Development of a Compact, Reliable, and Electrostatically Actuated Device for Microfluidic-Based Active Glasses †

Abstract

1. Introduction

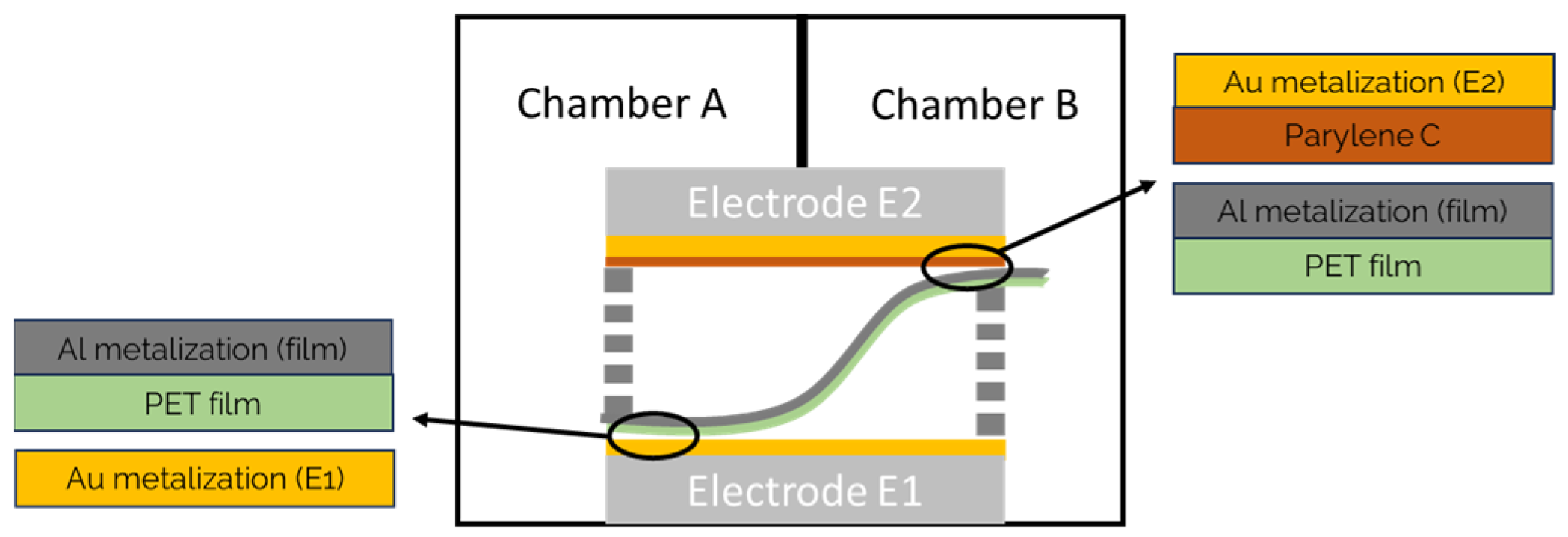

2. Materials and Methods

3. Results and Discussion

3.1. Benefits of the New Concept

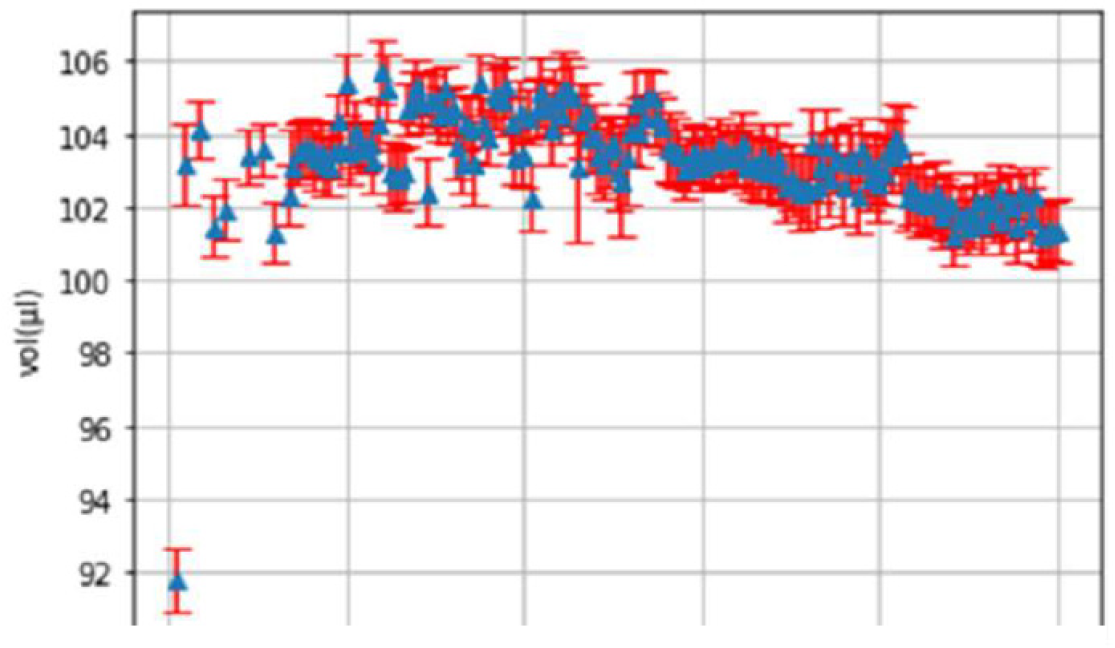

3.2. Fiability

3.3. Transparent Actuator

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jarosz, J.; Lavigne, Q.; Molliex, N.; Chenon, G.; Noetinger, G.; Tran, D.-D.; Berge, B. Experimental optical analysis of an original presbyopia-correcting variable focus lens. Investig. Ophthalmol. Vis. Sci. 2018, 59, 255. [Google Scholar]

- Jarossz, J.; Molliex, N.; Kulifaj, S.; Granier, C.; Savitri, D.; Waoussi, S.; Trone, M.C.; Thuret, G.; Gain, P.; Berge, B. Pilot Clinical Investigation of Adaptative Eyeglasses for the Correction of Presbyopia. In Proceedings of the ARVO 2023, New Orleans, LA, USA, 23–27 April 2023. [Google Scholar]

- Lavigne, Q.; Terrier, N.; Noetinger, G.; Tran, D.-D.; Kulifaj, S.; Kleimann, P.; Pittet, P.; Berge, B. Novel concept of a low-power high- volume microfluidic actuator: Theory of operation and experimental characterization. Sens. Actuators A Phys. 2019, 291, 13–22. [Google Scholar] [CrossRef]

- Laser, D.J.; Santiago, J.G. A review of micropumps. J. Micromech. Microeng. 2004, 14, R35. [Google Scholar] [CrossRef]

- Patrascu, M.; Gonzalo-Ruiz, J.; Goedbloed, M.; Crego-Calama, M.; Brongersma, S.H. Design, fabrication and characterization of electrostatic micro actuators for microfluidic platforms. In Proceedings of the Eurosensors XXV, Athens, Greece, 4–7 September 2011. [Google Scholar]

