The Use of Particulate Injection Moulding for Fabrication of Sports and Leisure Equipment from Titanium Metals †

Abstract

:1. Introduction

2. Background

3. Metal Injection Moulding

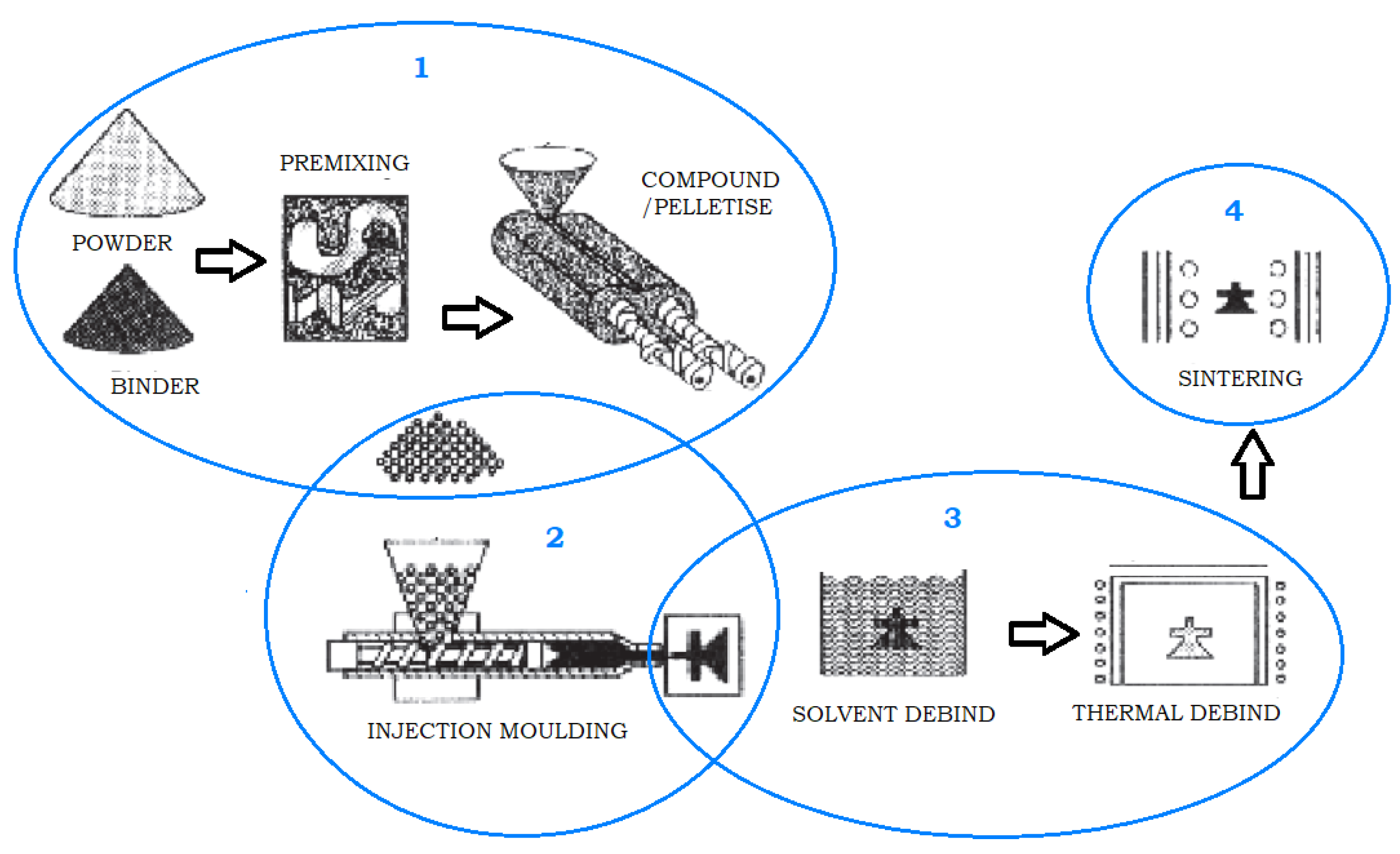

3.1. An Overview of the Fabrication Process

- Feedstock formulation

- 2.

