Experimental Investigation on the Explosive Substitute by Drop Test †

Abstract

:1. Introduction

2. Experiment

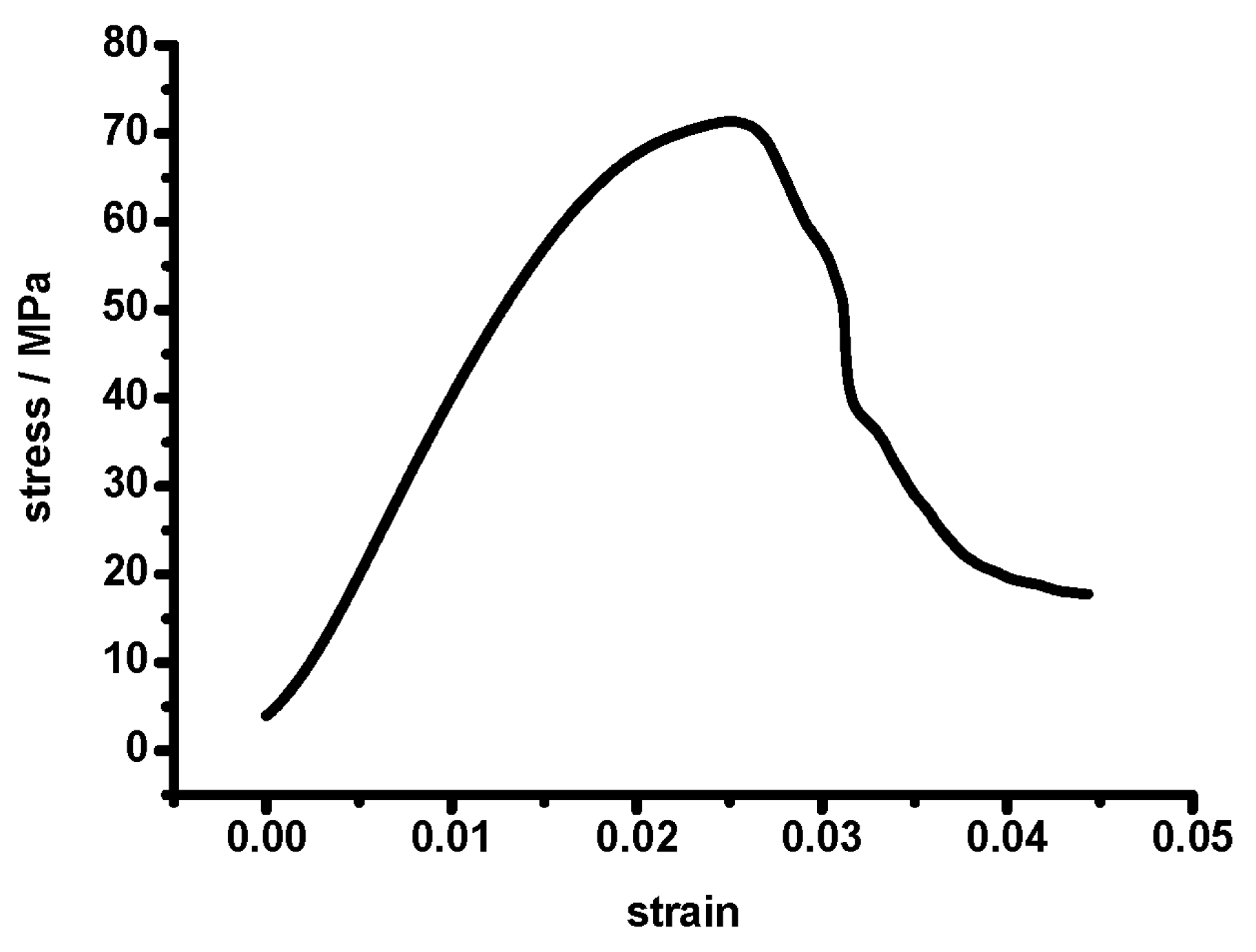

2.1. PBX Simulation Material

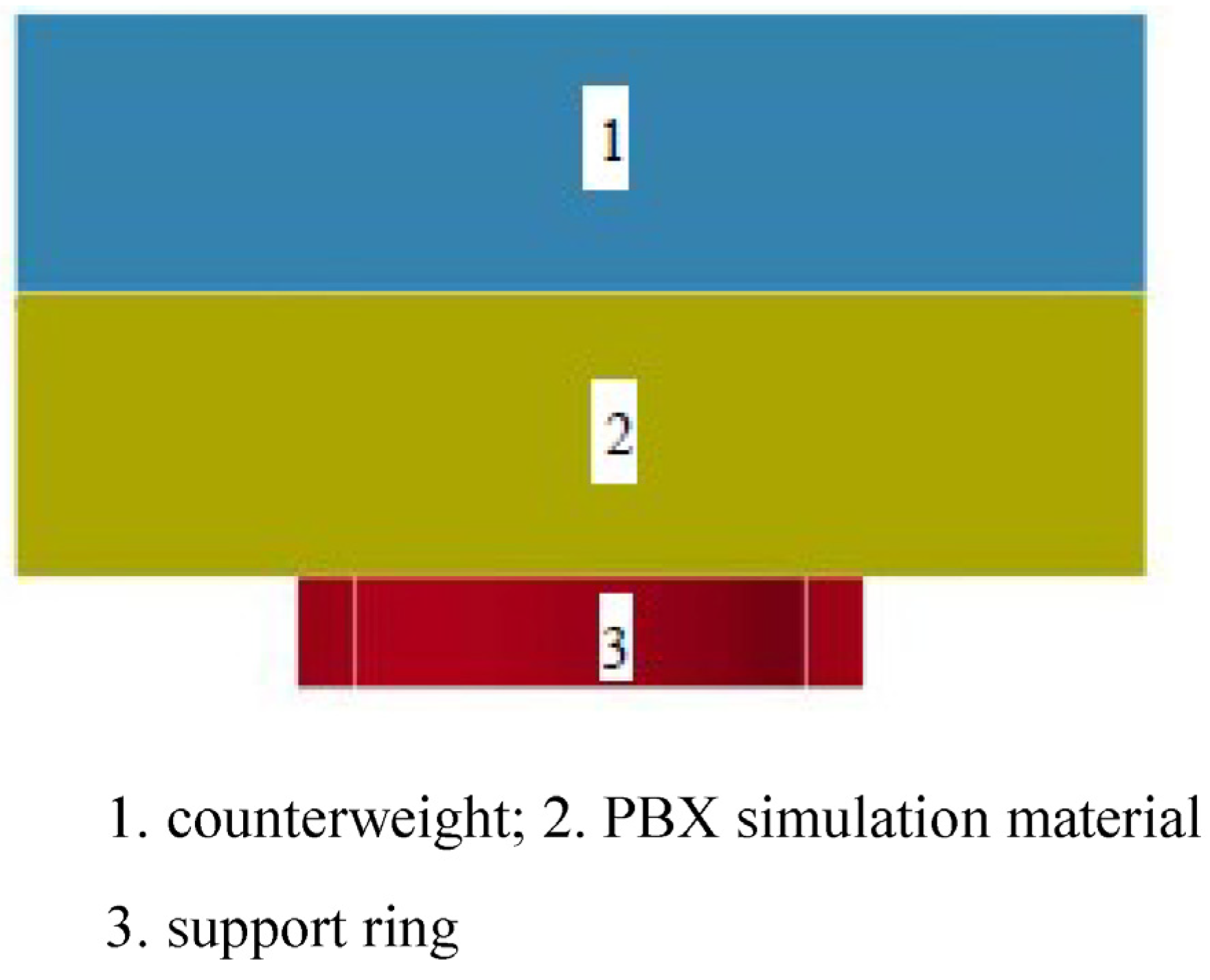

