Study on the Transient Performance of a Liquid Desiccant Dehumidifier under Changing Boundary Conditions †

Abstract

:1. Introduction

2. Development of the Dynamic Model

3. Simulation Results

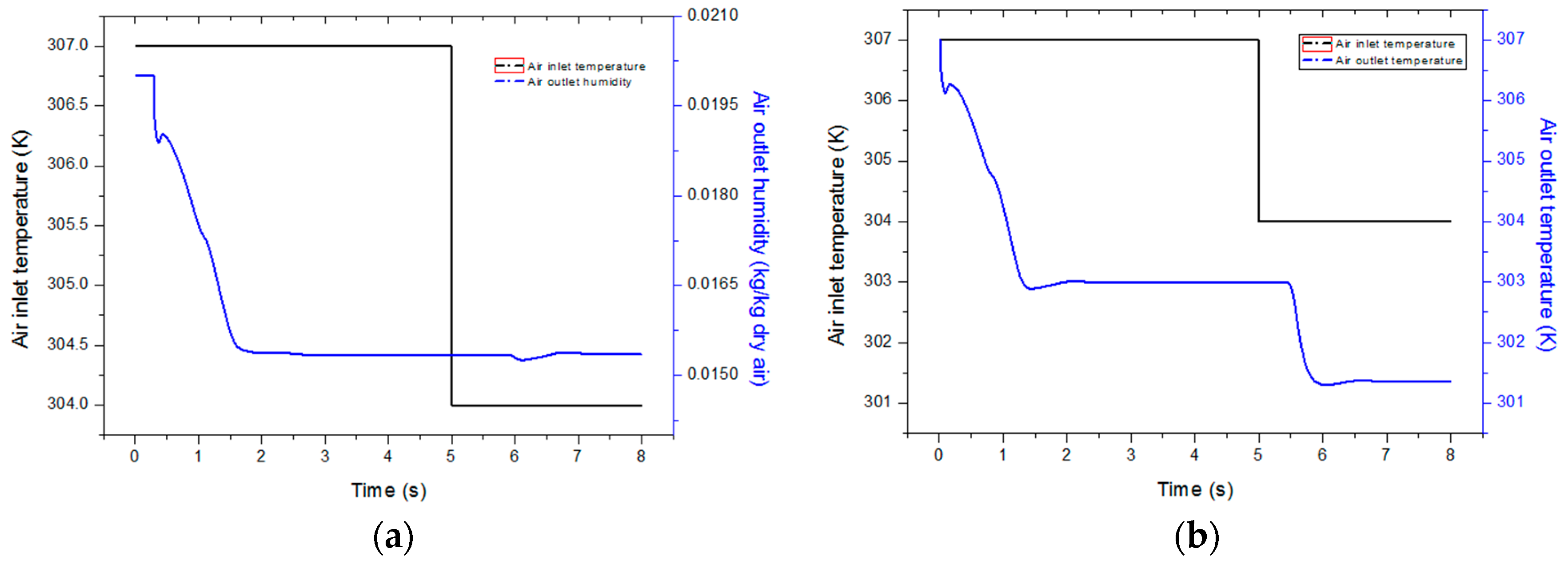

3.1. Step Change of Air Inlet Temperature

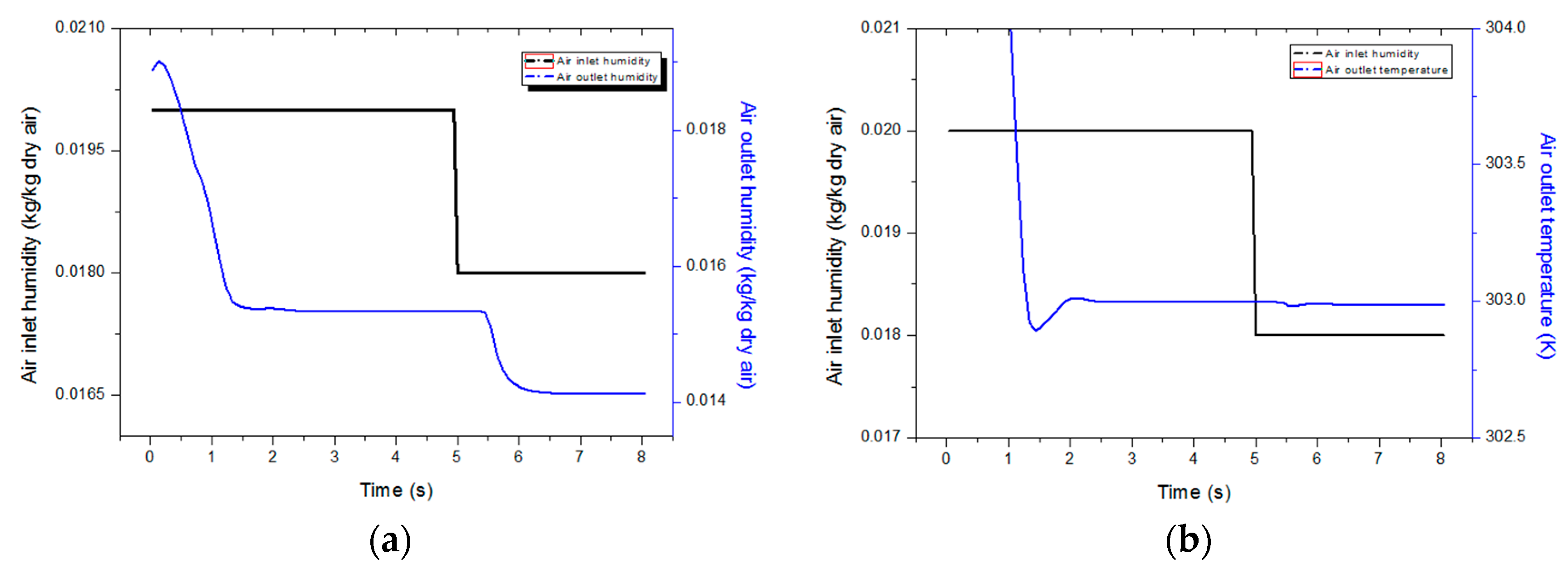

3.2. Step Change of Air Humidity

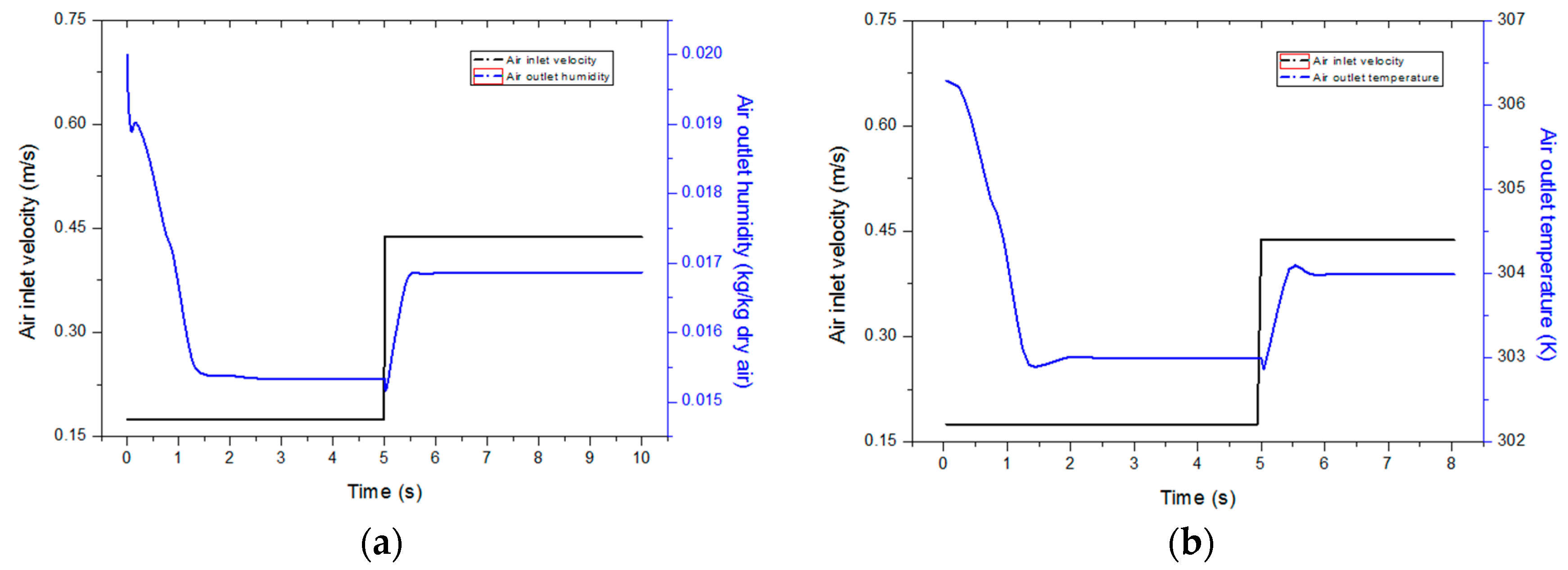

3.3. Step Change of Air Inlet Velocity

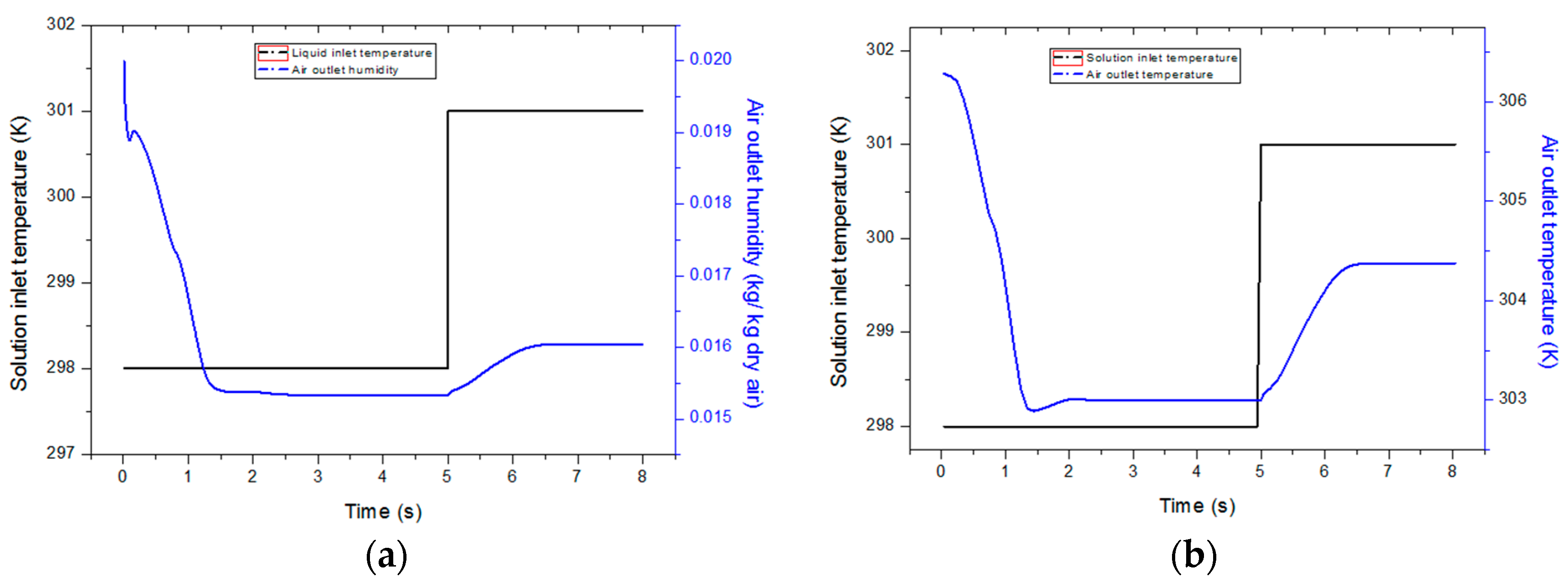

3.4. Step Change of Solution Temperature

3.5. Step Change of Solution Concentration

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Ge, G.M.; Xiao, F.; Niu, X.F. Control strategies for a liquid desiccant air-conditioning system. Energy Build. 2011, 43, 1499–1507. [Google Scholar] [CrossRef]

