1. Introduction

The actuation of HDMMs is a unique field of research. Especially the mainly linear actuators for HDMM implements, which fulfill the actual work task, must generally meet particular requirements, such as high safety, robustness, compactness, and low price. Thus far, valve-controlled centralized hydraulic actuator systems have been the state-of-the-art technology to fulfill these requirements. Different valve-control actuator concepts exist, such as load sensing (LS) systems, negative flow control, or open-center systems [

1], but they all have the presence of high metering losses in common. The resulting low energy efficiency is problematic, facing rising energy prices but especially the tightening emission legislation in many countries all over the world. As a result, academia and industry have proposed numerous novel actuator concepts over the last decades as alternatives to valve-controlled actuators on HDMMs. Main examples are independent metering [

2], multi-pressure rail systems [

3], displacement control [

4], EHAs [

5], hydraulic-transformer-based systems [

6], digital hydraulics [

7], and even non-hydraulic electro-mechanic actuators [

8]. Moreover, just for EHAs themselves, a further eight subclasses could be identified by Ketelsen et al. [

5].

The result of this development trend can be seen in

Figure 1: One the one hand, a high number of actuator concepts exists—different conventional valve-controlled and novel concepts. On the other hand, a variety of different HDMM types has to be considered for the application of these actuator concepts. The class of HDMMs covers machines from small road-sweapers or skidsteers to big combine harvesters or mining excavators. Between those machines, power levels, number of actuators, environments, work cycles, and other application factors can vary significantly. Thus, there cannot be an ideal one-fits-all actuator concept for HDMMs, and each potential actuator–HDMM match has to be evaluated separately. As can be seen in

Figure 1, this results in a very high number of potential actuator–HDMM matches—each red line represents one—that need to be evaluated to get a complete overview.

With traditional design-process methods such as decision/evaluation matrices, each match had to be evaluated separately, which would require a lot of effort. Therefore, this paper proposes a novel approach to numerically evaluate multiple actuator–application (in this case, HDMM) matches with low effort at the same time. This can help HDMM manufacturers easily select the best option out of multiple actuator concepts for their next product generation, while actuator suppliers can identify suitable applications for their actuator products. Furthermore, the novel evaluation algorithm is modular and allows to add more actuator concepts or HDMM types to the evaluation process later on.

The paper is structured as follows. First, the novel numerical match evaluation concept is proposed alongside the specific application on HDMMs. Second, four different representative actuator concepts are analyzed and rated in order to be evaluated by the novel algorithm. Third, the paper rates four HDMM types for the evaluation. Fourth, potential matches between the rated HDMMs types and actuator concepts are evaluated with the novel algorithm and discussed. Finally, limitations that apply to the concept are analyzed and addressed in the last section before the conclusion.

2. Machine–Actuator-Match Evaluation Concept

2.1. Definition of a “Good Match”

To create a novel match evaluation concept, first, the fundamentals that make an actuator–application match a good match have to be known. The general assumption is that the development of every new actuator concept and respectively achieving a better application–actuator match is based on solving problems that other actuator concepts show. The best application–actuator match is the match with the least problems. An example for a problem aspect is “energy losses”, which lead to increased energy costs and emissions. Conventional valve-controlled actuator concepts have the characteristic “causing high energy losses”, so a new actuator concept is developed with the characteristic “causing low energy losses” in order to reduce the problem aspect “energy losses”.

However, an issue might be that the new actuator concept has higher costs per actuator than the old concept and thus increases another problem aspect “high capital costs”. Consequently, each actuator concept can improve but also worsen problem aspects and will only be a promising alternative or a better match if overall the problem improvement is more significant than the problem worsening. This highly depends on the application or HDMM, respectively. Improving the problem “energy losses” is more significant for a HDMM with high energy turnover than for a machine with low energy energy consumption, and high costs per actuator are more problematic for a HDMM with a lot of actuators than for a HDMM with only a few.

