Fatigue of Additive Manufacturing Specimens: A Comparison with Casting Processes †

Abstract

:1. Introduction

2. Materials and Methods

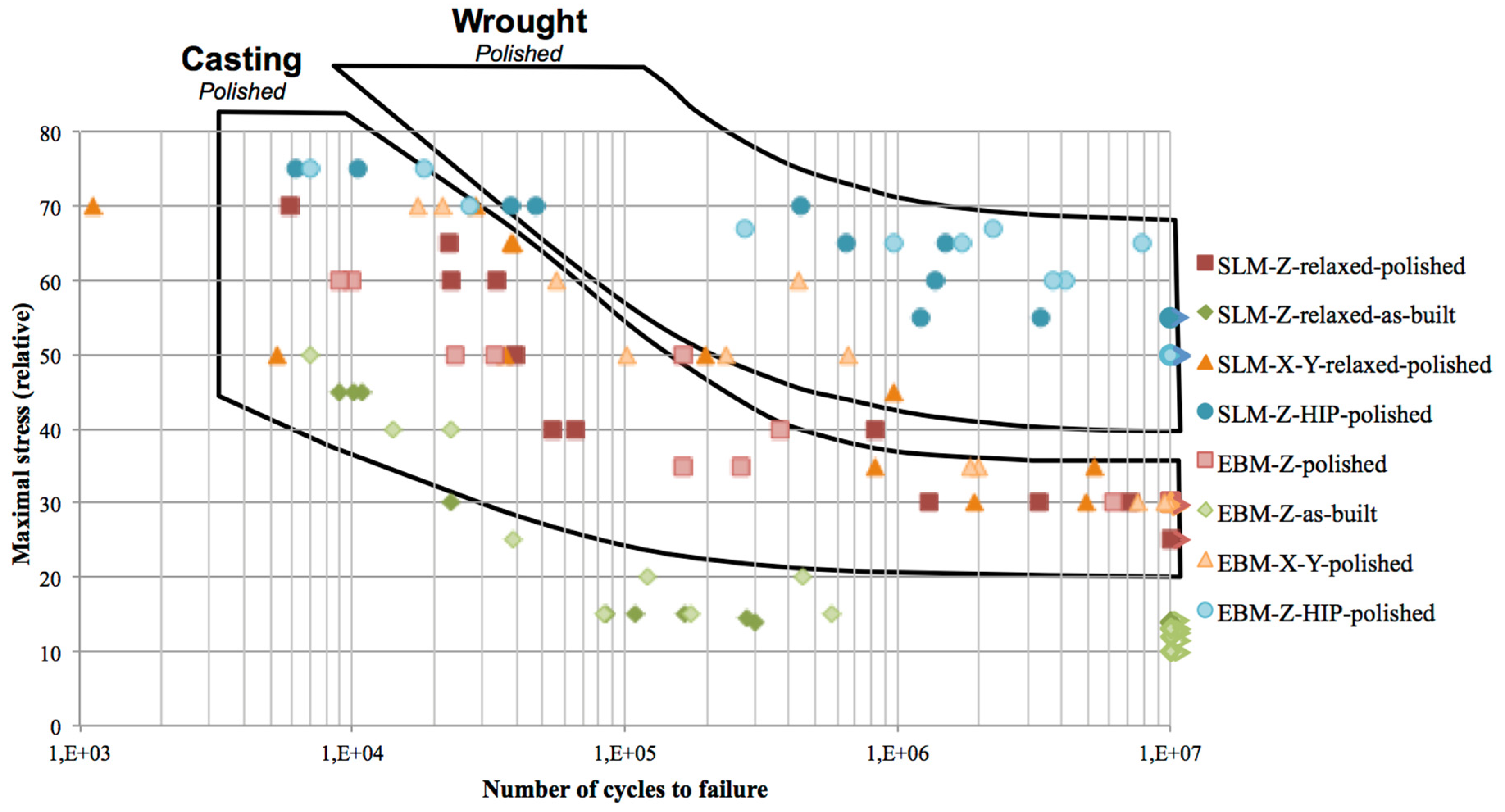

3. Fatigue Lifetimes

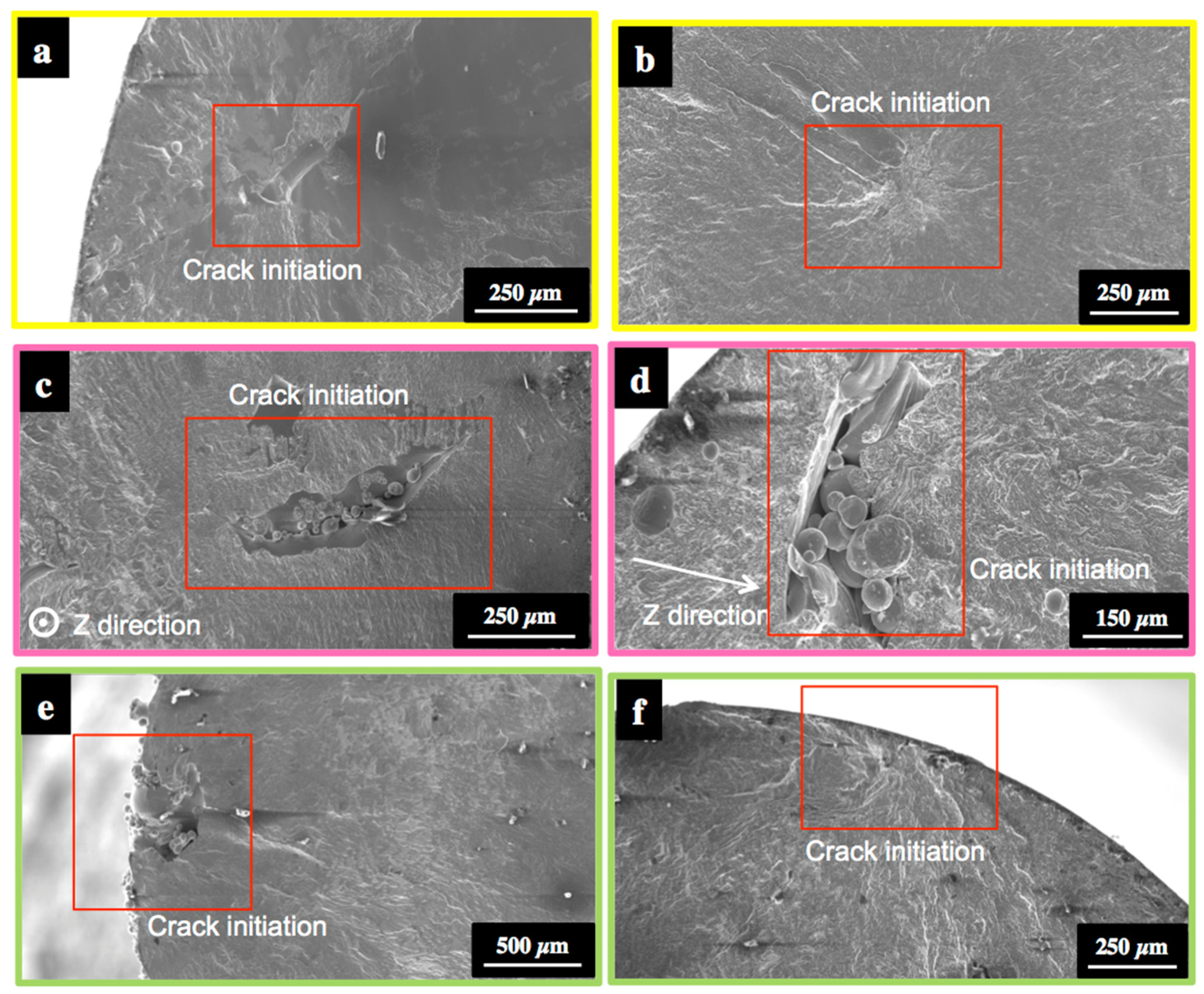

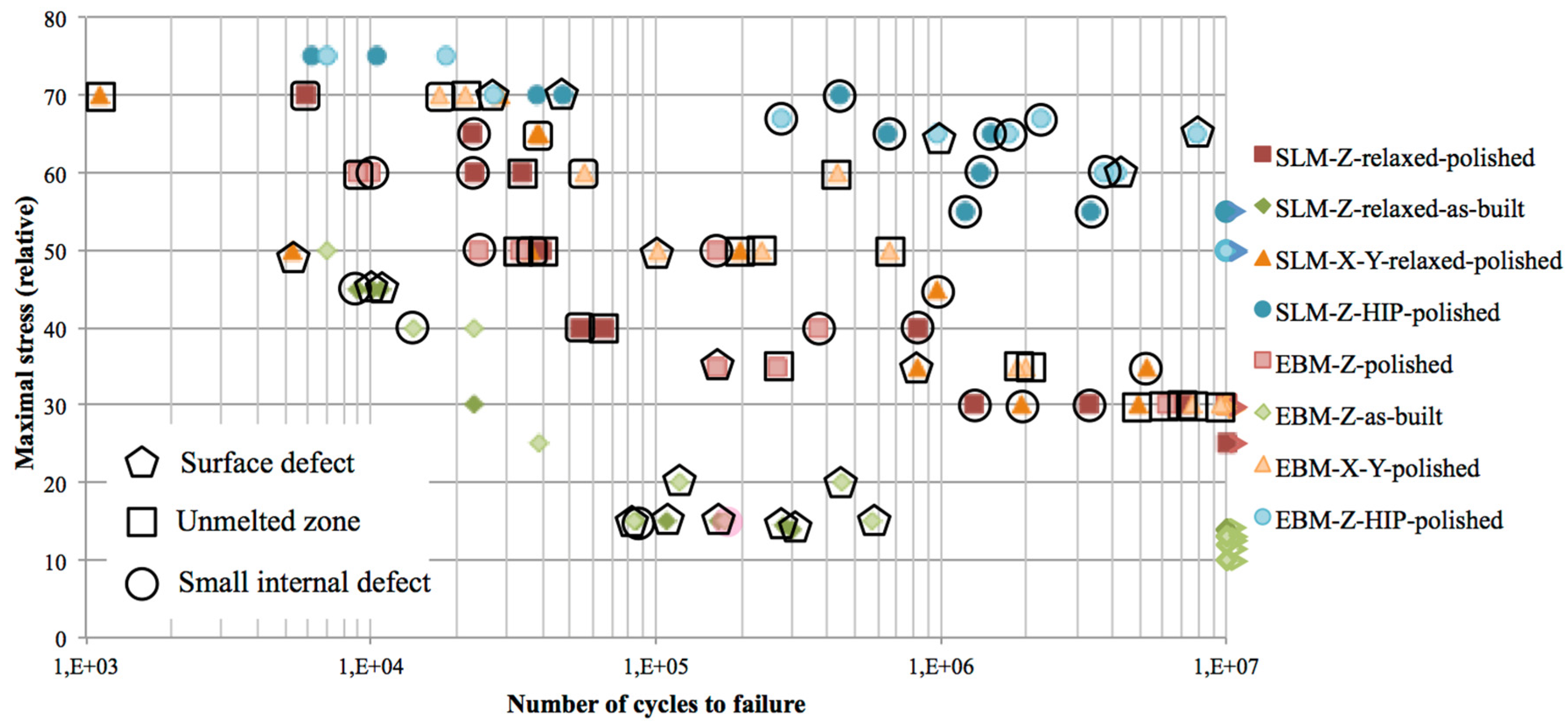

4. Damage Mechanisms

4.1. Observations on Ti6Al4V Specimens

4.2. Discussion and Comparison with Casting Processes

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Bagehorn, S.; Wehr, J.; Maier, H.J. Application of mechanical surface finishing processes for roughness reduction and fatigue improvement of additively manufactured Ti-6Al-4V parts. Int. J. Fatigue 2017, 102, 135–142. [Google Scholar] [CrossRef]

- Günther, J.; Krewerth, D.; Lippmann, T.; Leuders, S.; Tröster, T.; Weidner, A.; Biermann, H.; Niendorf, T. Fatigue life of additively manufactured Ti-6Al-4V in the very high cycle fatigue regime. Int. J. Fatigue 2017, 94, 236–245. [Google Scholar]