- Luo, Y.M.; Yang, H.X.; Lu, L. Liquid desiccant dehumidifier: Development of a new performance predication model based on CFD. Int. J. Heat Mass Transf. 2014, 69, 408–416. [Google Scholar] [CrossRef]

- Gandhidasan, P.; Al-Farayedhi, A.A.; Antar, M.A. Investigation of heat and mass transfer in a gauze-type structured packing liquid desiccant dehumidifier. Int. J. Energy Res. 2002, 26, 1035–1044. [Google Scholar] [CrossRef]

- Peng, S.W.; Pan, Z.M. Heat and mass transfer in liquid desiccant air-conditioning process at low flow conditions. Commun. Nonlinear Sci. Numer. Simul. 2009, 14, 3599–3607. [Google Scholar] [CrossRef]

| Air | Desiccant | |||||

|---|---|---|---|---|---|---|

| Parameter | Ta,in (K) | xa,in (g/kg dry air) | ua,in (m·s−1) | Ts,in (K) | xs,in (%) | us,in (m·s−1) |

| Initial value | 307 | 2.0 | 0.2 | 298 | 30.0 | 0.07 |

| Final value | 304 | 1.8 | 0.5 | 301 | 32.0 | 0.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, D.; Chen, Y.; Luo, Y. Study on the Transient Performance of a Liquid Desiccant Dehumidifier under Changing Boundary Conditions. Proceedings 2018, 2, 1373. https://doi.org/10.3390/proceedings2221373

Zhong D, Chen Y, Luo Y. Study on the Transient Performance of a Liquid Desiccant Dehumidifier under Changing Boundary Conditions. Proceedings. 2018; 2(22):1373. https://doi.org/10.3390/proceedings2221373

Chicago/Turabian StyleZhong, Dan, Yi Chen, and Yimo Luo. 2018. "Study on the Transient Performance of a Liquid Desiccant Dehumidifier under Changing Boundary Conditions" Proceedings 2, no. 22: 1373. https://doi.org/10.3390/proceedings2221373

APA StyleZhong, D., Chen, Y., & Luo, Y. (2018). Study on the Transient Performance of a Liquid Desiccant Dehumidifier under Changing Boundary Conditions. Proceedings, 2(22), 1373. https://doi.org/10.3390/proceedings2221373