mapping and modelling fractures using ground penetrating radar for ornamental stone assessment and recovery optimization: Two case studies. Min. Geol. Pet. Bull. 2017, 32, 63–76. [Google Scholar] [CrossRef]

- Luodes, H. Natural Stone Assessment with Ground Penetrating Radar. Estonian J. Earth Sci. 2008, 57, 149. [Google Scholar] [CrossRef]

- Neal, A. Ground-Penetrating Radar and Its Use in Sedimentology: Principles, Problems and Progress. Earth Sci. Rev. 2004, 66, 261–330. [Google Scholar] [CrossRef]

- Bianchini Ciampoli, L.; Tosti, F.; Economou, N.; Benedetto, F. Signal Processing of GPR Data for Road Surveys. Geosciences 2019, 9, 96. [Google Scholar] [CrossRef]

- Elkarmoty, M.; Colla, C.; Gabrielli, E.; Papeschi, P.; Bonduà, S.; Bruno, R. In-Situ GPR Test for Three-Dimensional Mapping of the Dielectric Constant in a Rock Mass. J. Appl. Geophys. 2017, 146, 1–15. [Google Scholar] [CrossRef]

- Elkarmoty, M.; Tinti, F.; Kasmaeeyazdi, S.; Giannino, F.; Bonduà, S.; Bruno, R. Implementation of a Fracture Modeling Strategy Based on Georadar Survey in a Large Area of Limestone Quarry Bench. Geosciences 2018, 8, 481. [Google Scholar] [CrossRef]

- Grandjean, G.; Gourry, J.C. GPR Data Processing for 3D Fracture Mapping in a Marble Quarry (Thassos, Greece). J. Appl. Geophys. 1996, 36, 19–30. [Google Scholar] [CrossRef]

- Kulich, J.; Bleibinhaus, F. Fault Detection with Crosshole and Reflection Geo-Radar for Underground Mine Safety. Geosciences 2020, 10, 456. [Google Scholar] [CrossRef]

- Zanzi, L.; Hojat, A.; Ranjbar, H.; Karimi-Nasab, S.; Azadi, A.; Arosio, D. GPR Measurements to Detect Major Discontinuities at Cheshmeh-Shirdoosh Limestone Quarry, Iran. Bull. Eng. Geol. Environ. 2019, 78, 743–752. [Google Scholar] [CrossRef]

- Colorado, J.; Devia, C.; Perez, M.; Mondragon, I.; Mendez, D.; Parra, C. Low-Altitude Autonomous Drone Navigation for Landmine Detection Purposes. In Proceedings of the 2017 International Conference on Unmanned Aircraft Systems (ICUAS), Miami, FL, USA, 13–16 June 2017; pp. 540–546. [Google Scholar] [CrossRef]

- Catapano, I.; Gennarelli, G.; Ludeno, G.; Noviello, C.; Esposito, G.; Renga, A.; Fasano, G.; Soldovieri, F. Small Multicopter-UAV-Based Radar Imaging: Performance Assessment for a Single Flight Track. Remote Sens. 2020, 12, 774. [Google Scholar] [CrossRef]

- Ludeno, G.; Catapano, I.; Renga, A.; Vetrella, A.R.; Fasano, G.; Soldovieri, F. Assessment of a Micro-UAV System for Microwave Tomography Radar Imaging. Remote Sens. Environ. 2018, 212, 90–102. [Google Scholar] [CrossRef]

- González-Aguilera, D.; Fernández-Hernández, J.; Mancera-Taboada, J.; Rodríguez-Gonzálvez, P.; Hernández-López, D.; Felipe-García, B.; Arias-Perez, B. 3D Modelling and Accuracy Assessment of Granite Quarry Using Unmmanned Aerial Vehicle. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2012, 3. [Google Scholar] [CrossRef]

- Salvini, R.; Riccucci, S.; Gullì, D.; Giovannini, R.; Vanneschi, C.; Francioni, M. Geological Application of UAV Photogrammetry and Terrestrial Laser Scanning in Marble Quarrying (Apuan Alps, Italy). In Engineering Geology for Society and Territory—Volume 5; Lollino, G., Manconi, A., Guzzetti, F., Culshaw, M., Bobrowsky, P., Luino, F., Eds.; Springer International Publishing: Cham, Germany, 2015; pp. 979–983. [Google Scholar] [CrossRef]