- Greenpart formation

- 3.

- Brownpart formation

- 4.

- Consolidation

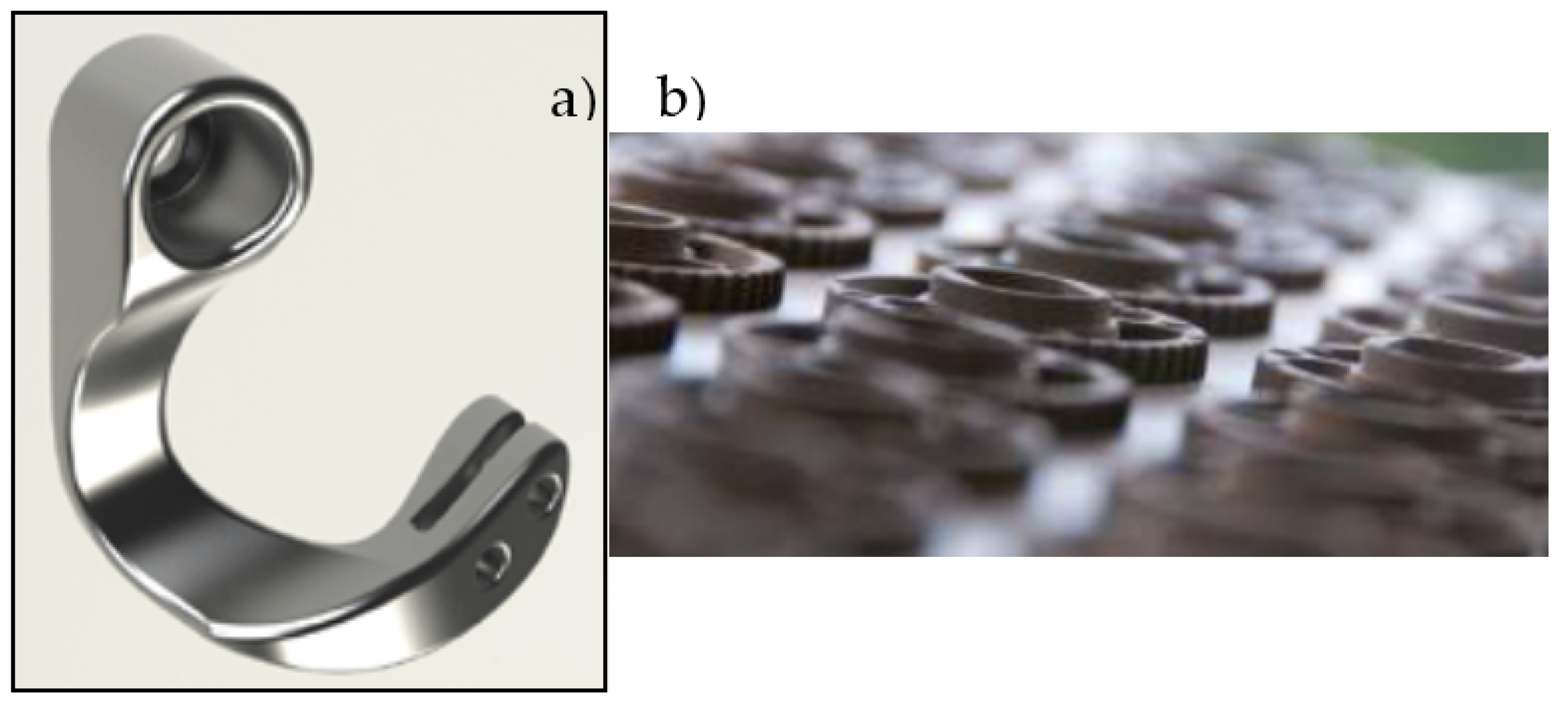

3.2. Component Design

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Boyer, R. Attributes, characteristics and applications of titanium and its alloys. J. Mater. 2010, 62, 21–24. [Google Scholar] [CrossRef]

