New Power Train Concept for a City Hybrid Vehicle †

Abstract

:1. Introduction

2. The Proposed Task

- (1)

- For turbine stages, the focus is on the investigation and development of technologies that would improve on-engine exhaust energy utilization compared to the conventional radial turbines in widespread use today;

- (2)

- For compressor stages, the focus is on investigating compressor design parameters beyond the range typically utilized in production (i.e., higher pressure ratios), to determine the potential efficiency benefits thereof;

- (3)

- For TC units, the focus is on the development of a robust bearing system that would provide higher bearing efficiencies compared to systems used in turbo-compound power turbines in production.

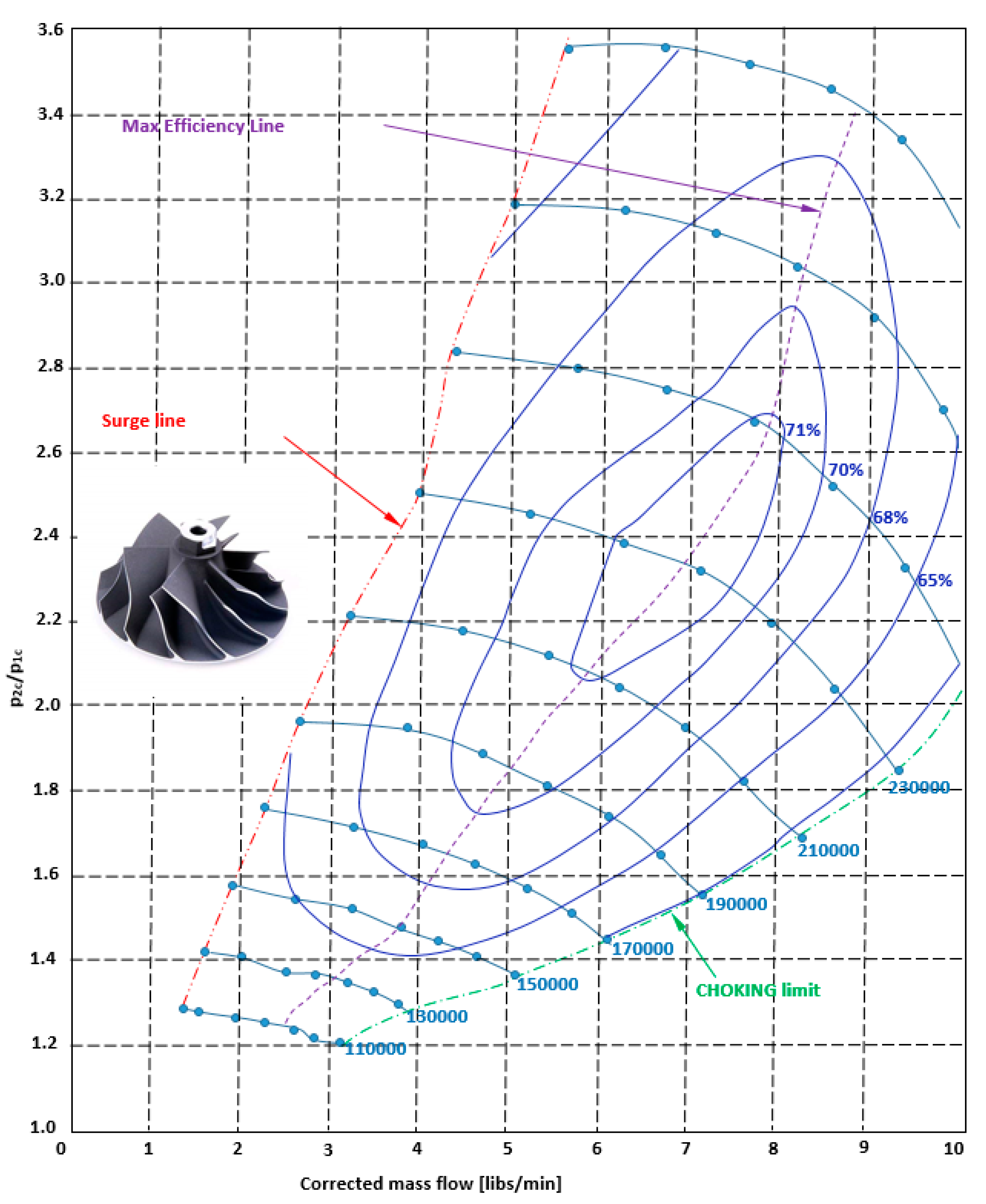

3. Turbocompressor Specifications

- It calculates the design volumetric suction flow rate (calculated at “standard conditions” specified by design standards);

- Once the flow rate and the pressure ratio are known, the preliminary “shape” of the compressor occurs; the specific work is given by:

- 3.

