Abstract

Emissivity is a key parameter if one intends to use quantitative thermography. The importance of temperature, surface characteristics, wavelength and the direction of the emitted radiation in the emissivity is well documented in the literature. However, no research was found concerning the effect of moisture content. In this research, an experimental campaign was carried out with two main objectives: compare the emissivity value measured with an emissometer with the value measured with infrared thermography; assess the importance of moisture content in the emissivity value measured with an emissometer. A ceramic brick was used as an example case.

1. Introduction

The non-destructive nature of infrared thermography contributes to its widespread use in building monitoring. The most common example is in inspections regarding buildings energy efficiency, namely to detect thermal bridges [1,2] and leakage points [3,4]. Typically, in these inspections, only a qualitative assessment is carried out. However, if one intends to perform a quantitative analysis, the correct measurement of the surface temperature requires the knowledge of its emissivity.

Emissivity (ε) quantifies the capacity of a material to emit energy and can be defined as the ratio of the radiation emitted by the surface at a given temperature to the radiation emitted by a blackbody at the same temperature. The emissivity values range between 0 (perfect reflector − mirror) and 1 (perfect emitter − black body) [5]. The emissivity of a real surface is not a constant as it varies with the temperature of the surface and its characteristics (roughness) as well as the wavelength and the direction of the emitted radiation. Most common building materials, with the exception of metals, have emissivity values over 0.8.

It is possible to measure the emissivity of a material by means of infrared thermography. The ASTM standard E1933 - 14 [6] provides guidelines to measure the emissivity of materials using infrared imaging systems. Another possibility is to use the emissometer in accordance with the standard ASTM C1371 - 04a [7]. Barreira et al. [8] carried out an experiment to measure the emissivity of ten different materials using the two methods. Moreover, several databases can be found in the literature providing emissivity values for different materials in accordance with the surface characteristics, temperature and wavelength of the measurement. However, the effect of moisture content is never taken into account. In this paper, the importance of moisture content for materials emissivity is discussed, using the results of a ceramic brick as an example case.

2. Methodology

2.1. Procedure

The experiment included two steps: i) the measurement of the emissivity of the 10 specimens (all the measurements were carried out in dry specimens) using the emissometer and using infrared thermography, considering three different camera positions (45°, 90° and 135°) and the black tape method as described in ASTM E1933-14 [6]; and ii) the specimens were immersed in water until constant mass was reached and afterward the emissometer is used to measure the emissivity during the drying process. In the two phases, all the measurements were repeated three times. The specimens under study were placed inside a cardboard box, before each thermal image was taken, to reduce the influence of reflections. No relevant variations on air temperature, relative humidity and velocity occurred in the laboratory during the tests.

2.2. Materials and Equipment

The experiment was carried out in 10 ceramic bricks. The properties of the material are presented in Table 1. In the literature, the emissivity of this material ranges between 0.88 and 0.93.

Table 1.

Properties of the ceramic brick.

The infrared camera was the NEC TH9100 MR (accuracy of ±2 °C or 2% and resolution of 0.06 at 30 °C). According to the manufacturer, the accuracy of the emissometer is ±0.02.

3. Results

3.1. Step i): Infrared Thermography Versus Emissometer

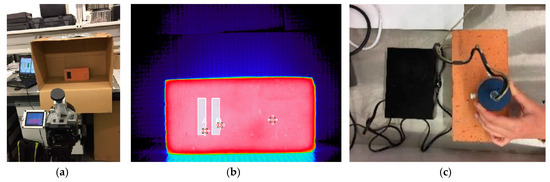

Figure 1 shows the experimental set-up for the measurement with infrared thermography, the thermal image of the ceramic brick, including black tape used as reference (ε = 0.90) and the measurement with the emissometer.

Figure 1.

(a) Experimental set-up; (b) Thermal image of the ceramic brick;(c) measurement with the emissometer.

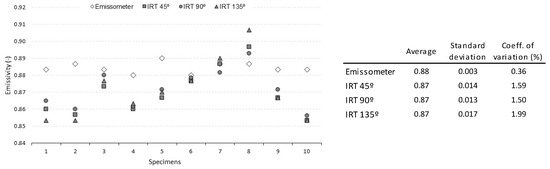

The results of the emissivity measured with the two methods are depicted in Figure 2, were for each specimen and method the result is the average of three measurements. The two methods returned a very similar average emissivity: 0.88 and 0.87, for the emissometer and for the infrared thermography, respectively. These values are in line with the lower limit of the range found in the literature. However, a larger variability can be observed when using infrared thermography. The effect of the camera position was not important, which was already expected, as angles below 60 ° do not influence the measurement in non-metallic materials [9].

