Measuring Pleated Knitted Sensors †

Abstract

:1. Introduction

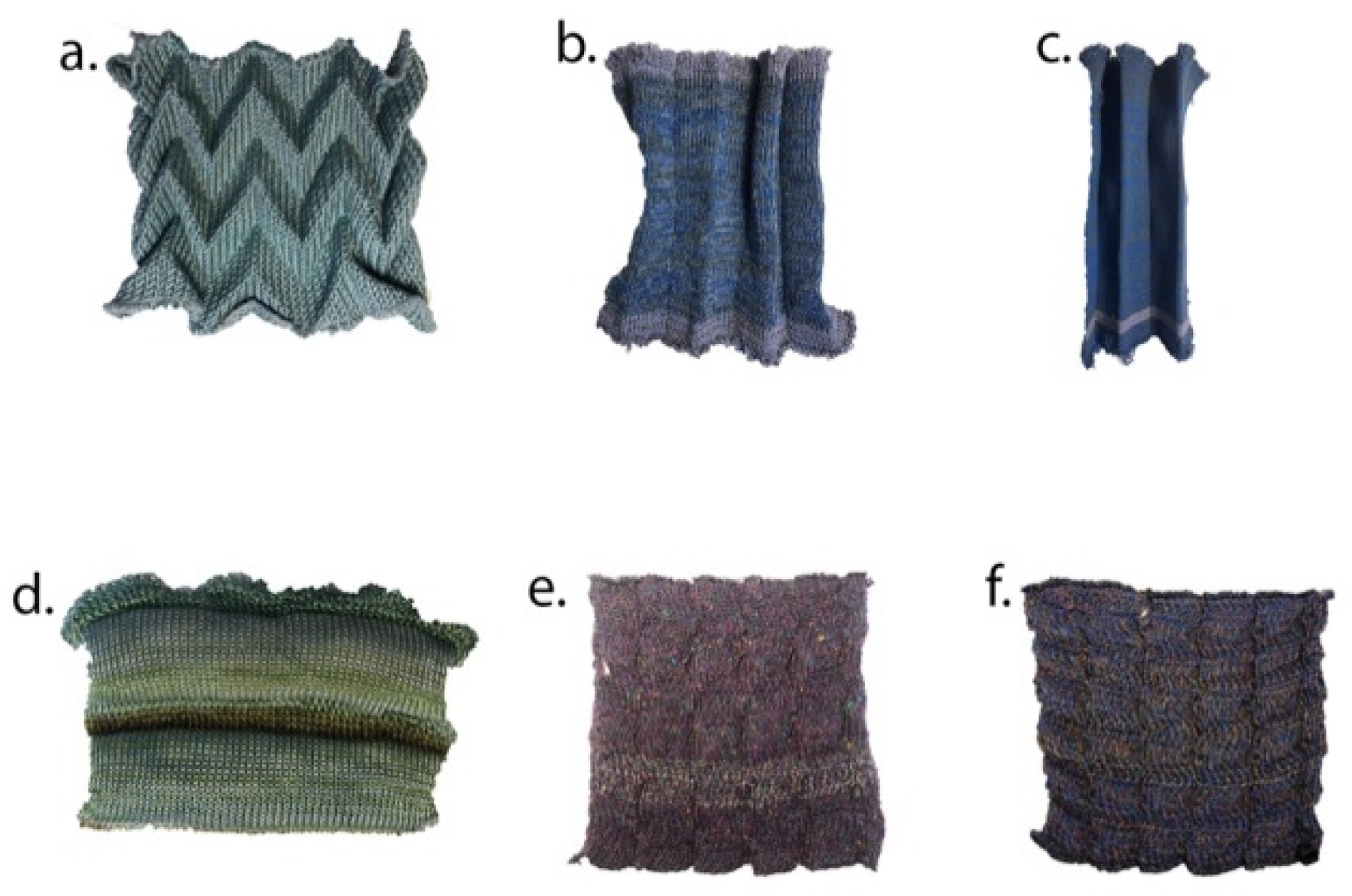

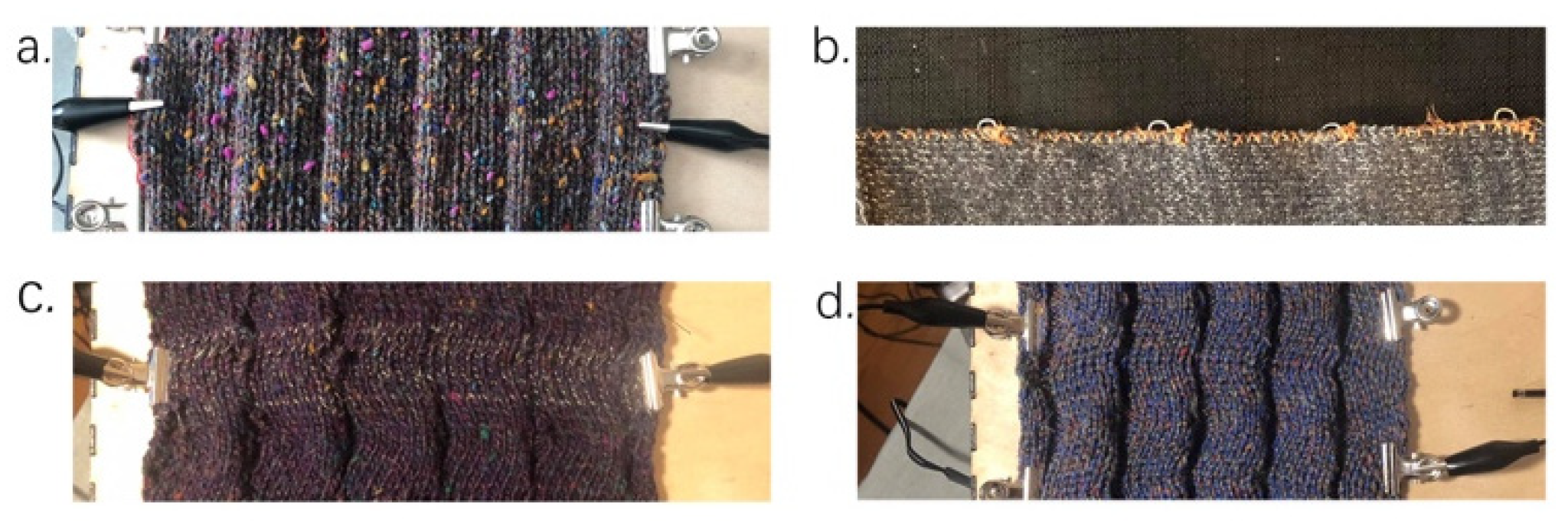

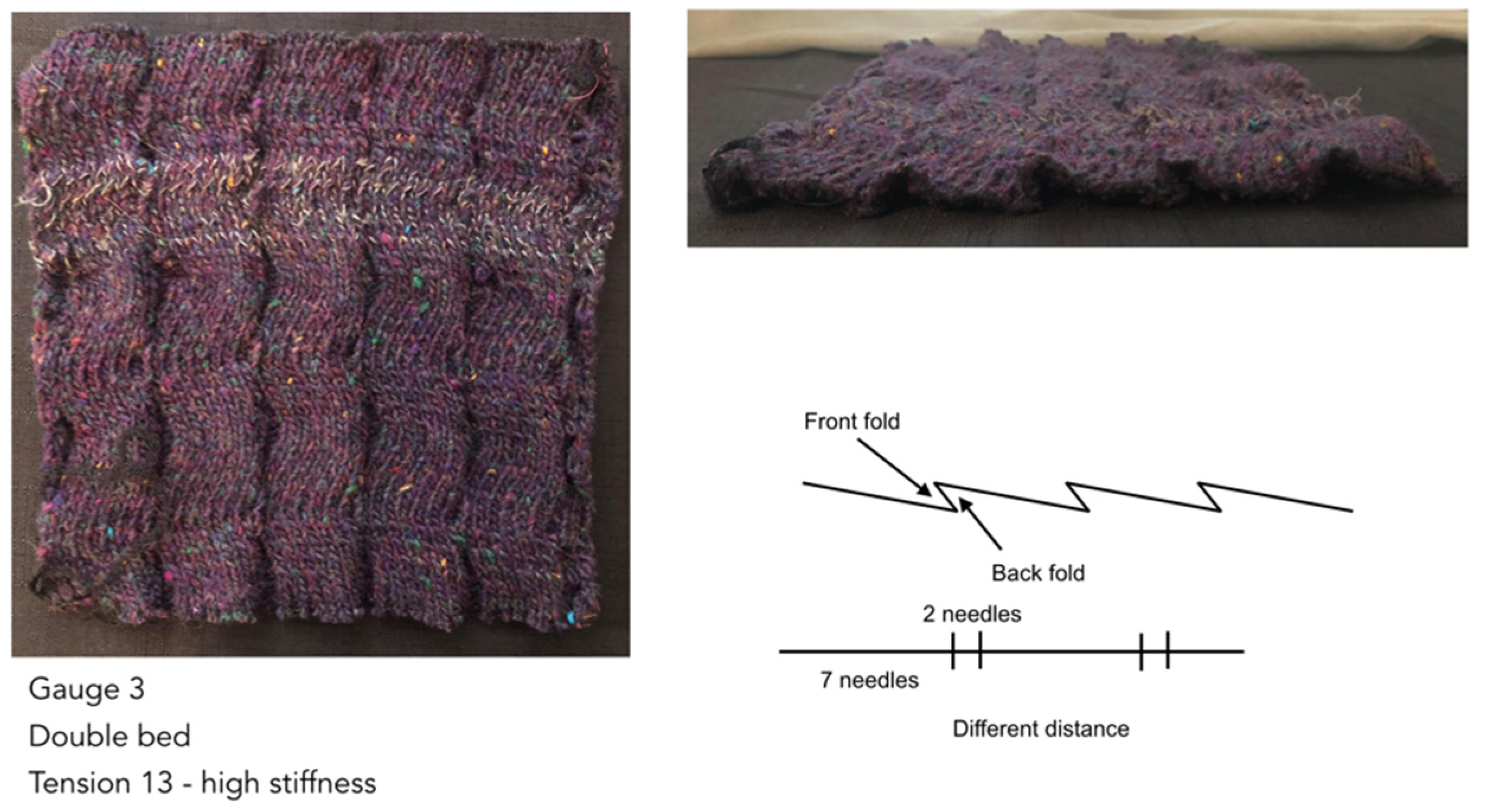

2. Material and Knitting Techniques

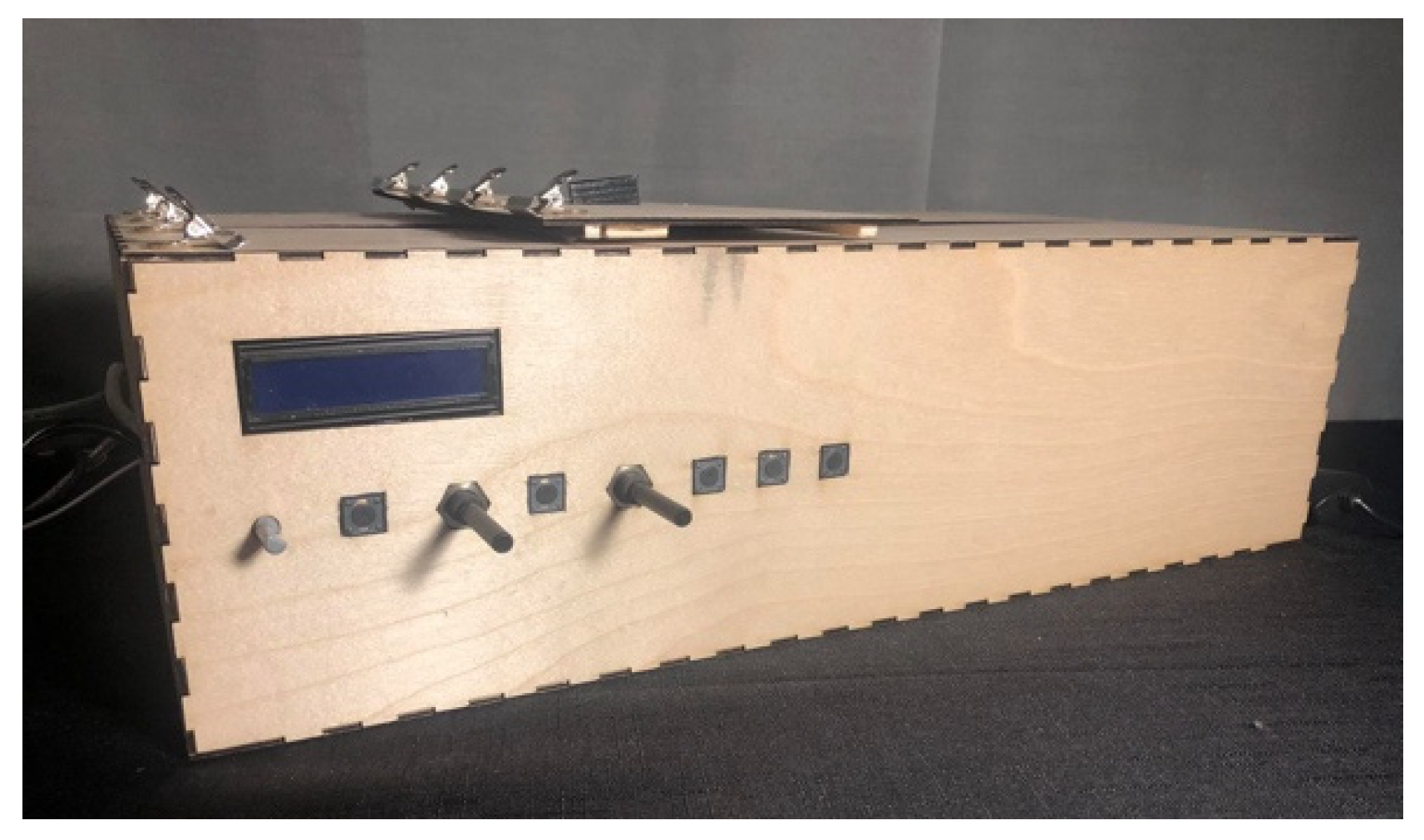

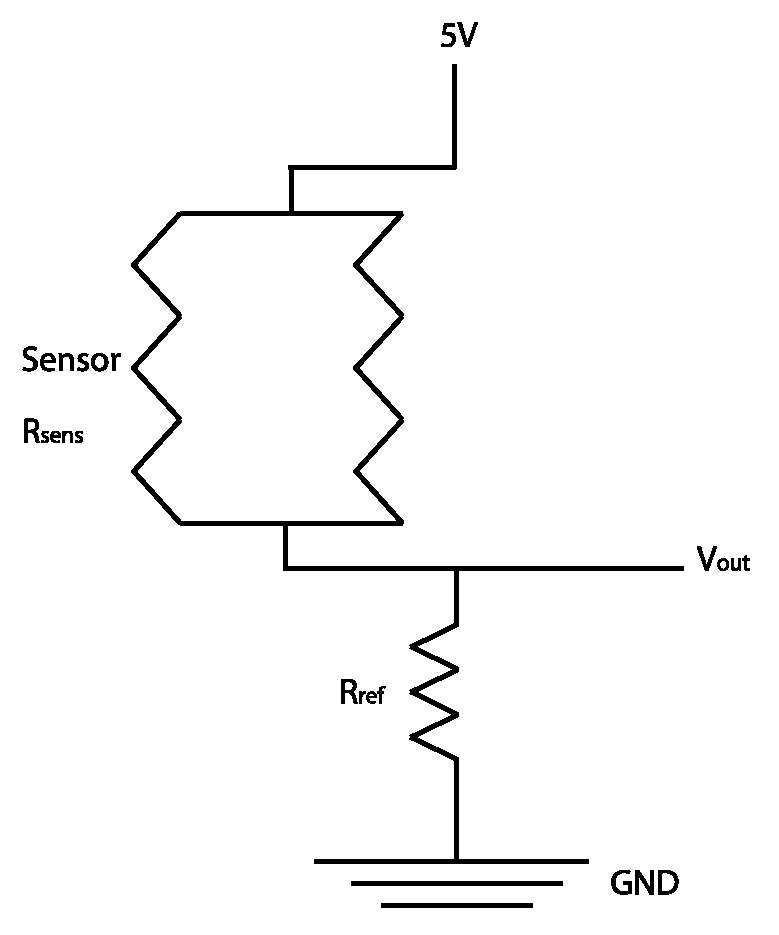

3. Measurement Setup

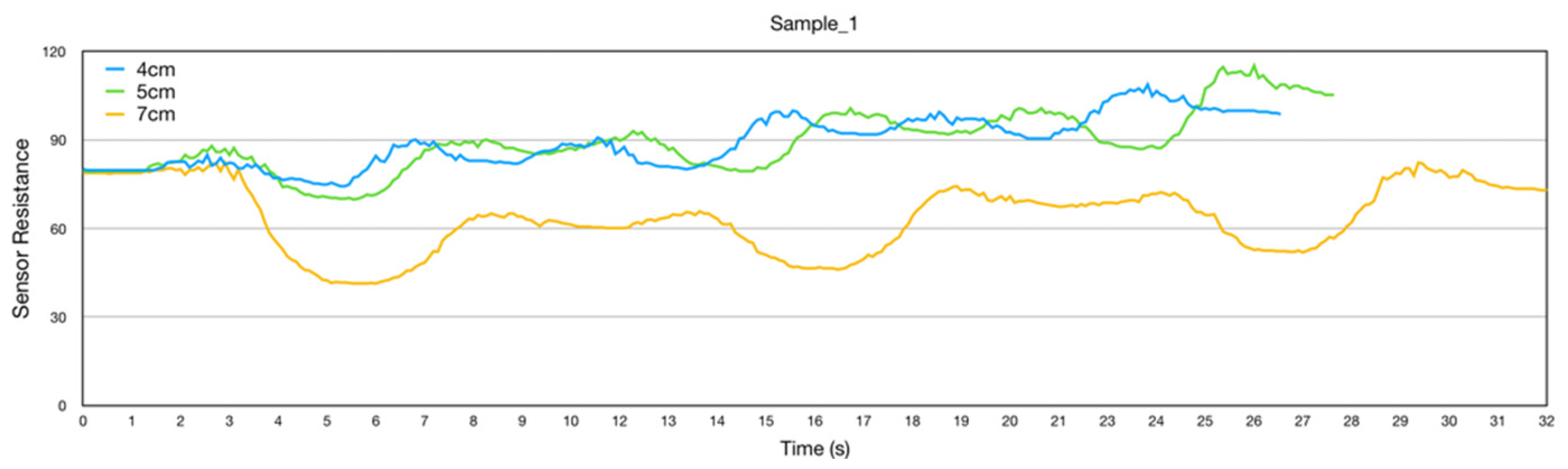