The best actuator–HDMM match is determined by being least problematic concerning a set ofproblem aspects. This can be identified by looking at theproblematic actuator characteristicsconcerning each problem aspect and theHDMM attributesthat define how significant each problem aspect is.

2.2. Evaluation Algorithm

After developing this general definition, it is step-by-step numerically applied for the match evaluation:

- (1)

For each actuator–HDMM-match evaluation, problem aspects are taken into account.

- (2)

For each problem aspect , a problematic actuator characteristic and an HDMM attribute exist.

- (3)

Every actuator concept receives a number where 0 means the problematic actuator characteristic for problem aspect i is “not applying” and 5 it is “strongly applying”.

- (4)

For each HDMM type, the numbers mean that the HDMM attribute for problem aspect i is 0 “not expressed” to 5 "strongly expressed".

- (5)

If and are multiplied, the problem degree of the match concerning problem aspect i is obtained.

- (6)

Summing up the problem degrees for all n aspects, the so-called mismatch value results.

- (7)

Finally, among multiple possible matches, the match with the highest mismatch value is the worst, and the match with the lowest mismatch value is the best or “perfect match”.

For convenient handling, the evaluation concept is expressed as a vector operation in Equation (

1). The mismatch value is calculated by the scalar product of a HDMM-attribute vector

and an actuator-characteristics vector

. The vector

contains HDMM attribute expressions for each of the

n problem aspect and the vector

contains the

n problematic actuator characteristics. Due to the nature of the scalar product, the result equals the sum of all

n problem degrees.

2.2.1. Considered Match Aspects

The quality of the match evaluation depends highly on choosing the right set of problem aspects. No important problem aspects should be neglected, and, at the same time, unessential aspects should be avoided because they would decrease the influence of the other, more significant aspects. Furthermore, the right set of aspects depends on the range of actuator concepts that are supposed to be evaluated. The design engineer has to consider every potential application problem of the actuator concepts that are evaluated and formulate them in the form of

problem aspect,

problematic actuator characteristic, and

HDMM attribute. This requires sufficient knowledge of the technologies and should be ideally done by a group of experienced engineers. For this paper, a first approach of identifying the essential aspects for the actuator concepts in

Section 3 is presented in

Table 1. The problematic nature of those aspects for certain actuator concepts becomes more apparent after the analyses in

Section 3.

2.2.2. Non-Scalable Factors

Another aspect that is not covered by the concept so far is that problem aspects such as Aspect 1 in

Table 1, the actuator costs, might not only scale with the extent of the HDMM attribute expression but also involve a fixed, application-independent term. In the example of Aspect 1, this could be the costs of a centralized supply for a centralized hydraulic actuator concept, which is almost independent from the HDMM attribute, number of actuators. Therefore, a fixed problem term

can be added for each problem aspect that has an application-independent component. Equation (

2) shows this for Aspect 1 in

Table 1 and is also the final form of the evaluation algorithm used in

Section 5.

3. Characterization of Heavy-Duty Actuator Concepts

This section analyzes a few exemplary actuator concepts and rates their problematic characteristics in the form of a vector , as described in the previous section.

3.1. Valve-Controlled Load-Sensing Actuators

Valve-controlled actuators are the current state-of-the-art concept to drive HDMM implements, and the LS concept is among the most common forms of supplies for those actuators. Therefore, the concept is chosen for this paper to represent a state-of-the-art baseline.