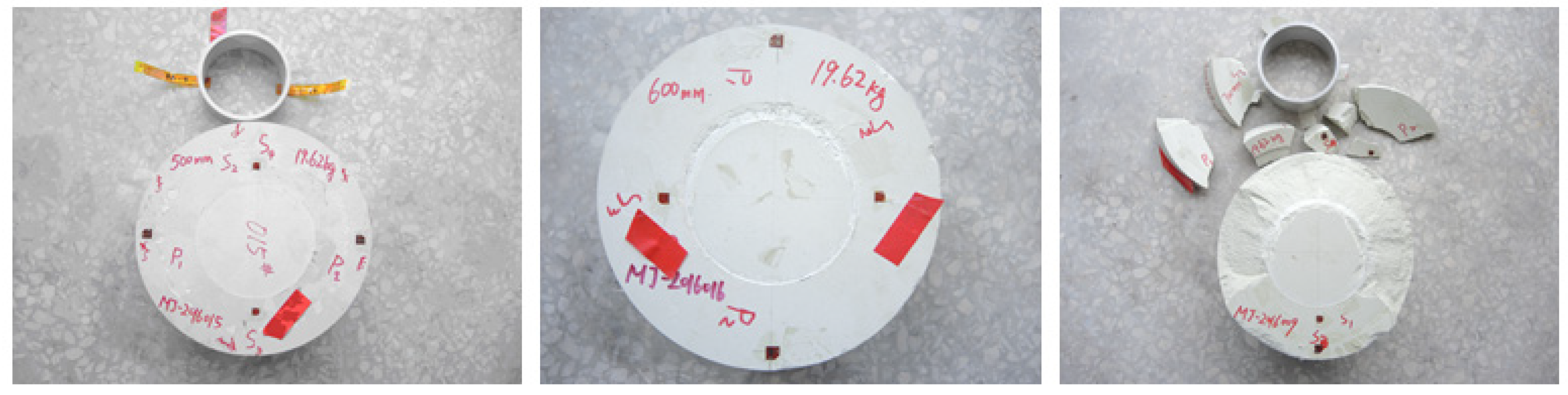

2.2. Drop Test Piece

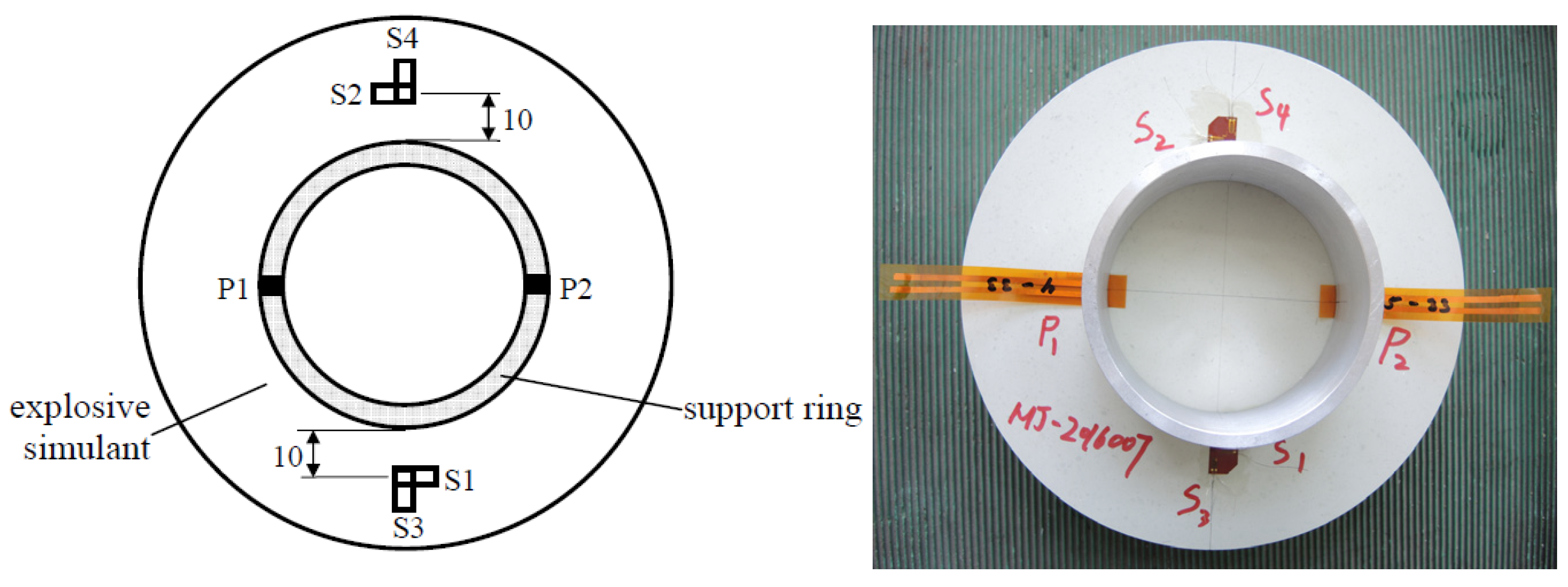

2.3. Test Items

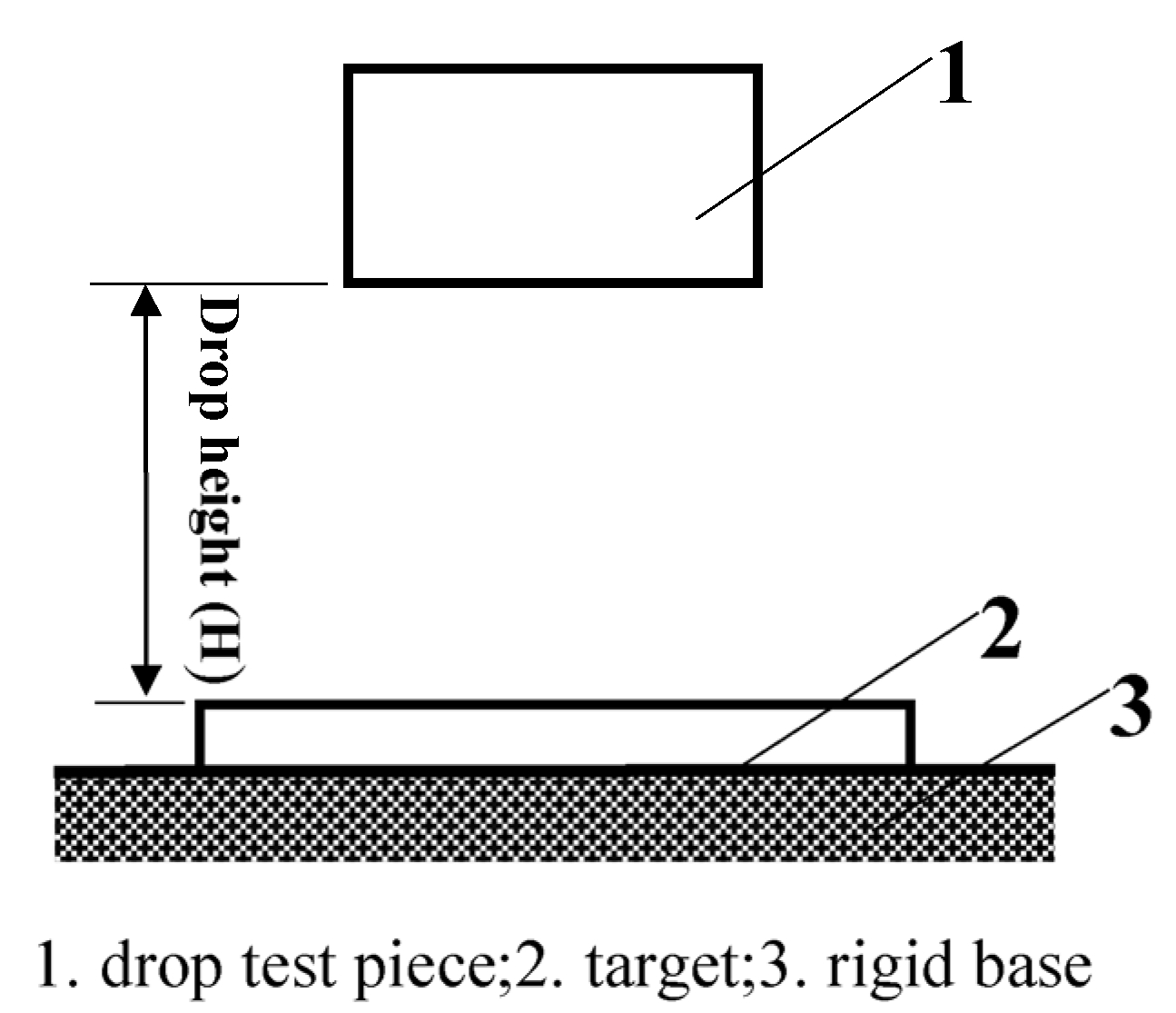

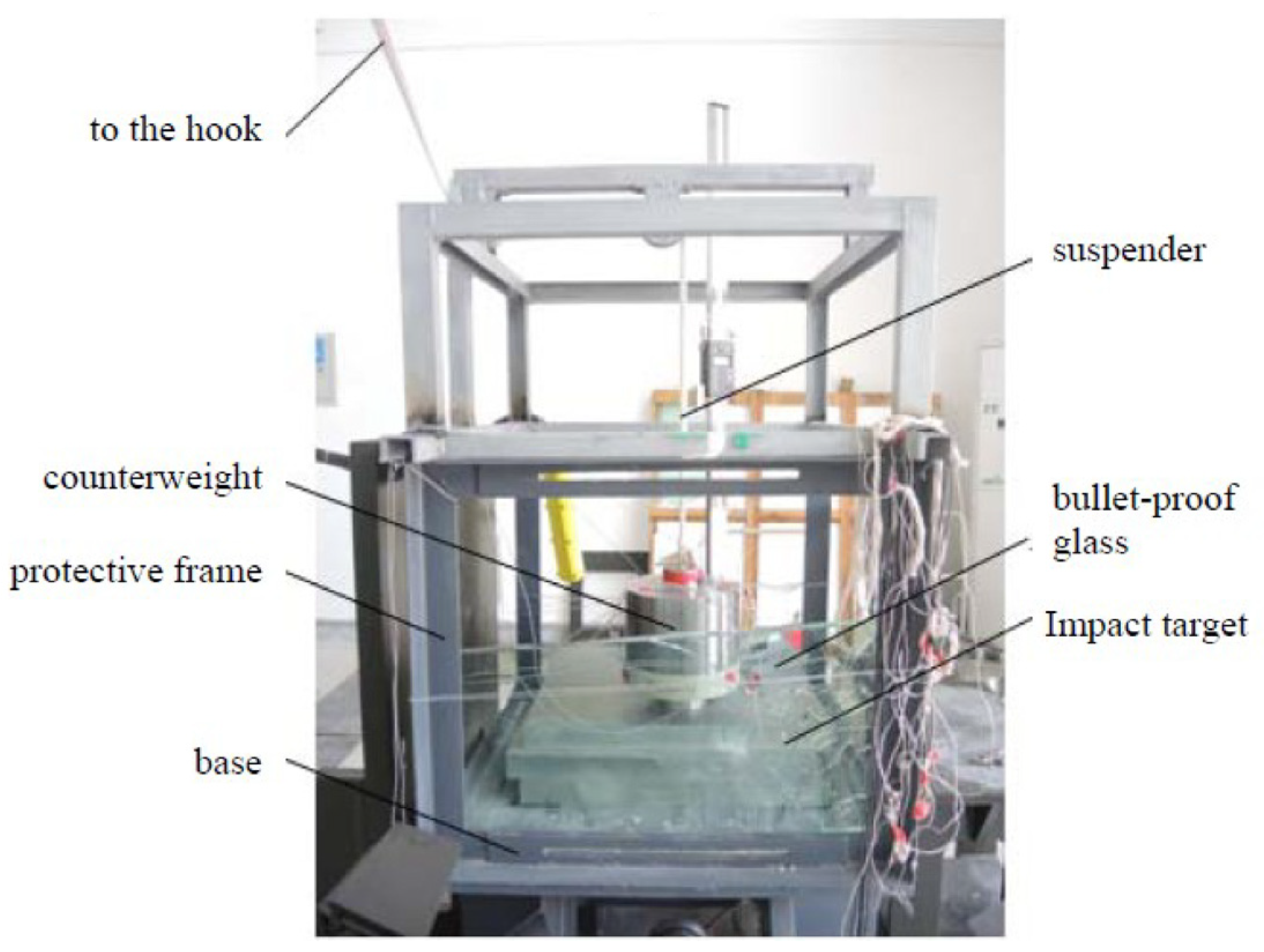

2.4. Drop Device

