Influence of Plate Orifice in the Pre-Mixing of Gas-Powered Water Heaters †

Abstract

:1. Introduction

2. Materials and Methods

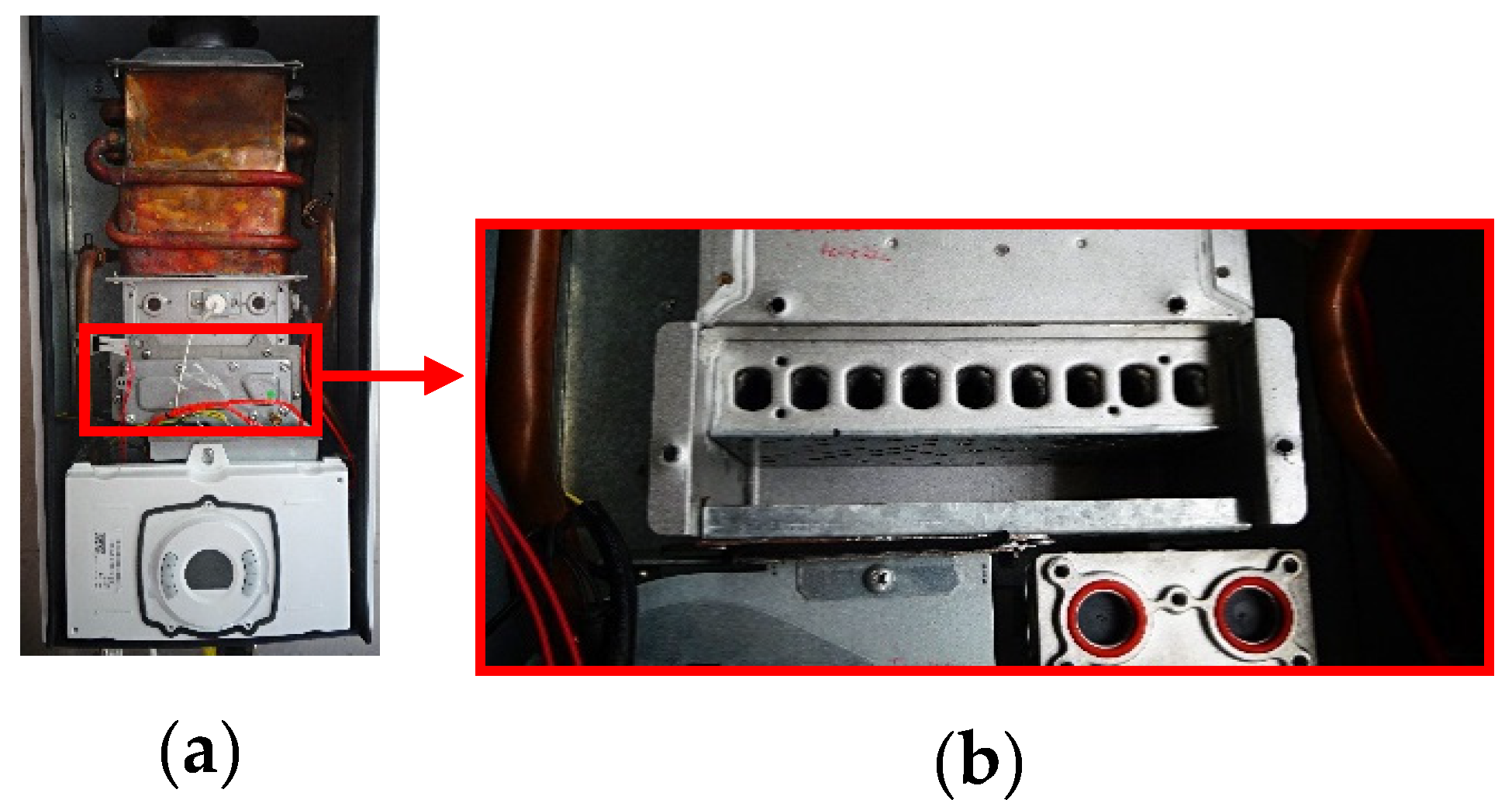

2.1. The Water Heater

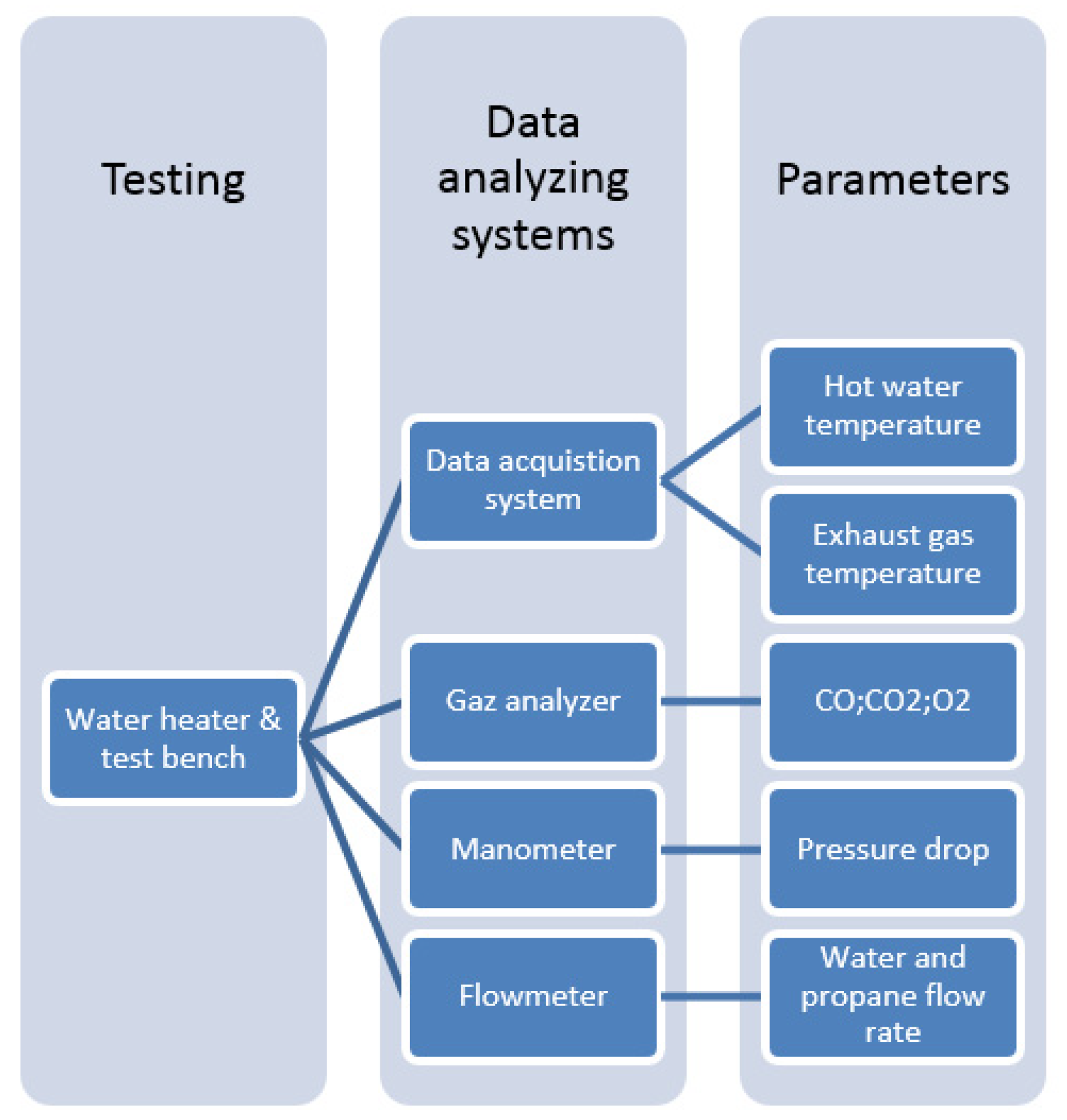