- Nagendran, S.K.; Mohamad Ismail, M.A. Application of UAV Photogrammetry for Quarry Monitoring. Warta Geol. 2020, 46, 76–81. [Google Scholar] [CrossRef]

- Raeva, P.L.; Filipova, S.L.; Filipov, D.G. Volume computation of a stockpile—a study case comparing GPS and UAV measurements in an open pit quarry. Int. Arch. Photogramm. Remote Sens. Spatial Inf. Sci. 2016, XLI-B1, 999–1004. [Google Scholar] [CrossRef]

- Rossi, P.; Mancini, F.; Dubbini, M.; Mazzone, F.; Capra, A. Combining Nadir and Oblique UAV Imagery to Reconstruct Quarry Topography: Methodology and Feasibility Analysis. Eur. J. Remote Sens. 2017, 50, 211–221. [Google Scholar] [CrossRef]

- Török, Á.; Bögöly, G.; Somogyi, Á.; Lovas, T. Application of UAV in Topographic Modelling and Structural Geological Mapping of Quarries and Their Surroundings—Delineation of Fault-Bordered Raw Material Reserves. Sensors 2020, 20, 489. [Google Scholar] [CrossRef] [PubMed]

- Colomina, I.; Molina, P. Unmanned Aerial Systems for Photogrammetry and Remote Sensing: A Review. ISPRS J. Photogramm. Remote Sens. 2014, 92, 79–97. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Sam, L.; Martín-Torres, F.J.; Kumar, R. UAVs as Remote Sensing Platform in Glaciology: Present Applications and Future Prospects. Remote Sens. Environ. 2016, 175, 196–204. [Google Scholar] [CrossRef]

- Garcia-Fernandez, M.; Alvarez-Lopez, Y.; Heras, F.L.; Gonzalez-Valdes, B.; Rodriguez-Vaqueiro, Y.; Pino, A.; Arboleya-Arboleya, A. GPR System Onboard a UAV for Non-Invasive Detection of Buried Objects. In Proceedings of the 2018 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, Boston, MA, USA, 8–13 July 2018; pp. 1967–1968. [Google Scholar] [CrossRef]

- Garcia-Fernandez, M.; Morgenthaler, A.; Alvarez-Lopez, Y.; Las Heras, F.; Rappaport, C. Bistatic Landmine and IED Detection Combining Vehicle and Drone Mounted GPR Sensors. Remote Sens. 2019, 11, 2299. [Google Scholar] [CrossRef]

- Garcia-Fernandez, M.; Alvarez-Lopez, Y.; Gonzalez-Valdes, B.; Arboleya-Arboleya, A.; Rodriguez-Vaqueiro, Y.; Las Heras, F.; Pino, A. UAV-Mounted GPR for NDT Applications. In Proceedings of the 2018 15th European Radar Conference EuRAD IEEE, Madrid, Spain, 26–28 September 2018; pp. 2–5. [Google Scholar]

- Kalyashin, S.V.; Karpuk, A.N. State and Prospects of Antennas Development for the Multicopter-Georadar Systems. Bull. Russ. Acad. Nat. Sci. 2020.

- Geoportale Regione Calabria, Open Data, Carta Geologica Vettoriale (.Shp File) Digitalizzata Dalla Carta Geologica d’Italia, Scale 1:500,000. 2016.

- Console, F.; Fabbri, S.; Pantaloni, M. La Cartografia Geologica in Calabria Nel XIX Secolo. Rend Online Soc. Geol It. 2018, 119–126. [Google Scholar] [CrossRef]

- Ogniben, L. Nota Illustrativa Sullo Schema Geologico Della Sicilia Nord-Orientale. Riv. Min. Sicil. 1960, 11, 183–212. [Google Scholar]

- Gueguen, E.; Doglioni, C.; Fernandez, M. Lithospheric Boudinage in the Western Mediterranean Back-Arc Basin. Terra Nova 1997, 9, 184–187. [Google Scholar] [CrossRef]

- Polonia, A.; Torelli, L.; Mussoni, P.; Gasperini, L.; Artoni, A.; Klaeschen, D. The Calabrian Arc Subduction Complex in the Ionian Sea: Regional Architecture, Active Deformation, and Seismic Hazard: The Calabrian Arc Subduction Complex. Tectonics 2011, 30. [Google Scholar] [CrossRef]

- Geoportale Regione Calabria, Open Data, Carta Litologica Vettoriale (.Shp File) Digitalizzata Dalla Carta Litologica, Scale 1: 100.000. 2016.

