A Global Energy Management System to Support Sustainable Decision Making †

Abstract

:1. Introduction

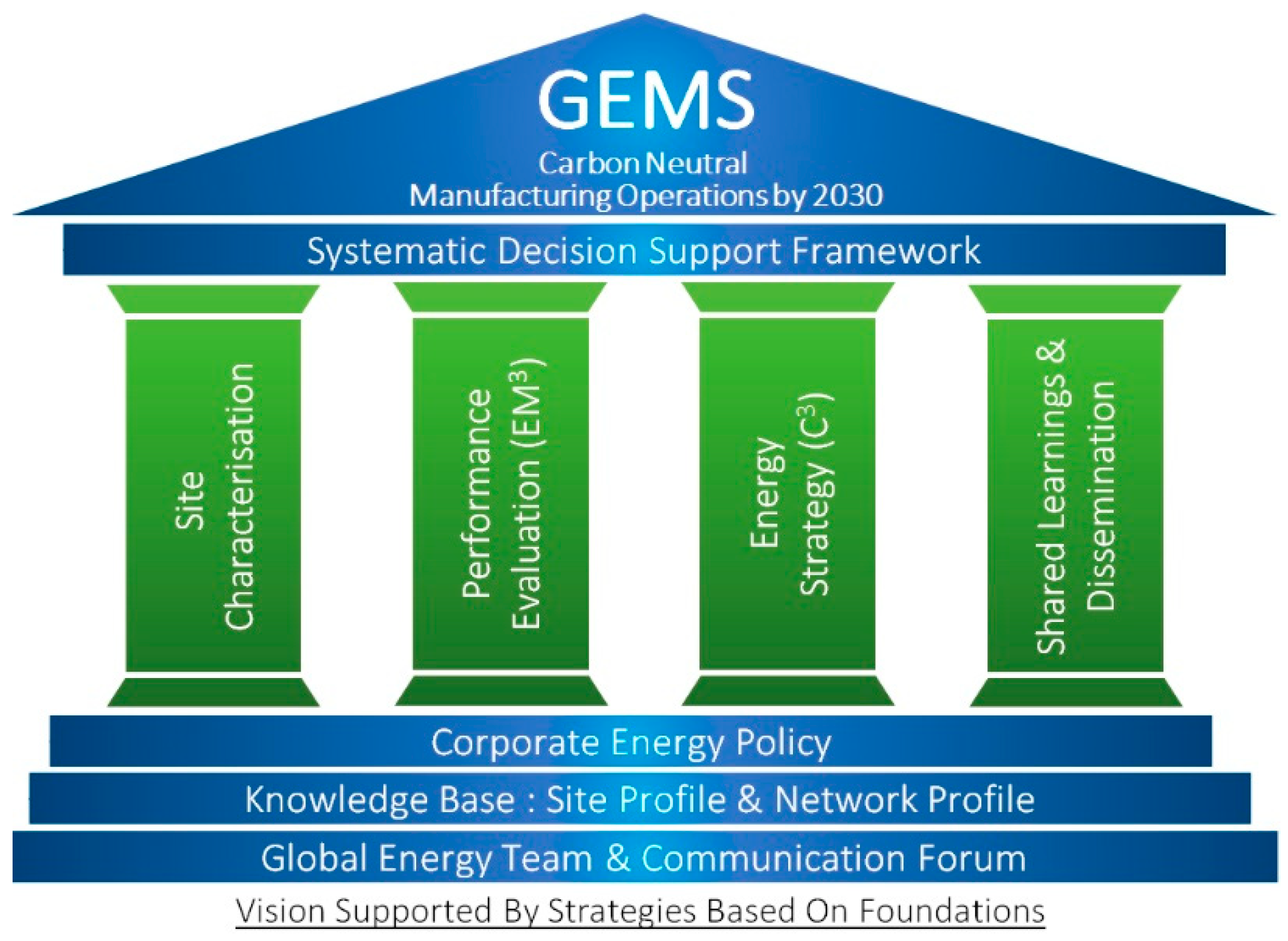

2. GEMS Concept and Approach

2.1. Pillars

2.1.1. Site Characterisation

2.1.2. Performance Evaluation:

2.1.3. Shared Learning and Dissemination

2.1.4. Energy Strategy

2.2. Foundations

2.2.1. Global Energy Team and Communication Forum

2.2.2. Knowledge Base at Site and Global Level

2.2.3. Corporate Energy Policy

3. Pilot Demonstration

4. Conclusions

5. Future Work

- Corporate level metering plan to support the KPI’s.