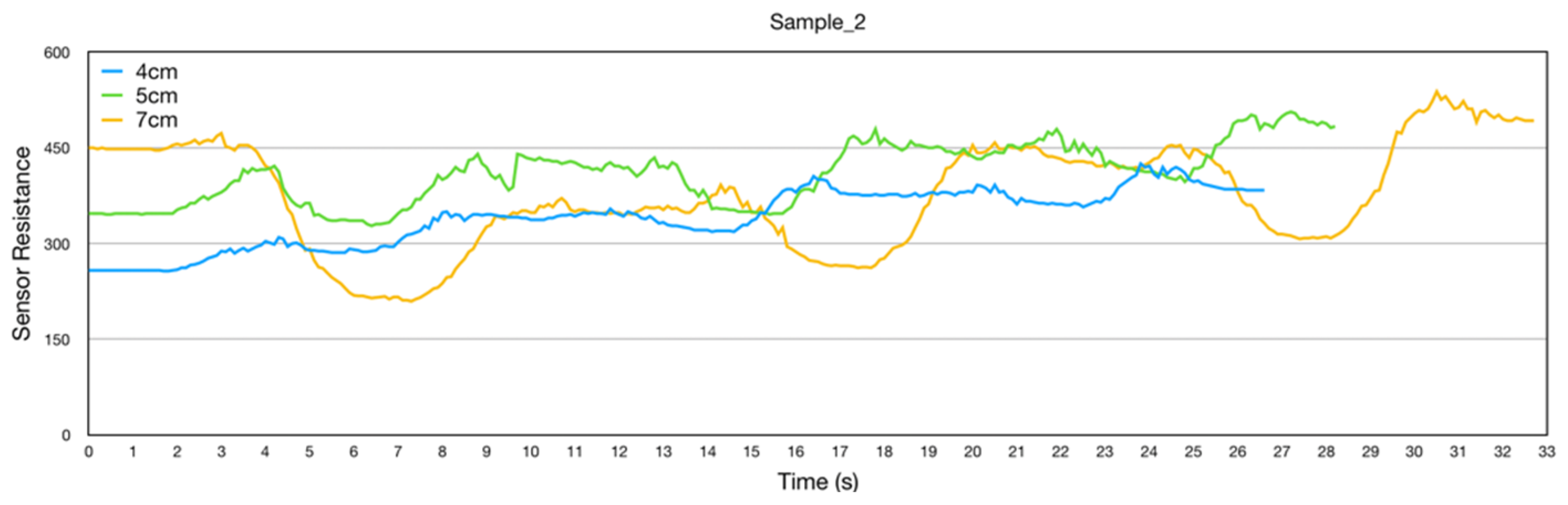

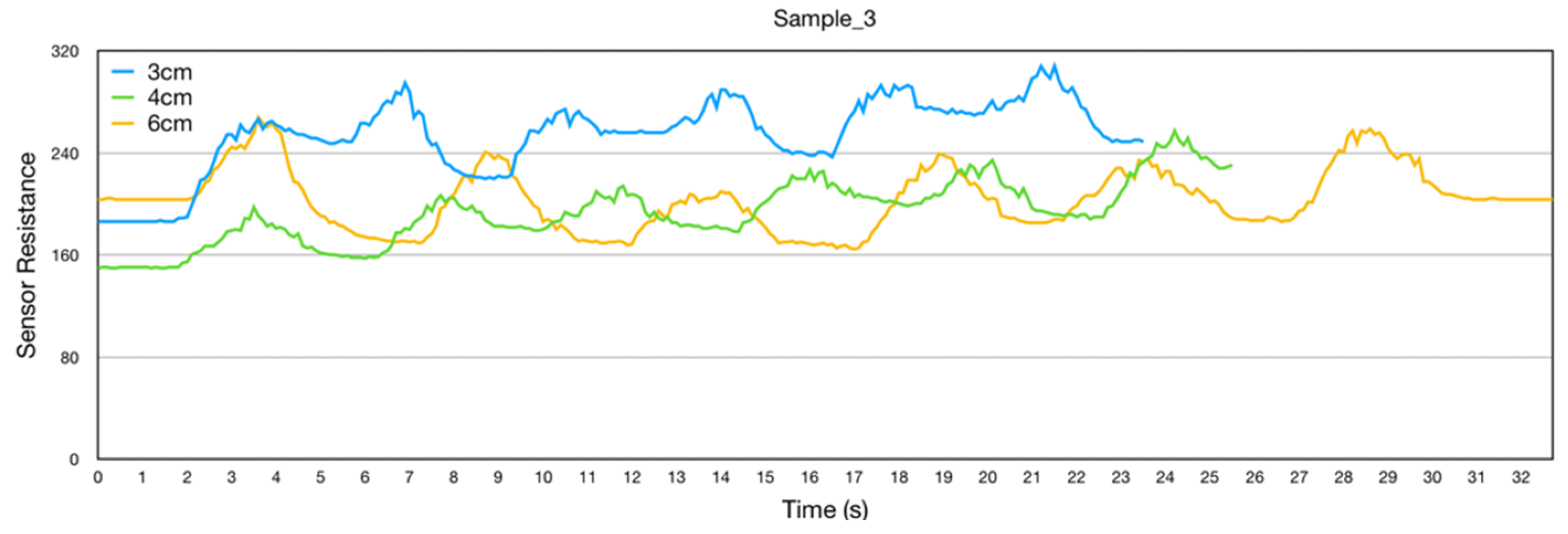

4. Results

5. Conclusions

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

References

- Deleuze, G. The Fold, 3rd ed.; The Athlone Press: London, UK, 1993. [Google Scholar]

- Smelik, A. Gilles Deleuze: Bodies-without Organs in the Folds of Fashion. In