1. Introduction

Rock drills expose operators for high vibration levels, which can lead to vibration injuries. These machines are frequently used for stabilising rock faces by drilling holes for securing bolts and steel nets to prevent rocks from falling on people and infrastructure. For operators in the rock face stabilising sector in Norway, pneumatic rock drills have been identified as a major source of vibrations [

1,

2]. Their work situation is also ergonomically challenging since the work is often performed on steep cliffs with heavy equipment and a substantial degree of dust exposure [

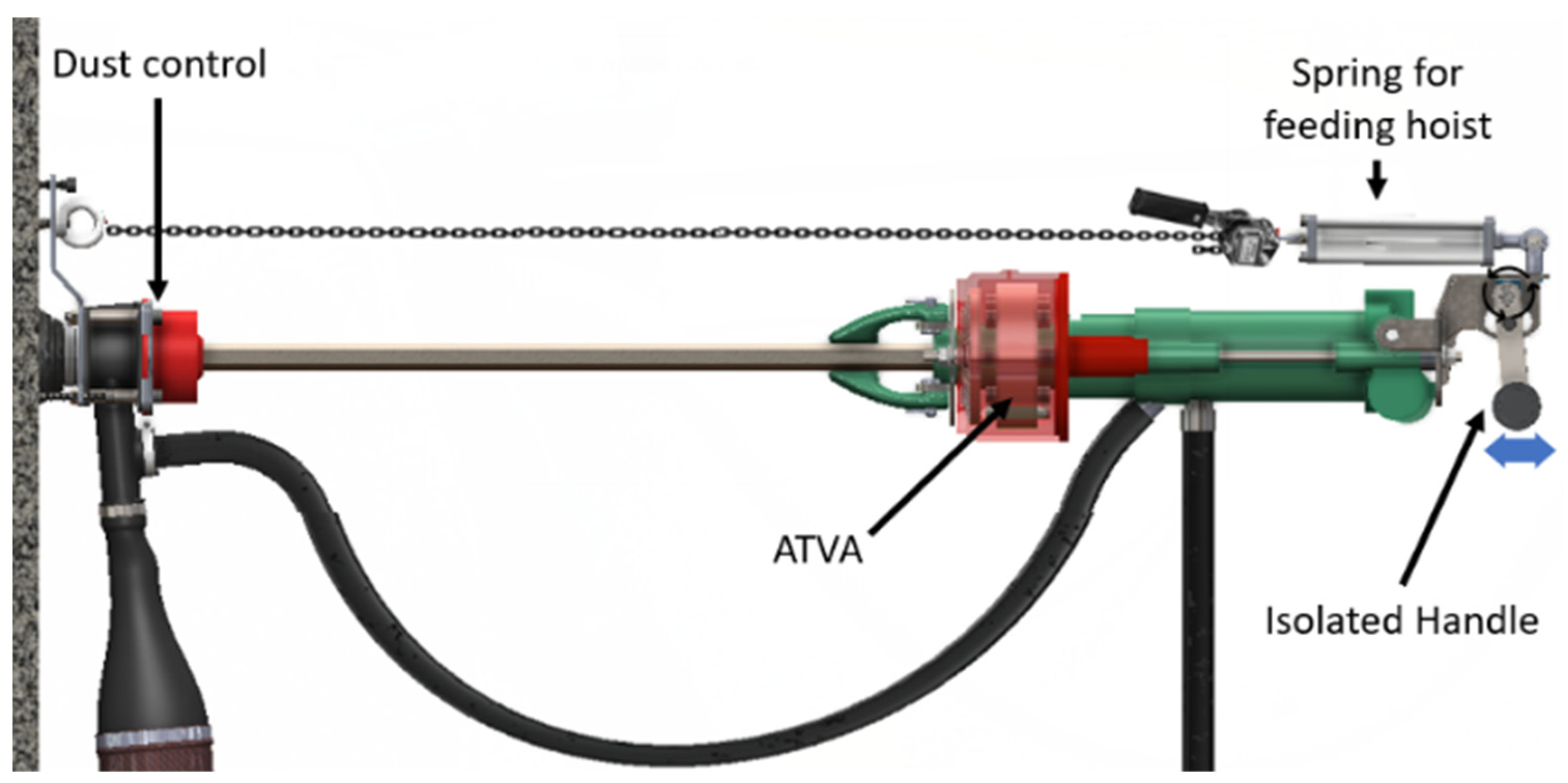

3]. Drilling is also further complicated since the majority of holes are made horizontally into the rock for attaching fastening bolts and securing steel nets. The vertical force from the weight of the machine is supported by climbing ropes, and a horizontal feeding force of approximately 200 N to the drill is produced by a lever hoist attached to a drill and via a steel chain to a bolt in the rock. A common rock drill used for this work is Montabert T18. The operator is subjected to high levels of vibration in both hands, while operating the hoist and controlling the drill with the handle. During the ongoing project, improvements were made to the drill and supporting equipment to reduce the exposure to vibrations. The drilling setup can be seen in

Figure 1. An important objective in this study is to show that there is a substantial potential for improvements on these type of machines for encouraging increased demands from operators and redesign activities from manufacturers.

