Methodological Evaluation of Family House with Different Thermo-Physical Parameters of Building Materials †

Abstract

:1. Introduction

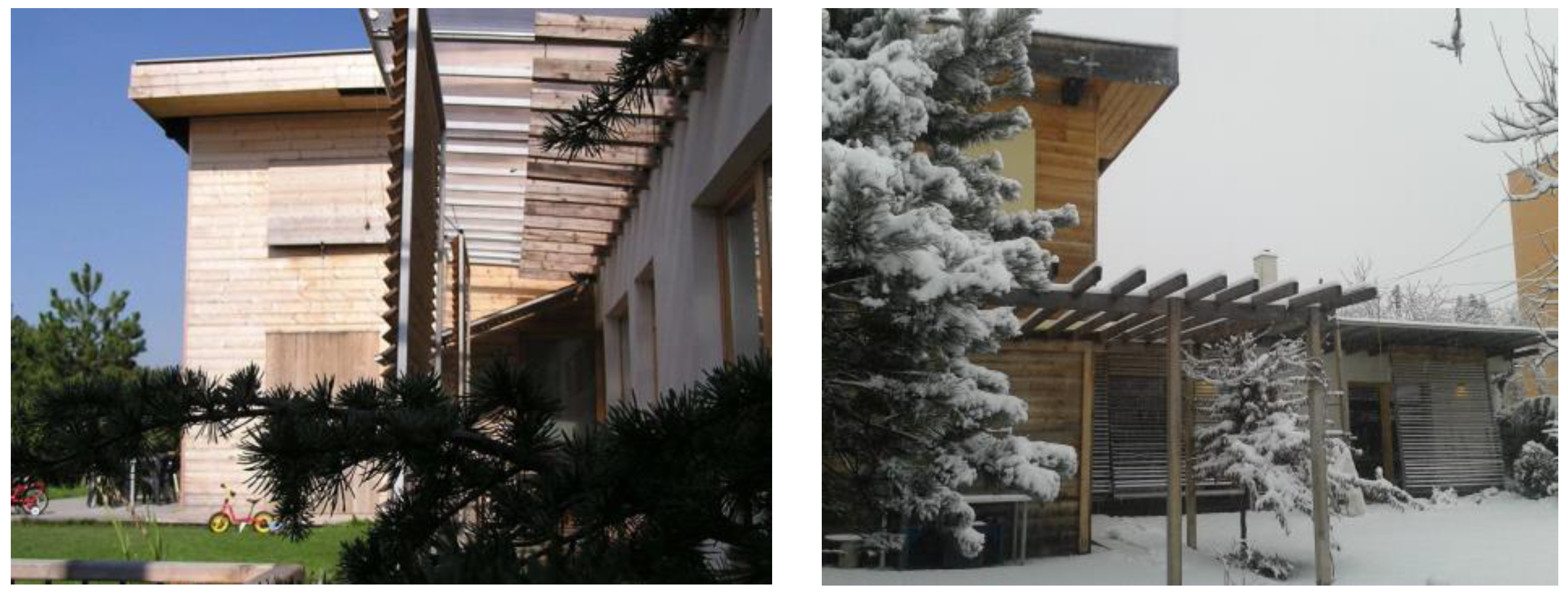

2. Design of Assessed Family House

Material Compositions

3. Experimental Method

4. Results

5. Conclusions

Acknowledgments

References

- Garcia-Ceballos, L.; de Andres-Díaz, J.R.; Contreras-Lopez, M.A. Life cycle study of different constructive solutions for building enclosures. Sci. Total Environ. 2018, 626, 1167–1174. [Google Scholar] [CrossRef] [PubMed]

- Tumminia, G.; Guarino, F.; Longo, S.; Ferraro, M.; Cellura, M. Life cycle energy performances and environmental impacts of a prefabricated building module. Renew. Sustain. Energy Rev. 2018, 92, 272–283. [Google Scholar] [CrossRef]

- Skombar, P.; Rackova, J. Family House in Rozhanove. Available online: http://www.zelenarchitektura.sk (accessed on 1 July 2012).

- Passive House. Available online: http://www.pasivnydom.tvojdom.eu/ (accessed on 2 December 2011).

- TVOJ DOM.EU: TVOJDOM je teraz aj ZDRAVYDOM.SK na Východe. Available online: http://www.tvojdom.eu/ (accessed on 1 July 2012).

- eTool. eToolLCD Software. Available online: https://etoolglobal.com/ (accessed on 1 January 2018).

