Abstract

The stress wave attenuation and energy absorption in the coral sand were respectively investigated. A series of experiments were carried out by using a new methodology with an improved split Hopkinson pressure bar (SHPB). Four types of coral sand, i.e., particle sizes of 1.18–0.60 mm, 0.60–0.30 mm, 0.30–0.15 mm, and 0.15–0.075 mm, were carefully sieved and tested. Significant effects of coral sand on stress wave attenuation and energy absorption were observed. Correlation between stress wave attenuation and energy absorption of coral sand was validated. Conclusions on particle size effect of stress wave attenuation and energy absorption, which support each other, were drawn. There existed a common critical stress zone for coral sand with different particle sizes. When the stress below this zone, sand with small particle sizes attenuates stress wave better and absorb energy more; when the stress beyond this zone, sand with larger particle sizes behave better on stress wave attenuation and energy absorption.

1. Introduction

Sand is a commonly used material in engineering construction, which attributes to its easy availability and cheapness. In addition, the remarkable ability on stress wave attenuation and energy absorption make the sand appropriate apply to blast mitigation and vibration isolation. Coral sand is widely distributed in the marine environment between 30 degrees north latitude and 30 degrees south latitude. Different composition and granular structure from the terrigenous sand (such as silica sand) make the coral sand behaves better on stress wave attenuation [1].

Mechanisms of propagation and energy absorption of the stress wave in sand is primary determined by its physical and mechanical properties. Some published literatures [2,3] demonstrated that the particle size exhibited significant influence on the physical and mechanical properties of sand, such as density, porosity, elastic modulus, yield stress, and compressibility. Therefore, a study on the effect of particle size of coral sand on stress wave attenuation and energy absorption is meaningful for design and construction of marine engineering.

To study the effect of particle size of coral sand under impact loads, experiments for coral sand on stress wave attenuation and energy absorption were respectively performed. The experimental results were analyzed and compared, identical conclusions on effect of particle size were drawn.

2. Materials and Methodology

2.1. Coral Sand

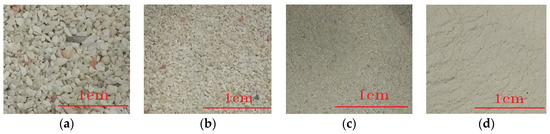

The as-received coral sand is wet with strong fishy smell. The sand was firstly dried in the drying oven at 105 °C for 24 h, and then sorted by the standard sieves and a vibrating screen machine [4]. Four types of dry coral sand with particle sizes of 1.18–0.60 mm, 0.60–0.30 mm, 0.30–0.15 mm, and 0.15–0.075 mm, as shown in Figure 1, were tested under impact through SHPB. The coral particles own angular appearance which contains numerous micro-holes and cavities. The specific gravities (Gs) and the maximum & minimum densities of four types of coral sand are tabulated in Table 1. Good agreements on Gs with previous studies, 2.88 of Lade et al. [5] and 2.82 of Lv et al. [6], show the credibility of the experimental data. In the following impact tests, all the specimens of four types of coral sand are assembled by the same relative density of 0.5.

Figure 1.

Coral sand with different particle sizes: (a) 1.18–0.60 mm (b) 0.60–0.30 mm; (c) 0.30–0.15 mm; (d) 0.15–0.075 mm.

Table 1.

Initial physical parameters of coral sand.

2.2. Improved SHPB for Stress Wave Attenuation

The improved SHPB for stress wave attenuation was consisted of a 0.8 m striker, a 5 m incident bar and a 4 m transmission bar with a common diameter of 75 mm. The low-mechanical-impedance technique, i.e., hollow-aluminum bars, was used to raise the accuracy of the results. The inner diameter and outer diameter of the bars were 50 mm and 75 mm, respectively. The rubber pulse-shapers were used to filter out the high-frequency pulse and elongate the rise time of the stress wave. The impact velocity of the striker was ~10 m/s, which correspondingly generated stress wave with amplitude of ~5 MPa at the front end of the specimen.