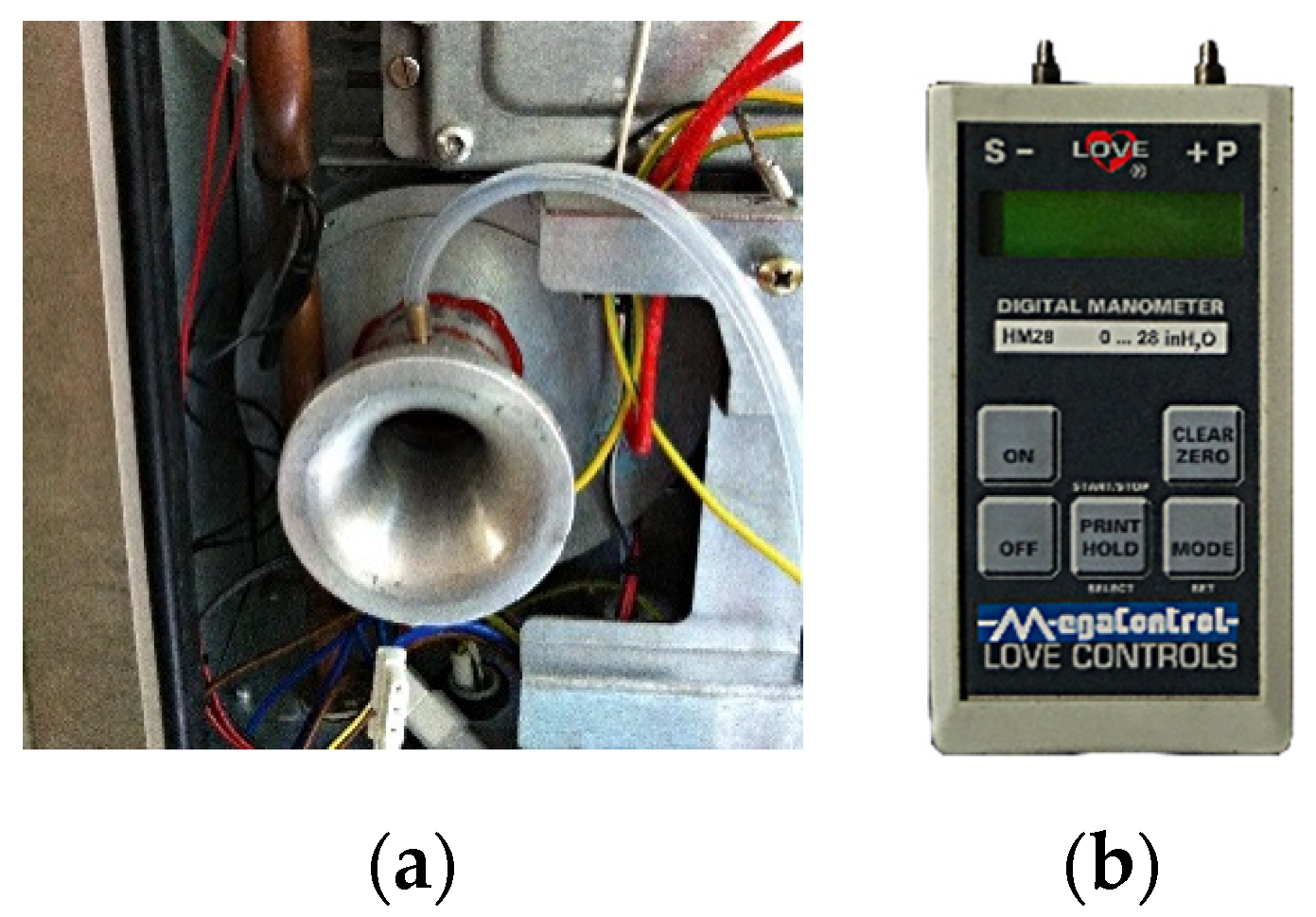

2.2. Experimental Facility

2.3. Experimental Techniques

3. Results and Discussion

- Comparison between the experimental data and the reference data from the technical catalog (Vulcano);

