Overview of Current Challenges in Self-Pierce Riveting of Lightweight Materials †

Abstract

:1. Introduction

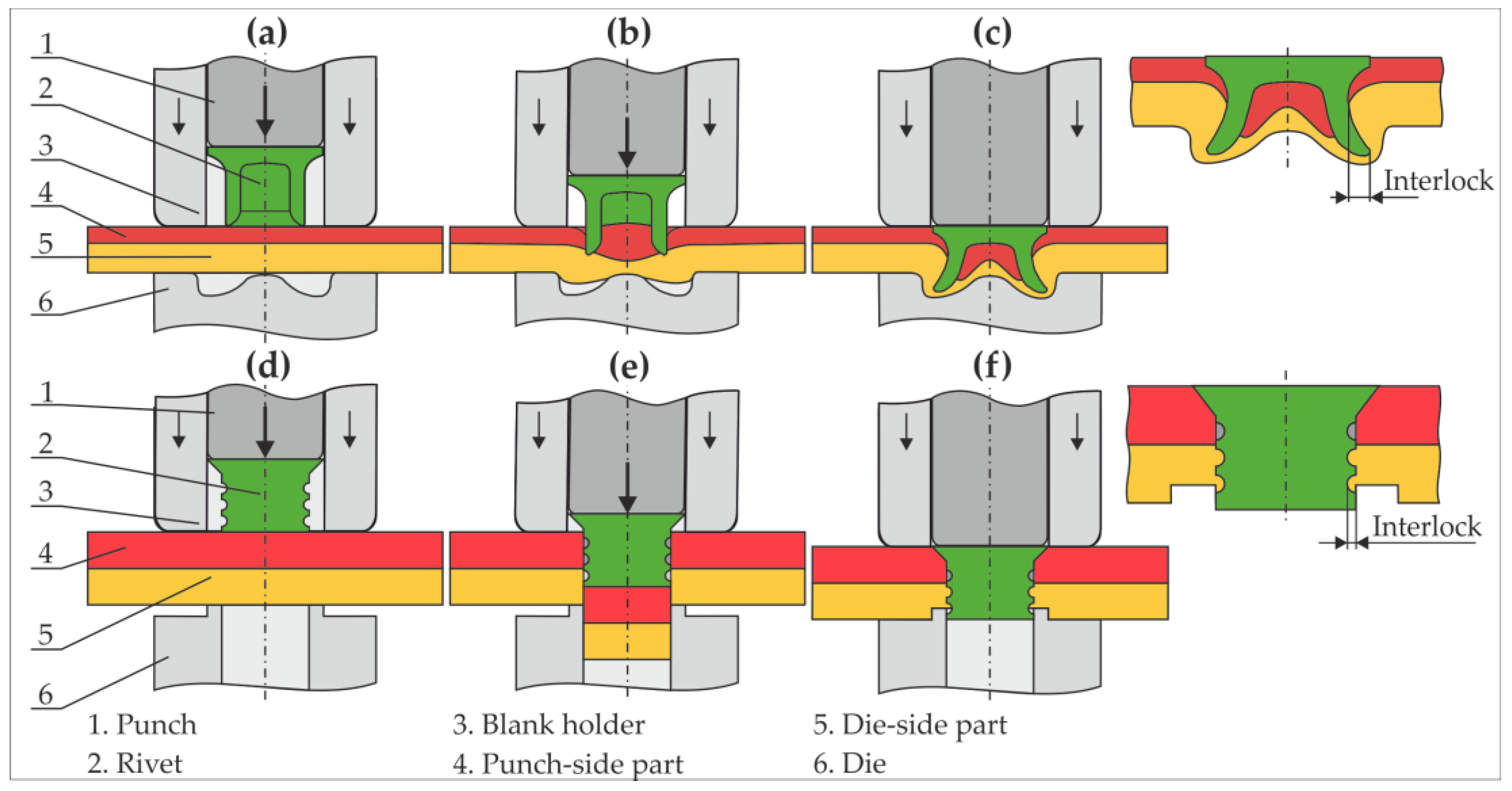

2. Joining Methods and Materials

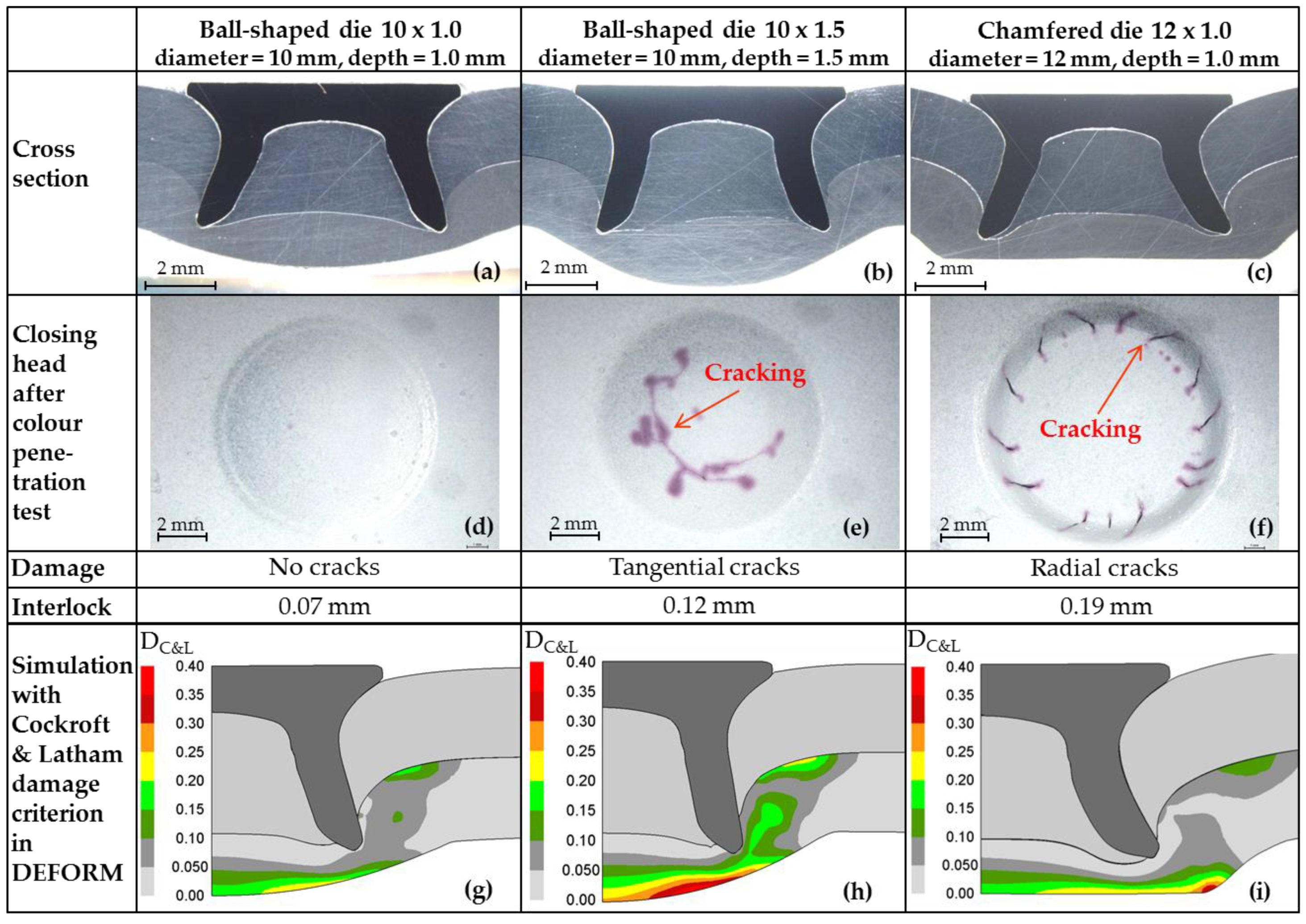