- Chastand, V.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Comparative study of fatigue properties of Ti-6Al-4V specimens built by electron beam melting (EBM) and selective laser melting (SLM). Mater. Charact. 2018, in press. [Google Scholar] [CrossRef]

- Limodin, N.; el Bartali, A.; Wang, L.; Lachambre, J.; Charkaluk, E. Application of X-ray microtomography to study the influence of the casting microstructure upon the tensile behaviour of an Al-Si alloy. Nucl. Inst. Methods Phys. Res. B 2014, 324, 57–62. [Google Scholar] [CrossRef]

- Wang, L.; Limodin, N.; el Bartali, A.; Witz, J.-F.; Seghir, R.; Buffière, J.-Y.; Charkaluk, E. Influence of pores on crack initiation in monotonic tensile and cyclic loadings in lost foam casting A319 alloy by using 3D in-situ analysis. Mater. Sci. Eng. A 2016, 673, 362–372. [Google Scholar] [CrossRef]

- Buffière, J.-Y.; Savelli, S.; Jouneau, P.H.; Maire, E.; Fougères, R. Experimental study of porosity and its relation to fatigue mechanisms of model Al-Si7-Mg0.3 cast Al alloys. Mater. Sci. Eng. A 2001, 316, 115–126. [Google Scholar] [CrossRef]

- Chastand, V. Etude du Comportement Mécanique et des Mécanismes D’endommagement de Pièces Métalliques Réalisées par Fabrication Additive. Ph.D. Thesis, Ecole Centrale de Lille, Villeneuve-d’Ascq, France, 2016. Available online: https://tel.archives-ouvertes.fr/tel-01484725/document (accessed on 10 November 2016). (In French).

- Donachie, M.J. Titanium: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Fatemi, A.; Molaei, R.; Sharifimehr, S.; Shamsaei, N.; Phan, N. Torsional fatigue behavior of wrought and additive manufactured Ti-6Al-4V by powder bed fusion including surface finish effect. Int. J. Fatigue 2017, 99, 187–201. [Google Scholar] [CrossRef]

- Fatemi, A.; Molaei, R.; Sharifimehr, S.; Phan, N.; Shamsaei, N. Multiaxial fatigue behavior of wrought and additive manufactured Ti-6Al-4V including surface finish effect. Int. J. Fatigue 2017, 100, 347–366. [Google Scholar] [CrossRef]

- Szmytka, F.; Limodin, N.; Wang, L.; Osmond, P.; Adrien, J.; Charkaluk, E.; Buffiere, J.Y. Probabilistic thermal-mechanical fatigue criterion for lost foam casting aluminium alloys based on 2D/3D porosities distribution. MATEC Web Conf. 2014, 12, 05005. [Google Scholar] [CrossRef]

| Process | Manufact. Direction | Number of Specimens | Thermal Treatment | Surface Finishing |

|---|---|---|---|---|

| SLM | Z | 12 | 640 °C/4 h | Polishing |

| X-Y | 12 | 640 °C/4 h | Polishing | |

| Z | 12 | 640 °C/4 h | None | |

| Z | 12 | 640 °C/4 h + HIP | Polishing | |

| EBM | Z | 12 | None | Polishing |

| X-Y | 12 | None | Polishing | |

| Z | 12 | None | None | |

| Z | 12 | HIP | Polishing |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Charkaluk, E.; Chastand, V. Fatigue of Additive Manufacturing Specimens: A Comparison with Casting Processes. Proceedings 2018, 2, 474. https://doi.org/10.3390/ICEM18-05352

Charkaluk E, Chastand V. Fatigue of Additive Manufacturing Specimens: A Comparison with Casting Processes. Proceedings. 2018; 2(8):474. https://doi.org/10.3390/ICEM18-05352

Chicago/Turabian StyleCharkaluk, Eric, and Victor Chastand. 2018. "Fatigue of Additive Manufacturing Specimens: A Comparison with Casting Processes" Proceedings 2, no. 8: 474. https://doi.org/10.3390/ICEM18-05352

APA StyleCharkaluk, E., & Chastand, V. (2018). Fatigue of Additive Manufacturing Specimens: A Comparison with Casting Processes. Proceedings, 2(8), 474. https://doi.org/10.3390/ICEM18-05352