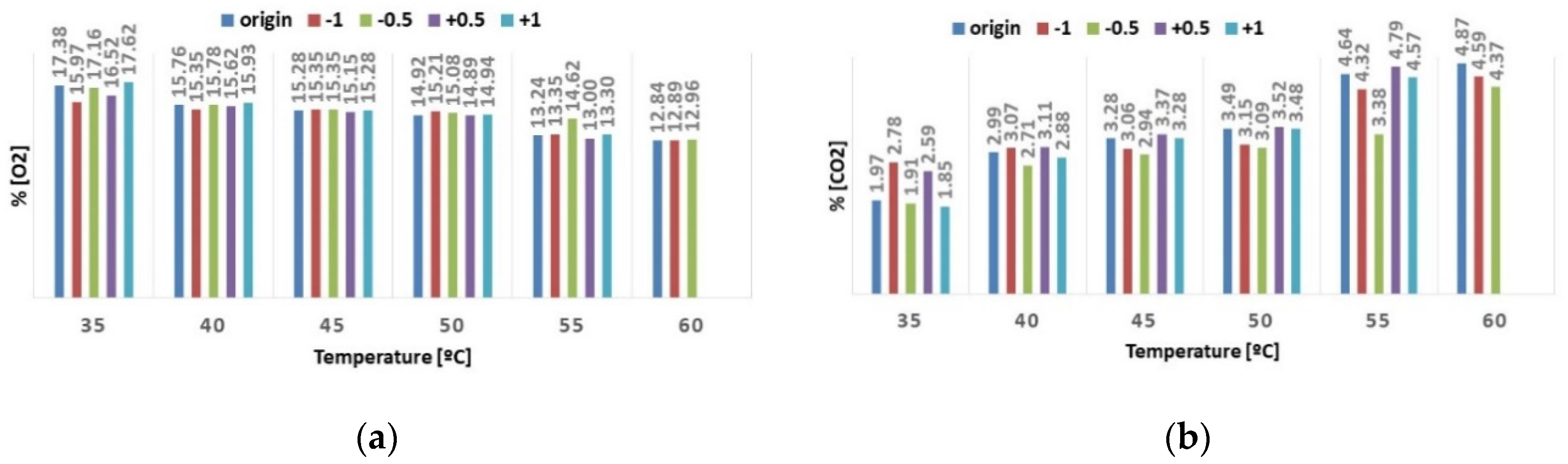

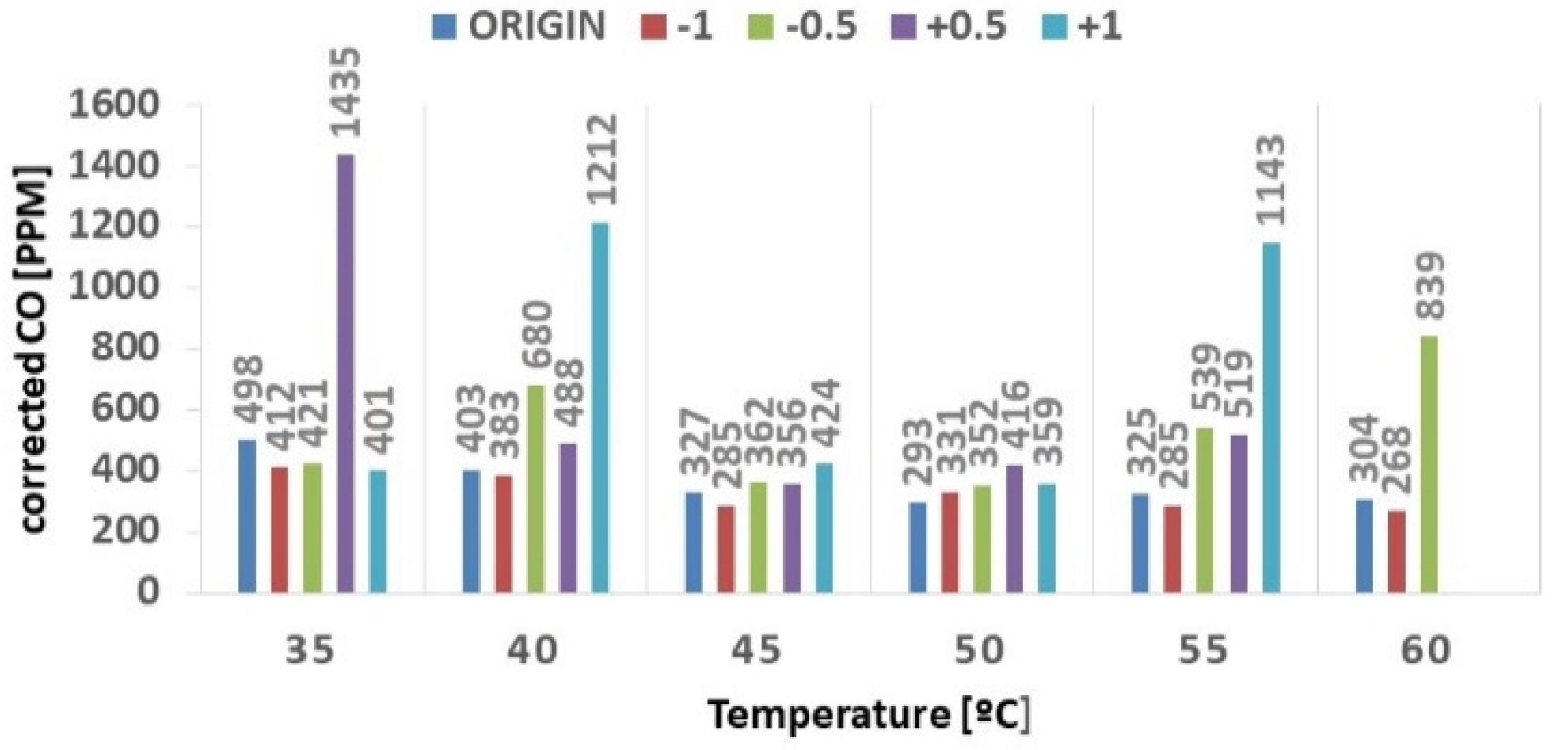

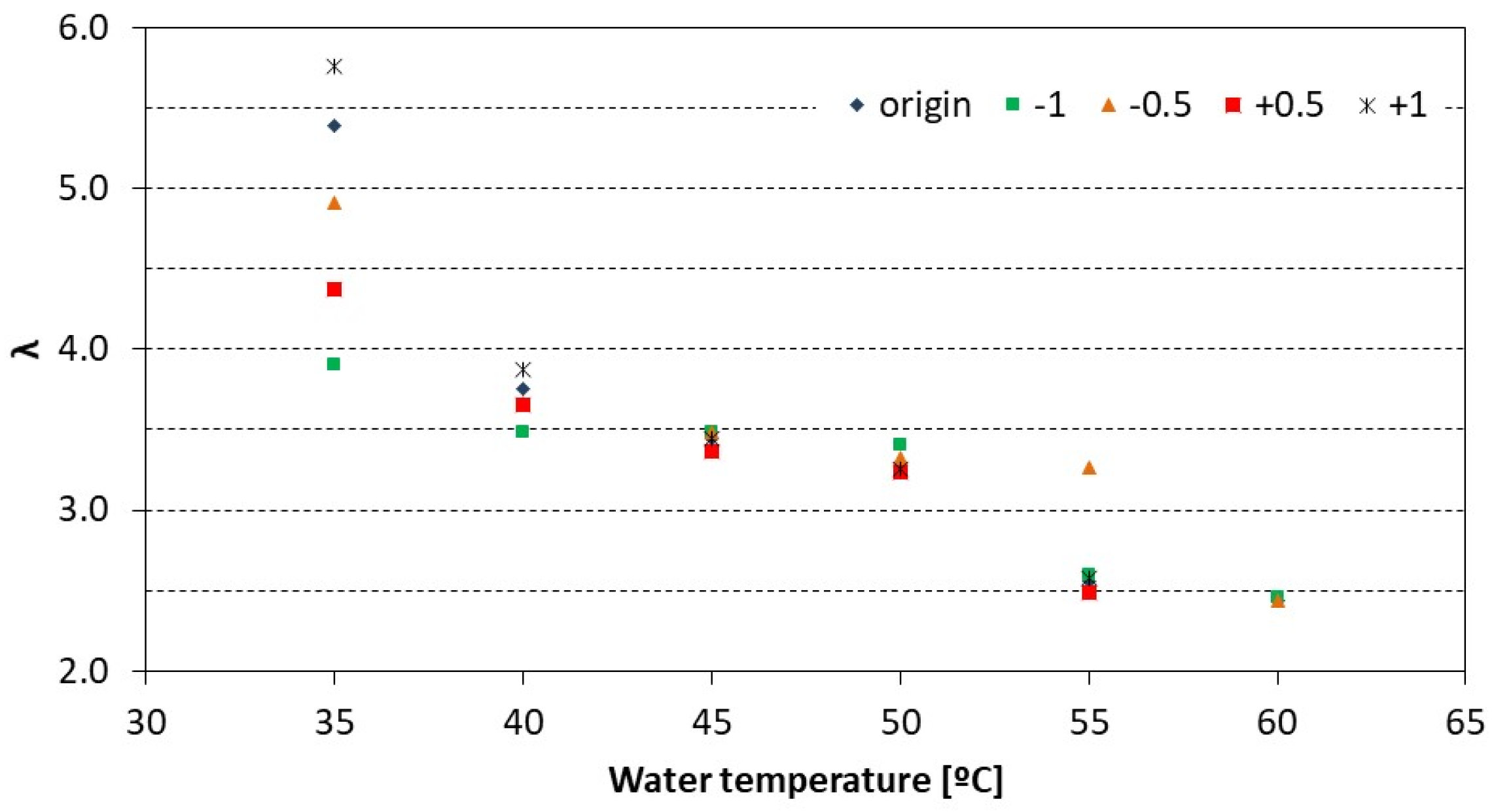

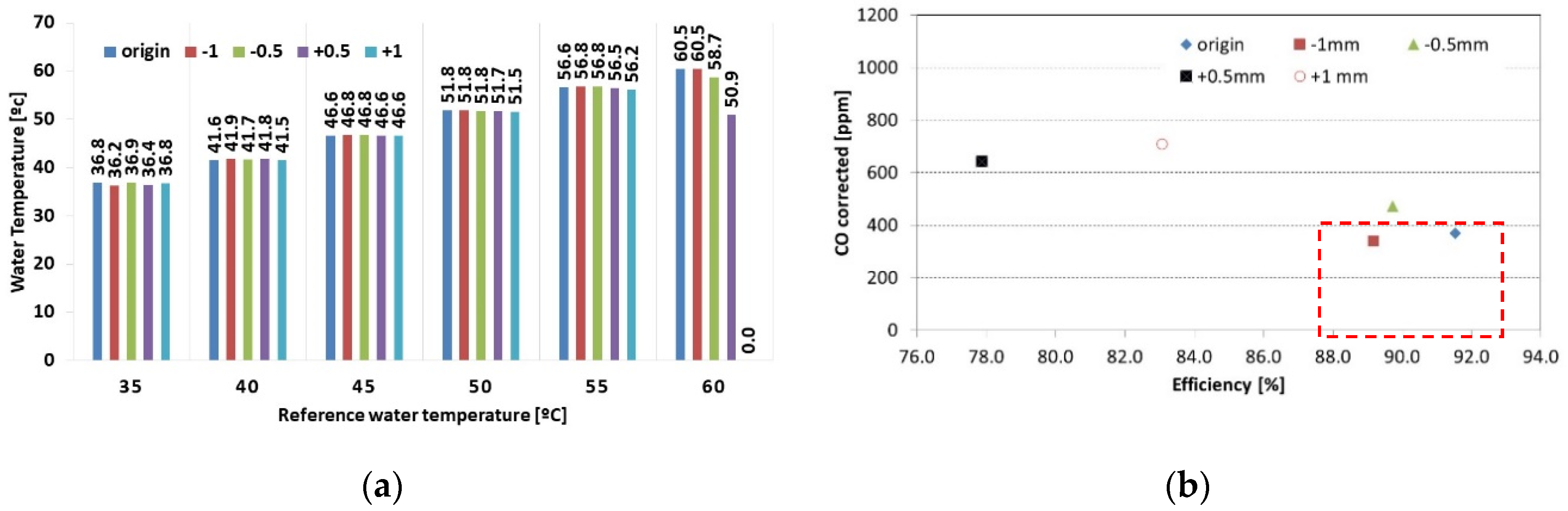

