Abstract

We developed a new approach to the fabrication of MEMS (Microelectromechanical system) substrates for gas sensors. This full screen-printing approach consists in the application of sacrificial material, which is solid at the near-room temperature of printing and becomes powder after firing of the elements of the sensor and, therefore, can be removed from under the suspended elements of the MEMS structure in an ultrasonic bath. The glass–ceramic MEMS is a cantilever structure equipped with a Pt-based microheater on the end edge with the sensing layer. Screen-printing provides cheap fabrication, robustness, and low power (~120 mW at 450 °C) for the sensing element.

1. Introduction

The application of MEMS structures mainly fabricated using silicon technology is a modern trend in the sensors of both semiconductor and thermocatalytic types. These devices have low power consumption (down to ~20 mW) and are suitable for mass production. However, they have some drawbacks: poor adhesion of platinum, limited operation temperature (~350 °C), and relatively high cost when they are not produced in billions. We tried to develop a new approach consisting of the application of full screen-printing technology for the fabrication of thin glass ceramic cantilevers as a main element of the MEMS sensor.

2. Materials and Methods

The fabrication of the MEMS sensor using screen-printing technology includes the following operations: (1) preparation of the ceramic substrate; (2) laser cutting of the rectangular windows in the substrate; (3) filling of the windows with sacrificial pastes consisting of solid unsinterable particles and organic composition; (4) drying and polishing of the substrate with filling; and (5) screen printing of the elements of the gas sensor onto the substrate with sacrificial filling that are the body of the cantilever, leads to the microheater, leads to the sensing layer, isolation between the microheater and the sensing layer, and contacts to the sensing layer. After deposition, the substrate is fired, and the sacrificial layer is removed in an ultrasonic bath. The last operation is the deposition of the sensing layer paste with a robotic system, firing of the sensing layer, and cutting of the substrate, forming individual chips. The chips are packaged into TO5 using the flip-chip technique.

We developed the following set of pastes used for the fabrication of the sensor: Pt-based composite for the heater with a resistance of ~4 Ohm per square; glass–ceramic material for the cantilever body, isolation, and SnO2-based material for the sensing layer with a particlesize of about 10 nm. The microheater material assures long-term stability of the microheater; the drift of resistance is <1.5% per year at 450 °C. The resistor of the microheater is also used as a temperature sensor; the temperature coefficient of resistance of the material (TCR) is equal to 2980 ppm per degree centigrade.

3. Discussion

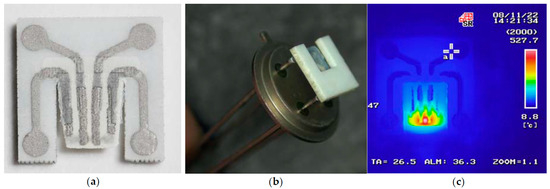

The ceramic MEMS sensor fabricated using screen printing technology is presented in Figure 1a. On the top of the sensor, the microheater, isolation, and contacts to the sensing layer are fabricated. The sensor in TO5 (flip-chip packaging) is presented in Figure 1b. The application of glass–ceramic materials provides robustness to the cantilever; it is not damaged by falls or transportation vibrations, and it enables the contact deposition of the sensing layer after fabrication.

Figure 1.

Photo of ceramic MEMS sensors fabricated using screen-printing technology. (a) Top view of the microchip with a thin (20 μm) ceramic cantilever, microheater, and contacts to the sensing layer. (b) Sensor chip packaged into the TO5 housing. (c) Temperature distribution over the microheater and cantilever.

Figure 1c presents the temperature distribution over the surface of the sensor chip. High-temperature regions are concentrated over the microheater, which enables the minimization of power consumption. Power consumption is a linear function of the temperature of the microheater; the microheater consumes 120 mW at a working temperature of 450 °C.

The sensing layer made by sol-gel technology by precipitating tin dioxide with hydrogen peroxide from SnSO4 solution was prepared as a printable paste and deposited over the microheater by a robotic system. The particle size of the sensing layer is of about 10 nm, and the particles can be decorated with catalyst clusters (Pd and/or Pt). The response of the sensor to hydrogen, methane, and other gases was studied using mass-flow controller-based equipment and lies in the usual range of values. For example, the response to 1% of CH4 Rair/Rgas is in a range from 10 to 20 at 50% relative humidity and 20 °C ambient temperature.

4. Patents

A.A.Vasiliev and O.V.Kul. Supporting module of sensing elements of microelectronic sensor and method for manufacturing the same. Patent of the Russian Federation #2022101088/28(002089). Priority 18.01.2022. M.K.Kutuzov, O.V.Kul, and A.A.Vasiliev. Platinum-resistant paste. Patent of the Russian Federation #202213189., Priority 07.12.2022.

Author Contributions

Conceptualization, A.V. and O.K.; materials, O.K., A.V. and A.D.; fabrication, A.D., A.N. and A.B.; measurements and validation, A.N. and A.V.; writing, A.V.; project administration, O.K.; funding acquisition, O.K. and A.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the IraSME program (2020) titled “Selective ceramic MEMS sensor for leakage detection in systems utilizing H2/CH4 gas mixtures”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors acknowledge the help of V.V.Sysoev (Technical University of Saratov) and his research group for the opportunity to measure temperature distribution over a microcantilever surface.

Conflicts of Interest

The authors declare no conflicts of interest. LLC “C-Component” does not have any potential commercial conflict of interest.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).