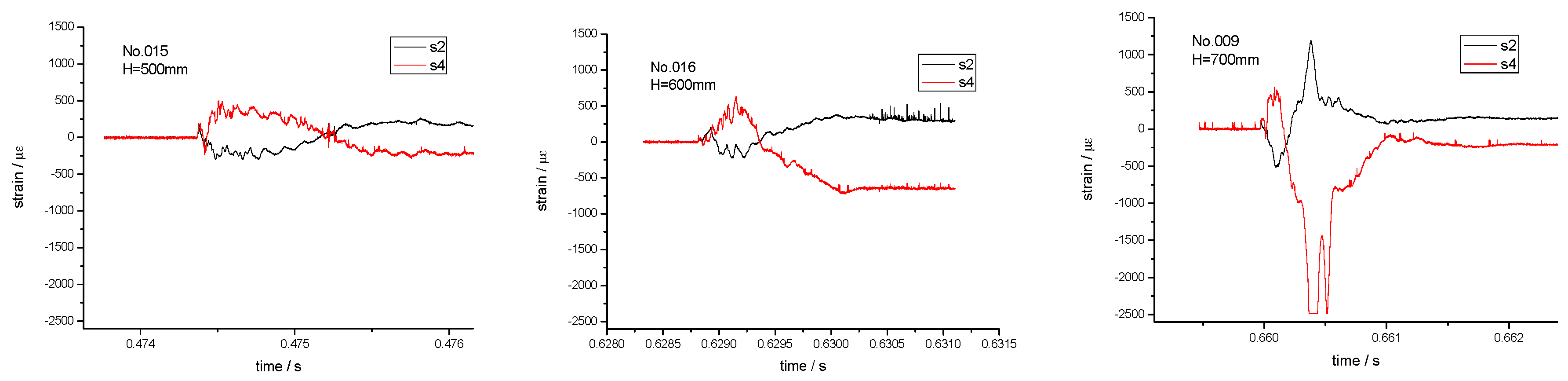

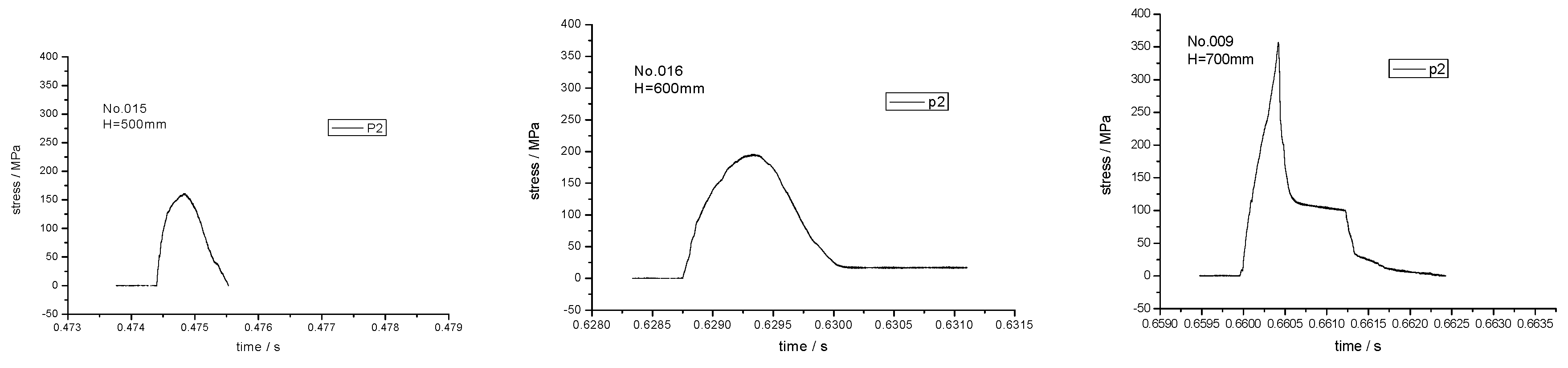

2.5. Test System

3. Experimental Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Sun, Y.B.; Hui, J.M.; Cao, X.M. Military Mixed Explosives; Weapon Industry Press: Beijing, China, 1995. [Google Scholar]

- Jin, Z.Y.; Zhan, C.Q. Summary of Explosives and Dynamition; Weapon Industry Press: Beijing, China, 1986. [Google Scholar]

- Akhavan, J. The Chemistry of Explosives; The Royal Society of Chemistry, Thomas Graham House: Cambridge, UK, 1998. [Google Scholar]

- Menikoff, R.; Sewell, T.D. Constituent Properties of HMX Needed for Mesoscale Simulations. Combust. Theory Model. 2002, 6, 103–125. [Google Scholar] [CrossRef]

- Singh, G.; Prem, F.S.; Soni, P. Studies on Energetic Compounds Part 28: Thermo Analysis of HMX and Its Plastic Bonded Explosives Containing Estane. Thermochim. Acta 2003, 399, 153–165. [Google Scholar] [CrossRef]