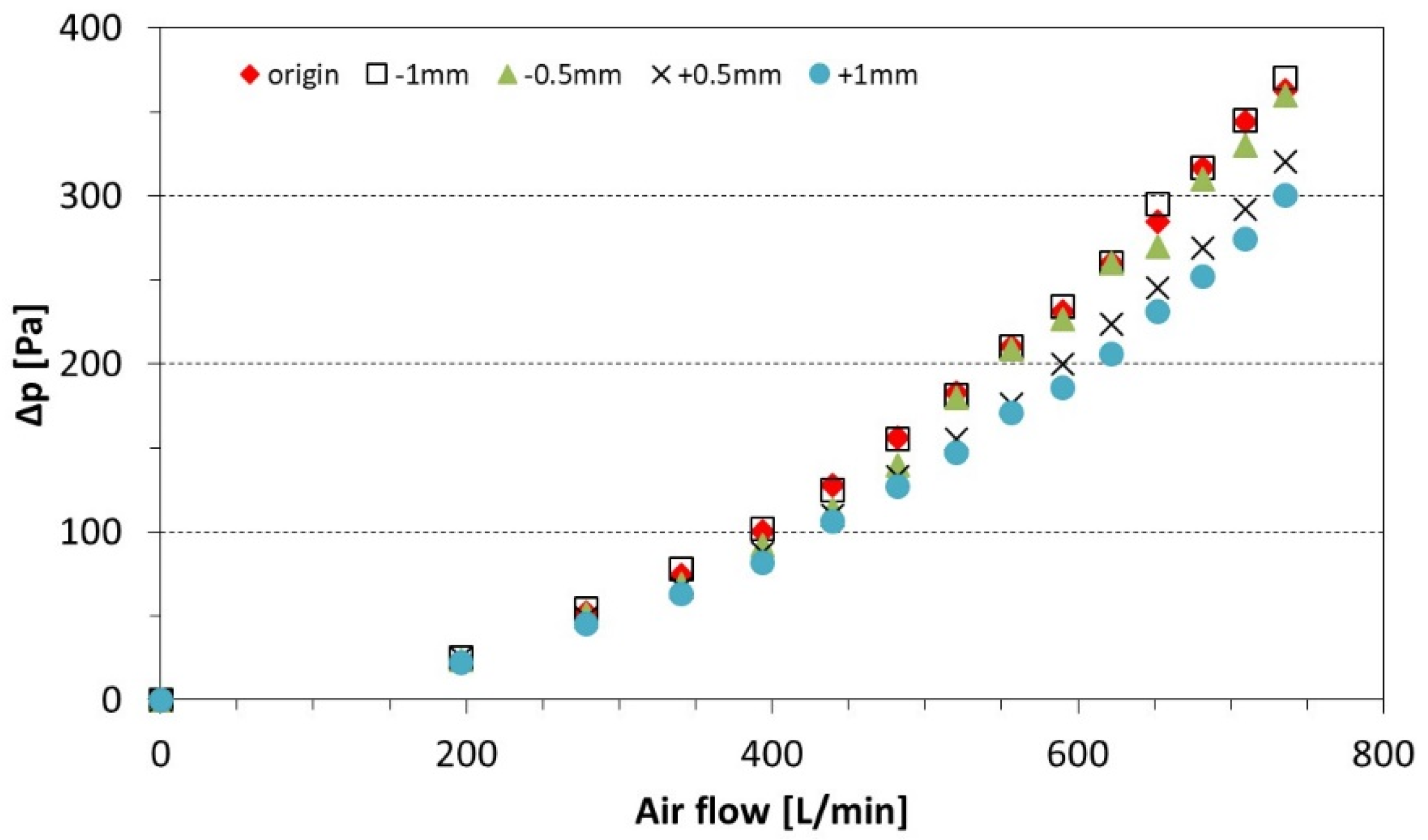

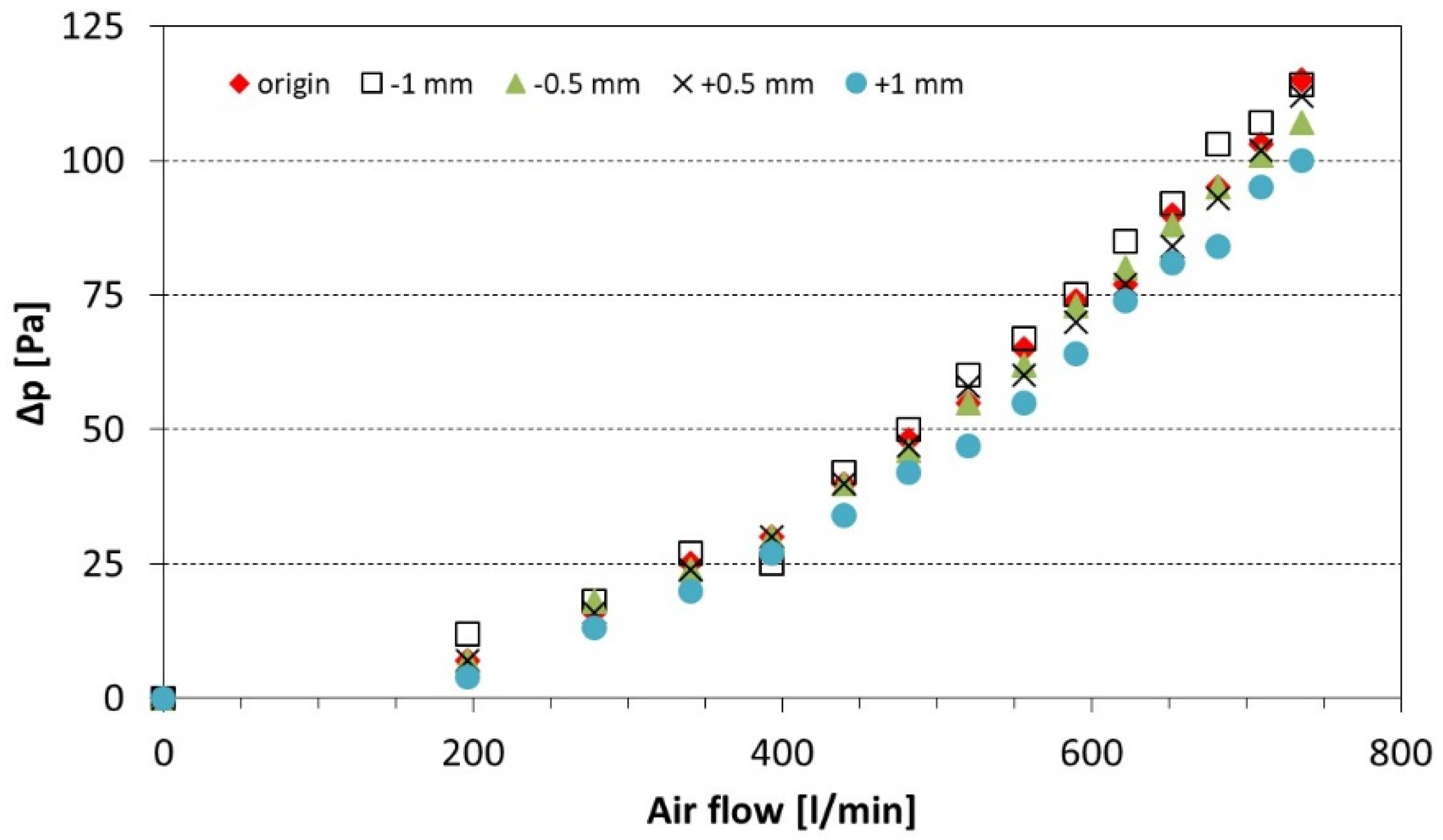

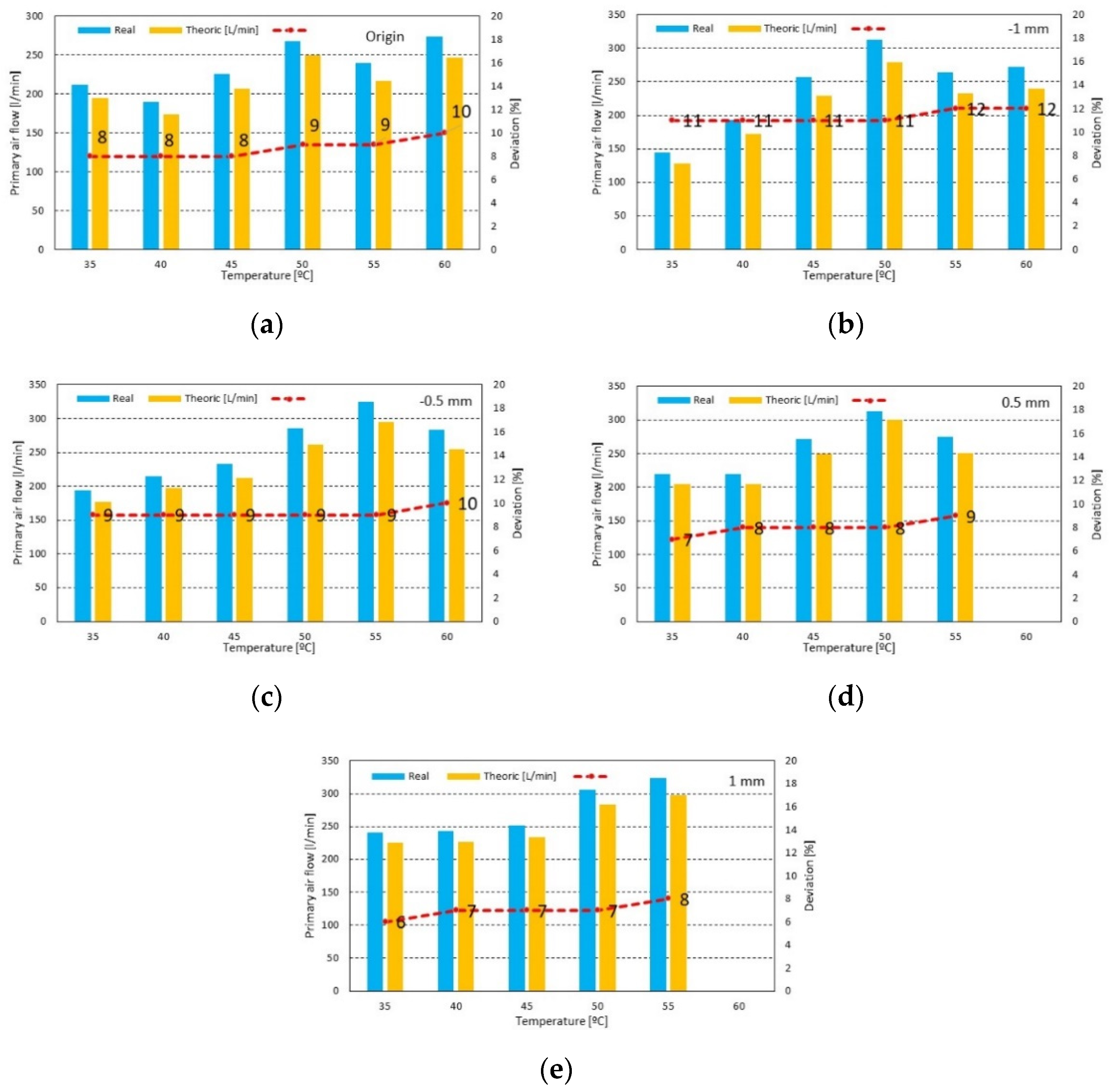

- comparison between the thermal performance and the flow of combustion gas with the different plates namely (“origin”; “−1 mm”; “−0.5 mm”; “+0.5 mm”; “+1 mm”);

- influence of the nozzle on the water heater behavior;

- influence of the plates on the distribution of primary and secondary air.