3. Self-Pierce Riveting with Semi-Tubular of Aluminum Die Casting

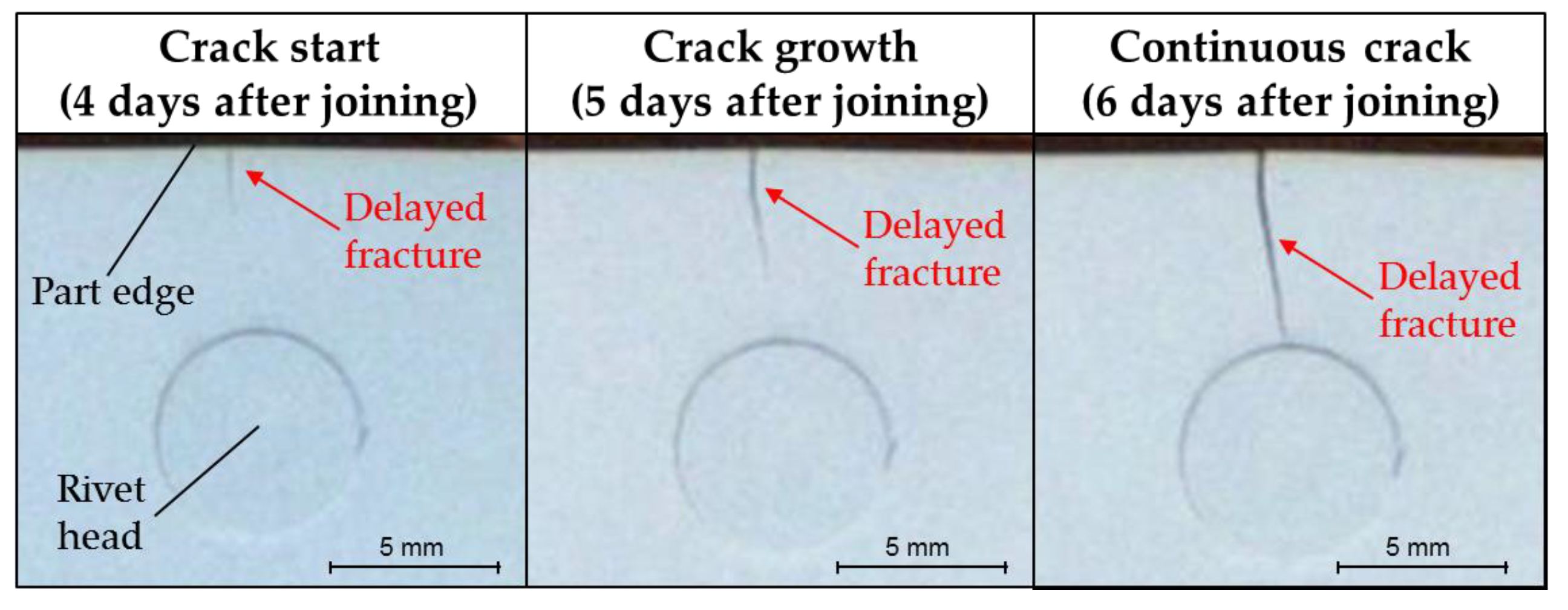

4. Self-Pierce Riveting with Solid Rivets of 7xxx Series Aluminum Alloys

- Improvement of the surface quality to avoid notches at the part edge, e.g., by laser cutting

- Local regression annealing of the joining zone of the 7xxxer aluminum part as pre-treatment before joining

- Immediate warming treatment of the joined parts, comparable to the cathodic dip painting furnace in automotive production

