Development of Gluten-Free Breads Using Andean Native Grains Quinoa, Kañiwa, Kiwicha and Tarwi †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Conditioning and Characterization of Raw Materials

2.2. Experimental Design

2.3. Dough and Bread Preparation

2.4. Dough Textural Properties

2.5. Specific Volume

2.6. Textural Properties of Bread

3. Results and Discussion

4. Conclusions

Funding

References

- Ramos Diaz, J.M.; Kirjoranta, S.; Tenitz, S.; Penttilä, P.A.; Serimaa, R.; Lampi, A.M.; Jouppila, K. Use of Amaranth, Quinoa and Kañiwa in Extruded Corn-Based Snacks. J. Cereal Sci. 2013, 58, 59–67. [Google Scholar] [CrossRef]

- Rosell, C.M.; Cortez, G.; Repo-Carrasco, R. Breadmaking Use of Andean Crops Quinoa, Kañiwa, Kiwicha, and Tarwi. Cereal Chem. 2009, 86, 386–392. [Google Scholar] [CrossRef]

- Schoenlechner, R. Pseudocereals in Gluten-Free Products. In Pseudocereals: Chemistry and Technology; John Wiley & Sons, Ltd.: Chichester, UK, 2017; pp. 193–216. [Google Scholar] [CrossRef]

- Benavent-Gil, Y.; Rosell, C.M. Technological and Nutritional Applications of Starches in Gluten-Free Products. Starches for Food Application; Elsevier Inc.: London, UK, 2018. [Google Scholar] [CrossRef]

- Vidaurre-Ruiz, J.M.; Salas-Valerio, W.F.; Repo-Carrasco-Valencia, R. Propiedades de Pasta y Texturales de las Mezclas de Harinas de Quinua (Chenopodium Quinoa), Kiwicha (Amaranthus Caudatus) y Tarwi (Lupinus Mutabilis) En un Sistema Acuoso. Rev. Investig. Altoandinas J. High. Andean. Res. 2019, 21, 5–14. [Google Scholar] [CrossRef]

- Repo-Carrasco-Valencia, R.A.M.; Encina, C.R.; Binaghi, M.J.; Greco, C.B.; Ronayne de Ferrer, P.A. Effects of Roasting and Boiling of Quinoa, Kiwicha and Kañiwa on Composition and Availability of Minerals in Vitro. J. Sci. Food Agric. 2010, 90, 2068–2073. [Google Scholar] [CrossRef] [PubMed]

- Stikic, R.; Glamoclija, D.; Demin, M.; Vucelic-Radovic, B.; Jovanovic, Z.; Milojkovic-Opsenica, D.; Jacobsen, S.-E.; Milovanovic, M. Agronomical and Nutritional Evaluation of Quinoa Seeds (Chenopodium Quinoa Willd.) as an Ingredient in Bread Formulations. J. Cereal Sci. 2012, 55, 132–138. [Google Scholar] [CrossRef]

- Burgos, V.E.; Binaghi, M.J.; Ronayne de Ferrer, P.A.; Armada, M. Effect of Precooking on Antinutritional Factors and Mineral Bioaccessibility in Kiwicha Grains. J. Cereal Sci. 2018, 80, 9–15. [Google Scholar] [CrossRef]

- Dirección Regional Agraria Puno. Variabilidad Genética de Cañihua En Las Provincias de Puno; Editora DISKCOPY S.A.C.: Puno, Peru, 2012; ISBN 978-612-46286-0-3. [Google Scholar]

- Repo-Carrasco-Valencia, R. Andean Indigenous Food Crops: Nutritional Value and Bioactive Compounds. Ph.D. Thesis, University of Turku, Turku, Finland, 2011. [Google Scholar]

- Jacobsen, S.-E.; Mujica, A. El Tarwi (Lupinus Mutabilis Sweet.) y Sus Parientes Silvestres. Bot. Econ. Los Andes Cent. Univ. Mayor San Andrés 2006, 28, 458–482. [Google Scholar]

- AOAC. Official Methods of Analysis, 17th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Vidaurre-Ruiz, J.; Matheus-Diaz, S.; Salas-Valerio, F.; Barraza-Jauregui, G.; Schoenlechner, R.; Repo-Carrasco-Valencia, R. Influence of Tara Gum and Xanthan Gum on Rheological and Textural Properties of Starch-Based Gluten-Free Dough and Bread. Eur. Food Res. Technol. 2019, 245, 1347–1355. [Google Scholar] [CrossRef]

- Alvarez-Jubete, L.; Auty, M.; Arendt, E.K.; Gallagher, E. Baking Properties and Microstructure of Pseudocereal Flours in Gluten-Free Bread Formulations. Eur. Food Res. Technol. 2010, 230, 437–445. [Google Scholar] [CrossRef]