- Nex, F.; Remondino, F. UAV for 3D Mapping Applications: A Review. Appl. Geomat. 2014, 6, 1–15. [Google Scholar] [CrossRef]

- Pipan, M.; Baradello, L.; Forte, E.; Prizzon, A. GPR Study of Bedding Planes, Fractures, and Cavities in Limestone. In Proceedings of the Eighth International Conference on Ground Penetrating Radar, Gold Coast, Australia, 23–26 May 2020; Noon, D.A., Stickley, G.F., Longstaff, D., Eds.; pp. 682–687. Available online: https://www.spiedigitallibrary.org/conference-proceedings-of-spie/4084/0000/GPR-study-of-bedding-planes-fractures-and-cavities-in-limestone/10.1117/12.383499.short?SSO=1 (accessed on 18 May 2021).

- Maheswari, K.; Senthil Kumar, P.; Mysaiah, D.; Ratnamala, K.; Sri Hari Rao, M.; Seshunarayana, T. Ground Penetrating Radar for Groundwater Exploration in Granitic Terrains: A Case Study from Hyderabad. J. Geol. Soc. India 2013, 81, 781–790. [Google Scholar] [CrossRef]

- Griffin, R.H. Geophysical Exploration for Engineering and Environmental Investigations; US Army Corps of Engineers: Washington, DC, USA, 1995. [Google Scholar]

- Orlando, L. Semiquantitative Evaluation of Massive Rock Quality Using Ground Penetrating Radar. J. Appl. Geophys. 2003, 52, 1–9. [Google Scholar] [CrossRef]

- Geoportale Regione Calabria, Open Data, Carta Vettoriale Della Rete Idrografica (.Shp File). 2016.

- Longhitano, S.G.; Chiarella, D.; Di Stefano, A.; Messina, C.; Sabato, L.; Tropeano, M. Tidal Signatures in Neogene to Quaternary Mixed Deposits of Southern Italy Straits and Bays. Sediment. Geol. 2012, 279, 74–96. [Google Scholar] [CrossRef]

- Widess, M.B. How thin is a thin bed? Geophysics 1973, 38, 1176–1180. [Google Scholar] [CrossRef]

- Booth, A.D.; Clark, R.A.; Murray, T. Influences on the Resolution of GPR Velocity Analyses and a Monte Carlo Simulation for Establishing Velocity Precision. Near Surf. Geophys. 2011, 9, 399–411. [Google Scholar] [CrossRef]

- Massaro, A.; Galiano, A. Handbook of Research on Intelligent Data Processing and Information Security Systems. In Advances in Information Security, Privacy, and Ethics; Bilan, S.M., Al-Zoubi, S.I., Gupta, M., Eds.; IGI Global USA: Hershey, PA, USA, 2020. [Google Scholar] [CrossRef]

- Massaro, A.; Galiano, A. Handbook of Research on Advanced Mechatronic Systems and Intelligent Robotics. In Advances in Computational Intelligence and Robotics; Habib, M.K., Giannoccaro, I., Eds.; IGI Global USA: Hershey, PA, USA, 2020. [Google Scholar] [CrossRef]

- QGIS Development Team. QGIS Geographic Information System; Release 3.4 Madeira; Open Source Geospatial Foundation Project. 2021. Available online: https://ads.nipr.ac.jp/gis/quantarctica/Quantarctica3/Software/QGIS_UserGuide.pdf (accessed on 18 May 2021).

