Synthesis and Piezoelectric Characterization of UV-Curable Nanocellulose/ZnO/AlN Polymeric Flexible Films for Green Energy Generation Applications †

Abstract

:1. Introduction

2. Materials and Methods

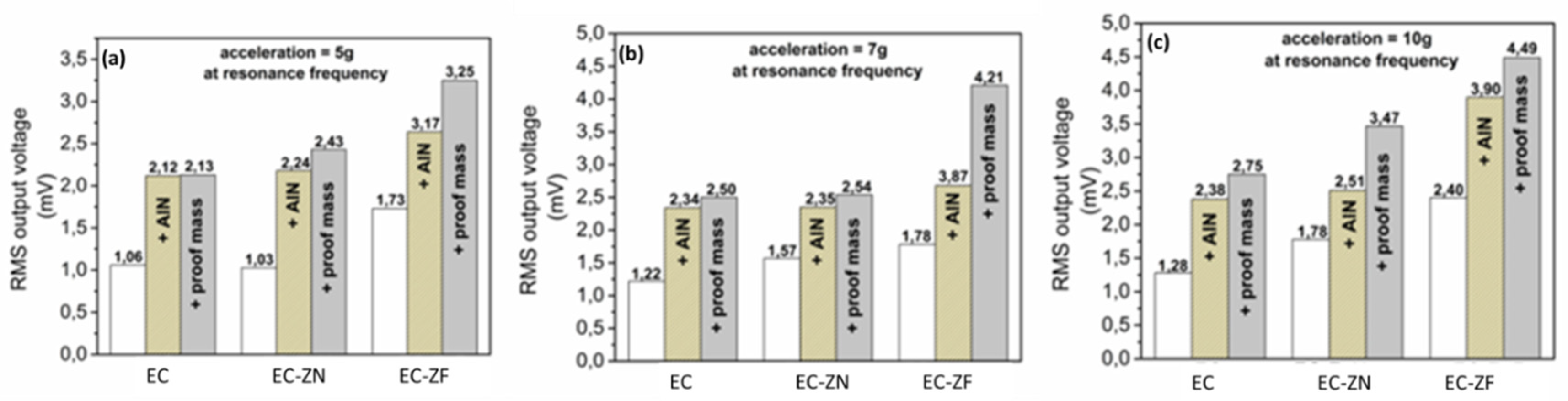

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Reference

- Covaci, C.; Gontean, A. Piezoelectric Energy Harvesting Solutions: A Review. Sensors 2020, 20, e3512. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Signore, M.A.; Malucelli, G.; Duraccio, D.; De Pascali, C.; Fioravanti, A.; Siciliano, P.; Francioso, L. Synthesis and Piezoelectric Characterization of UV-Curable Nanocellulose/ZnO/AlN Polymeric Flexible Films for Green Energy Generation Applications. Proceedings 2020, 56, 36. https://doi.org/10.3390/proceedings2020056036

Signore MA, Malucelli G, Duraccio D, De Pascali C, Fioravanti A, Siciliano P, Francioso L. Synthesis and Piezoelectric Characterization of UV-Curable Nanocellulose/ZnO/AlN Polymeric Flexible Films for Green Energy Generation Applications. Proceedings. 2020; 56(1):36. https://doi.org/10.3390/proceedings2020056036

Chicago/Turabian StyleSignore, Maria Assunta, Giulio Malucelli, Donatella Duraccio, Chiara De Pascali, Ambra Fioravanti, Pietro Siciliano, and Luca Francioso. 2020. "Synthesis and Piezoelectric Characterization of UV-Curable Nanocellulose/ZnO/AlN Polymeric Flexible Films for Green Energy Generation Applications" Proceedings 56, no. 1: 36. https://doi.org/10.3390/proceedings2020056036

APA StyleSignore, M. A., Malucelli, G., Duraccio, D., De Pascali, C., Fioravanti, A., Siciliano, P., & Francioso, L. (2020). Synthesis and Piezoelectric Characterization of UV-Curable Nanocellulose/ZnO/AlN Polymeric Flexible Films for Green Energy Generation Applications. Proceedings, 56(1), 36. https://doi.org/10.3390/proceedings2020056036