Abstract

Moisture is one of the major causes of building decay, compromising the indoor air quality and the durability of building components. Infrared thermography is a non-destructive technique that can be used to prevent damage caused by the presence of water. In this study, the potential of Principal Component Analysis (PCA) was assessed as a quantitative technique for processing the thermal images captured during 24 hours of water absorption by a lightweight concrete specimen. PCA showed that the first principal component is the one that better explains the phenomenon. The initial instant was the most interesting to identify the water level in the sample and the final instant allowed defining the first 8h as the most relevant.

1. Introduction

Moisture is one of the major causes of building decay, compromising not only indoor air quality but also the durability of building components. Infrared thermography (IRT) is a non-destructive technique that allows the inspection of buildings and can be used to prevent damage caused by the presence of water.

Changes in moisture content can be detected by IRT because they cause variations on surface temperature, due to three physical phenomena: evaporative cooling at the moist area, reduced thermal resistance and increased heat storage capacity of the moist material.

The authors that applied IRT to detect moisture in building components used mostly a qualitative approach [1,2,3,4,5,6,7,8]. Only a few were able to establish a criterion for a quantitative assessment of the problem [9,10,11,12,13].

The quantitative analysis of the results of IRT can be carried out using different techniques, as Principal Component Analysis (PCA). Several authors [9,11,12,14,15,16] have used this method, mostly to reduce the data set and to highlight defects in building materials and components. Other advantage of this method is to minimize the influence of external parameters as emissivity variation and environmental reflections. Despite the potential of using PCA to analyze quantitatively the results of IRT, it is still not sufficiently widespread and, therefore, additional research is required.

In this study, the potential of PCA was assessed as a quantitative technique for processing the thermal images captured during 24 hours of water partial absorption by the top of a lightweight concrete specimen. The temporal approach was used, as the data in each instant was subtracted, separately, by: (a) the data of the initial instant and (b) the data of the final instant.

2. Materials and Methods

2.1. Test Procedures

In this experimental campaign a lightweight concrete specimen was used. Table 1 shows the main characteristics of the material under study. The specimen was partially humidified by the top surface, inside a climatic chamber (20 ± 0.5 °C and 60 ± 2%). Before the water absorption began, the specimen was dried in an oven at 110 ± 5 °C, until mass stabilization was reached, and then was cooled during 24 hours in a desiccator to 20 ±.5 °C. The water absorption was guarantee by maintaining a water level of 5 ± 2 mm at the top of the specimen during 24 hours, by using a silicone sealant of about 10 mm thickness near the specimen edges. The amount of water absorbed was 58 g.

Table 1.

Main characteristics of the lightweight concrete under study (measured).

Thermal images were taken every 5 min during the first 8 hours and every 10 min during the remaining 16 hours, in a total of 24 hours of humidification process. A passive approach was used and the infrared (IR) camera remained in the same position during the entire test. The climatic chamber was lined with black cardboard and the IR camera was programmed to capture the images automatically, to avoid reflections. All compensations imposed by the IR camera were carried out before the beginning of the test. The specifications of the IR camera are displayed in Table 2.

Table 2.

Main specifications of the IR camera.

2.2. Imaging Processing—Principal Component Analysis (PCA)

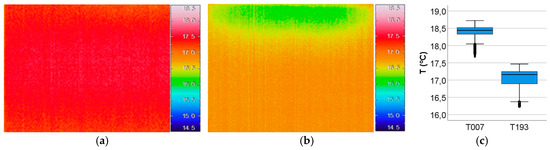

The PCA was used to reduce the data set and define the representative image of the absorption phenomenon. The data was analysed for the entire humidification period (24 hours) and for three periods with 8 hours each. The temporal approach was adopted as each thermal image corresponded to an instant of the measurement. To avoid or to reduce the influence of any eventual noise in the measurements, which could mask the effect of humidification on the temperature patterns, each thermal image of the data set was subtracted by a reference thermal image captured at a key instant during the test. Two instants were selected as reference: initial instant (thermal image T007) and final instant (thermal image T193). Figure 1 shows the reference thermal images (T007 and T193) and the respective boxplots representations. Temperatures were higher on the initial thermal image than on the final one, as at the beginning of the test the specimen was completely dry and at the end the absorbed water induced the surface cooling due to evaporation.

Figure 1.

Reference thermal images: (a) At the initial instant (T007); (b) At the final instant (T193); (c) Boxplots representations.

3. Results and Discussion

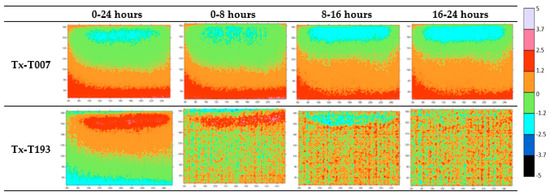

Figure 2 shows the temperature maps resulting from the application of PCA, considering the four periods of analysis (0-24 hours, 0-8 hours, 8-16 hours and 16-24 hours) and the two reference instants for image subtraction (T007 and T193). Only the first Principal Component (PC) is displayed, as it was the one that better explained the variance of the data set. Table 3 presents the number of PC and the respective percentage of explained variance for every tested scenarios.

Figure 2.

First Principal Component considering the four periods of analysis (0-24 hours, 0-8 hours, 8-16 hours and 16-24hours) and the two reference instants for image subtraction (T007 and T193).

