Experimental Investigation of the Confined Behavior of Concrete under Shear Loading at High Strain Rates †

Abstract

:1. Introduction

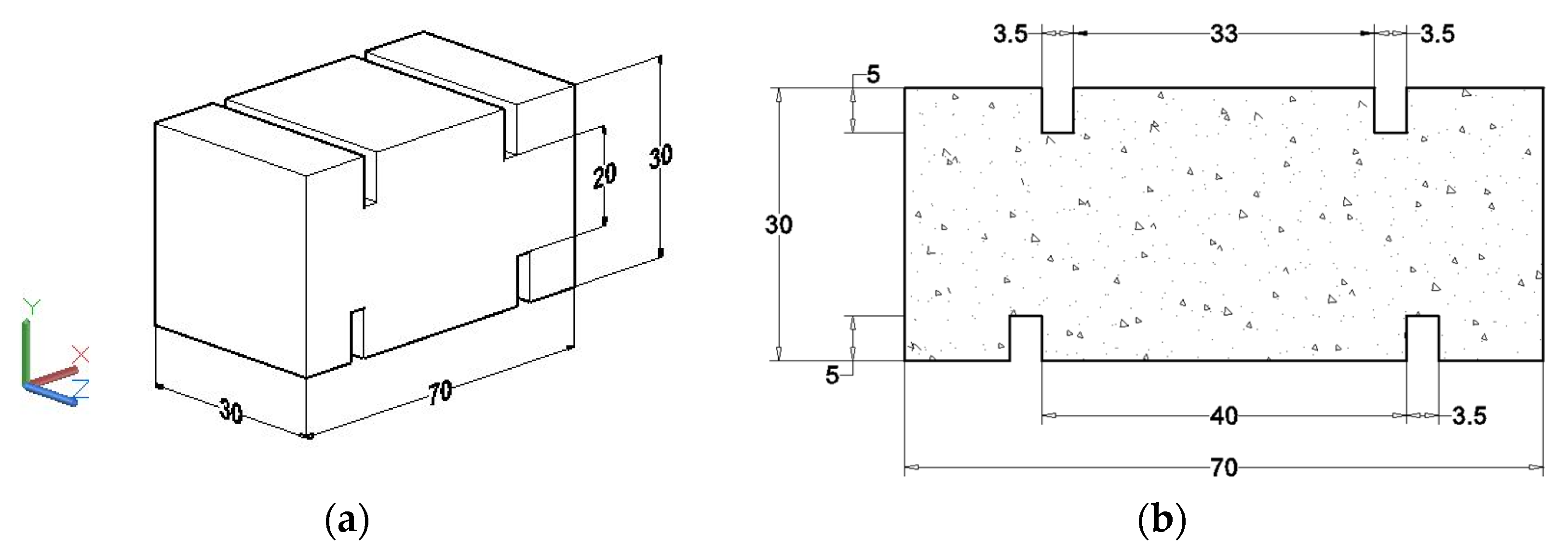

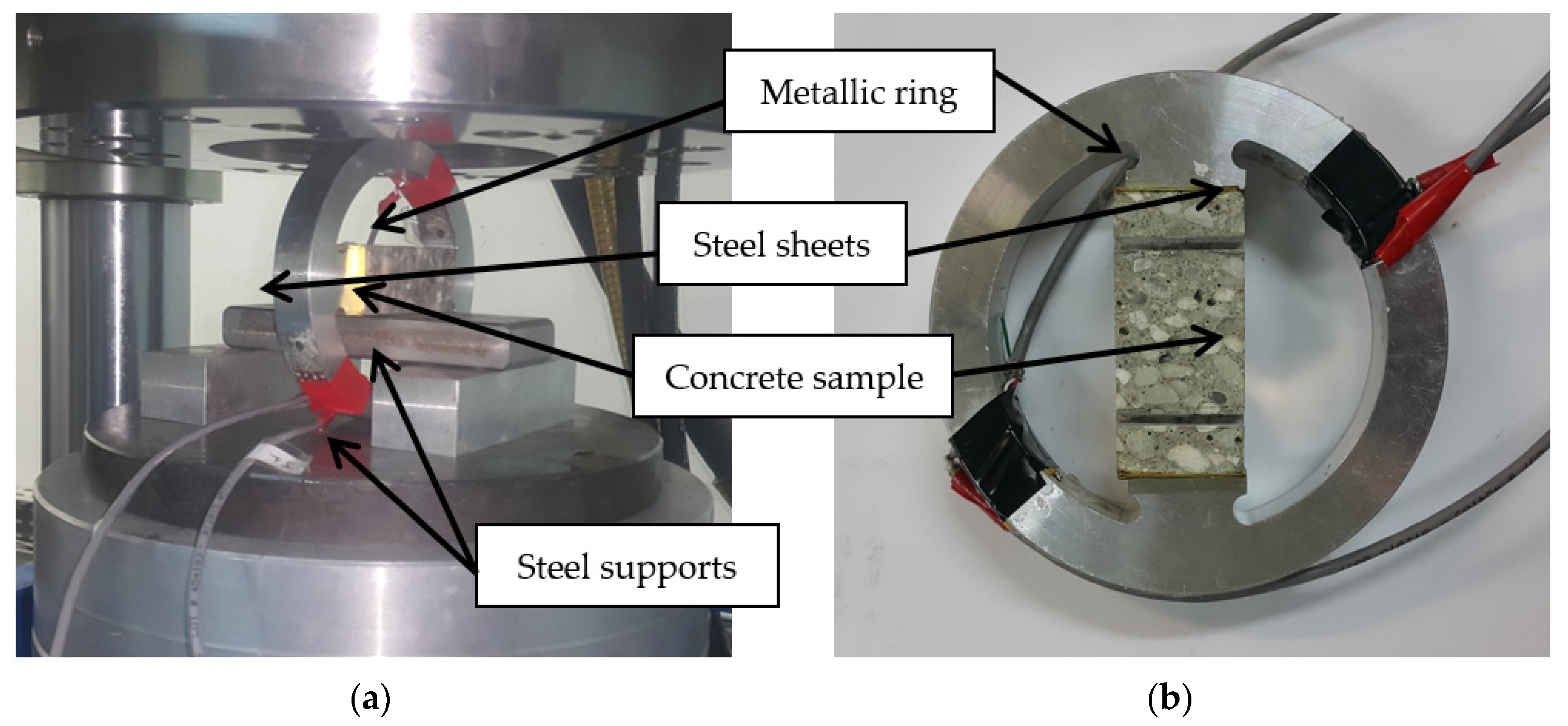

2. Materials and Methods

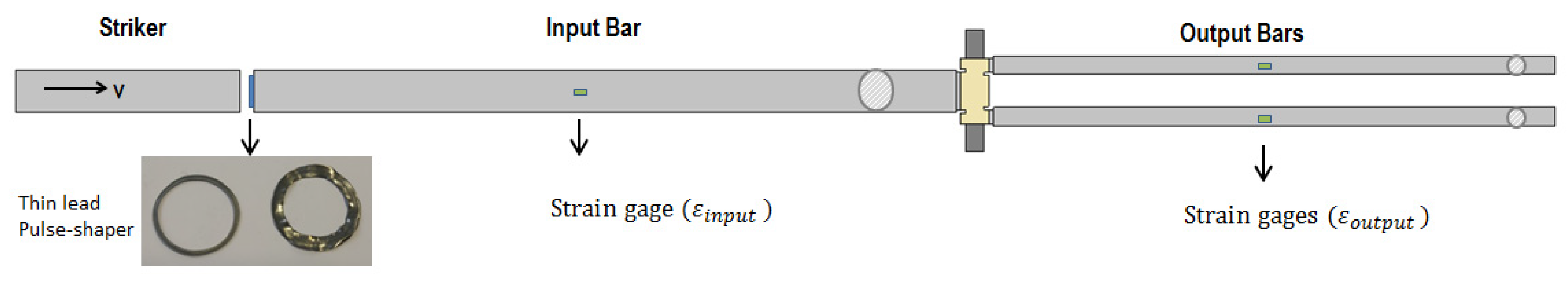

3. Experimental Procedure

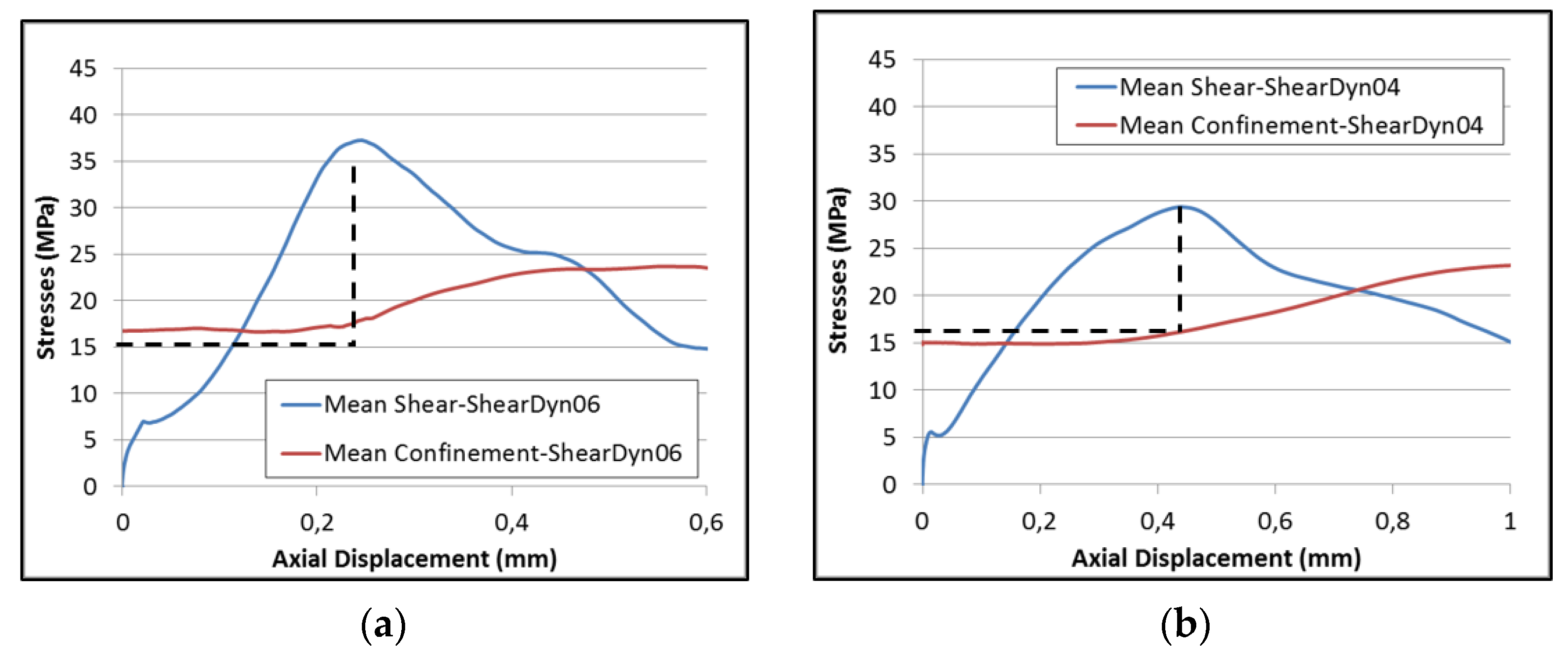

4. Results

5. Conclusions

Acknowledgments

References

- Zukas, J. Penetration and Perforation of Solids. Impact Dynamics; Krieger Publishing Co.: Malabar, FL, USA, 1992. [Google Scholar]

- Li, Q.M.; Reid, S.R.; Wen, H.M.; Telford, A.R. Local impact effects of hard missiles on concrete targets. Int. J. Fract. 2005, 32, 224–284. [Google Scholar] [CrossRef]

- Backers, T.; Stephansson, O.; Rybacki, E. Rock fracture toughness testing in mode II—Punch-through shear test. Int. J. Rock Mech. Min. Sci. 2002, 39, 755–769. [Google Scholar] [CrossRef]

