Abstract

The straightening and forming of metal parts are typical and usual tasks within shipbuilding industries. They may expose boilermakers to high levels of vibration, leading to potential health risks (musculoskeletal disorders and vascular syndromes). This study consisted of helping a company evaluate their hammering machines that were activated by ultrasound, comparing them to conventional impact tools. Vibration measurements were therefore carried out in the field. These were followed by an analysis of the signals according to the regulations and additional assessment tools.

1. Introduction

Context: To achieve the final shape of a component or a metal part, it is often necessary to carry out straightening or forming operations. These activities are common in aeronautical and naval construction. They are conventionally performed by hammering processes that use different tools: (i) a sledgehammer and flattener; (ii) a trolley-mounted pneumatic chipping hammer; or (iii) a pneumatic riveting hammer.

These operations can expose personnel to high vibration and sound levels. One technology that is present in the market is the ultrasound-activated hammer [1]. A high-frequency generator supplies a piezoelectric transmitter, generating mechanical waves. These are amplified to the sonotrode and this energy is then transmitted to a media, which is made up of needle-type impactors for the straightening–forming.

Purpose: To support a shipbuilding company in its prevention approach during the qualification tests of a hammering process activated by ultrasound, we characterised the vibration emissions of this technology and compared them to conventional tools.

2. Materials and Method

2.1. Tools Tested and Test Conditions

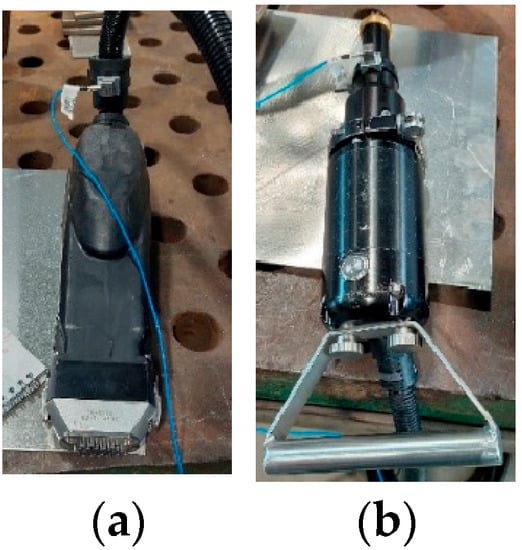

We first tested the manual hammering technique with a flattener (Figure 1).

Figure 1.

Hammer (a) and flattener (b).

Then, a riveting hammer and a chipping hammer on a trolley were characterised (Figure 2).

Figure 2.

Atlas Copco RRH 12 (a), and (b) RRC 75 B-01.

Finally, we characterised two hammers that were activated by ultrasound (Figure 3).

Figure 3.

SONATS Stress Voyager PR10 mouthpiece ER18-03 (a), and SONATS Nomad (b).

The parts that were used were made up of metal elements of steel or aluminium, clamped on a test marble in the boiler-making workshop: (i) steel and aluminium sheets; and (ii) mechanically welded steel parts.

2.2. Metrology

The measurements of the hand-transmitted vibrations were carried out in accordance with the NF EN ISO 5349-1 and NF EN ISO 5349-2 [2,3] standards, using a triaxial accelerometer that was rigidly fastened to the machine handle, as close as possible to the palm of the hand.

The signal conditioning of our triaxial accelerometer (model 356B20, PCB Piezotronics) and the vibration data acquisition were carried out using our acquisition front-end (Scadas XS, Siemens), with a sampling rate of 2560 Hz.