| Trace | Roll (°) | Pitch (°) | Yaw (°) | Latitude (°) | Longitude (°) | Altitude (m) |

|---|---|---|---|---|---|---|

| 1 | 0.45 | 1.11 | 58.70 | 39.2879524 | 16.0973279 | −0.14 |

| 2 | 0.41 | 1.08 | 58.68 | 39.2879524 | 16.0973279 | −0.13 |

| 2 | 0.43 | 0.81 | 58.61 | 39.2879524 | 16.0973279 | −0.13 |

| 3 | 0.42 | 0.72 | 58.70 | 39.2879524 | 16.0973280 | −0.13 |

| 4 | 0.43 | 0.70 | 58.67 | 39.2879524 | 16.0973280 | −0.12 |

| 5 | 0.41 | 0.78 | 58.66 | 39.2879524 | 16.0973280 | −0.12 |

| 6 | 0.43 | 0.71 | 58.69 | 39.2879524 | 16.0973280 | −0.11 |

| 7 | 0.43 | 0.53 | 58.71 | 39.2879524 | 16.0973280 | −0.10 |

| 8 | 0.46 | 0.59 | 58.74 | 39.2879524 | 16.0973280 | −0.10 |

| 9 | 0.44 | 0.97 | 58.66 | 39.2879524 | 16.0973280 | −0.10 |

| 11 | 0.45 | 1.19 | 58.69 | 39.2879524 | 16.0973279 | −0.11 |

| 11 | 0.41 | 0.97 | 58.72 | 39.2879524 | 16.0973279 | −0.12 |

| 12 | 0.40 | 0.66 | 58.69 | 39.2879524 | 16.0973280 | −0.11 |

| 13 | 0.43 | 0.64 | 58.78 | 39.2879524 | 16.0973280 | −0.11 |

| 14 | 0.44 | 0.83 | 58.68 | 39.2879524 | 16.0973280 | −0.09 |

| 15 | 0.44 | 1.05 | 58.70 | 39.2879524 | 16.0973280 | −0.08 |

| 16 | 0.45 | 0.85 | 58.67 | 39.2879524 | 16.0973280 | −0.08 |

| 17 | 0.52 | 0.64 | 58.72 | 39.2879524 | 16.0973280 | −0.08 |

| 18 | 0.49 | 0.64 | 58.69 | 39.2879524 | 16.0973280 | −0.07 |

| 19 | 0.49 | 0.76 | 58.70 | 39.2879524 | 16.0973280 | −0.08 |

| Material | Relative Dielectric Constant | Conductivity (mS/m) | Velocity (m/ns) | Attenuation (dB/m) |

|---|---|---|---|---|

| Air | 1 | 0 | 3 | 0 |

| Fresh Water | 80 | 5 | 033 | 1 |

| Dry Sand | 3–5 | 01 | 15 | 01 |

| Wet Sand | 20–30 | 1–1 | 06 | 03–3 |

| Limestone | 4–8 | 5–2 | 12 | 4–1 |

| Granite | 4–6 | 01–1 | 13 | 01–1 |

| Ice | 3–4 | 01 | 16 | 01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saponaro, A.; Dipierro, G.; Cannella, E.; Panarese, A.; Galiano, A.M.; Massaro, A. A UAV-GPR Fusion Approach for the Characterization of a Quarry Excavation Area in Falconara Albanese, Southern Italy. Drones 2021, 5, 40. https://doi.org/10.3390/drones5020040

Saponaro A, Dipierro G, Cannella E, Panarese A, Galiano AM, Massaro A. A UAV-GPR Fusion Approach for the Characterization of a Quarry Excavation Area in Falconara Albanese, Southern Italy. Drones. 2021; 5(2):40. https://doi.org/10.3390/drones5020040

Chicago/Turabian StyleSaponaro, Annamaria, Giovanni Dipierro, Emanuele Cannella, Antonio Panarese, Angelo Maurizio Galiano, and Alessandro Massaro. 2021. "A UAV-GPR Fusion Approach for the Characterization of a Quarry Excavation Area in Falconara Albanese, Southern Italy" Drones 5, no. 2: 40. https://doi.org/10.3390/drones5020040

APA StyleSaponaro, A., Dipierro, G., Cannella, E., Panarese, A., Galiano, A. M., & Massaro, A. (2021). A UAV-GPR Fusion Approach for the Characterization of a Quarry Excavation Area in Falconara Albanese, Southern Italy. Drones, 5(2), 40. https://doi.org/10.3390/drones5020040