- Based on the type of compressor, the tentative maximum peripheral speed, Umax, is fixed and the necessary Euler’s work is obtained:

- 4.

- If the value of the φ2 obtained from the calculation is acceptable (i.e., falls within the field of values historically adopted in similar machines with technically satisfactory results), only one stage will be sufficient. Otherwise, there are two possibilities:

- (a)

- Increase the Umax, choose a different geometry and return to step (3);

- (b)

- Keep the specification values for Umax and φ2, and calculate the number of stages from the equation:

- β = 1.5

- = 0.02–0.06 kg/s

- n = 140000–210000 rpm (corresponding to ICE minimum and maximum rotational speed assumed equal to 2000–5000 rpm, respectively).

4. Turbine Definition

5. Preliminary Analysis and Future Development

6. Conclusions

References

- Balje, O. Turbomachines; J. Wiley & Sons: Hoboken, NY, USA, 1981. [Google Scholar]

- Shepherd, D.G. Principles of Turbomachinery; J. Macmillan Pub. Co: New York, NY, USA, 1956. [Google Scholar]

- ATIP (Asian Technology Information Program) Scoop, Japan Office. Micro Gas Turbine Development, Tokyo, Japan, 2005 (https://www.atip.org/index.php/atip-publications-2/atip-scoops/2005-2?start=40).

- Peirs, J.; Reynaerts, D.; Verplaetsen, F.; Norman, F.; Lefever, S. Development of a Micro Gas Turbine for Electric Power Generation; Proc. 17th European Conference on Solid-state Transducers: Eurosensors. 21–24 September, Guimaraes, Portugal, 2003. [Google Scholar]

- Ishihama, M.; Sakai, I.; Matsuzuki, K.; Hikone, T. Structural Analysis of Rotating Parts of An Ultra Micro Gas Turbine. In Proceedings of the International Gas Turbine Congress, Tokyo, Japan, 2–7 November, 2003. [Google Scholar]

- Gaydamaka, I.V.; Efimov, A.V.; Ivanov, M.J.; Ivanov, O.I.; Nigmatullin, R.Z.; Ogarko, N.I. Some Aerodynamic Performances of Small Size Compressor and Turbine Stages. In Proceedings of the International Gas Turbine Congress, Tokyo, Japan, 2–7 November, 2003. [Google Scholar]

- Van den Braembussche, R.A. Web Paper: Thermo-Fluid-Dynamic Design of Ultra Micro Gas-Turbine Components; RTO-EN-AVT-131 Nato Educational report. 2019. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwjX4aHE3eLrAhWdyosBHYqhAoMQFjAQegQICRAB&url=https%3A%2F%2Fwww.sto.nato.int%2Fpublications%2FSTO%2520Educational%2520Notes%2FRTO-EN-AVT-131%2FEN-AVT-131-01.pdf&usg=AOvVaw2hqOTBoTPzhaDOMRayYUha (accessed on 1 December 2019).

- Cuturi, N.E. Sciubba: Improvements in the design of a tandem compressor for an innovative turbocharger configuration for a hybrid city car. Int. J. Turbomach. Propuls. Power, in press. 2020.

- Matsuura, K.; Kato, C.; Yoshiki, H.; Matsuo, E.; Ikeda, H.; Nishimura, K.; Sapkota, R. Prototyping of Small-Sized Two Dimensional Radial Turbines. In Proceedings of the International Gas Turbine Congress, Tokyo, Japan, 2–7 November, 2003. [Google Scholar]

- Capata, R. Ultra Micro Gas Turbines. In Konstantin Volkov. Efficiency, Performance and Robustness of Gas Turbines; Intech Open Publication: London, UK, 2012. [Google Scholar]

