1. Introduction

The integrity of composite structures gradually degrades due to the onset of damage such as matrix cracking, fiber/matrix debonding, and delamination. Over the last two decades, great strides have been made in structural health monitoring (SHM) community using various sensing techniques such as acoustic emission, eddy current, strain gages, etc., to diagnose damage in aerospace, mechanical and civil infrastructures. While various conventional non-destructive evaluation (NDE) techniques are used to detect, monitor, and visualize damage of composite structures under fatigue loading, they all have a common limitation in that continuous damage assessment cannot be made in real-time while in service [

1,

2,

3,

4]. Our current research examines the possibilities of embedding nanomaterials into composite laminates as a minimally invasive, non-contacting, nondestructive evaluation and sensing technique. The embedded sensing composite effectively becomes a smart structure with the capability of self-sensing damage by evaluating the integrity of the material in real-time.

Ferromagnetics possess unpaired electronic spins that line up parallel with each other in a region called a domain. The domains are randomly oriented when the ferromagnetic material is not under an external magnetic field. Once an external magnetic field is applied the electronic spins line with each other and become magnetized. Magnetostriction is a property of ferromagnetic materials such that when an external magnetic field is applied the domains align to the external field causing their shape or dimensions to change during the process of magnetization. For example, TerFenol-D, (Tb

0.3Dy

0.7Fe

1.92) strains to about 2000 microstrain in a field of 2 kOe when under a mechanical-bias [

5,

6,

7]. Due to their high magnetostrictive coefficients TerFenol-D serves as an excellent candidate for in-situ sensing of damage in various kinds of polymer composites under different mechanical loading situations [

8,

9].

Ferromagnetic materials have proven useful as strain transducers in harsh-environment applications. Magnetostrictive materials such as Galfenol (Fe-Ga alloy), Alfenol (Fe-Al alloy), and Terfenol-D (Tb0.3Dy0.7Fe1.92) (TdVib, LLC., Ames, IA, USA) in a polymer composite are great candidates for embedded damage assessment of composite structures. In this study, magnetostrictive particles such as Terfenol-D were embedded in a composite structure, along with acoustic emissions technique, to validate the damage in a composite system undergoing qausi static and fatigue loading. As the applied load and fatigue cycles increased, the change in the magnetization flux density was captured using a non-contact magnetic field sensor. It was confirmed through numerous tests that a change in the magnetic properties of the composite served as an indicator of early stage damage detection.

2. Experimental

A 12 in. wide unidirectional carbon fiber reinforced polymer (CFRP) prepreg (Hexcel IM7/8552, 190gsm Prepreg) was used to fabricate the panels. 20 wt% of Terfenol-D particles were embedded into gage length of each layer of carbon fiber reinforced polymer unidirectional pre-pregs with a total of 8 plies. The particle size of the powders ranged from 1-200 microns and were distributed evenly within the gage length of the ply. The prepreg was chosen for being well known as a high performance material in the aerospace industry, also allowing for easy embedding of the magnetostrictive particles due to its sticky nature. Panels were produced using eight plies of the prepreg arranged with the (0/90) orientation. The laminate was then vacuum bagged with the construction. The temperature of the vacuum bagged panel was ramped from RT to 225 ºF at 5 ºF/min and then held for 60 min at approximately 15 psi absolute pressure (ambient). Pressure was then increased to 100 psi, and the temperature was ramped up to 300 ºF at 5 ºF/min. As the temperature surpassed 240 ºF, a 120-min soak clock was started, and the vacuum, vented. At the end of the 120-min soak period, temperature was ramped down to 70 ºF at 5 ºF/min and then the pressure was released. The dimensions of the specimen were water jet cut into 1 in. width and 10 in. in length, according to ASTM standard D3039 for polymer matrix composite materials. Tabs were applied to the ends of the samples using G-10 fiberglass laminate to aid in distributing the loads to the center of the specimens. Baseline samples (non-embedded Terfenol-D panels) were prepared with exactly the same dimension and thickness to serve as a standard.

