Undervoltage Identification in Three Phase Induction Motor Using Low-Cost Piezoelectric Sensors and STFT Technique †

Abstract

:1. Introduction

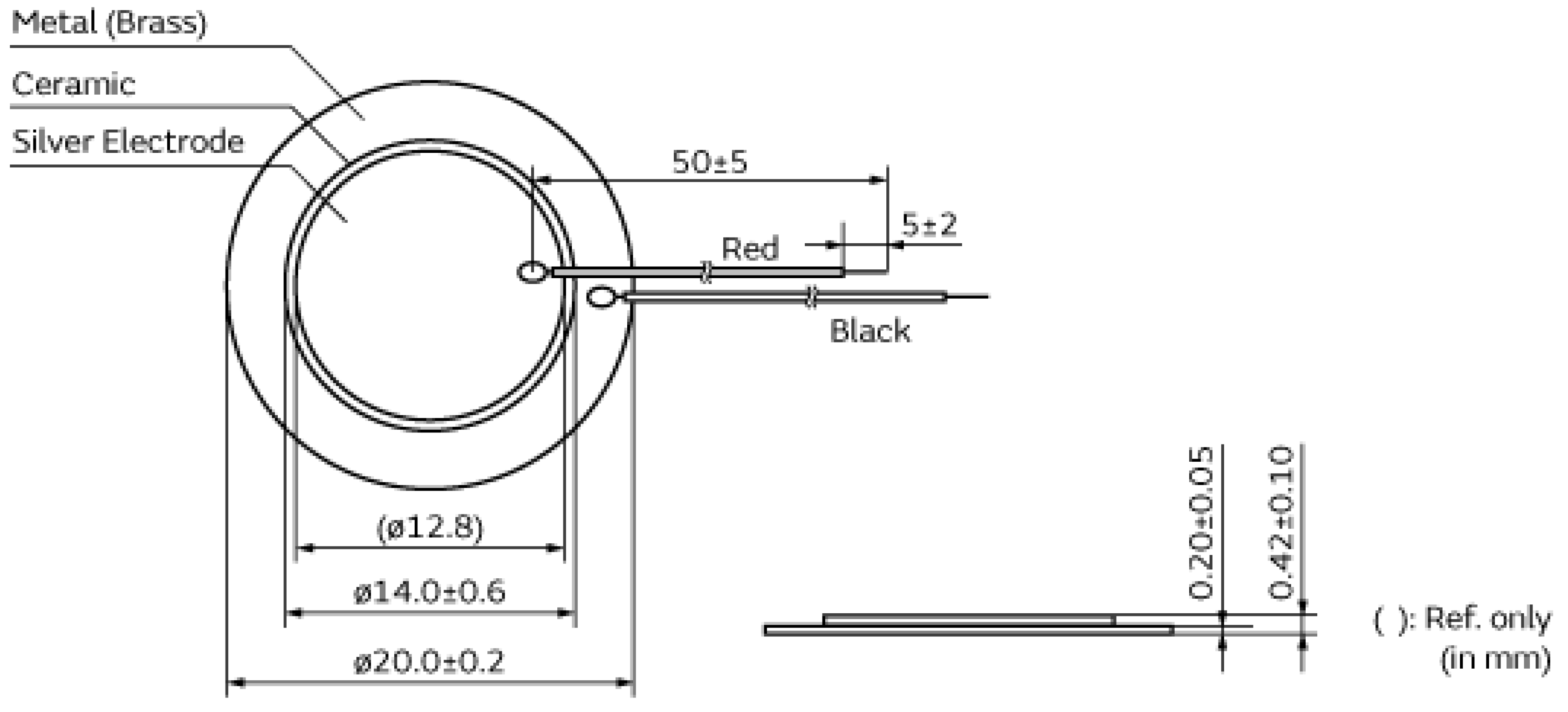

2. Piezoelectric Sensors

3. Short-Time Fourier Transform

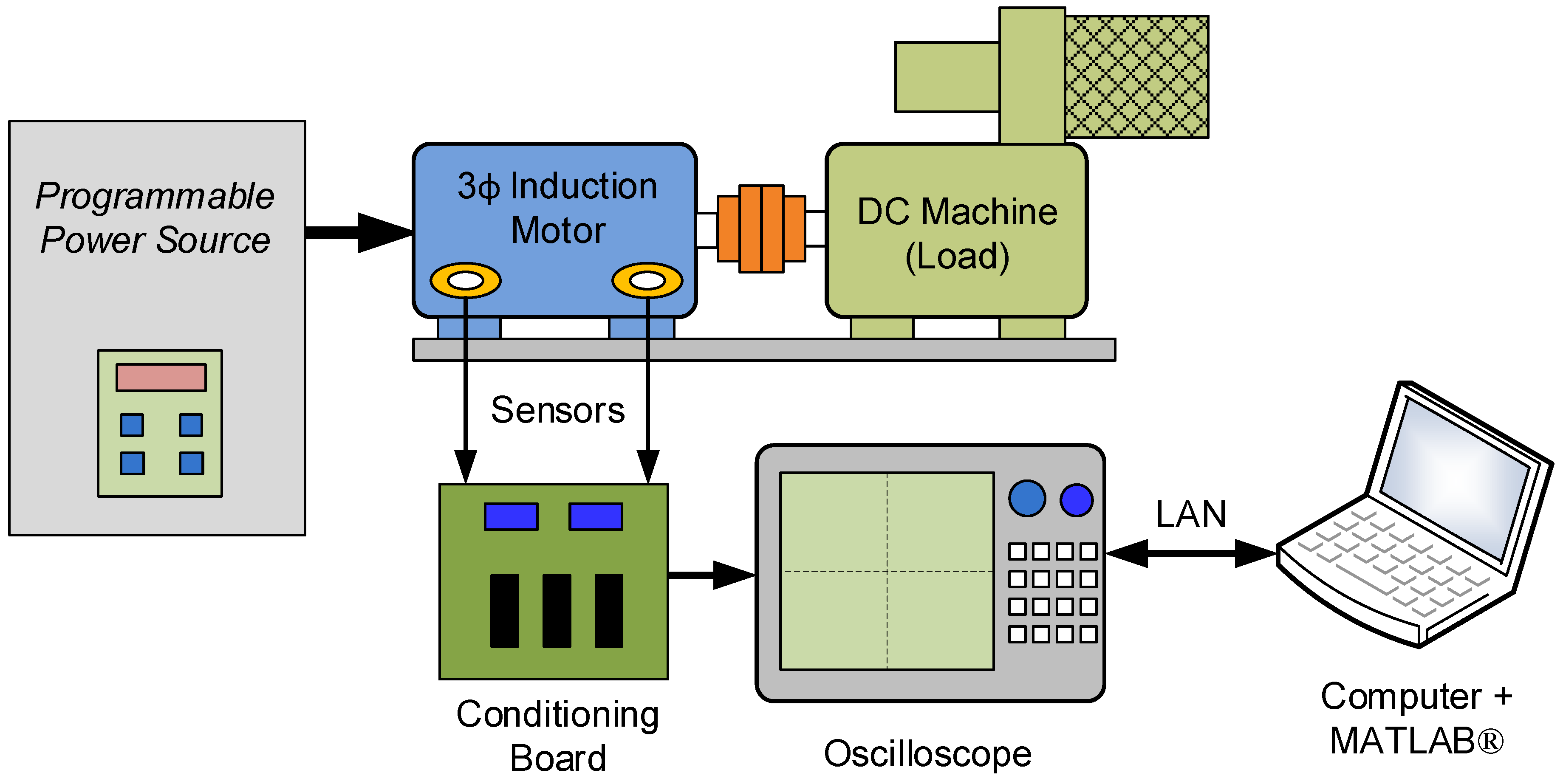

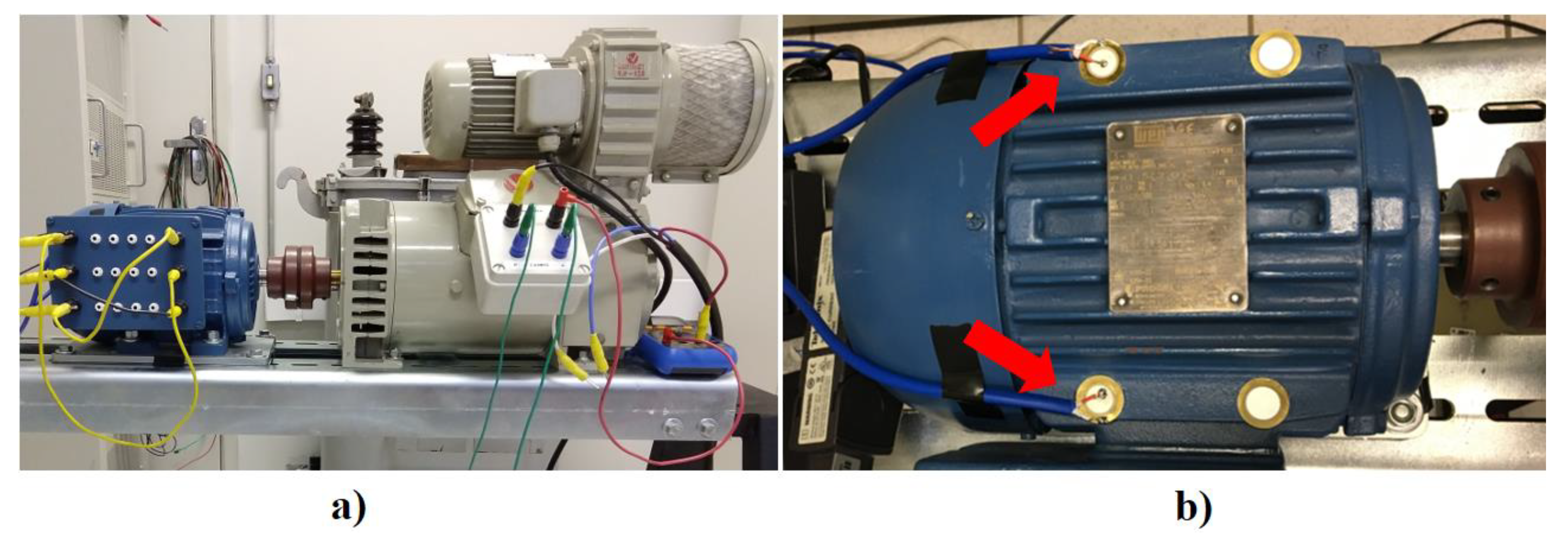

4. Materials and Methods

4.1. Machinery Setup

4.2. Sensor and Data Acquisition

5. Results

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Li, C.; Xu, D.; Wang, G. High efficiency remanufacturing of induction motors with interior permanent-magnet rotors and synchronous-reluctance rotors. