Optimization of Micro-Electromechanical Lorentz Actuator Using a Surrogate Model Accelerated Genetic Algorithm †

Abstract

1. Introduction

2. Method

3. Results and Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, P.; Lu, Q.; Fan, Z. Evolutionary Design Optimization of MEMS: A Review of its History and Start-of-the-art. Clust. Comput. 2019, 22, 9105–9111. [Google Scholar] [CrossRef]

- Park, B.; Afsharipour, E.; Chrusch, D.; Shafai, C.; Andersen, D.; Burley, G. A Low Voltage and Large Stroke Lorentz Force Continuous Deformable Polymer Mirror for Wavefront Control. Sens. Actuators A 2018, 280, 197–204. [Google Scholar] [CrossRef]

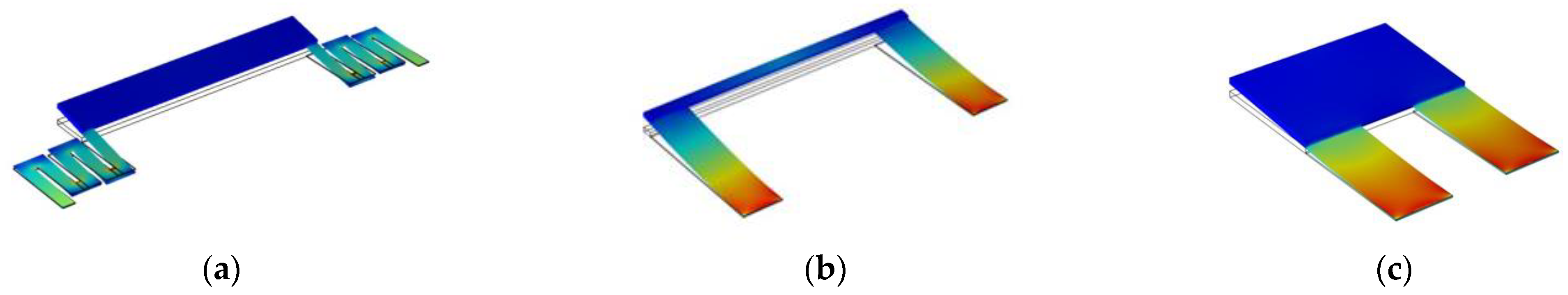

| Actuation Current (mA) | Temperature Increase (°C) | Mechanical Stress (MPa) | Resonance Frequency, f0 (kHz) | Comments |

|---|---|---|---|---|

| 4.68 | 7.35 | 2.89 | 2.58 | Original design (a) |

| 14.0 | 2.25 | 2.22 | 5.96 | Best stress and f0 (b) |

| 36.0 | 0.99 | 2.33 | 4.61 | Best temp. increase (c) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buhr, P.; Shafai, C.; Park, B.; Wang, Y.; Belov, M. Optimization of Micro-Electromechanical Lorentz Actuator Using a Surrogate Model Accelerated Genetic Algorithm. Proceedings 2024, 97, 191. https://doi.org/10.3390/proceedings2024097191

Buhr P, Shafai C, Park B, Wang Y, Belov M. Optimization of Micro-Electromechanical Lorentz Actuator Using a Surrogate Model Accelerated Genetic Algorithm. Proceedings. 2024; 97(1):191. https://doi.org/10.3390/proceedings2024097191

Chicago/Turabian StyleBuhr, Phiona, Cyrus Shafai, Byoungyoul Park, Yunli Wang, and Miroslav Belov. 2024. "Optimization of Micro-Electromechanical Lorentz Actuator Using a Surrogate Model Accelerated Genetic Algorithm" Proceedings 97, no. 1: 191. https://doi.org/10.3390/proceedings2024097191

APA StyleBuhr, P., Shafai, C., Park, B., Wang, Y., & Belov, M. (2024). Optimization of Micro-Electromechanical Lorentz Actuator Using a Surrogate Model Accelerated Genetic Algorithm. Proceedings, 97(1), 191. https://doi.org/10.3390/proceedings2024097191