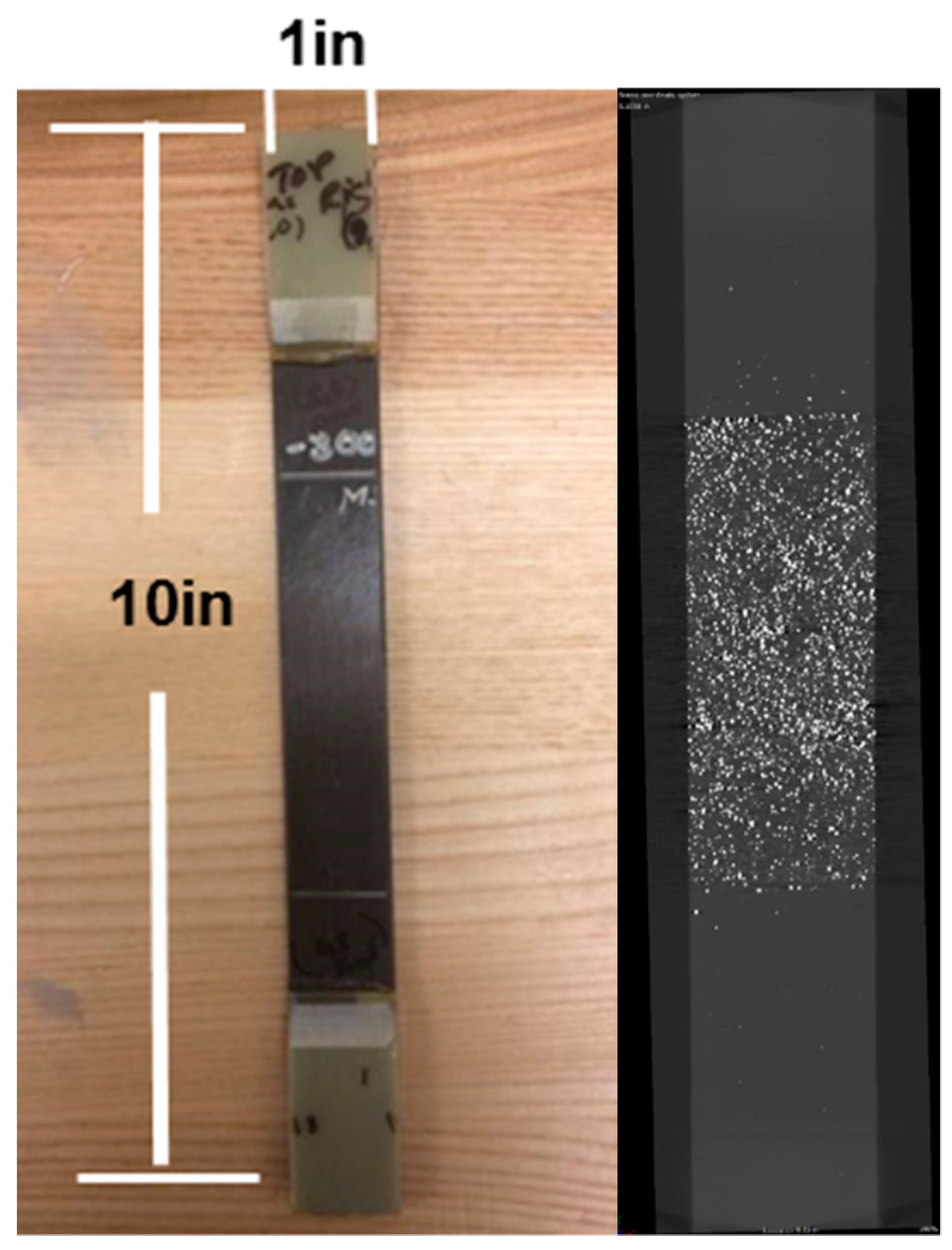

A Zeiss X-ray Micro CT revealed that the Terfenol-D particulates were uniformly distributed within the gage length of the samples as shown in

Figure 1. This characterization tool allowed us to visualize the structural detail of the addition of the magnetostrictive particles at every layer.