The simplified schematics of a LS system in

Figure 2 is used to analyze the characteristics vector of this concept in Equation (

4). The LS supply can be formed by a constant-speed motor (e.g., combustion engine) and variable-displacement pump or a variable-speed motor (e.g., electric) and a fixed-displacement pump. Furthermore, each actuator requires its own control valve(s). A main advantage is that one LS supply can be used for multiple actuators and only needs to be scaled up for more flow if actuators have to operate simultaneously at high speeds. Moreover, the concept is very mature, and standardized, compact valve assemblies are available at low prices. Thus, adding more actuators requires minimal financial effort and

is low (1). On the other hand, the fixed costs for the LS supply are rather high, which is expressed by:

Because the size of the actuator only influences the required supply flow, bigger actuators can be easily handled by choosing components with higher nominal flow, and is rated 1. Since the system is centralized, expensive hydraulic high-pressure lines need to connect each actuator with the supply, which leads to a high (3). For higher power demands, pump and motor can easily be increased in size, and LS systems can often be found on large HDMMs with high power demands. Thus, is rated low (1).

In terms of energy efficiency, the pressure-flow diagram in

Figure 2 provides more insights. If Actuator 1 were operated alone, only the small shaded loss area would be present and the system efficiency relatively high, which is why

is still rated medium (3). Regardless, the efficiency can be extremely low when another actuator with lower load pressure is operated simultaneously such as Actuator 2 in

Figure 2. In this case, the load pressure difference is compensated by throttling valves, and the power represented by the red area is dissipated into heat. Accordingly, Aspect 6 and factor

were introduced especially for valve-controlled actuator concepts that generally all have a highly problematic characteristic concerning this aspect.

is thus rated 3 (not worse because the effect is only significant if the load pressures differ greatly).

Furthermore, braking energy can only be dissipated by valves in this system and not recuperated, which leads to a high

value (5). However, cooling is easy because the centralized design allows utilizing a common cooler for all actuators together. Thus,

is rated 2 but not 1 because the cooler still requires extra costs, space, and energy.

3.2. Electro-Hydraulic Actuators

In research, EHAs are one of the most focused concepts for replacing conventional actuator concepts on HDMMs and, therefore, considered here as well. The common principle is using electric variable-speed motors in combination with fixed-displacement pumps in direct connection to a single actuator. This allows controlling the pump flow and thus the actuator flow and speed. A detailed review of this actuator concept can be found in [

5], where eight subclasses of EHAs are defined. For this paper, three different types of EHAs are considered for the match evaluation, which can be seen in