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 7–10 August 2017; pp. 1–6. [Google Scholar]

- Campbell, M.; Arce, G. Effect of Motor Voltage Unbalance on Motor Vibration: Test and Evaluation. IEEE Trans. Ind. Appl. 2018, 54, 905–911. [Google Scholar] [CrossRef]

- Guerra de Araujo Cruz, A.; Delgado Gomes, R.; Antonio Belo, F.; Cavalcante Lima Filho, A. A Hybrid System Based on Fuzzy Logic to Failure Diagnosis in Induction Motors. IEEE Lat. Am. Trans. 2017, 15, 1480–1489. [Google Scholar] [CrossRef]

- Yu, Y.; Zhao, Y.; Wang, B.; Huang, X.; Xu, D. Current Sensor Fault Diagnosis and Tolerant Control for VSI-Based Induction Motor Drives. IEEE Trans. Power Electron. 2018, 33, 4238–4248. [Google Scholar] [CrossRef]

- Naha, A.; Thammayyabbabu, K.R.; Samanta, A.K.; Routray, A.; Deb, A.K. Mobile Application to Detect Induction Motor Faults. IEEE Embed. Syst. Lett. 2017, 9, 117–120. [Google Scholar] [CrossRef]

- Abd-el-Malek, M.; Abdelsalam, A.K.; Hassan, O.E. Induction motor broken rotor bar fault location detection through envelope analysis of start-up current using Hilbert transform. Mech. Syst. Sig. Process. 2017, 93, 332–350. [Google Scholar] [CrossRef]