- Vilcekova, S.; Culakova, M.; Kridlova Burdova, E.; Katunska, J. Energy and Environmental Evaluation of Non-Transparent Constructions of Building Envelope for Wooden Houses. Energies 2015, 8, 11047–11075. [Google Scholar] [CrossRef]

| Alternative 1 | d [m] | λ [W/m·K] | c [J/kg·K] | Alternative 2 | d [m] | λ [W/m·K] | c [J/kg·K] |

|---|---|---|---|---|---|---|---|

| PE foil | 0.0005 | 0.350 | 1470 | Plasterboard | 0.0125 | 0.220 | 1470 |

| Mineral wool | 0.100 | 0.0400 | 840 | Cellulose | 0.100 | 0.045 | 2020 |

| Vapor barrier | 0.0002 | 0.390 | 1700 | Vapor barrier | 0.0002 | 0.390 | 1700 |

| Mineral wool | 0.140 | 0.0400 | 840 | Cellulose | 0.240 | 0.045 | 2020 |

| Wooden boards | 0.025 | 0.180 | 2510 | Wooden boards | 0.0250 | 0.180 | 2510 |

| PE foil | 0.0005 | 0.350 | 1470 | PE foil | 0.0005 | 0.350 | 1470 |

| Reinforced concrete | 0.060 | 1.430 | 1020 | Reinforced concrete | 0.060 | 1.430 | 1020 |

| EPS | 0.300 | 0.037 | 1270 | EPS | 0.300 | 0.037 | 1270 |

| Vapor barrier | 0.0012 | 0.350 | 960 | Vapor barrier | 0.0012 | 0.350 | 960 |

| Substrate | 0.300 | 2.300 | 920 | Substrate | 0.300 | 2.300 | 920 |

| Alternative 1 | d [m] | λ [W/m.K] | c [J/kg.K] | Alternative 2 | d [m] | λ [W/m.K] | c [J/kg.K] |

|---|---|---|---|---|---|---|---|

| Plasterboard | 0.0125 | 0.220 | 1060 | Plasterboard | 0.0125 | 0.220 | 1060 |

| Mineral wool | 0.050 | 0.0400 | 840 | Wooden-fiber insulation | 0.050 | 0.038 | 2000 |

| Vapor barrier | 0.0002 | 0.390 | 1700 | Vapor barrier | 0.0002 | 0.390 | 1700 |

| Mineral wool | 0.200 | 0.040 | 840 | Wooden-fiber insulation | 0.200 | 0.038 | 2000 |

| OSB BOARD | 0.018 | 0.130 | 1700 | OSB board | 0.018 | 0.130 | 1700 |

| Mineral wool | 0.200 | 0.038 | 840 | Wooden-fiber insulation | 0.200 | 0.038 | 2000 |

| Wooden panel | 0.025 | 0.180 | 2510 | Wooden panel | 0.025 | 0.180 | 2510 |

| Alternative 1 | d [m] | λ [W/m·K] | c [J/kg·K] | Alternative 2 | d [m] | λ [W/m·K] | c [J/kg·K] |

|---|---|---|---|---|---|---|---|

| Wooden boards | 0.025 | 0.180 | 2510 | Wooden boards | 0.025 | 0.180 | 2510 |

| Concrete | 0.100 | 1.230 | 1020 | Concrete | 0.100 | 1.230 | 1020 |

| Sand | 0.300 | 0.950 | 960 | Sand | 0.300 | 0.950 | 960 |

| EPS | 0.300 | 0.037 | 1270 | Celulose | 0.300 | 0.045 | 2020 |

| Damp-proofing | 0.0015 | 0.350 | 960 | Damp-proofing | 0.0015 | 0.350 | 960 |

| Assessed characteristic impacts | Alt. 1 | Alt. 2 | Savings | ||

|---|---|---|---|---|---|

| Global warming potential | GWP | kg CO2eq | 3680 | 3490 | 6% |

| Acidification potential | AP | kg SO2eq | 59.8 | 26.7 | 24% |

| Eutrophication potential | EP | kg PO43−eq | 50.2 | 20.5 | 44% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vilcekova, S.; Monokova, A.; Meciarova, L.; Selecka, I. Methodological Evaluation of Family House with Different Thermo-Physical Parameters of Building Materials. Proceedings 2018, 2, 1277. https://doi.org/10.3390/proceedings2201277

Vilcekova S, Monokova A, Meciarova L, Selecka I. Methodological Evaluation of Family House with Different Thermo-Physical Parameters of Building Materials. Proceedings. 2018; 2(20):1277. https://doi.org/10.3390/proceedings2201277

Chicago/Turabian StyleVilcekova, Silvia, Andrea Monokova, Ludmila Meciarova, and Iveta Selecka. 2018. "Methodological Evaluation of Family House with Different Thermo-Physical Parameters of Building Materials" Proceedings 2, no. 20: 1277. https://doi.org/10.3390/proceedings2201277

APA StyleVilcekova, S., Monokova, A., Meciarova, L., & Selecka, I. (2018). Methodological Evaluation of Family House with Different Thermo-Physical Parameters of Building Materials. Proceedings, 2(20), 1277. https://doi.org/10.3390/proceedings2201277