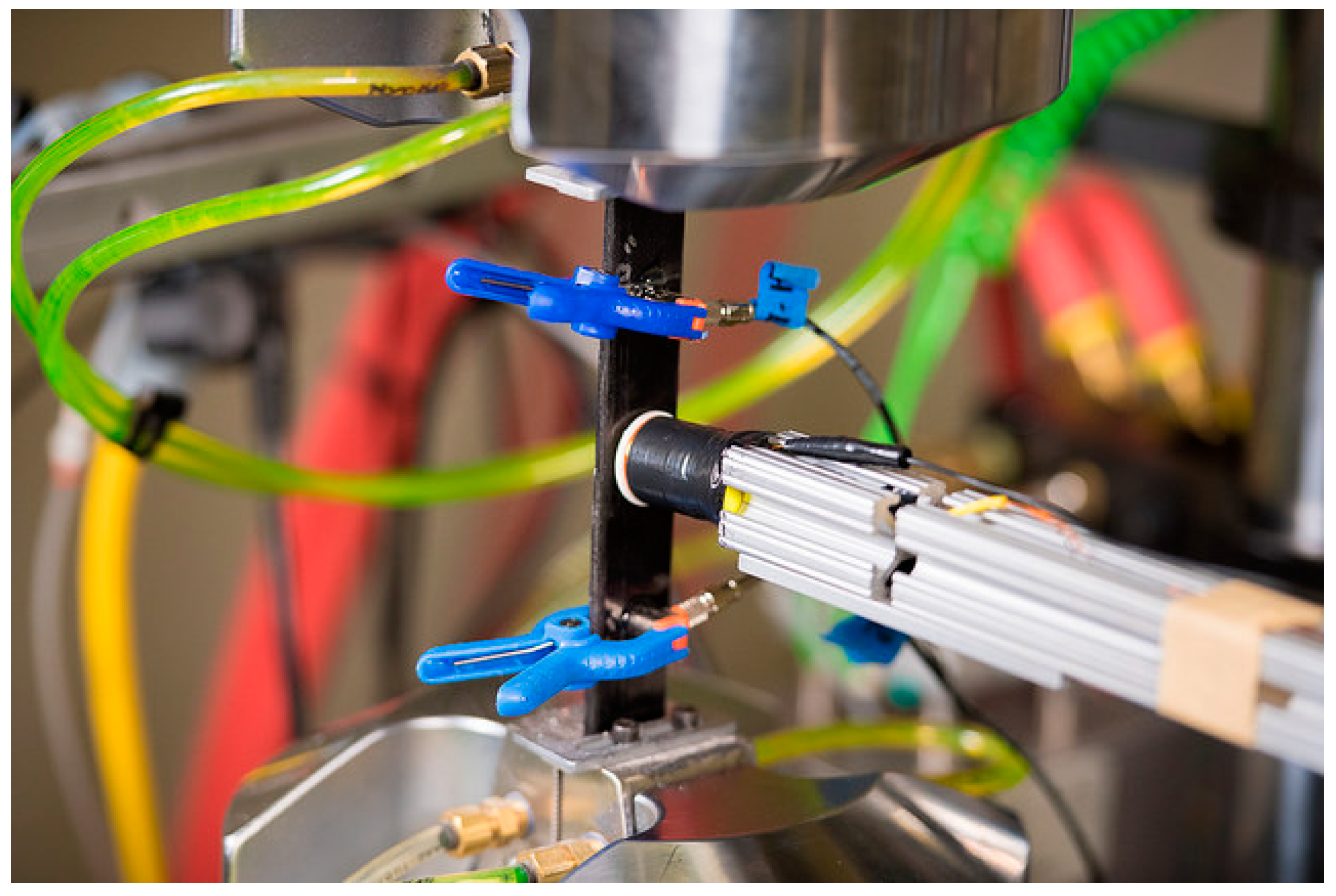

Figure 2 depicts the CFRP sample inserted into a Mechanical Testing System (MTS) machine for preparation of a quasi-static tension-tension test. The driving coil/pick-up coil sensor is mounted about 2 mm from the surface of the sample. The driving coil sends a magnetic field to the specimen while the pick-up coil receives the change in voltage signal/magnetic flux density.