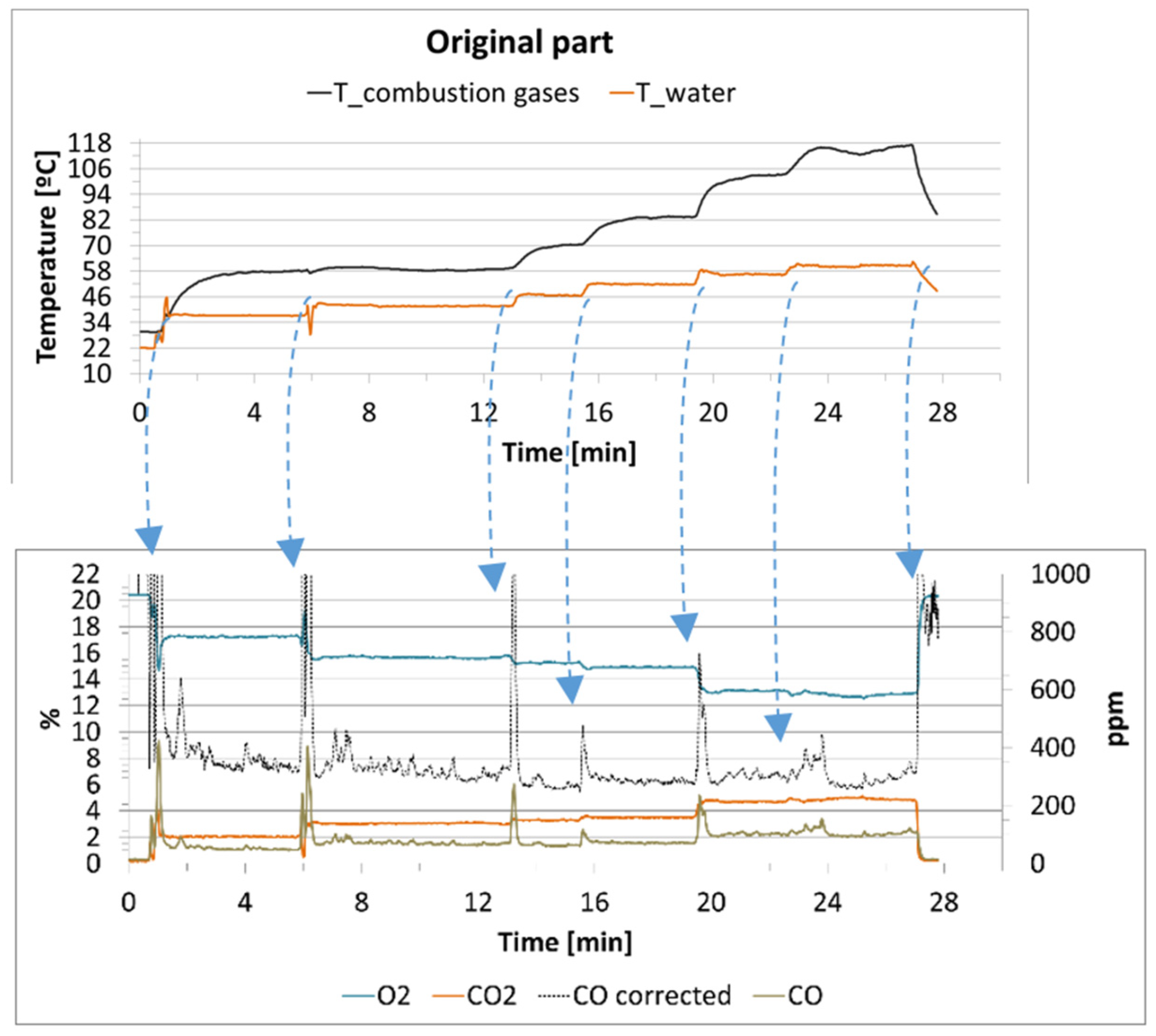

3.1. Operation in Standard Conditions

3.2. Influence of the Restrictor Plate

3.3. Influence of the Bell Mouth

3.4. Influence of the Restrictor Plates on the Distribution of Primary and Secondary Air

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ibrahim, O.; Fardoun, F.; Louahlia-Gualous, H. Review of Water-Heating Systems: General Selection Approach Based on Energy and Environmental Aspects. Build. Environ. 2014, 72, 259–286. [Google Scholar] [CrossRef]

- Hohne, P.A.; Kusakana, K.; Numbi, B.P. A Review of Water Heating Technologies: An Application to the South African Context. Energy Rep. 2019, 5, 1–19. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Water Heater Market Profile 2009; ENERGY STAR: Washington, DC, USA, 2009; p. 20.

- Ma, X.; Zhang, H.; You, S.; Zheng, X.; Miao, Q.; Li, H. Numerical Investigations on Combustion Characteristics, NO and CO Emission of Gas Instantaneous Water Heater with Partial Premixed Combustion. Energy Procedia 2019, 158, 1372–1379. [Google Scholar] [CrossRef]

- Johnson, G.; Beausoleil-Morrison, I. The Calibration and Validation of a Model for Predicting the Performance of Gas-fired Tankless Water Heaters in Domestic Hot Water Applications. Appl. Energy 2016, 177, 740–750. [Google Scholar] [CrossRef]

- Li, G. Parallel Loop Configuration for Hybrid Heat Pump—Gas Fired Water Heater System with Smart Control Strategy. Appl. Therm. Eng. 2018, 138, 801–807. [Google Scholar] [CrossRef]

- Choudhury, S.; McDonell, V.G.; Samuelsen, S. Combustion Performance of low-NOx and Conventional Storage Water Heaters Pperated on Hydrogen Enriched Natural Gas. Int. J. Hydrog. Energy 2020, 45, 2405–2417. [Google Scholar] [CrossRef]

- Czerski, G.; Gebhardt, Z.; Strugala, A.; Butrymowicz, C. Gas-fired Instantaneous Water Heaters with Combustion Chamber Sealed with Respect to the Room in Multi-Storey Residential Buildings—Results of Pilot Plants Tests. Energy Build. 2013, 57, 237–244. [Google Scholar] [CrossRef]

- De Paepe, M.; T’Joen, C.; Huisseune, H.; van Belleghem, M.; Kessen, V. Comparison of Different Testing Methods for Gas Fired Domestic Boiler Efficiency Determination. Appl. Therm. Eng. 2013, 50, 275–281. [Google Scholar] [CrossRef]

- NP 1037-1_2002; Ventilação e Evacuação dos Produtos da Combustão dos Locais com Aparelhos a Gás. IPQ: Lisbon, Portugal, 2002.

- EN 437:2003 E; Test Gases—Test Pressures—Appliance Categories. IPQ: Lisbon, Portugal, 2003; p. 39.

- EN 26:2002; Gas-Fired Instantaneous Water Heaters for the Production of Domestic Hot Water. IPQ: Lisbon, Portugal, 2002.

- Silva, J.P.V.; Fraga, L.G.; Ferreira, M.E.C.; Chapela, S.; Porteiro, J.; Teixeira, S.F.C.; Teixeira, J.C.F. Combustion Modelling of a 20 kW Pellet Boiler. In Energy: Volume 6B; ASME, Ed.; ASME: New York, NY, USA, 2018; p. V06BT08A036. [Google Scholar] [CrossRef]

- El-Mahallawy, F.; El-Din Habik, S. Fundamental and Technology of Combustion; Elsevier Science Ltd., Digital Version 2002. Available online: https://www.sciencedirect.com/book/9780080441061/fundamentals-and-technology-of-combustion (accessed on 1 February 2020).