- Frechette, L.G.; Jacobson, S.A.; Breuer, S.K.; Ehrich, F.F.; Ghodssi, R.; Khanna, R.; Wong, C.W.; Zhang, X.; Schimdt, M.A.; Epstein, A.H. Demonstration of a Micro-Fabricated High-Speed Turbine Supported on Gas Bearings. In Proceedings of the 17th European Conference on Solid-state Transducers: Eurosensors, Guimaraes, Portugal, 21–24 September 2003; 2003. [Google Scholar]

- Iwai, M. Thermodynamic Table for Performance Calculations in Gas Turbine Engine. In Proceedings of the International Gas Turbine Congress, Tokyo, Japan, 2–7 November, 2003. [Google Scholar]

- Capata, R. Experimental tests of the operating conditions of a micro gas turbine device. J. Energy Power Eng. 2015, 9, 326–335. [Google Scholar]

- Silvestri, T. CFD Analysis of a Radial Turbine Stage with Variable NGV Control. Master Degree Thesis, Dept. of Mechanical and Aerospace Engineering, U. of Roma Sapienza, Roma, Italy.

- Capata, R.; Sciubba, E. The low emission Turbogas hybrid vehicle concept-preliminary simulation and vehicle packaging. J. Energy Resour. Techno. 2013, 135, 032203. [Google Scholar] [CrossRef]

- Capata, R.; Sciubba, E. The Lethe (Low Emissions Turbo-Hybrid Engine) city car of the university of Roma 1: Faxinal proposed configuration. Energy 2013, 58, 178–184. [Google Scholar] [CrossRef]

- Capata, R.; Coccia, A.; Lora, M. A proposal for the CO2 abatement in urban areas: The Udr1–Lethe© turbo-hybrid vehicle. Energies 2011, 4, 368–388. [Google Scholar] [CrossRef]

- Capata, R. Urban and extra-urban hybrid vehicles: A technological review. Energies 2018, 11, 2924. [Google Scholar] [CrossRef]