- Jiang, C.; Li, S.; Habetler, T.G. A review of condition monitoring of induction motors based on stray flux. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 5424–5430. [Google Scholar]

- Moheimani, S.O.R.; Fleming, A.J. Piezoelectric Transducers for Vibration Control and Damping; Advances in Industrial Control; Springer: London, UK, 2006; ISBN 978-1-84628-331-4. [Google Scholar]

- Lucas, G.B.; de Castro, B.A.; Rocha, M.A.; Andreoli, A.L. Study of a Low-Cost Piezoelectric Sensor for Three Phase Induction Motor Load Estimation. Proceedings 2019, 4, 46. [Google Scholar]

- Barusu, M.R.; Sethurajan, U.; Deivasigamani, M. Non-invasive method for rotor bar fault diagnosis in three-phase squirrel cage induction motor with advanced signal processing technique. J. Eng. 2019, 2019, 4415–4419. [Google Scholar] [CrossRef]

- MURATA—Piezoelectric Sound Components Catalog. Available online: https://www.murata.com/en-us/products/productdata/8796782788638/E84G0211.gif?1473046207000 (accessed on 14 October 2019).

- Benkedjouh, T.; Zerhouni, N.; Rechak, S. Deep Learning for Fault Diagnosis based on short-time Fourier transform. In Proceedings of the 2018 International Conference on Smart Communications in Network Technologies (SaCoNeT), El Oued, Algeria, 27–31 October 2018; pp. 288–293. [Google Scholar]

- Ojeda-Aguirre, N.A.; Martinez, D.C.; Garcia-Perez, A.; Troncoso, R.J.R.; Valtierra-Rodriguez, M.; Amezquita-Sanchez, J.P. Reassignment technique for detection of broken rotor bar fault in induction motors. In Proceedings of the 2017 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Mexico, 8–10 November 2017; pp. 1–6. [Google Scholar]

- Bossio, G.R.; De Angelo, C.H.; Donolo, P.D.; Castellino, A.M.; Garcia, G.O. Effects of voltage unbalance on IM power, torque and vibrations. In Proceedings of the 2009 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cargaese, France, 31 August–3 September 2009; pp. 1–6. [Google Scholar]

| VF/VN 1 [%] | VAN RMS Voltage [V] | VAB RMS Voltage [V] | VBC RMS Voltage [V] | VCA RMS Voltage [V] |

|---|---|---|---|---|

| 0 | 0 | 127 | 220 | 127 |

| 20 | 25,4 | 141.4 | 220 | 141.4 |

| 40 | 50.8 | 158.6 | 220 | 158.6 |

| 60 | 76.2 | 177.8 | 220 | 177.8 |

| 80 | 101.6 | 198.4 | 220 | 198.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carvalho, L.; Lucas, G.; Rocha, M.; Fraga, C.; Andreoli, A. Undervoltage Identification in Three Phase Induction Motor Using Low-Cost Piezoelectric Sensors and STFT Technique. Proceedings 2020, 42, 72. https://doi.org/10.3390/ecsa-6-06644

Carvalho L, Lucas G, Rocha M, Fraga C, Andreoli A. Undervoltage Identification in Three Phase Induction Motor Using Low-Cost Piezoelectric Sensors and STFT Technique. Proceedings. 2020; 42(1):72. https://doi.org/10.3390/ecsa-6-06644

Chicago/Turabian StyleCarvalho, Leonardo, Guilherme Lucas, Marco Rocha, Claudio Fraga, and Andre Andreoli. 2020. "Undervoltage Identification in Three Phase Induction Motor Using Low-Cost Piezoelectric Sensors and STFT Technique" Proceedings 42, no. 1: 72. https://doi.org/10.3390/ecsa-6-06644

APA StyleCarvalho, L., Lucas, G., Rocha, M., Fraga, C., & Andreoli, A. (2020). Undervoltage Identification in Three Phase Induction Motor Using Low-Cost Piezoelectric Sensors and STFT Technique. Proceedings, 42(1), 72. https://doi.org/10.3390/ecsa-6-06644