3. Results and Discussion

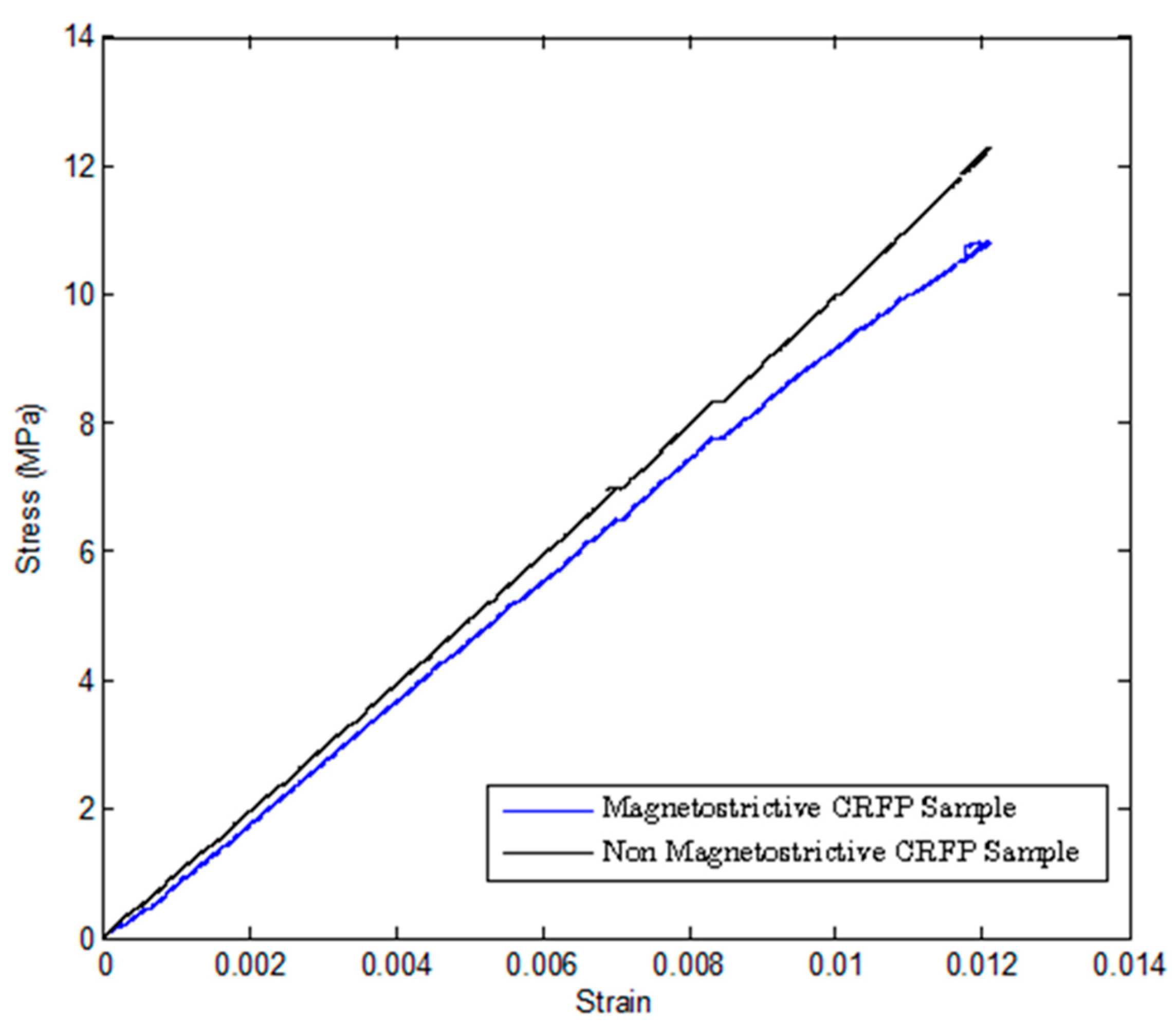

Figure 3 depicts a stress—strain curve of a magnetostrictive CFRP sample. The elastic modulus of the Non Magnetostrictive CFRP sample was 120 GPa, while the Elastic Modulus of the magnetostrictive sample is 115 GPa, which is a 7% decrease in the failure stress. This indicates a slight decrease in strength for the Terfenol-D composite samples. The slope of the linear elastic region of the baseline CFRP yielded a yield strength of 12.8 MPa. The specimen fractured in the middle of the gage with longitudinal splitting and tearing. The magnetostrictive specimens were also tested to failure in order to compare the yield strength of the pristine versus magnetostrictive.

The results from experimental tensile testing of unidirectional carbon fiber reinforced polymer composite specimens with and without magnetostrictive particles showed that the particle layer was slightly intrusive on the quasi-static tension properties of the beam. Based on the number of samples tested, the amount of change seen in both the tensile strength and the modulus was statistically negligible. Future tests will be conducted incorporating acoustic emission to further validate the correlation between the changes in magnetic flux intensity to the increase in microcrack density.