- Easterling, K.E. Fundamentals of advanced materials. In Advanced Materials in Sports Equipment; Easterling, K.E., Ed.; Springer: Dordrecht, The Netherlands, 1993. [Google Scholar]

- Ewart, P. Micro-Mechanical Predictive Modelling as an Aid to CAD Based Analysis of Composite Sporting Equipment. Master’s Thesis, The University of Waikato, Hamilton, New Zealand, 2008. [Google Scholar]

- Franz, P.; Mukthar, A.; Downing, W.; Smith, G.; Jackson, B. Mechanical behaviour of gas nitrided Ti6Al4V bars produced by selective laser melting. In Powder Metallurgy of Titanium II; Ebel, T., Pyczak, F., Eds.; Trans Tech Publications Ltd: Pfaffikon, Switzerland, 2016. [Google Scholar]

- Caine, M.; Hopkinson, N.; Joku, U.; Lever, G. The feasibility of producing bespoke football boots comprising selective laser sintered outsoles. In The Impact of Technology on Sport; Subic, A., Ujihashi, S., Eds.; Australasian Sports Technology Alliancety. Ltd: Melbourne, Australia, 2005. [Google Scholar]

- German, R. Metal Injection Molding A Comprehensive MIM Design Guide; Metal Powder Indusrries Federation: Princeton, NJ, USA, 2011. [Google Scholar]

- German, R.; Bose, A. Injection Molding of Metals and Ceramics; Metal Powder Industries Federation: Princeton, NJ, USA, 1997. [Google Scholar]

- Heaney, D. Handbook of Metal Injection Molding, 1st ed.; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- Schwartzwalder, K. Refractory Body and Method of Making the Same. U.S. Patent 2122960, 5 July 1938. [Google Scholar]

- German, R. Final Report on the Workshop on Scientific Issues for Medical and Dental Applications of Micro/Nano Powder Injection Molding—Molding, Sintering, Modeling, and Commercial Applications; Metal Powder Industries Federation: Princeton, NJ, USA, 2009. [Google Scholar]

- ATW Companies. Profile. Available online: http://www.parmatech.com/parmatech/profile.html (accessed on 31 October 2011).

- Williams, N. Parmatech: The MIM industries first commercial producer, and still going strong. Powder Inject. Mould. Int. 2010, 4, 5. [Google Scholar]

- Bellamy, H.T. Production of Molded Metallic Articles. U.S. Patent 2397831, 2 April 1946. [Google Scholar]

- Ewart, P. The Formulation of Titanium—Based Metal Feedstocks and the Fabrication of Parts Using the Powder Injection Moulding Process. Ph.D. Thesis, The University of Waikato, Hamilton, New Zealand, 2015. [Google Scholar]

- Clarke, J.L. (Ed.) Structural Design of Polymer Composites: EUROCOMP Design Code and Handbook; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- U.S. Department of Defense. Polymer Matrix Composites: Materials, Usage, Design and Analysis. In Composite Materials Handbook; MIL-17; U.S. Department of Defense: Washington, DC, USA, 2002; Volume 3. [Google Scholar]

- Ebel, T. PMTi 2017 Xi’an: Titanium MIM comes of age as Additive Manufacturing drives awareness. Powder Inject. Mould. Int. 2017, 11, 61–73. [Google Scholar]

- Laschowski, B.; McPhee, J. Body segment parameters of Paralympic athletes from dual-energy X-ray absorptiometry. Sports Eng. 2016, 19, 155–162. [Google Scholar] [CrossRef]

- Cavacece, M.; Smarrini, F.; Valentini, P.P.; Vita, L. Kinematic and dynamic analysis of a sit-ski to improve vibrational comfort. Sports Eng. 2005, 8, 13–25. [Google Scholar] [CrossRef]

- Al Muderis, M.; Aschoff, H.H.; Bosley, B.; Raz, G.; Gerdesmeyer, L.; Burkett, B. Direct skeletal attachment prosthesis for the amputee athlete: The unknown potential. Sports Eng. 2016, 19, 141–145. [Google Scholar] [CrossRef]