The confined “long” specimens, which are long enough to prevent internal axial reflection of the stress wave during the experiment duration, with length of 75 mm, 150 mm, 225 mm, and 300 mm were designed for the test. All the lengths are tested three times for cross calibration. The specimen was assembled by a length adjustable sleeve and two thin platens. The tubular sleeve is made of stainless steel with inner diameter of 75 mm and outer diameter of 95 mm. The cylindrical platens are made of high-strength aluminum with diameter of 75 mm and height of 10 mm.

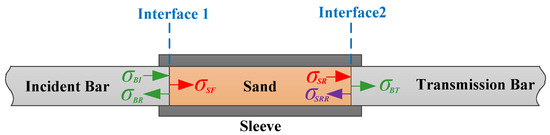

The stress waves transmit between the specimen and the bars is shown in Figure 2. The peak stress of the stress wave at the front end of the specimen, , is calculated by

where and are the peak stress of the incident wave and the peak stress of the reflected wave, respectively.

Figure 2.

The stress waves transmit between the specimen and the bars.

The peak stress of the stress wave at the rear end of the specimen, , is calculated from [7]

where is the peak stress of the transmitted stress wave, equals to at the interface 2; is the transmission coefficient of interface 2 which is obtained by the reflected coefficient of interface 1, , through relation [8]

is fitted by experimental data of and by

where is equal to at interface 1, as express by Equation (1).

Therefore, a non-dimensional peak stress of stress wave, D, for certain length of the specimen can be calculated

2.3. SHPB for Energy Absorption

The SHPB for energy absorption contains a 0.8 m striker, a 6 m incident bar and a 3.5 m transmission bar with a common diameter of 20 mm. The material of the bars is high-strength aluminum. The rubber pulse-shapers were used to filter out the high-frequency pulse and elongate the rise time of the incident pulses for stress equilibrium of the specimen. The impact velocity of the striker was ~10 m/s, which corresponds to a peak stress of ~15 MPa in the specimen.

The diameter and thickness of the confined specimen are 20 mm and 10 mm. The specimen was assembled by a sleeve and two thin platens, which are made of stainless steel. The tubular sleeve has an inner diameter of 20 mm and an outer diameter of 26 mm. The cylindrical platen have a diameter of 75 mm and a height of 10 mm.

The experimental data is processed through two-wave method, the stress equilibrium of the specimen is firstly verified by

where , and are incident wave, transmitted wave, and reflected wave, respectively.

Then the stress, strain rate, strain histories of the specimen can be calculated from Equations (7)–(9) [9]

where and are Young’s modulus and elastic wave velocity of the bar material, respectively; is length of the specimen.

The absorbed energy by the granular material per unit volume can be obtained from the integration of the stress-strain curves through Equation (10)