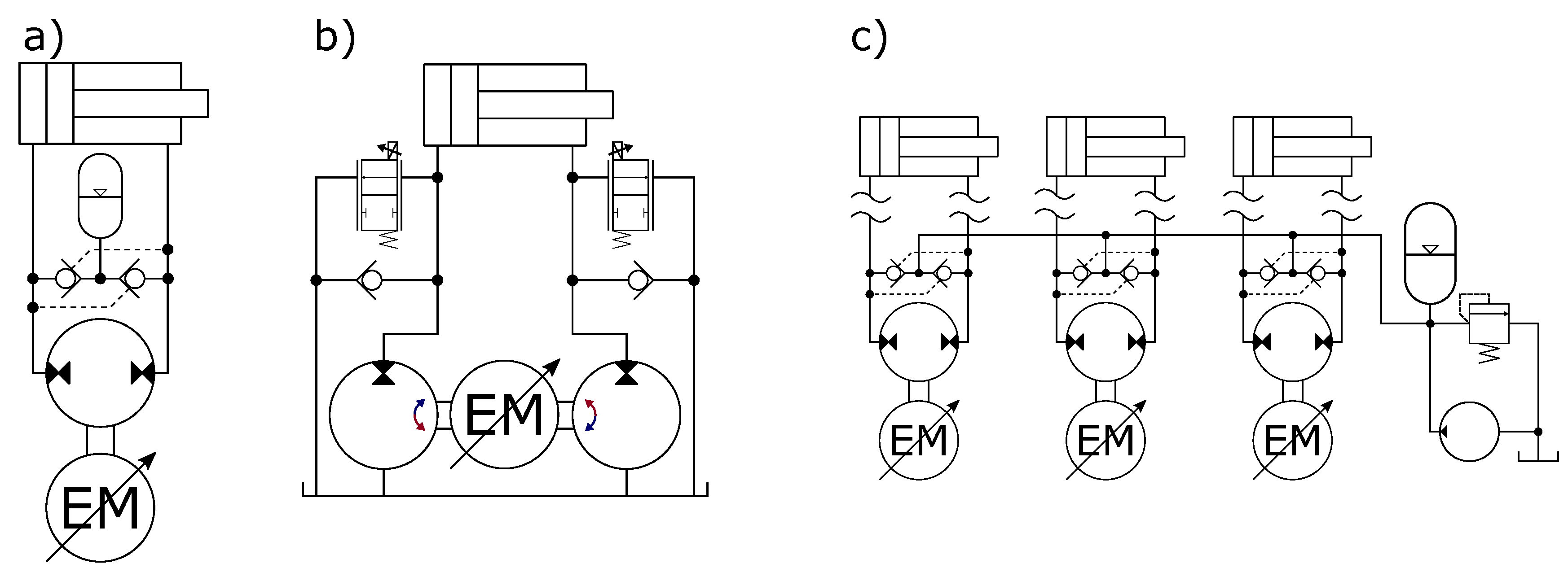

Figure 3.

3.2.1. Baseline Electro-Hydraulic Actuator: Compact Single-Pump Type

The single-pump EHA is one of the most common EHA concepts and thus chosen as a baseline EHA here. For the other two EHA concepts, only the differences to this baseline EHA are discussed.

Figure 3a shows typical schematics of this type. Due to the unbalanced flow between symmetrical pump and asymmetric cylinder, compensating valves are required. The accumulator provides the pendulum volume and pressure to avoid cavitation.

Because each actuator requires its own electric motor, pump and flow compensation mechanism, the costs for additional actuators

in Equation (

6) are high (4). One the other hand, there are no components that cause fixed costs except for the energy supply, which is necessary for each actuator concept anyway and

Very large or long actuators are critical because the pendulum volume is large in these cases as well, and the accumulator size must be rapidly increased [

10]. Therefore,

is rated 4. The only necessary supply line for these actuators is an electric cable. Because long electric cables are significantly less expensive than hydraulic high-pressure lines,

is only rated 1.

Power can be scaled up by using bigger pumps and motors, which is less problematic. A minor issue can be the lack of flow-compensating valves that can handle higher flows, and two valves in parallel might need to replace a single valve [

11]. Thus,

is rated 2. Efficiencies of these actuators are relatively high—at least compared to valve-controlled actuators. In [

12], hydraulic circuit efficiencies of 75% could be achieved for different EHAs in experiments. Accordingly,

is rated 2. Because the actuators are individual, and each have their own pump, simultaneous actuation has no influence on the efficiency and

is 0. Energy can be electrically recuperated, which is only compromised by the hydraulic circuit efficiency and the need for additional electric hardware; therefore,

is rated 2.

Michel and Weber [

13] showed that passive cooling of these actuators can be sufficient for low powers (max 1.5 kW in experiments) and at medium ambient temperature. However, for the higher power levels common for HDMMs, active cooling is necessary. This requires a cooler for each actuator because the actuators have no hydraulic connection, which is expensive and results in a high

(4).

3.2.2. Compact Dual-Pump Electro-Hydraulic Actuator

Using two pumps of different size for each actuator allows compensating the differential cylinder flow with the pumps themselves. The additional valves in

Figure 3b only manage small flows to avoid cavitation or over-pressurization due to slight mismatches between pump and cylinder ratios [

9]. The additional pump makes the EHA more expensive and

is increased to 5. On the other hand, no pressurized reservoir is necessary and a vented tank instead of an accumulator can be used. This makes bigger actuators less problematic and reduces

to 1. At the same time, it might be necessary to install the tank further away from the cylinder because the tank must remain in a stable orientation in order to avoid leakage. Thus,

is increased to 2. Scaling up the power is less problematic because only the pumps, not the valves, need to be increased in size (