| 0.02 | kg/s | ||||||

| β | 1.4 | p1 | 101000 | Pa | |||

| cp | 1004 | J/kg K | |||||

| T1 | 293 | K | T2 | 337 | K | ||

| ω | 14653 | rad/s | |||||

| ε | 0.42 | ||||||

| ψ2 | 1 | Rρ | 0.5 | ||||

| LEUL | cp (T2-T1) | 44652.74 | J/kg K | ψ1 | 0 | ||

| U2 | (LEUL/φ2)1/2 | 211.3119 | m/s | ϕ1 | 0.3 | ||

| r2 | U/ω | 0.014421 | m/s | ϕ2 | 0.55 | ||

| δp | 0.98 | ||||||

| ΔΤ | 22.23742 | χ | 0.65 | (1-χ2) | 0.5775 | ||

| ρ1 | 1.20108 | ||||||

| 1 | 0.016652 | ||||||

| r1e | 0.011005 | m | |||||

| r1i | 0.007153 | m |

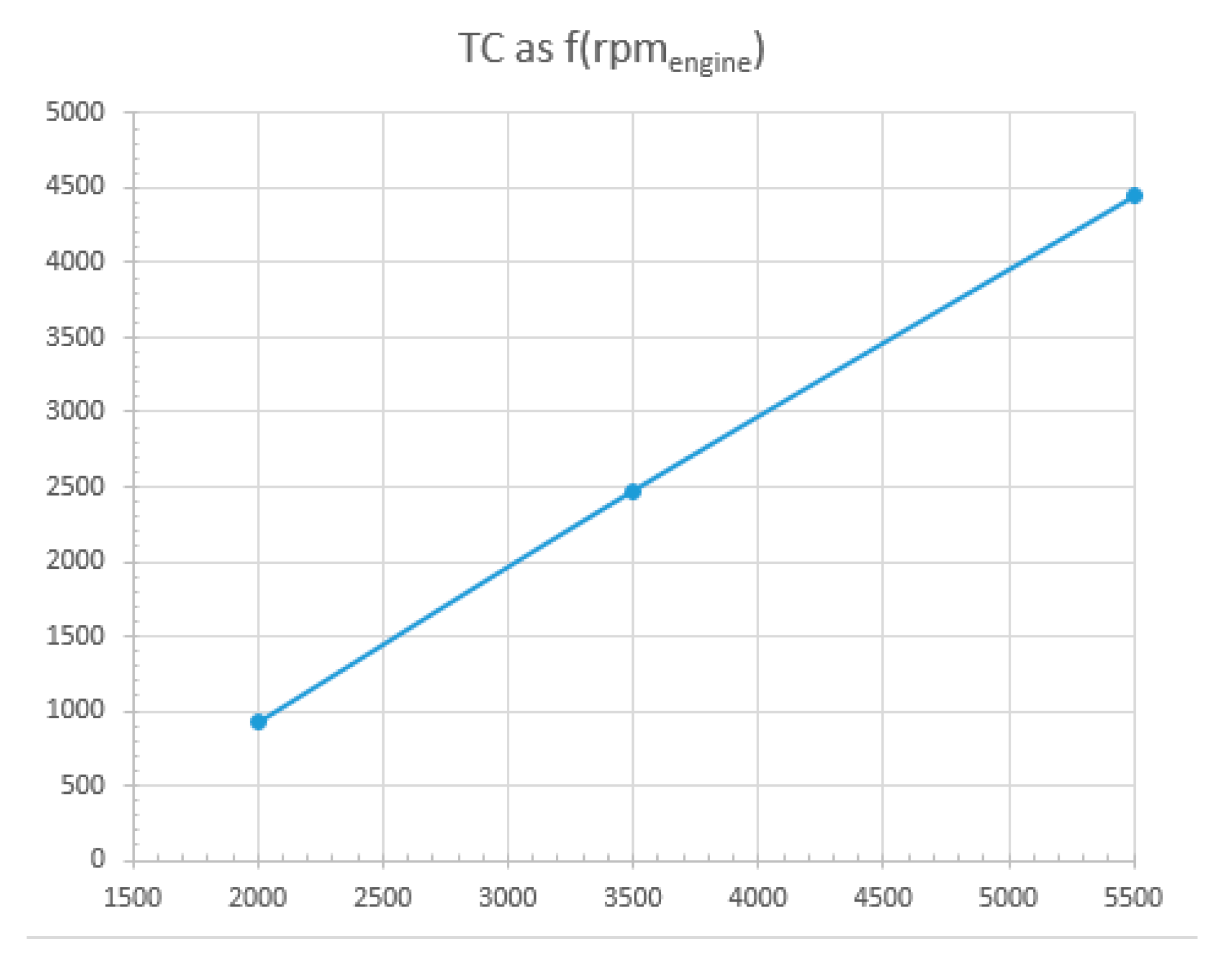

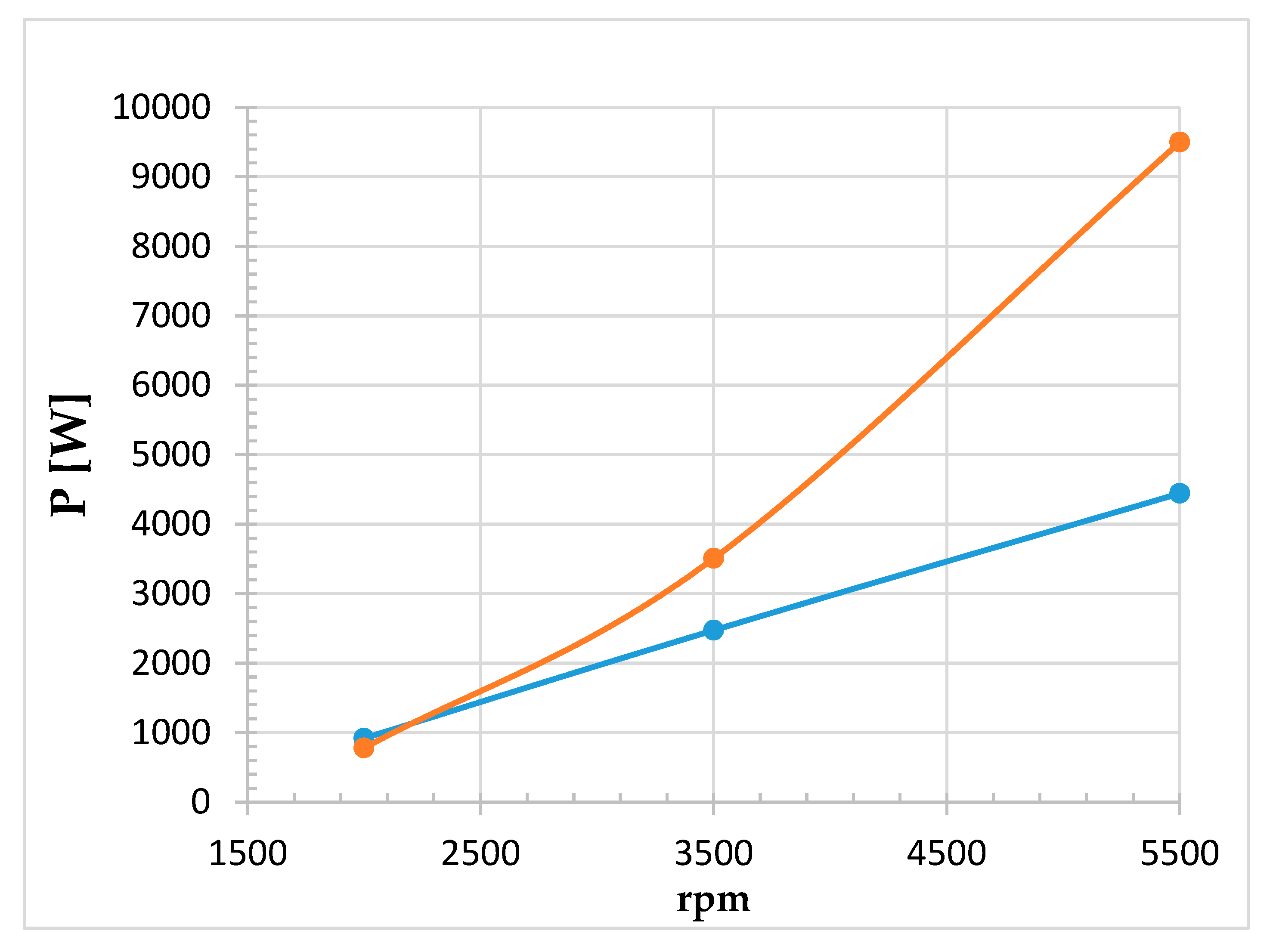

| rpm ICE | rpm | βc | Tin [K] | Tout [K] | P [W] | η | |

|---|---|---|---|---|---|---|---|

| 2000 | 0.021 | 145000 | 1.42 | 298.4 | 344 | 920.71 | 0.68 |