2. Method

Initial measurements were performed in a laboratory and a granite quarry to establish a baseline for the vibration level using standard equipment. Initial measurements of the tool showed two problem areas (see

Table 1). The first one, as expected, was the high level of vibration of the handles. The second one was the high vibration level of the handle of the hoist. During drilling, the operator must keep one hand on the lever hoist to increase the feed force every few seconds. The problem with the current hoist is that the chain used is almost inelastic, which results in lots of variations in the feed force, i.e., when the operator uses the hoist, the feeding force rises sharply, but as soon as the drill is moved a few mm into the rock, the feeding tension drops to be close to zero.

The concept was split into three parts: spring–damper mechanism for lever hoist, isolated handle and auto-tuning vibration absorber (ATVA) on the machine to counteract the force from the impact mechanism. Since the overall objective of the project is to improve the working environment, a device that uses exhaust air for dust removal was also developed and is included in the new concept.

2.1. Spring–Damper Mechanism for Lever Hoist

A spring was added between the lever hoist and the machine. The spring has two functions. The first one is to limit the variation in the feed force. The spring can be stretched to its maximum length, and the operator does not have to use the hoist as often to avoid slack in the chain. The second function is to protect the hoist from the movement of the machine. By having the hoist fixed to the stationary rock wall and isolated from the machine, the vibration of the hoist lever can be reduced. The spring is contained in aluminium housing. The housing contains a small amount of oil for lubrication and prevents the spring from pinching the operator. The spring can be seen in

Figure 2 and

Figure 3.

2.2. Isolated Handle Solution

The vibration of the handle is determined by the drilling direction. The handle solution consists of a baseplate that is attached to the machine and handles that are connected to the machine with a lever arm. The lever arm is connected to the baseplate with two torsional isolators. This design was chosen to maximize vibration attenuation in the drilling direction without sacrificing controllability in the other two directions. Lever arm solutions have successfully been developed for similar rock drills in the past [

4].

2.3. Auto-Tuning Vibration Absorber (ATVA)

Vibrations in the drilling direction were further reduced by adding an ATVA to the machine. The ATVA consists of 3 kg auxiliary mass with springs. The springs are not always in contact with the machine due to a gap, which gives the system a non-linear character. The springs’ stiffness and the gap are optimized as described in [

5]. The combined concept can be seen in

Figure 2.

3. Results

A picture of the current prototype with the combined solutions, the hoist spring, isolated handle and ATVA, can be seen in

Figure 3. The results from all the measurements in the project can be seen in

Table 1.

The prototypes are currently being field tested by rock securers at Mesta AS in Norway. The prototype that is intended for use in the field can be seen in

Figure 4.

4. Discussion and Conclusions

Initial measurements of the handle revealed extreme vibration levels of 34.6–40.8 m/s2haw. Combining an ATVA and isolated handle reduced the vibration level to 11.6 m/s2haw, which was measured during rock drilling. Implementing these solutions for current tools could reduce the operator’s exposure to vibrations significantly. If these solutions were implemented by the manufacturer, as a part of a revision of the rock drill, the reduction could be even greater, and the weight of the machines could be reduced. The added weigh of the prototype with all the modification is 5–6 kg, which was compared with the original machine’s weight of 22.3 kg. Although the operators want machines with a low weight, the benefits offset the added weight.

The hand–arm vibration level of the current hoist lever is 25–40.9 m/s2haw. By isolating the lever hoist from the machine, the vibration level of the lever was reduced to 5.4 m/s2. This upgrade can be implemented without any modification of the rock drills; so, supplying all workers with this upgrade is simple. The results clearly show that there is a considerable potential for improving the very harsh working conditions for operators of these machines, where very few aspects have been improved over the last five decades.

Author Contributions

Conceptualization, methodology, writing and validation H.L., T.C. and S.L.G.; Investigation, formal analysis, data curation H.L. and S.L.G.; software and visualization, S.L.G.; project administration and funding acquisition H.L. and T.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Statens arbeidsmiljøinstitutt (STAMI) as a part of IA-Bransjeprogrammet for bygg og anlegg.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

RISE hold patents for ATVA technology, and H. Lindell is the inventor.

References

- Clemm, T. Hand-Arm Vibration Exposure in Rock Drill Workers: A Comparison between Measurements with Hand-Attached and Tool-Attached Accelerometers. Ann. Work. Expo. Health 2021, 65, 1123–1132. [Google Scholar] [CrossRef] [PubMed]

- Clemm, T.; Lunde, L.K.; Ulvestad, B.; Færden, K.; Nordby, K.C. Exposure-response relationship between hand-arm vibration exposure and vibrotactile thresholds among rock drill operators: A 4-year cohort study. Occup. Environ. Med. 2022, 79, 775–781. [Google Scholar] [CrossRef] [PubMed]

- Drilling and Rock bolting at Vøringsfossen. Fjellsikring. Available online: https://www.youtube.com/watch?v=OgsV05CeprI&t=84s (accessed on 14 January 2023).

- Marcotte, P. Development of antivibration handle for pneumatic jackleg rock drills. In The Southern African Institute of Mining and Metallurgy Narrow Vein and Reef; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2008. [Google Scholar]

- Lindell, H.; Berbyuk, V.; Josefsson, M.; Grétarsson, S.L. Nonlinear Dynamic Absorber to Reduce Vibration in Hand-held Impact Machines. In Proceedings of the International Conference on Engineering Vibration, Ljubljana, Slovenia, 7–10 September 2015. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).