Table 3.

Number of Principal Component (PC) and respective percentage of explained variance.

The results show that, when using the initial thermal image (T007) as reference and the entire absorption period is analysed, it is possible to identify on the temperatures map the area affected by the absorbed water as well as the different levels of humidification, related to different amount of evaporated water at the surface. If the analysis is based on the three 8-hours periods (0–8 hours, 8–16 hours and 16–24 hours), the maps allow visualizing the growth of the wet area over time, specially near the top of the specimen where the liquid water is in direct contact with the material.

using the final thermal image (T193) as reference, and if the entire absorption period is analysed, the results are very similar to the ones obtained when subtracting image T007. However, in this case, the temperature differences, at the wet area, are now positive, as the surface temperatures at the end of the humidification period are the lowest. For the three 8-hours periods under analyses, the temperature maps do not highlight the humidification in a very effective way, since its components explain the variance in smaller percentages. However, one can state that the first 8 hours of humidification are the most relevant as, in this period, the explained variance achieve values closer to the ones obtained for the entire period.

4. Conclusions

Principal Component Analysis (PCA) was used as a quantitative technique for processing the thermal images captured during 24 h of water absorption by a lightweight concrete specimen. PCA showed that the first principal component is the one that better explains the phenomenon. The initial instant was the most interesting to identify the water level in the sample and the final instant allowed defining the first 8 h as the most relevant.

Author Contributions

All authors have contributed equally in the development of the work reported.

Acknowledgments

This work was financially supported by UID/ECI/04708/2019- CONSTRUCT—Instituto de I&D em Estruturas e Construções funded by national funds through the FCT/MCTES (PIDDAC).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Balaras, C.; Argiriou, A. Infrared thermography for building diagnostics. Energy Build. 2002, 34, 171–183. [Google Scholar] [CrossRef]

- Avdelidis, N.; Moropoulou, A.; Theoulakis, P. Detection of water deposits and movement in porous materials by infrared imaging. Infrared Phys. Technol. 2003, 44, 183–190. [Google Scholar] [CrossRef]

- Menezes, A.; Gomes, M.G.; Flores-Colen, I. In-situ assessment of physical performance and degradation analysis of rendering walls. Constr. Build. Mater. 2015, 75, 283–292. [Google Scholar] [CrossRef]

- Edis, E.; Flores-Colen, I.; Brito, J. Passive thermographic detection of moisture problems in façades with adhered ceramic cladding. Constr. Build. Mater. 2014, 51, 187–197. [Google Scholar] [CrossRef]

- Barreira, E.; Almeida, R.M.S.F.; Ferreira, J.P.B. Assessing the humidification process of lightweight concrete specimens through infrared thermography. Energy Procedia 2017, 132, 213–218. [Google Scholar] [CrossRef]

- Camino, M.S.; León, F.J.; Llorente, A.; Olivar, J.M. Evaluation of the behaviour of brick tile masonry and mortar due to capillary rise of moisture. Mater de Construcción 2014, 64, 020. [Google Scholar]

- Lerma, C.; Mas, Á.; Gil, E.; Vercher, J.; Peñalver, M.J. Pathology of building materials in historic buildings. Relationship between laboratory testing and infrared thermography. Materiales de Construcción 2014, 64, 009. [Google Scholar] [CrossRef]

- Barreira, E.; Almeida, R.M.S.F.; Ferreira, J.P.B. Assessing the humidification process of lightweight concrete specimens through infrared thermography. Energy Procedia 2017, 132, 213–218. [Google Scholar] [CrossRef]

- Grinzato, E.; Cadelano, G.; Bison, P. Moisture map by IR thermography. J. Modern. Optics. 2010, 57, 1770–1778. [Google Scholar] [CrossRef]

- Bison, P.; Cadelano, G.; Grinzato, E. Thermographic signal reconstruction with periodic temperature variation applied to moisture classification. Quant Infrared Thermography J. 2011, 8, 221–238. [Google Scholar] [CrossRef]

- Lerma, J.; Cabrelles, M.; Portalés, C. Multitemporal thermal analysis to detect moisture on a building façade. Constr. Build. Mater. 2011, 25, 2190–2197. [Google Scholar] [CrossRef]

- Edis, E.; Flores-Colen, I.; Brito, J. Quasi-quantitative infrared thermographic detection of moisture variation in facades with adhered ceramic cladding using principal component analysis. Build. Environ. 2015, 94, 97–108. [Google Scholar] [CrossRef]

- Barreira, E.; Almeida, R.M.S.F.; Delgado, J.M.P.Q. Infrared thermography for assessing moisture related phenomena in building components. Constr. Build. Mater. 2016, 110, 251–269. [Google Scholar] [CrossRef]

- Rajic, N. Principal component thermography for flaw contrast enhancement and flaw depth characterisation in composite structures. Compos. Struct. 2002, 58, 521–528. [Google Scholar] [CrossRef]

- Griefahn, D.; Wollnack, J.; Hintze, W. Principal component analysis for fast and automated thermographic inspection of internal structures in sandwich parts. J. Sens. Sens. Syst. 2014, 3(1), 105–111. [Google Scholar]

- Marinetti, S.; Finesso, L.; Marsilio, E. Matrix factorization methods: Application to thermal NDT/E. NDT&E Int. 2006, 39, 611–616. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).