). The other characteristics do not vary from the baseline EHA:

3.2.3. Centralized Electro-Hydraulic Actuator

Centralizing multiple EHAs by installing the main circuit components on the rear of the HDMM with a common low-pressure supply and long hydraulic lines supplying the actuators has multiple effects on the characteristics compared to the baseline EHA: First, the common low pressure supply increases the fixed costs, and

but the price per actuator decreases, and

becomes smaller. Furthermore, larger actuators are less problematic because a very large accumulator can still be acceptable when it is mounted on the rear of the vehicle and not next to the cylinder. Thus,

is reduced to 3. Moreover, long hydraulic lines across the HDMM are more expensive than electric cables and

increased to 3.

The maximum efficiency will decrease because more line losses are present [

14] and the charge pump causes losses. This leads to a higher

(3). Regardless, a further benefit is the cooling capability. Instead of using a separate cooler for each EHA, a single cooler can be located in the common low-pressure supply, which is more convenient and reduces

to 2. Other characteristics do not change compared to the baseline EHA:

4. Classification of Heavy-Duty Mobile Machine Types

In this section, the attributes of four typical HDMM types are analyzed to use them for the match evaluation in

Section 5. This requires the definition of attribute vectors

.

4.1. Compact Excavators

Excavators are one of the most common HDMMs and their attributes are representative for a number of similar HDMMs. Moreover, the here considered compact excavator EC15E from Volvo [

15] is a typical representative of a low-power HDMM. Shield and bucket are both actuator functions with a low energy turnover because they are rarely actuated or see low loads, while boom and stick actuators have higher energy demands; thus,

is rated 2. For other excavators with actuators for, e.g., boom adjustment or special tools, this number could be rated higher. Due to the compact size of the machine, the actuators are rather small as well, and

is rated 1. Furthermore, most actuators are located close to the main vehicle body, but the bucket actuator is mounted at the end of the relatively long excavator arm. Accordingly,

is chosen to be 2.

On the exemplary excavator, each actuator can be supplied with up to 10 kW of hydraulic power [

15], which is relatively low; thus,

is rated 2. Moreover, typical excavator tasks, such as truck loading, digging, or grading, involve mainly the linear implement actuators and less driving. As a result, the attribute

, representing the relative energy consumption of the implements, is rated high (5). Furthermore, analyses of work cycles show that simultaneous actuation of multiple work functions is common especially for expert operators; thus,

is rated 5.

The amount of load braking, which can be used for recuperation, always depends on the work task. Grading does not offer a lot of recuperation potential, but most other tasks are cyclic and involve up and down movement. Down movement can be used for recuperation, but typically the boom is lifted with load, the load is dumped and then the boom is lowered empty, which offers less potential energy. The potential

is rated high 3, but it could be adjusted if a specific work cycle is supposed to be considered for the match evaluation. The attribute

can also only be specified if a concrete application is known and is thus rated with a neutral/medium value of 3 here. The resulting attribute vector is

4.2. Mid-Size Wheel Loader

The actuated implement parts of wheel loaders, such as the here considered Volvo LH90 [

16], typically comprise boom, shovel, steering, and sometimes an additional tool. All of those are frequently actuated and see medium to high loads during common work cycles. Accordingly,

is rated low (2). Especially the tilt cylinders can be large in diameter (cylinder bore of 180 mm at a stroke of 430 mm [

16]); thus,

is rated 3. Because the boom is rather short, all actuators are relatively close to each other and the main vehicle body, which leads to a low

(2). On the considered conventional wheel loader [

16], a single actuator can be supplied with up to 88 kW of hydraulic power, which is considered high and leads to a high

(4). Because common wheel loader work cycles such as truck loading or Y-cycles involve significant amounts of driving,

is only rated medium (3). Simultaneous operation of boom and shovel cylinders is common but not necessarily constantly the case, which leads to

being 3. Lowering the boom involves braking against gravity, which can be used for recuperation, but the boom is most often lowered empty, and lowering makes up only a short part of common work cycles, which involve more driving instead. Accordingly,

is rated 3.