- Machauf, A.; Nemirovsky, Y.; Dinnar, U. A membrane micropump electrostatically actuated across the working fluid. J. Micromech. Microeng. 2005, 15, 2309. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulifaj, S.; Chauvin, C.; Bouvier, A.; Meinier, S.; Gu, F.; Degouttes, J.; Terrier, N.; Pittet, P.; Berge, B. Development of a Compact, Reliable, and Electrostatically Actuated Device for Microfluidic-Based Active Glasses. Proceedings 2024, 97, 22. https://doi.org/10.3390/proceedings2024097022

Kulifaj S, Chauvin C, Bouvier A, Meinier S, Gu F, Degouttes J, Terrier N, Pittet P, Berge B. Development of a Compact, Reliable, and Electrostatically Actuated Device for Microfluidic-Based Active Glasses. Proceedings. 2024; 97(1):22. https://doi.org/10.3390/proceedings2024097022

Chicago/Turabian StyleKulifaj, Simon, Clément Chauvin, Antoine Bouvier, Solène Meinier, Fengzhi Gu, Jérôme Degouttes, Nicolas Terrier, Patrick Pittet, and Bruno Berge. 2024. "Development of a Compact, Reliable, and Electrostatically Actuated Device for Microfluidic-Based Active Glasses" Proceedings 97, no. 1: 22. https://doi.org/10.3390/proceedings2024097022

APA StyleKulifaj, S., Chauvin, C., Bouvier, A., Meinier, S., Gu, F., Degouttes, J., Terrier, N., Pittet, P., & Berge, B. (2024). Development of a Compact, Reliable, and Electrostatically Actuated Device for Microfluidic-Based Active Glasses. Proceedings, 97(1), 22. https://doi.org/10.3390/proceedings2024097022