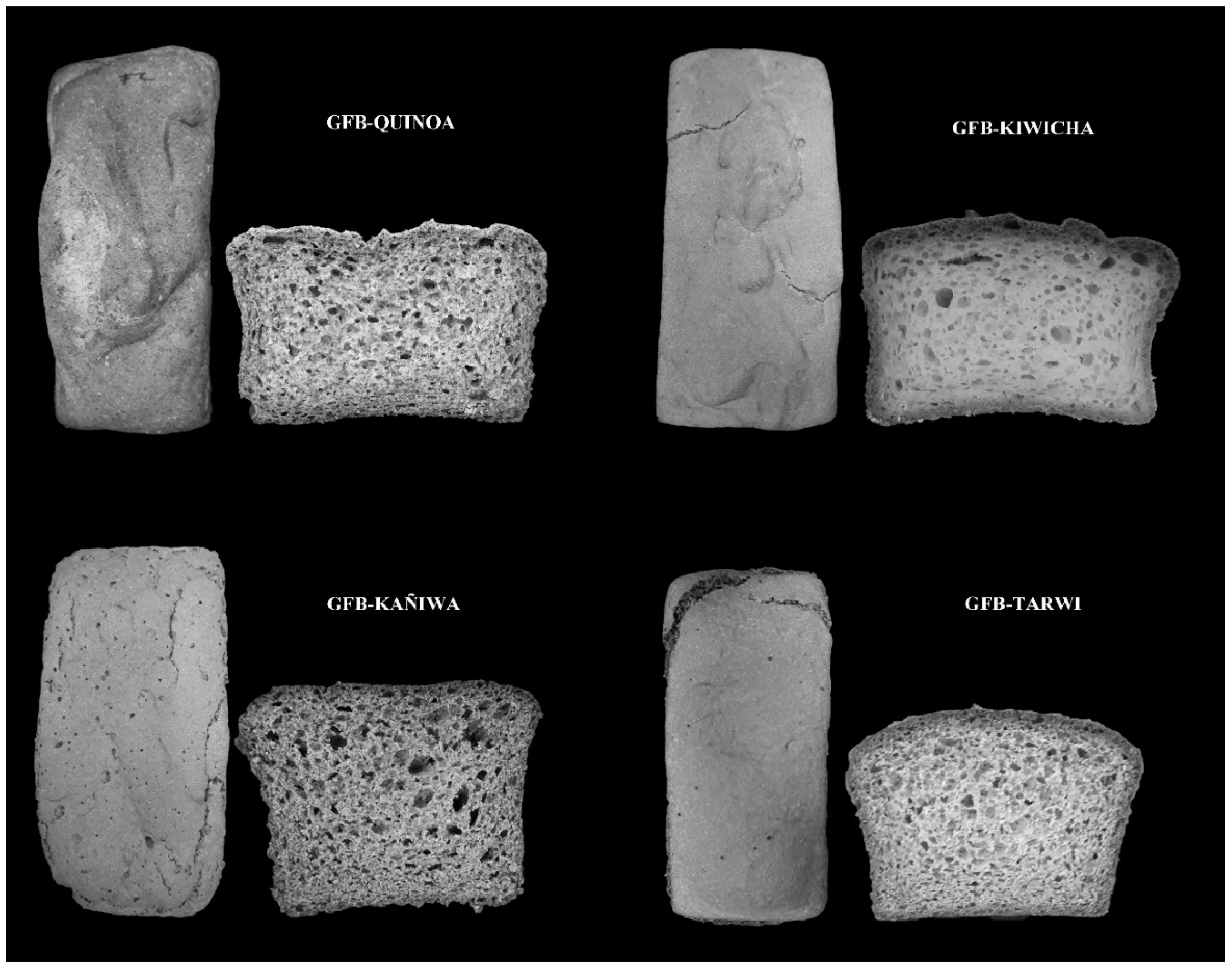

| Quality Parameters | GFB-Quinoa | GFB-Kiwicha | GFB-Kañiwa | GFB-Tarwi |

|---|---|---|---|---|

| Baking loss (%) | 26.9 ± 0.5 | 27.3 ± 0.8 | 28.2 ± 0.7 | 30.2 ± 0.8 |

| Specific volume (mL/g) | 2.3 ± 0.0 | 2.4 ± 0.1 | 2.73 ± 0.0 | 2.13 ± 0.00 |

| Crumb hardness (N) | 1.8 ± 0.3 | 3.6 ± 0.3 | 1.4 ± 0.2 | 2.3 ± 0.3 |

| Cohesiveness | 0.31 ± 0.0 | 0.21 ± 0.0 | 0.32 ± 0.00 | 0.39 ± 0.00 |

| Springiness | 0.8 ± 0.1 | 0.65 ± 0.00 | 0.87 ± 0.00 | 0.89 ± 0.00 |

| Gumminess (N) | 0.5 ± 0.1 | 0.8 ± 0.1 | 0.5 ± 0.1 | 0.9 ± 0.1 |

| Chewiness (N) | 0.45 ± 0.1 | 0.49 ± 0.0 | 0.38 ± 0.1 | 0.80 ± 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Repo-Carrasco-Valencia, R.; Vidaurre-Ruiz, J.; Luna-Mercado, G.I. Development of Gluten-Free Breads Using Andean Native Grains Quinoa, Kañiwa, Kiwicha and Tarwi. Proceedings 2020, 53, 15. https://doi.org/10.3390/proceedings2020053015

Repo-Carrasco-Valencia R, Vidaurre-Ruiz J, Luna-Mercado GI. Development of Gluten-Free Breads Using Andean Native Grains Quinoa, Kañiwa, Kiwicha and Tarwi. Proceedings. 2020; 53(1):15. https://doi.org/10.3390/proceedings2020053015

Chicago/Turabian StyleRepo-Carrasco-Valencia, Ritva, Julio Vidaurre-Ruiz, and Genny Isabel Luna-Mercado. 2020. "Development of Gluten-Free Breads Using Andean Native Grains Quinoa, Kañiwa, Kiwicha and Tarwi" Proceedings 53, no. 1: 15. https://doi.org/10.3390/proceedings2020053015

APA StyleRepo-Carrasco-Valencia, R., Vidaurre-Ruiz, J., & Luna-Mercado, G. I. (2020). Development of Gluten-Free Breads Using Andean Native Grains Quinoa, Kañiwa, Kiwicha and Tarwi. Proceedings, 53(1), 15. https://doi.org/10.3390/proceedings2020053015