| 3500 | 0.0408 | 180000 | 1.64 | 297.5 | 354 | 2474.39 | 0.8 |

| 5500 | 0.0619 | 210000 | 1.84 | 297.5 | 366.8 | 4444.96 | 0.82 |

| 0.0021 | kg/s | ||||||

| β | 1.4 | p2 | 101000 | Pa | |||

| cp | 1414 | J/kg K | |||||

| T1 | 980 | K | T2 | 907 | K | ||

| ω | 6280 | rad/s | |||||

| ε | 0.23 | ||||||

| φ1 | 1 | Rρ | 0.5 | ||||

| LEUL | cp (T2-T1) | 103194.4 | J/kg K | φ2 | 0 | ||

| U1 | (LEUL/φ1))1/2 | 321.2389 | m/s | Φ1 | 0.3 | ||

| r1 | U/ω | 0.051153 | m/s | Φ2 | 0.4 | ||

| δp | 0.98 | ||||||

| ΔΤ | 36.49025 | χ | 0.65 | (1-χ2) | 0,5775 | ||

| ρ2 | 0.387992 | ||||||

| 2 | 0.005412 | ||||||

| r2e | 0.011159 | m | |||||

| r2i | 0.007253 | m |

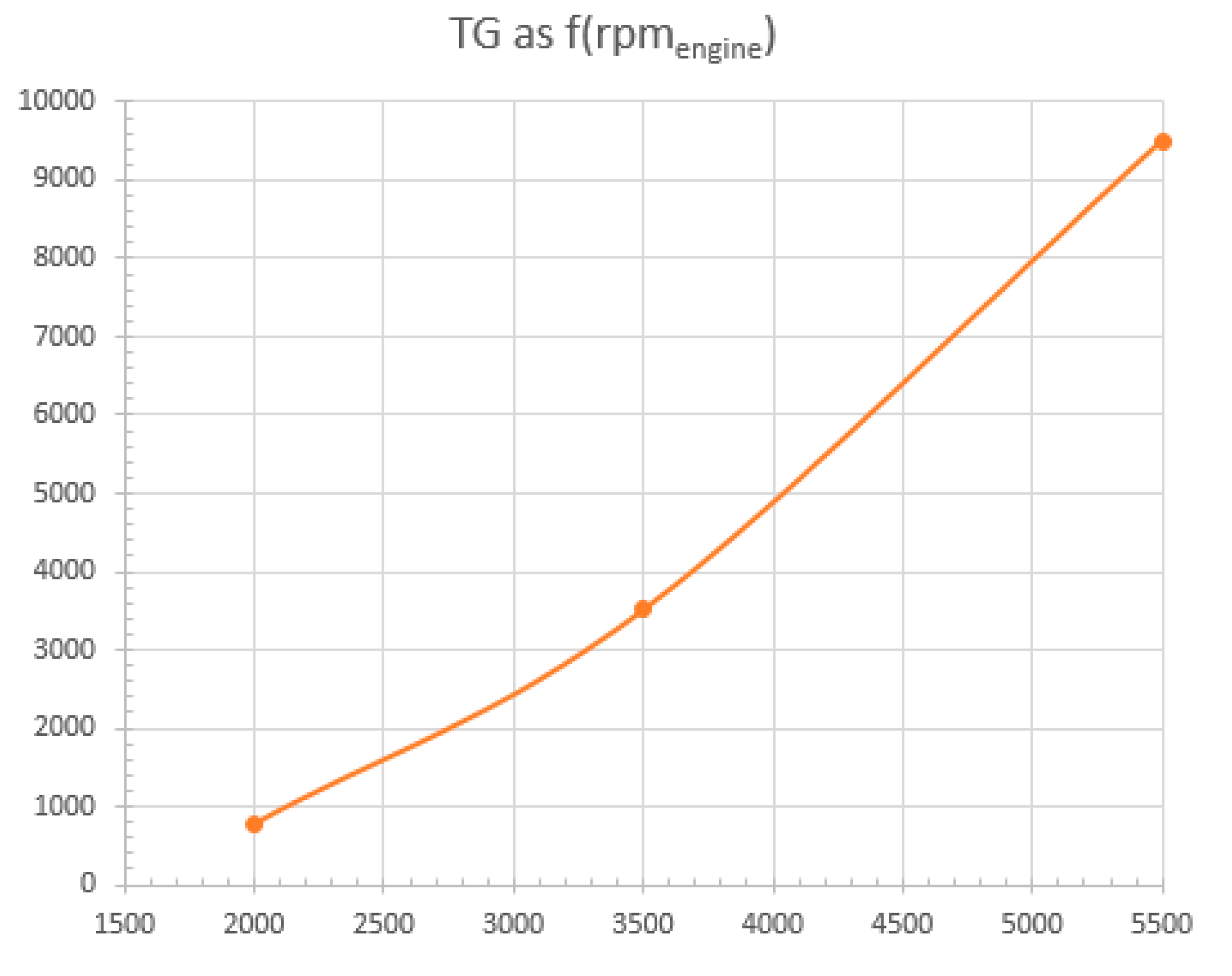

| rpm ICE | rpm | βe | Tin [K] | Tout [K] | P [W] | η | |

|---|---|---|---|---|---|---|---|

| 2000 | 0.024 | 82170 | 1.2 | 954 | 922 | 780 | 0.87 |

| 3500 | 0.04 | 134483 | 1.6 | 1005 | 930 | 3510 | 0.86 |

| 5500 | 0.07 | 164002 | 2.00 | 1045 | 932 | 9500 | 0.81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Capata, R. New Power Train Concept for a City Hybrid Vehicle. Proceedings 2020, 58, 6. https://doi.org/10.3390/WEF-06926

Capata R. New Power Train Concept for a City Hybrid Vehicle. Proceedings. 2020; 58(1):6. https://doi.org/10.3390/WEF-06926

Chicago/Turabian StyleCapata, Roberto. 2020. "New Power Train Concept for a City Hybrid Vehicle" Proceedings 58, no. 1: 6. https://doi.org/10.3390/WEF-06926

APA StyleCapata, R. (2020). New Power Train Concept for a City Hybrid Vehicle. Proceedings, 58(1), 6. https://doi.org/10.3390/WEF-06926