3. Results and Discussion

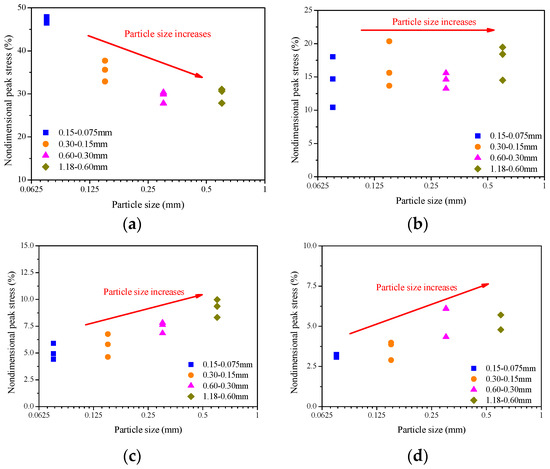

The non-dimensional peak stress of four types of coral sand at different distances are shown in Figure 3, every symbol represents an available individual experimental data. The stress wave is attenuated significantly in the coral sand, which agrees well with the previous investigation [1]. At the distance of 75 mm, coral sand of 1.18–0.60 mm, 0.60–0.30 mm, 0.30–0.15 mm, and 0.15–0.075 mm, attenuate stress wave to ~30%, ~30%, ~35%, and, ~46%, respectively. It indicates specimen with larger particles attenuate stress wave faster within this distance. At the distance of 150 mm, coral sand of four particle sizes share a similar D of ~15%, which indicates D of specimens with smaller particles catch up with D of specimens with larger particles after propagating through this distance. At the distance of 225 mm, D of specimens with smaller particles surpass D of specimens with larger particles. Coral sand of 1.18–0.60 mm, 0.60–0.30 mm, 0.30–0.15 mm, and 0.15–0.075 mm, attenuate the stress wave to ~8%, ~7%, ~6%, ~5%, respectively. Similarly, at distance of 300mm, specimens with smaller particles attenuate stress wave better. Coral sand of 1.18–0.60 mm, 0.60–0.30 mm, 0.30–0.15 mm, and 0.15–0.075 mm, attenuate the stress wave to ~5%, ~4%, ~3%, ~2.8%, respectively.

Figure 3.

Peak stress attenuation of coral sand with different particle sizes at different distances. (a) 75 mm; (b) 150 mm; (c) 225 mm; (d) 300 mm.

The aforementioned phenomenon should be derived from the intrinsic mechanical properties of four types of coral sand. It is reasonable to assume that a critical stress (a point or a range of zone) should be obtained when stress wave propagates within the distance of 75–150 mm. Attenuation mechanisms of coral sand with different particle sizes reverse at the critical stress. At distance of 75 mm, the maximum of four sizes of coral sand is 1.98 MPa; at distance of 150 mm, the minimum of four sizes of coral sand is 0.39 MPa. Therefore, the critical stress should be in range of 1.98–0.39 MPa.

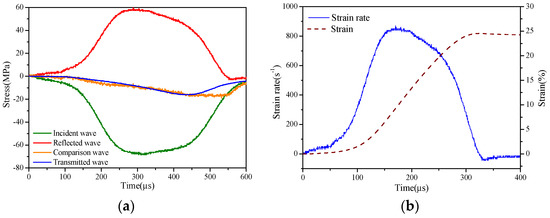

A typical set of stress waves for the energy absorption experiment is shown in Figure 4a. Benefitting from suitable pulses shaping technique, the incident wave with a rise time of ~300 μs is generated. The long rise time of the incident pulse makes the stress in the specimen in equilibration, as shown the nearly overlapped “comparison wave” and “transmitted wave” in Figure 4a. The strain-rate history and the strain history are shown in Figure 4b, the strain rate is nearly a constant (800/s) from ~150 to 250 μs that correspond to the strains from 5% to 20%. Therefore, the specimen is deformed uniformly at the nearly constant strain rate, resultant of the stress-strain curve is validated.

Figure 4.

Typical stress equilibrium and strain & strain-rate histories for a coral sand specimen with particle size 1.18–0.60 mm. (a) Stress equilibrium; (b) Strain & strain-rate histories.

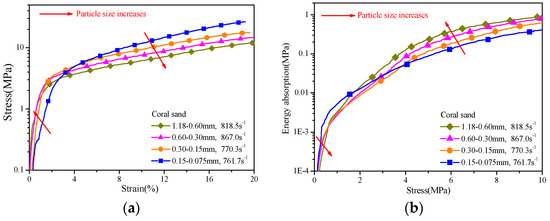

The stress-strain curves and energy absorption curves for coral sand with different particle sizes are shown in Figure 5a,b, every curve is averaged from three experiments. The particle size significantly affect the compressive behavior and energy absorption. A clear critical zone in the range of 3.93–0.59 MPa, which covers the yield stresses of coral sand with different particle sizes, are observed in Figure 5a. This critical zone almost covers that of 1.98–0.39 MPa for stress wave attenuation. Moreover, when the stress below the critical zone, larger sand particles tend to carry higher stress and deform less, which indicates less energy absorption of the specimen in macro-scale. It agrees with the stress wave attenuation at distances of 225 mm and 300 mm, as shown in Figure 3c,d. When the stress beyond the critical zone, the curves shift upside down. To the right of the critical zone, the stress-strain curves for smaller size sand shift upwards, indicating that smaller size particles carry higher compressive stress than the larger size particles; and the energy absorption curves of coral sand with smaller sizes shift downwards, indicating that coral sand with smaller particles absorb less energy than that of coral sand with larger particles. The stress beyond the critical zone corresponds to the stress wave attenuation at distance of 75 mm, as shown in Figure 3a. Therefore, the results, which support each other, indicate stress wave attenuation and energy absorption of coral sand are correlated.