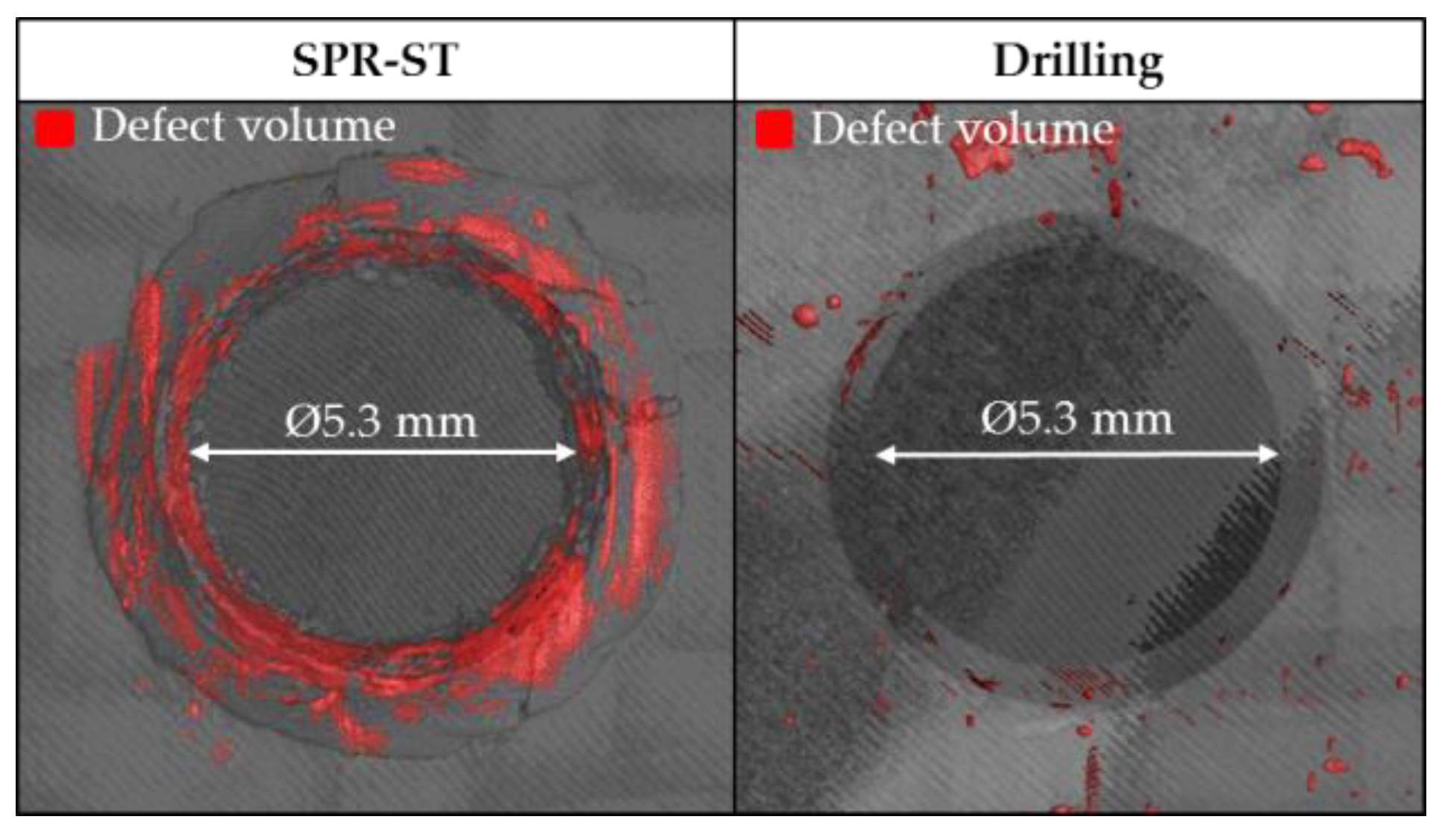

5. Self-Pierce Riveting with Semi-Tubular Rivets of Carbon Fiber Reinforced Plastics

Acknowledgments

Conflicts of Interest

References

- DVS Gemeinschaftsausschuss, Mechanisches Fügen. DVS/EFB Merkblatt 3410 Stanznieten-Überblick; DVS-Verlag: Düsseldorf, Germany, 2014. [Google Scholar]

- Jäckel, M.; Coppieters, S.; Hofmann, M.; Vandermeiren, N.; Landgrebe, D.; Debruyne, D.; Wallmersberger, T.; Faes, K. Mechanical joining of materials with limited ductility: Analysis of process-induced defects. AIP Conf. Proc. 2017, 1896, 110009. [Google Scholar]

- Böllhoff Group. Joining of Aluminium Cast with New Ring Groove Die. Available online: https://media.boellhoff.com/files/pdf12/rivset-ring-groove-die-6710-en.pdf (accessed on 14 February 2018).