is rated neutral (3) because the specific application environment is not known. The resulting attribute vector is

4.3. Backhoe Loader

Backhoes, such as the Case 580 Super N [

17] considered here, combine a lot of different implement functions. The loader function and excavator function cannot be used at the same time and are therefore frequently in standby. Furthermore, many auxiliary functions require cylinder actuators but are only used once in a while: side supports, boom swing, excavator telescope arm, bucket gripper, and others. Overall, this means a high number of actuators with low energy turnover and a high

(5).

Because backhoes are rather compact, actuator sizes are medium or small (more than half of the cylinders have bore diameters smaller than 100 mm [

17]) and

is rated 2. Furthermore, actuators are located close to the main body (

= 2). Moreover, up to 65 kW of hydraulic power is available but can most likely not be used for the small actuators entirely, and

is rated 3. No specific work cycle is considered here because backhoes are too versatile; however, driving is one of the main functions. Accordingly,

is rated medium (3). Actuation of more than one actuator at the same time is also common for backhoes, and

is rated 3.

The main implement parts, excavator boom and loader boom, move vertically; thus, there is a potential for energy recuperation, but the masses are commonly rather low. Therefore,

is rated 3.

is rated neutral (3) because the specific application environment is not known. The resulting attribute vector is

4.4. Telehandler

Telehandlers represent another type of HDMMs that is characterized by long-stroke actuators. The standard implement actuators of telehandlers such as the MHT 10130 [

18], which is considered for this analysis, are for steering, boom actuation, tool tilting, and extension. They are typically all frequently actuated, and

is rated 1. For other telhandler versions with actuators for auxiliary functions such as side supports, slope-compensation, or grippers, the value would be higher.

Characteristic is the telescopic actuator, which is large in volume due to the long stroke of more than 7 m [

18]. Accordingly,

is rated 5. Furthermore, the tilt actuator, which extends as well, requires a long and flexible connection to the main part of the vehicle, which results in a high

(5). Moreover, the actuators can be supplied with 90 kW of hydraulic power, which is significant and leads to a high

(4). Similar to wheel loaders, telehandler work cycles typically involve a significant amount of driving, and

is rated medium (3). Simultaneous operation of multiple actuators is common for telehandlers as well but not necessarily constantly the case (

).

The load braking and thus recuperation potential of telehandlers can be considered high because they are often equipped with forks to handle pallets or other compact objects. These objects typically cannot be dumped, and the telehandler must lower the heavy objects again. Compared to the empty lowering typical for HDMMs with bucket or shovel, the potential energy and recuperation potential are much higher in this case, and

is rated 4.

is rated neutral (3) because the specific application environment is not known. The resulting attribute vector is

5. Evaluation of Exemplary Matches and Discussion

Sixteen matches were formed out of the four actuator types analyzed in

Section 3 and the four HDMM types investigated in

Section 4. Each actuator–HDMM match was evaluated with the novel algorithm shown in Equation (

2), and the resulting mismatch values can be seen in

Table 2. The table is analyzed to get insights about the match qualities and make general statements about HDMM–actuator matches.

Marked in green, the best matches for each HDMM type can be seen in

Table 2. Except for the backhoe, all HDMMs match best with the dual-pump EHA. This is in line with the idea that this concept is especially suitable for HDMMs because of its high energy-efficiency and suitability for big actuator sizes. At the same time, it has to be considered that the other EHA concepts achieve similarly low mismatch values. If the mismatch-value differences are too small, such as for the excavator and backhoe, it cannot be said which concept is indeed more suitable for the HDMM because the evaluation algorithm is (at this stage) not trustful enough.