2.3. Data Processing

2.3.1. Vibration Frequency Weighting

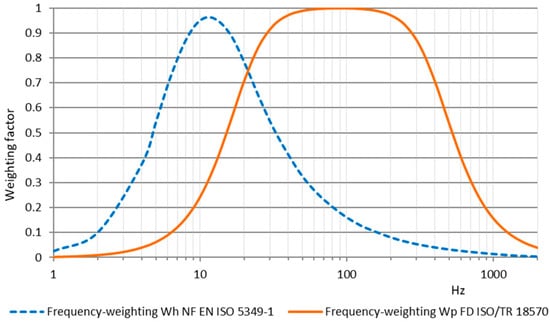

The signals that were measured on the three axes are weighted in frequency, according to the weighting factor Wh, as defined by the NF EN ISO 5349-1 standard [2]. The corresponding weighted accelerations are expressed as ahwx, ahwy, and ahwz.

The documentation booklet FD ISO/TR 18570 [4] defines an additional method for measuring the vibrations that are transmitted to the hands. It aims at improving the assessment of the risks of vascular disorders (vibration white finger, namely Raynaud syndrome).

This booklet defines, in particular, an additional frequency weighting, Wp (Figure 4), for the three axes, x, y, and z. The main difference between this weighting and the weighting Wh, as defined by the NF EN ISO 5349-1 standard [1], lies in its much greater consideration of the higher frequencies.

Figure 4.

Weighting curve Wp to assess the risk of vascular disorders.

2.3.2. Determination of Vibration Emission Levels

The level of the vibration emission, ahv (the vibration total value), is calculated according to the following expression (1):

As the ahv level is, the level of the vibration emission apv (the vibration total value) is a function of the frequency-weighted accelerations that are measured on the three axes (apx, apy, and apz) and is calculated by the following expression (2):

2.3.3. Spectral Analyses of Temporal Signals

Thanks to our SiemensScadas XS system and its TestXpress software, from the time signals, we analysed the vibration spectra of the hammering that was activated by ultrasound.

3. Results

The qualification tests of the hammering tools activated by ultrasound, in comparison to the conventional straightening tools, did not provide satisfaction to the company.

3.1. Vibration Levels of Conventional Processes

We calculated the vibration levels of the standard tools that were used by this shipbuilding company for the straightening and forming of parts (Table 1):

Table 1.

Vibration levels of conventional tools.

3.2. Vibration Levels of Ultrasound hammer

We calculated the vibration levels of the ultrasonically activated hammering tools that were tested for the straightening and forming of parts (Table 2).

Table 2.

Vibration levels of ultrasonically activated tools.

4. Discussion

Compared to conventional tools, ultrasound-activated hammering tools generally reduce vibration levels. There are, however, strong variations depending on the type of head and mouthpiece that are used for the same piece being hammered, with factors ranging from 1 to 4. This leads to limit durations of use of just over 2 h for reaching the regulatory action threshold value set at 2.5 m/s2. Our readings show significant spectral content in high frequencies (50 to 500 Hz). The use of the FD ISO/TR 18570 documentation booklet allowed us to estimate the vibration levels and their vascular risks. Without a limit value, however, it is difficult to assess the level of risk.

5. Conclusions

Synthesis: These new machines reduce risks when straightening and forming metal parts. However, we have noted that there are health risks depending on the type of tools that are used. These tests did not provide satisfaction to the shipbuilding company and the traditional processes were therefore retained.

Prospects: To characterise these new tools under operational conditions, giving satisfaction to the user, we have planned to carry out new tests with the manufacturer of these processes, in an establishment of one of their customers.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data not available due to legal/commercial restrictions.

Conflicts of Interest

The author declares no conflict of interest.

References

- STRESSONIC® Peening Process. Available online: https://sonats-et.com/en/peening-process/ (accessed on 15 February 2023.).

- NF EN ISO 5349-1:2002; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 1: General requirements. International Organization for Standardization: Geneva, Switzerland, 2002.

- NF EN ISO 5349-2:2001; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 2: Practical guidance for measurement at the workplace. International Organization for Standardization: Geneva, Switzerland, 2001.

- FD ISO/TR 18570:2017; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand Transmitted Vibration—Supplementary Method for Assessing Risk of Vascular Disorders. International Organization for Standardization: Geneva, Switzerland, 2017.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).