- Xie, F.-Y.; Zhang, Q.; Liu, W.; Huang, J.-H. Experimental Research on Formation Characteristics of Cutting Surface of Explosive Simulant. Chin. J. Explos. Propellants 2015, 38, 45–49. [Google Scholar]

- Zhao, J.-B.; Li, K.-W.; Fu, H.; Zhao, F. Research on the Friction Coefficient between Explosive and Different Materials. Chin. J. High Pressure Phys. 2014, 58, 591–596. [Google Scholar]

- Goudrean, G.; Moen, W.; Breithaupt, D. Evaluation of Mechanical Properties of PBX W-113 Explosive; UCID-20358; Lawrence Livermore National Lab.: Livermore, CA, USA, 1985. [Google Scholar]

- Gray, G.T., III; Idar, D.J.; Blumenthal, W.R.; Cady, C.M.; Peterson, P.D. High-and low-strain rate compression properties of several energetic material composites as a function of strain and temperature. In Proceedings of the 11th International Detonation Symposium, Snow Mass, CO, USA, 30 August–4 September 1998; pp. 76–84. [Google Scholar]

- Park, C.; Jeong, S.; Huh, H.; Park, J.S. Material Behaviors of PBX Simulant with Various Strain Rates. In Key Engineering Materials; Trans Tech Publications: Zürich, Switzerland, 2013. [Google Scholar]

- Dai, X.-G.; Xiang, Y. Study of Steven test and impact sensitivity for two explosives. Chin. J. Energ. Mater. 2006, 14, 10–13. [Google Scholar]

- Shen, C.-Y.; Xiang, Y.; Dai, X.-G. Study on the Spigot Tests of Polymer Bonder Explosive. Chin. J. Explos. Propellants 2010, 33, 29–32. [Google Scholar]

- Chen, P.; Huang, F.; Ding, Y. Microstructure, deformation and failure of polymer bonded explosives. J. Mater. Sci. 2007, 42, 5272–5280. [Google Scholar] [CrossRef]

- Luo, J.R. Study on Damage, Fracture and Constitutive Relation of PBX; CAEP: Mianyang, China, 2001. [Google Scholar]

- Yu, M. Advances in strength theories for materials under complex stress state in the 20th Century. Appl. Mech. Rev. ASME 2002, 55, 169–218. [Google Scholar] [CrossRef]

| Type | Number | Measuring Point | Remarks | |

|---|---|---|---|---|

| Strain | Circumferential | S1 | 10 mm from the outer edge of the support ring | — |

| S2 | 10 mm from the outer edge of the support ring | Symmetrical to S1 | ||

| Radial | S3 | 10 mm from the outer edge of the support ring | — | |

| S4 | 10 mm from the outer edge of the support ring | Symmetrical to S3 | ||

| Pressure | P1 | Between the PBX simulation material and support ring | — | |

| P2 | Between the PBX simulation material and support ring | Symmetrical to P1 | ||

| No. of PBX Simulation Material | Counterweight kg | Drop Height (H) mm | Temperature °C | Humidity % |

|---|---|---|---|---|

| 010 | 19.62 | 450 | 25 | 55 |

| 015 | 19.62 | 500 | 27 | 38 |

| 016 | 19.62 | 600 | 27 | 36 |

| 009 | 19.62 | 700 | 24 | 45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, R.; Zhang, Q.; Deng, Z.; Huang, X. Experimental Investigation on the Explosive Substitute by Drop Test. Proceedings 2018, 2, 424. https://doi.org/10.3390/ICEM18-05296

Xie R, Zhang Q, Deng Z, Huang X. Experimental Investigation on the Explosive Substitute by Drop Test. Proceedings. 2018; 2(8):424. https://doi.org/10.3390/ICEM18-05296

Chicago/Turabian StyleXie, Ruoze, Qingping Zhang, Zhifang Deng, and Xicheng Huang. 2018. "Experimental Investigation on the Explosive Substitute by Drop Test" Proceedings 2, no. 8: 424. https://doi.org/10.3390/ICEM18-05296

APA StyleXie, R., Zhang, Q., Deng, Z., & Huang, X. (2018). Experimental Investigation on the Explosive Substitute by Drop Test. Proceedings, 2(8), 424. https://doi.org/10.3390/ICEM18-05296