- Ewart, P.D.; Ahn, S.; Zhang, D.; Park, S.J.; German, R. Poster Progam, PowderMet2011. In Proceedings of the International Conference on Powder Metallurgy and Particulate Materials, San Francisco, CA, USA, 18–21 May 2011. [Google Scholar]

- Adelman, S.; Otto, S.; Strangwood, M. Modelling Vibration Frequency and Stiffness Variations in Welded Ti-Based Alloy Golf Driver Heads. In The Engineering of Sport 6; Moritz, F., Haake, S., Eds.; Springer: Munich, Germany, 2006. [Google Scholar]

- Timms, T.; Mase, M.; West, C. Player Fitting of Golf Equipment Using a Calibration Club. In The Engineering of Sport 6; Moritz, F., Haake, S., Eds.; Springer: Munich, Germany, 2006. [Google Scholar]

- Daniel, T.; Kamperman, N.; Ajoku, U.; Hopkinson, N.; Caine, M. Benchmarking Stiffness of Current Sprint Spikes and Concept Selective Laser Sintered Nylon Outsoles. In The Engineering of Sport 6; Springer: Dordrecht, The Netherlans; Munich, Germany, 2006. [Google Scholar]

- Burgess, S.; Lodge, C. Optimisation of the chain drive system on sports motorcycles. Sports Eng. 2004, 7, 65–73. [Google Scholar] [CrossRef]

- Easterling, K.E. Skis. In Advanced Materials in Sports Equipment; Easterling, K.E., Ed.; Springer: Dordrecht, The Netherlans, 1993. [Google Scholar]

- James, D.A. The Application of Inertial Sensors in Elite Sports Monitoring. In The Engineering of Sport 6; Moritz, F., Haake, S., Eds.; Springer: Dordrecht, The Netherlans; Munich, Germany, 2006. [Google Scholar]

- Easterling, K.E. Bicycles. In Advanced Materials in Sports Equipment; Easterling, K.E., Ed.; Springer: Dordrecht, The Netherlans, 1993. [Google Scholar]

- Plueddeman, C. Superbike: So radical it was banned until Barcelona, the forkless, monocoque-framed Lotus Sport bicycle turns high-tech into Olympic gold. Popular Mechanics, February 1993. [Google Scholar]

- Moxson, V.S.; Froes, F.H. Components via Powder Metallurgy. J. Mater. 2001, 53, 39–41. [Google Scholar]

- Ewart, P.; Zhang, D.; Ahn, S. Removal of the Water Soluble Components from Titanium and Titanium Alloy Powder Compacts produced by MIM. In Powder Metallurgy of Titanium; Qian, M., Ed.; Trans Tech Publications: Brisbane, Australia, 2012; p. 6. [Google Scholar]

- Ewart, P.; Jull, H.; Kunnemeyer, R.; Schaare, P. Identification of contamination levels and the microstructure of metal injection moulded titanium. Key Eng. Mater. 2016, 704, 161–169. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ewart, P.D. The Use of Particulate Injection Moulding for Fabrication of Sports and Leisure Equipment from Titanium Metals. Proceedings 2018, 2, 254. https://doi.org/10.3390/proceedings2060254

Ewart PD. The Use of Particulate Injection Moulding for Fabrication of Sports and Leisure Equipment from Titanium Metals. Proceedings. 2018; 2(6):254. https://doi.org/10.3390/proceedings2060254

Chicago/Turabian StyleEwart, Paul D. 2018. "The Use of Particulate Injection Moulding for Fabrication of Sports and Leisure Equipment from Titanium Metals" Proceedings 2, no. 6: 254. https://doi.org/10.3390/proceedings2060254

APA StyleEwart, P. D. (2018). The Use of Particulate Injection Moulding for Fabrication of Sports and Leisure Equipment from Titanium Metals. Proceedings, 2(6), 254. https://doi.org/10.3390/proceedings2060254