Figure 5.

Stress-strain curves and energy absorption curves for coral sand with different particle sizes. (a) Stress-strain curves; (b) Energy absorption curves.

4. Conclusions

The stress wave attenuation and energy absorption of coral sand with different particle sizes under impact loads were investigated. A clear correlation between the stress wave attenuation and energy absorption was observed and validated. A common critical stress zone (1.98–0.39 MPa of stress wave attenuation, 3.93–0.59 of energy absorption) for four types of coral sand exists. Coral sand with smaller particle sizes sustain lower stress and deform more when stress below the critical stress zone, which eventually results in a better performance on stress wave attenuation and energy absorption. On the contrary, coral sand of larger particle sizes sustain lower stress and deform more when stress beyond the critical stress zone, which eventually results in a better performance on stress wave attenuation and energy absorption.

It should be noted that the effects of stress wave attenuation and energy absorption in coral sand also depends on the length of the impulse, which should be carefully studied with intensive tests in the future.

Author Contributions

Q.F., L.C. and X.Y. conceived and designed the experiments; X.Y. performed the experiments; X.Y. analyzed the data; W.C. contributed analysis tools; X.Y. and L.C. wrote the paper.

Acknowledgments

The authors acknowledge selfless help from Xiquan Jiang in improving testing instruments, and the financial supports from National Key Research and Development Program of China (No.2016YFC0305200), the National Natural Science Foundation of China (Grant Nos. 51622812, 51427807), China Postdoctoral Science Foundation (No. 2017M613379), Creative project of Shanghai International Port (Group) Co., Ltd. (No. 17KZ-03B-13Z).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yu, X.; Chen, L.; Fang, Q. Experimental study on the attenuation of stress wave in coral sand. Chin. J. Rock Mech. Eng. 2018, 37, 1520–1529. [Google Scholar]

- Luo, H.; Cooper, W.L.; Lu, H. Effects of particle size and moisture on the compressive behavior of dense Eglin sand under confinement at high strain rates. Int. J. Impact Eng. 2014, 65, 40–55. [Google Scholar] [CrossRef]

- Huang, J.; Xu, S.; Hu, S. Effects of grain size and gradation on the dynamic responses of quartz sands. Int. J. Impact Eng. 2013, 59, 1–10. [Google Scholar] [CrossRef]

- Ministry of Water Resources of the People’s Republic of China. Specification of Soil Test; China Water & Power Press: Beijing, China, 1999; pp. 33–71. [Google Scholar]

- Lade, P.V.; Liggio, C.D.; Nam, J. Strain rate, creep, and stress drop-creep experiments on crushed coral sand. J. Geotech. Geoenviron. Eng. 2009, 135, 941–953. [Google Scholar] [CrossRef]

- Lv, Y.; Li, F.; Liu, Y.; Fan, P.; Wang, M. Comparative study of coral sand and silica sand in creep under general stress states. Can. Geotech. J. 2016, 54, 1–38. [Google Scholar] [CrossRef]

- Wang, L. Foundation of Stress Waves; National Defense Industry Press: Beijing, China, 1985; pp. 45–47. [Google Scholar]

- Yu, X.; Chen, L.; Fang, Q. A testing method on the attenuation of stress wave in loose porous media and its application to coral sand. Eng. Mech. 2018, 37, 1520–1529. [Google Scholar]

- Chen, W.; Song, B. Split Hopkinson (Kolsky) Bar; Springer: New York, NY, USA, 2011; pp. 7–17. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).