Thinking Through Fashion; Rocamora, A., Smelik, A., Eds.; Bloomsbury Publishing: London, UK, 2018; pp. 165–183. [Google Scholar]

- Liang, A.; Stewart, R.; Bryan-Kinns, N. Analysis of sensitivity, linearity, hysteresis, responsiveness, and fatigue of textile knit stretch sensors. Sensors (Switzerland) 2019, 19, 3618. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, W.; Guo, L.; Peterson, J.; Berglin, L.; Skrifvars, M. Knitted Wearable Stretch Sensor for Breathing Monitoring Application. In Proceedings of the Ambience’11, Borås, Sweden, 28–30 November 2011. [Google Scholar]

- Qiu, P.Z. Importance of Home-Based, Self-Monitoring Devices and the Role of Pressure-Sensing Socks in Diabetic Foot Ulceration Prevention; Preliminary Report; Department of Design Engineering, Imperial College London: London, UK, 2020. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petri, G.; Greinke, B. Measuring Pleated Knitted Sensors. Proceedings 2021, 68, 10. https://doi.org/10.3390/proceedings2021068010

Petri G, Greinke B. Measuring Pleated Knitted Sensors. Proceedings. 2021; 68(1):10. https://doi.org/10.3390/proceedings2021068010

Chicago/Turabian StylePetri, Giorgia, and Berit Greinke. 2021. "Measuring Pleated Knitted Sensors" Proceedings 68, no. 1: 10. https://doi.org/10.3390/proceedings2021068010

APA StylePetri, G., & Greinke, B. (2021). Measuring Pleated Knitted Sensors. Proceedings, 68(1), 10. https://doi.org/10.3390/proceedings2021068010