- A bespoke matrix of technology solutions that will be developed for the corporation appropriate to its geographical locations.

- Development of standardised templates for all sites to follow when requesting corporate funding for energy conservation projects.

- A strategy for rewards and recognition for both site and corporate-level personnel.

- Best in class techniques for internal and external communications.

- DSF automation and usability improvement.

- Further develop the ‘Policy’ foundation and the ‘Energy Strategy’ pillar methodologies.

- Development of ‘GEMS Implementation Guidebook for Industry’.

Acknowledgments

Conflicts of Interest

References

- Directorate-General for Climate Action (European Commission). Our Planet, Our Future—Fighting Climate Change Together; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- International Energy Agency (IEA). World Energy Outlook 2015; International Energy Agency (IEA): Paris, France, 2015. [Google Scholar]

- IPCC. Carbon Dioxide Capture and Storage; Metz, B., Davidson, O., de Coninck, H., Loos, M., Meyer, L., Eds.; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Fischedick, M.; Roy, J.; Abdel-Aziz, A.; Acquaye, A.; Allwood, J.M.; Ceron, J.-P.; Geng, Y.; Kheshgi, H.; Lanza, A.; Perczyk, D.; et al. Industry. In Climate Change 2014: Mitigation of Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Bunse, K.; Vodicka, M.; Schönsleben, P.; Brülhart, M.; Ernst, F.O. Integrating energy efficiency performance in production management—gap analysis between industrial needs and scientific literature. J. Clean. Prod. 2011, 19, 667–679. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2016 (Executive Summary); International Energy Agency (IEA): Paris, France, 2016; pp. 1–8. [Google Scholar]

- UNFCCC. Climate Change: Impacts, Vulnerabilities and Adaptation in Developing Countries; United Nations Framework Convention on Climate Change: Bonn, Germany, 2007. [Google Scholar]

- Costa-Campi, M.T.; García-Quevedo, J.; Segarra, A. Energy efficiency determinants: An empirical analysis of Spanish innovative firms. Energy Policy 2015, 83, 229–239. [Google Scholar] [CrossRef]

- ISO. Energy Management Systems—Requirements with Guidance for Use; ISO 50001:2011; International Organization for Standardization: Geneva, Switzerland, 2011; p. 16. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Angelo, L.; Finnerty, N.; Seri, F.; Piccinini, A.; Coffey, R.; Tighe, C.; Mealy, P.; Mellotte, M.; Keane, M. A Global Energy Management System to Support Sustainable Decision Making. Proceedings 2019, 20, 22. https://doi.org/10.3390/proceedings2019020022

D’Angelo L, Finnerty N, Seri F, Piccinini A, Coffey R, Tighe C, Mealy P, Mellotte M, Keane M. A Global Energy Management System to Support Sustainable Decision Making. Proceedings. 2019; 20(1):22. https://doi.org/10.3390/proceedings2019020022

Chicago/Turabian StyleD’Angelo, Letizia, Noel Finnerty, Federico Seri, Alessandro Piccinini, Ronan Coffey, Carlos Tighe, PJ Mealy, Marc Mellotte, and Marcus Keane. 2019. "A Global Energy Management System to Support Sustainable Decision Making" Proceedings 20, no. 1: 22. https://doi.org/10.3390/proceedings2019020022

APA StyleD’Angelo, L., Finnerty, N., Seri, F., Piccinini, A., Coffey, R., Tighe, C., Mealy, P., Mellotte, M., & Keane, M. (2019). A Global Energy Management System to Support Sustainable Decision Making. Proceedings, 20(1), 22. https://doi.org/10.3390/proceedings2019020022