- Behrens, B.A.; Bouguecha, A.; Vucetic, M.; Hübner, S.; Yilkiran, D.; Jin, Y.L.; Peshekhodov, I. FEA-Based Optimisation of a Clinching Process with a Closed Single-Part Die Aimed at Damage Minimization in CR240BH-AlSi10MnMg Joints. KEM 2015, 651–653, 1487–1492. [Google Scholar] [CrossRef]

- Briskham, P. Self-Pierce Riveting of High Strength Aluminium in Thick Stack Joints; Joining in Car Body Engineering: Bad Nauheim, Germany, 2015. [Google Scholar]

- Drossel, W.G.; Jäckel, M. New Die Concept for Self-Pierce Riveting Materials with Limited Ductility. KEM 2014, 611–612, 1452–1459. [Google Scholar] [CrossRef]

- Totten, G.E.; MacKenzie, D.S. Handbook of Aluminum; Dekker: New York, NY, USA, 2003. [Google Scholar]

- Jäckel, M.; Grimm, T.; Falk, T. Process Development for Mechanical Joining of 7xxx Series Aluminum Alloys; European Aluminium Congress: Düsseldorf, Germany, 2017. [Google Scholar]

- Landgrebe, D.; Jäckel, M.; Niegsch, R. Influence of Process Induced Damages on Joint Strength when Self-Pierce Riveting Carbon Fiber Reinforced Plastics with Aluminum. KEM 2015, 651–653, 1493–1498. [Google Scholar] [CrossRef]

- Drossel, W.-G.; Mauermann, R.; Grützner, R.; Mattheß, D. Numerical and Experimental Analysis of Self Piercing Riveting Process with Carbon Fiber-Reinforced Plastic and Aluminium Sheets. Key Eng. Mater. 2013, 554, 1045–1054. [Google Scholar] [CrossRef]

- Meschut, G.; Gude, M.; Augenthaler, F.; Geske, V. Evaluation of Damage to Carbon-fibre Composites Induced by Self-pierce Riveting. Procedia CIRP 2014, 18, 186–191. [Google Scholar] [CrossRef]

- Wilhelm, M.; Füssel, U.; Nancke, T.; Durschl, M. Herausforderungen CFK-Stahl-Mischbau: Quantifizierung von Delaminationen infolge des Umformtechnischen Fügens; DGZfP Jahrestagung: Dresden, Germany, 2013. [Google Scholar]

- Meschut, G.; Augenthaler, F. Schädigungsarmes Fügen von Faser-Kunststoff-Verbunden mit Metallischen Halbzeugen Mittels Neuartigem Stanznietverfahren; EFB: Hannover, Germany, 2018. [Google Scholar]

- Wanner, M.-C.; Fuchs, N.; Staschko, R.; Machens, M.; Ulbricht, V.; Kästner, M.; Müller, S. Simulation des Halbhohl-Stanznietprozesses von FVK durch Mehrskalige Modellierung; EFB: Hannover, Germany, 2015. [Google Scholar]

| Type | Material | Thickness t (mm) | Tensile strength RM (MPa) | Elongation A (%) | |

|---|---|---|---|---|---|

| Aluminum sheet | EN AW-6016 T4 | 1.2 | 233 | 24 | |

| EN AW-6016 T4 | 2.0 | 256 | 29 | ||

| EN AW-6016 T6 | 2.0 | 309 | 20 | ||

| EN AW-7021 T4 | 1.7 | 491 | 18 | ||

| Aluminum die casting | AlSi9Mn F | 2.0 | 311 | 9 | |

| Carbon fiber reinforced plastic | TEPEX Dynalite 201-C200 | 0° | 2.0 | 785 | 2 |

| 90° | 2.0 | 725 | 2 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jäckel, M.; Grimm, T.; Niegsch, R.; Drossel, W.-G. Overview of Current Challenges in Self-Pierce Riveting of Lightweight Materials. Proceedings 2018, 2, 384. https://doi.org/10.3390/ICEM18-05206

Jäckel M, Grimm T, Niegsch R, Drossel W-G. Overview of Current Challenges in Self-Pierce Riveting of Lightweight Materials. Proceedings. 2018; 2(8):384. https://doi.org/10.3390/ICEM18-05206

Chicago/Turabian StyleJäckel, Mathias, Thomas Grimm, Ronald Niegsch, and Welf-Guntram Drossel. 2018. "Overview of Current Challenges in Self-Pierce Riveting of Lightweight Materials" Proceedings 2, no. 8: 384. https://doi.org/10.3390/ICEM18-05206

APA StyleJäckel, M., Grimm, T., Niegsch, R., & Drossel, W.-G. (2018). Overview of Current Challenges in Self-Pierce Riveting of Lightweight Materials. Proceedings, 2(8), 384. https://doi.org/10.3390/ICEM18-05206