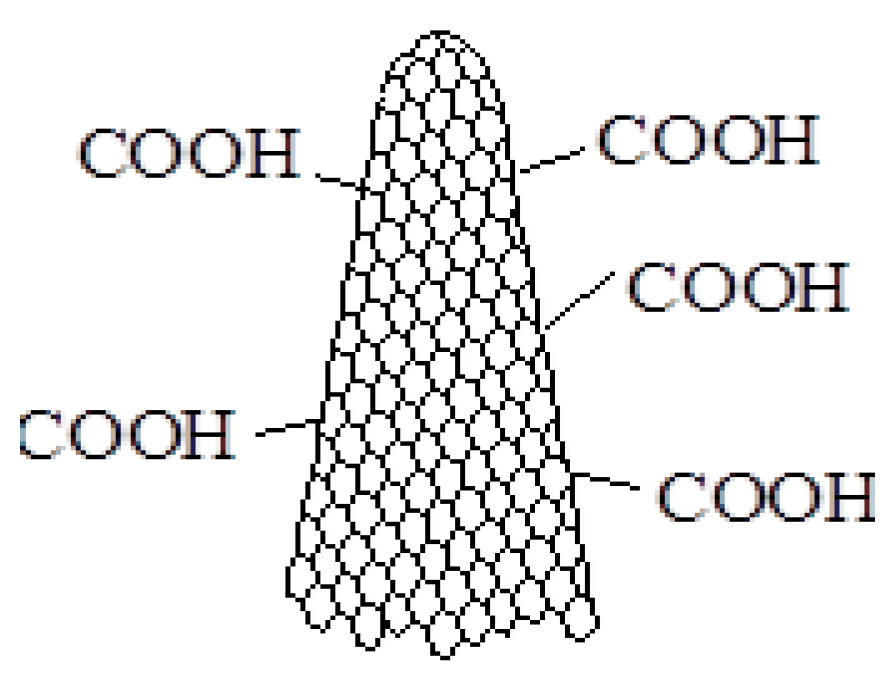

Ternary Carbon-Based Nanocomposite as Sensing Layer for Resistive Humidity Sensor †

Acknowledgments

References

- Serban, B.; Cobianu, C.; Brezeanu, M.; Buiu, O.; Bostan, C.; Stratulat, A. Relative Humidity Sensor and Method. European Granted Patent EP3078964B1, 24 May 2017. [Google Scholar]

- Serban, B.; Brezeanu, M.; Buiu, O.; Cobianu, C. Relative Humidity Sensor and Method. European Granted Panted EP3211408B1, 10 April 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Șerban, B.C.; Buiu, O.; Cobianu, C.; Avramescu, V.; Dumbrăvescu, N.; Brezeanu, M.; Bumbac, M.; Nicolescu, C.M.; Marinescu, R. Ternary Carbon-Based Nanocomposite as Sensing Layer for Resistive Humidity Sensor. Proceedings 2019, 29, 114. https://doi.org/10.3390/proceedings2019029114

Șerban BC, Buiu O, Cobianu C, Avramescu V, Dumbrăvescu N, Brezeanu M, Bumbac M, Nicolescu CM, Marinescu R. Ternary Carbon-Based Nanocomposite as Sensing Layer for Resistive Humidity Sensor. Proceedings. 2019; 29(1):114. https://doi.org/10.3390/proceedings2019029114

Chicago/Turabian StyleȘerban, Bogdan Cătălin, Octavian Buiu, Cornel Cobianu, Viorel Avramescu, Nicolae Dumbrăvescu, Mihai Brezeanu, Marius Bumbac, Cristina Mihaela Nicolescu, and Roxana Marinescu. 2019. "Ternary Carbon-Based Nanocomposite as Sensing Layer for Resistive Humidity Sensor" Proceedings 29, no. 1: 114. https://doi.org/10.3390/proceedings2019029114

APA StyleȘerban, B. C., Buiu, O., Cobianu, C., Avramescu, V., Dumbrăvescu, N., Brezeanu, M., Bumbac, M., Nicolescu, C. M., & Marinescu, R. (2019). Ternary Carbon-Based Nanocomposite as Sensing Layer for Resistive Humidity Sensor. Proceedings, 29(1), 114. https://doi.org/10.3390/proceedings2019029114