However, some more tendencies can be identified and statements made where the mismatch values differ: The centralized EHA achieves the lowest mismatch value for the backhoe, which can be explained by the fact that long hydraulic lines are less problematic due to the compact machine design and the high number of actuators that result in high costs for the other EHAs. On the other hand, the algorithm rates the centralized EHA as less suitable for the telehandler, which can be justified, for example, by the high costs for hydraulic high-pressure lines across the large vehicle.

The fact that the valve-controlled concept is evaluated to be a far worse match compared to EHAs for all HDMMs except for the backhoe is also significant. The low energy efficiency has most likely the biggest influence on that. However, it is important to notice that the valve-controlled concept seems to be able to keep up with the EHAs on machines like a backhoe. This means that, for certain HDMMs, introducing novel, supposed-to-be-better actuator concepts might not bring significant benefits after all.

6. Limitations of Evaluation Concept

When looking at the evaluation results in the previous section or using the novel algorithm to evaluate other matches, it has to be considered that certain assumptions have been made to apply this algorithm, and several limitations exist. Here, it should be shortly explained what they are, how they influence the evaluation results, and how they could be addressed in the future.

A first, important assumption for the concept is that only one actuator concept can be used for each HDMM. This is reasonable because using the same type of actuator has positive effects on, e.g., costs or maintenance effort, but using two actuator concepts on the same HDMM is still possible. A HDMM could have EHAs for its main actuators and centralized valve-controlled actuators for auxiliary functions. However, this aspect could be addressed by considering additional “actuator concepts” that are actually combinations out of two other original concepts.

Moreover, it is assumed that all problem aspects can in principle be handled by all actuator concepts with sufficient effort. In fact, for some actuator–HDMM pairings, problems can exist that make a match impossible, such as using electro-mechanical actuators for a HDMM that requires actuators with significantly high, continuous power output [

19].

Another issue is that all problem aspects are considered equally in Equation (

2). Adding weight factors that give certain problem aspects more influence than others can lead to more valuable results. By adapting the weights the evaluation could also be focused on different objectives such as achieving an especially cheap or especially low-emission match.

An easy step to improve the quality of the results is to include more problem aspects. Not involved yet are the problems of limited space for self-contained actuator concepts, increased weight of actuators, high noise emission, or performance issues of various natures.

Finally, it should be noticed that the problematic actuator characteristics and HDMM attributes have been rated by a single engineer in this study with only a few data points and personal knowledge. This might not be objective enough, and, if possible, multiple engineers should do the rating and validate their results. Using simulation tools for that process is recommended as well. Unfortunately, more advanced and objective machine learning methods cannot be applied. Sufficient data points in the form of, e.g., data-sheets exist, but the training required labeled data, which would mean validated mismatch values for match examples. Those could only be obtained with satisfactory trust by doing excessive simulations or experiments of a high number of random actuator–HDMM matches.

7. Conclusions

This paper proposes a novel algorithm for the numerical evaluation of matches between linear actuator concepts and HDMM implement applications. The algorithm allows evaluating quickly and with low effort how well a certain actuator concept matches a high number of different HDMM applications or how well different actuator concepts fit to a certain HDMM. Furthermore, the evaluation concept is modular and additional actuator concepts or HDMM types can easily be added to the evaluation process. In a next step, 16 matches between four actuator concepts and four HDMM types were evaluated. The results show that for most machines the three EHA concepts can perform similarly well, while the valve-controlled LS concept can only achieve a good match in combination with a backhoe. However, this shows that novel actuator concepts do not necessarily improve the over-all performance of every HDMM, and sticking to conventional concepts can be justified.

Moreover, remaining limitations of the concept were analyzed, which demonstrated that current results can only be used for qualitative statements. To make quantitative, precise evaluation statements, the concerns of

Section 6 should be addressed in a next step. In a second step, more actuator concepts such as displacement-control, electro-mechanical actuators, or hydraulic transformers could be included in the evaluation, as well as more HDMM types.