Figure 2.

Emissometer versus infrared thermography (for each specimen and method the result is the average of three measurements).

3.2. Step ii): Emissivity Versus Moisture

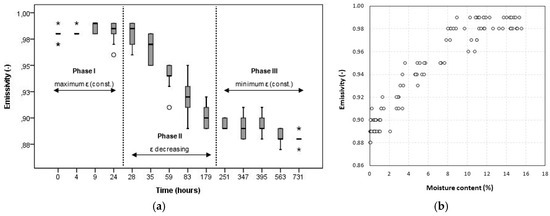

Figure 3 highlights the effect of moisture in the emissivity measurement, considering the average of three measurements for each one of the ten specimens under study. In Figure 3a it is possible to identify three phases during the drying process: in phase I (around 24 h) the emissivity is maximum and almost constant; in phase II the emissivity decreases and the variability is higher (between 24 and 180 h); and in phase III (after 180 h) the emissivity is minimum and approximately constant. The average emissivity ranged between 0.99 in phase I (wet specimen) and 0.88 in the end of the experiment (dry specimen).

Figure 3.

(a) Emissivity versus time; (b) Emissivity versus moisture content. (In both Figures, the average of three measurements for each one of the ten specimens under study was considered).

Figure 3b shows the relation between moisture content (ratio between the amount of water and the dry weight) and emissivity. The result confirms that emissivity is affected by moisture. Emissivity rapidly increases with moisture content and the effect is visible even for low values of moisture content (higher than 2%).

4. Conclusions

The main conclusions of this research were:

- The average emissivity measured by the emissometer and infrared thermography were similar (0.88 and 0.87, respectively) and in line with the values found in the literature;

- The emissometer returned more stable measurements while infrared thermography presented larger variability;

- Moisture affected the emissivity values, even for low values of moisture content;

- The average emissivity varied between 0.99 (wet specimen) and 0.88 (dry specimen). Three phases were identified during the drying process.

Author Contributions

All authors have contributed equally in the development of the work reported.

Acknowledgments

This work was financially supported by: UID/ECI/04708/2019-CONSTRUCT—Instituto de I&D em Estruturas e Construções funded by national funds through the FCT/MCTES (PIDDAC).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Balaras, C.A.; Argiriou, A.A. Infrared thermography for building diagnostics. Energy Build. 2002, 34, 171–183. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldinelli, G.; Bianchi, F. A quantitative methodology to evaluate thermal bridges in buildings. Appl. Energy 2012, 97, 365–373. [Google Scholar] [CrossRef]

- Ocaña, S.; Guerrero, I.; Requena, I. Thermographic survey of two rural buildings in Spain. Energy Build. 2004, 36, 515–523. [Google Scholar] [CrossRef]

- Lerma, C.; Barreira, E.; Almeida, R.M.S.F. A discussion concerning active infrared thermography in the evaluation of buildings air infiltration. Energy Build. 2018, 168, 56–66. [Google Scholar] [CrossRef]

- Avdelidis, N.P.; Moropoulou, A. Emissivity considerations in building thermography. Energy Build. 2003, 35, 663–667. [Google Scholar] [CrossRef]

- ASTM E1933-14; Standard Test Methods for Measuring and Compensating for Emissivity Using Infrared Imaging Radiometers. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C1371-04a; Standard Test Method for Determination of Emittance of Materials Near Room Temperature Using Portable Emissometers. ASTM International: West Conshohocken, PA, USA, 2004.

- Barreira, E.; Bauer, E.; Mustelier, N.; Freitas, V.P. Measurement of materials emissivity—Influence of the procedure. In Proceedings of the Advanced Infrared Technology and Applications (AITA 2015), Pisa, Italy, 29 September–2 October 2015. [Google Scholar]

- Hart, J.M. A Practical Guide to Infrared Thermography for Building Surveys; BRE: Watford, UK, 1991. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).