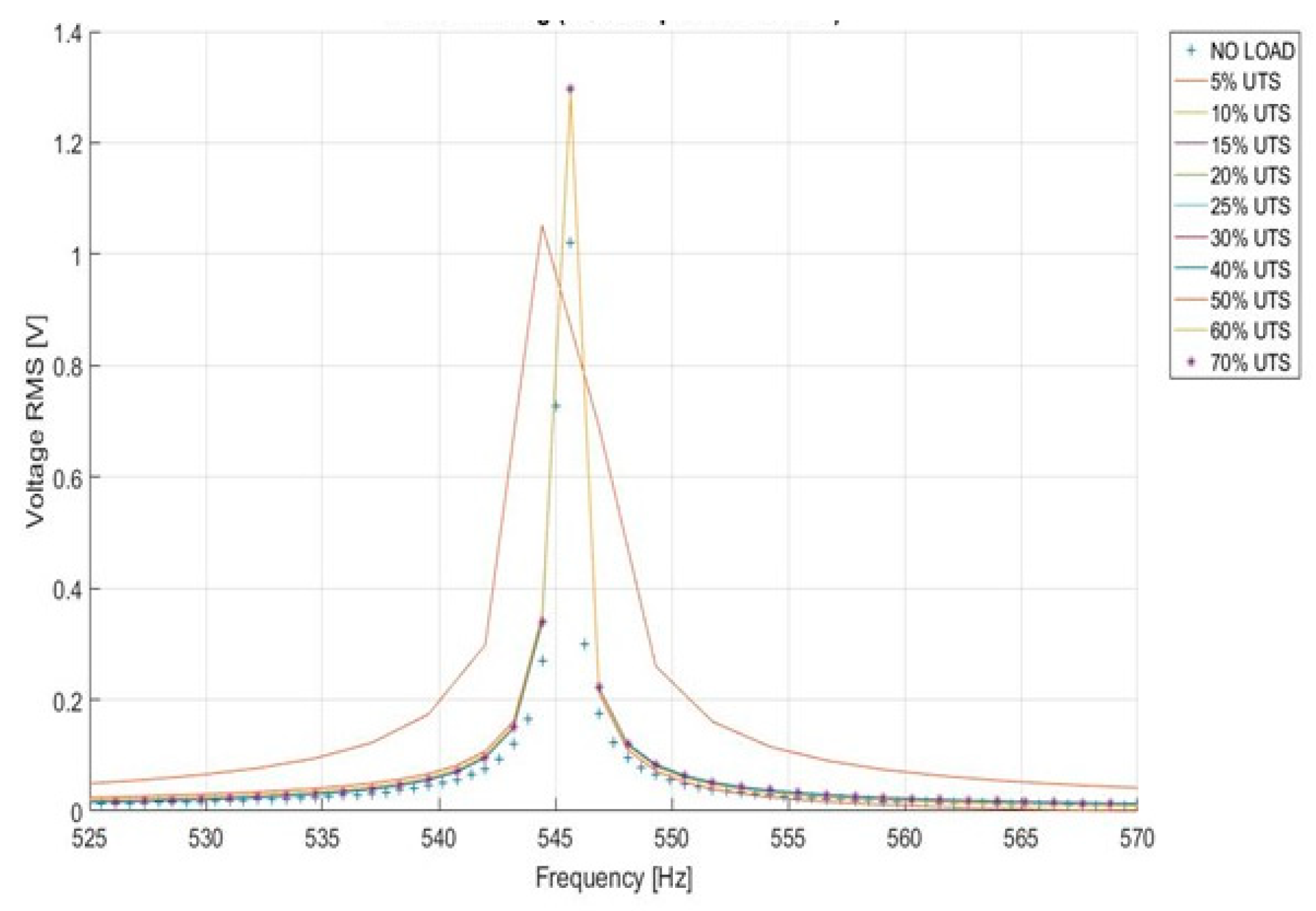

Initial tests were measured to find the ultimate tensile strength (UTS) of the 20 wt% specimens. Once the UTS was known, the next set of samples were loaded at 10% intervals, up to 70% of the UTS. At each load interval, the load was held while a signal was recorded for approximately 3 to 4 sec at a 5000 Hz sampling rate.

Figure 4 depicts the peak voltage of the sample as each load intervals were applied. At 50% applied load there is a decrease in voltage RMS (i.e., magnetic flux density) of the specimen as well as a slight frequency shift. There is a suspicion of micro cracking occurring at the 50% UTS applied load which would have shifted resonance frequency. On the contrary, as the UTS percentage increases to the 60% and 70% UTS the voltage RMS returns to the initial voltage RMS as recorded earlier in the loading regime. The presence of internal stresses in a structure could influence the domain boundary movement of magnetostrictive particles in the structure which can be detected by an external magnetic sensor thereby revealing the early stage of the initiation of damage.

4. Conclusions

In this study, magnetostrictive Terfenol-D powders were embedded in Terfenol-D composite specimens. This technique was performed to examine the changes in magnetostriction from tensile fatigue loading. The results from experimental tensile testing of (0/90) carbon fiber reinforced polymer composite specimens with and without magnetostrictive particles showed that the particle layer was minimally intrusive on the quasi-static tension properties of the beam. Based on the number of samples tested, the amount of change seen in both the tensile strength and the modulus was statistically negligible. Future tests will be conducted incorporating acoustic emission to further validate the correlation between the changes in magnetic flux intensity to the increase in microcrack density.