- Montenegro, O.; Sfer, D.; Lopez, C.M.; Carol, I. Experimental tests and numerical modeling to identify the asymptotic shear-compression mode IIa of concrete fracture. In Proceedings of the VIII International Conference on Fracture Mechanics of Concrete and Concrete Structures (Framcos 8), Toledo, Spain, 10–14 March 2013; pp. 271–277. [Google Scholar]

- Forquin, P. Influence of Free Water and Strain-Rate on the Shear Behavior of Concrete. Appl. Mech. Mater. 2011, 82, 148–153. [Google Scholar] [CrossRef]

- Forquin, P.; Sallier, L. A Testing Technique to Characterize the Shear Behavior of Concrete at High Strain-Rates. In Dynamic Behavior of Materials; Chalivendra, V., Song, B., Casem, D., Eds.; Conference Proceedings of the Society for Experimental Mechanics Series; Springer: New York, NY, USA, 2013; Volume 1. [Google Scholar]

- Lukić, B.; Forquin, P. Experimental characterization of the punch through shear strength of an ultra-high performance concrete. Int. J. Impact Eng. 2016, 91, 34–45. [Google Scholar] [CrossRef]

| Concrete Composition | kg/m3 |

|---|---|

| Water | 169 |

| Sand | 838 |

| Coarse aggregate | 1007 |

| Cement | 263 |

| Mechanical properties | |

| Density (kg/m3) | 2380 |

| Compressive strength (MPa) | 28.6 |

| Porosity (%) | 12 |

| W/C ratio | 0.64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdul-Rahman, R.; Saletti, D.; Forquin, P. Experimental Investigation of the Confined Behavior of Concrete under Shear Loading at High Strain Rates. Proceedings 2018, 2, 496. https://doi.org/10.3390/ICEM18-05408

Abdul-Rahman R, Saletti D, Forquin P. Experimental Investigation of the Confined Behavior of Concrete under Shear Loading at High Strain Rates. Proceedings. 2018; 2(8):496. https://doi.org/10.3390/ICEM18-05408

Chicago/Turabian StyleAbdul-Rahman, Reem, Dominique Saletti, and Pascal Forquin. 2018. "Experimental Investigation of the Confined Behavior of Concrete under Shear Loading at High Strain Rates" Proceedings 2, no. 8: 496. https://doi.org/10.3390/ICEM18-05408

APA StyleAbdul-Rahman, R., Saletti, D., & Forquin, P. (2018). Experimental Investigation of the Confined Behavior of Concrete under Shear Loading at High Strain Rates. Proceedings, 2(8), 496. https://doi.org/10.3390/ICEM18-05408