- Persoons, T.; Vanierschot, M.; Van den Bulck, E. Oblique inlet pressure loss for swirling flow entering a catalyst substrate. Exp. Therm. Fluid Sci. 2008, 32, 1222–1231. [Google Scholar] [CrossRef]

| Family | Gas | HHV (MJ/m3) | sg (Air = 1) | Wobbe (MJ/m3) | p (mbar) |

|---|---|---|---|---|---|

| 1st | City gas Methane air | 17.6 20.9 | 0.58 0.82 | 23.1 23.1 | 8 8 |

| 2nd | Natural gas Propane air | 41.9 56.7 | 0.65 1.31 | 52.1 50.5 | 20 20 |

| 3rd | Propane Butane | 100.5 125.6 | 1.6 2 | 79.5 87.9 | 37 30 |

| Fuel | Min. Pressure Supply (mbar) | Consumption of Propane Gas (m3/h) |

|---|---|---|

| Nat. gas G23 | 20 | 2.4 |

| Butane G30 | 28–30 | 0.705 |

| Propane G31 | 37 | 0.890 |

| Variable | Minimum | Maximum |

|---|---|---|

| Thermal power (kW) | 3.0 | 22.5 |

| Output power (kW) | 2.9 | 20.5 |

| Water flow (L/min) | 2.2 | 12 |

| Exhaust gas temperature (-°C) | 50 | 170 |

| Propane consumption (kg/h) | 1.7 | |

| CO2 (%) | 6.6 | |

| Combustion gas flow (kg/h) | 38.5 | |

| Analyzed Gas | CO | CO2 | O2 |

|---|---|---|---|

| Scale | 1000, 5000, 10,000 ppm | 5, 10, 20% | 5, 10, 25% |

| Response time | <15 s | <15 s | 5 s |

| Linearity | <0.5% of the range | ||

| Zero offset and span | <0.1% of the range, in 1 h, at constant temperature and pressure | ||

| Exits | 0–10 V; 4–20 mA; RS232 | ||

| Acquisition Plate SCXI-1300 | Signal Module SCXI-1102 | |

| Thermocouples | Accuracy of 1.3 -°C Repeatability of 0.5 -°C | 2 Hz low pass filter 32 channels |

| Acquisition plate SCXI-1303 | Signal module SCXI-1180 | |

| Gas analyzer | Accuracy of 1.3 -°C Repeatability of 0.5 -°C | 2 Hz low pass filter |

| Gas Name | G25; G231 | G26 | G30 | G31; G130 |

| (𝐶𝑂2)𝑁 | 1155 | 11.9 | 14.0 | 13.7 |

| Gas name | G120 | G140 | G141 | G150 |

| (𝐶𝑂2)𝑁 | 8.35 | 7.8 | 7.9 | 11.8 |

| Combustion gas | T. Selected. (ºC) | 35 | 40 | 45 | 50 | 55 | 60 |

| O2 (%) | 17.38 | 15.76 | 15.28 | 14.92 | 13.24 | 12.84 | |

| CO2 (%) | 1.97 | 2.99 | 3.28 | 3.49 | 4.64 | 4.87 | |

| CO (ppm) | 64 | 79 | 77 | 73 | 108 | 106 | |

| Corrected CO (ppm) | 498 | 403 | 327 | 293 | 325 | 304 | |

| Flow combustion gas (kg/s) | 0.0114 | 0.0102 | 0.0122 | 0.0148 | 0.0130 | 0.0149 | |

| Excess air coeff. λ | 5.39 | 3.75 | 3.44 | 3.24 | 2.56 | 2.44 | |

| Energy behavior | T. hot water (ºC) | 37 | 42 | 47 | 52 | 57 | 60 |

| T. exhaust gas (ºC) | 53 | 59 | 68 | 81 | 100 | 114 | |

| Propane flow (kg/s) | 0.00013 | 0.00017 | 0.00022 | 0.00029 | 0.00032 | 0.00038 | |

| Air flow (m3/s) | 0.0092 | 0.0082 | 0.0098 | 0.0119 | 0.0104 | 0.0119 | |

| Power output (kW) | 5.74 | 7.58 | 9.54 | 11.53 | 13.40 | 14.89 | |

| Power thermal (kW) | 6.20 | 7.97 | 10.33 | 13.28 | 14.75 | 17.70 | |

| Efficiency (%) | 92.7 | 95.2 | 92.4 | 86.9 | 90.8 | 84.1 |

| Catalog | Experimental | |

|---|---|---|

| Propane consumption (kg/h) | 1.7 | Max 1.4 |

| CO2 (%) | 6.6 | Max 4.8 |

| Flow of flue gases (kg/h) | 38.5 | Aver. 45.9 |

| Air split | Origin | −1 mm | −0.5 mm | +0.5 mm | +1 mm |

|---|---|---|---|---|---|

| Primary air [%] | 38.3 | 37.8 | 39.1 | 41.2 | 42.8 |

| Secondary air [%] | 61.7 | 62.2 | 60.9 | 58.8 | 57.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magalhães, R.; Teixeira, S.; Ferreira, M.; Teixeira, J. Influence of Plate Orifice in the Pre-Mixing of Gas-Powered Water Heaters. Proceedings 2020, 58, 17. https://doi.org/10.3390/WEF-06930

Magalhães R, Teixeira S, Ferreira M, Teixeira J. Influence of Plate Orifice in the Pre-Mixing of Gas-Powered Water Heaters. Proceedings. 2020; 58(1):17. https://doi.org/10.3390/WEF-06930

Chicago/Turabian StyleMagalhães, Roberto, Senhorinha Teixeira, Manuel Ferreira, and José Teixeira. 2020. "Influence of Plate Orifice in the Pre-Mixing of Gas-Powered Water Heaters" Proceedings 58, no. 1: 17. https://doi.org/10.3390/WEF-06930

APA StyleMagalhães, R., Teixeira, S., Ferreira, M., & Teixeira, J. (2020). Influence of Plate Orifice in the Pre-Mixing of Gas-Powered Water Heaters. Proceedings, 58(1), 17. https://doi.org/10.3390/WEF-06930