Displacement Sensor with Inherent Read-Out Circuit Using Water-Gated Field Effect Transistor (WG-FET) †

Abstract

:1. Introduction

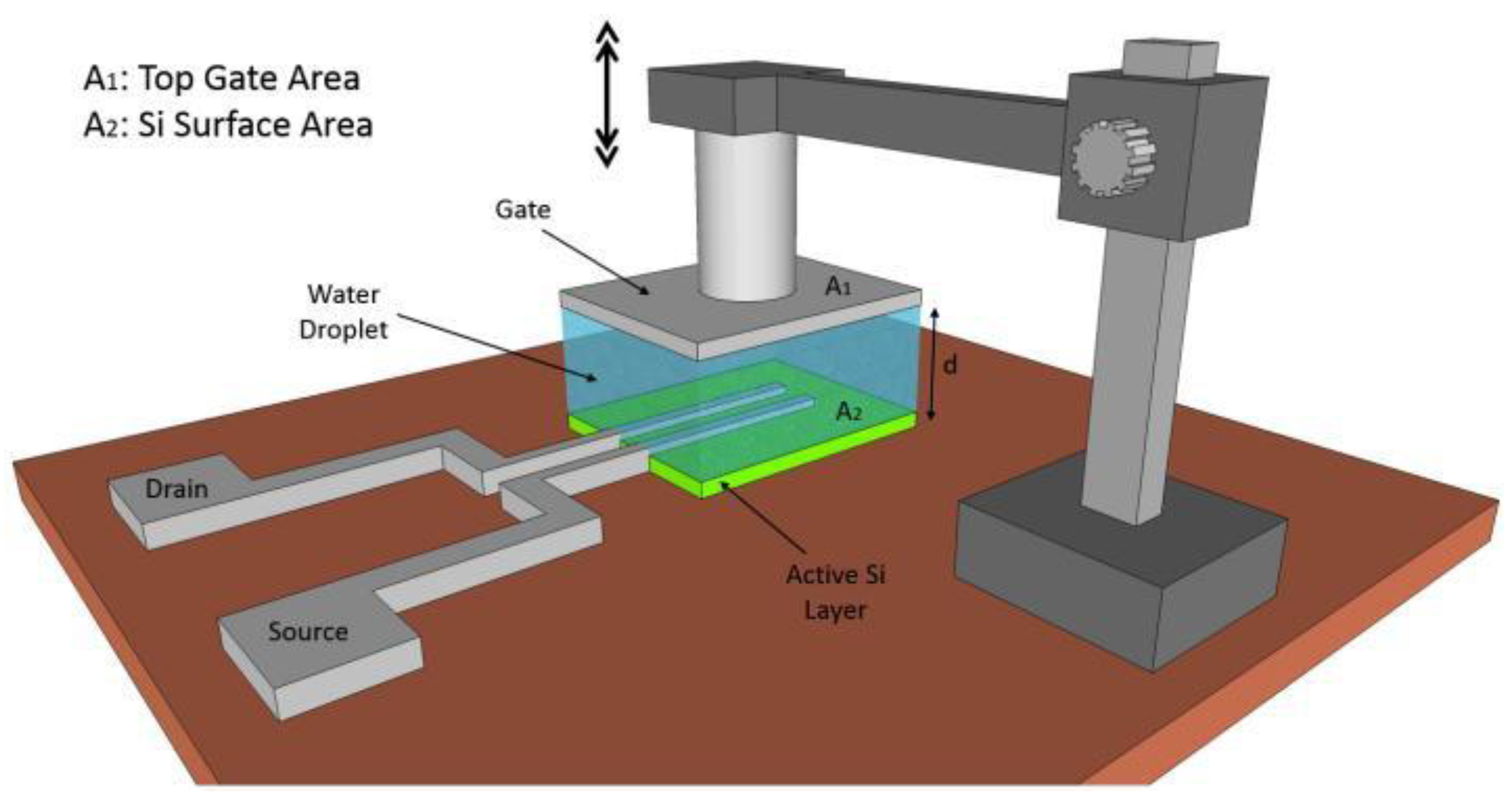

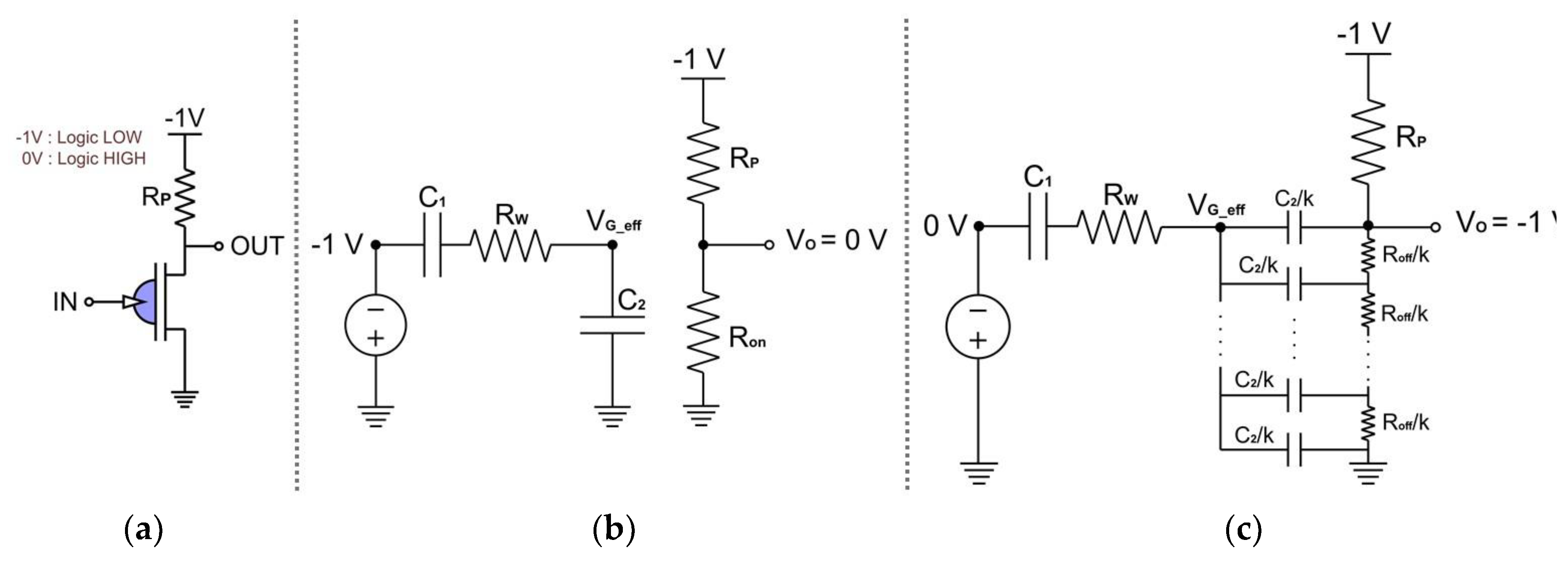

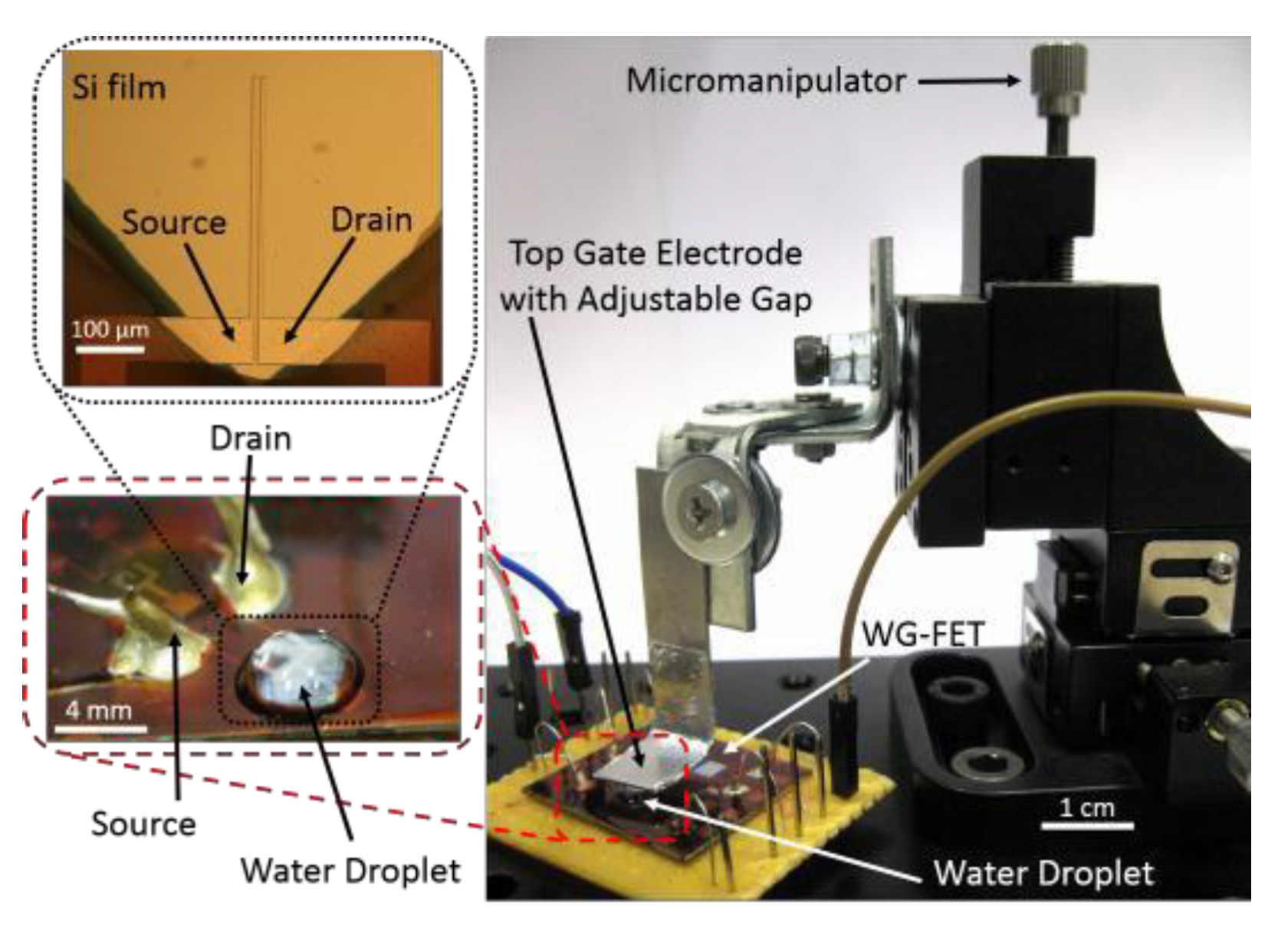

2. Materials and Methods

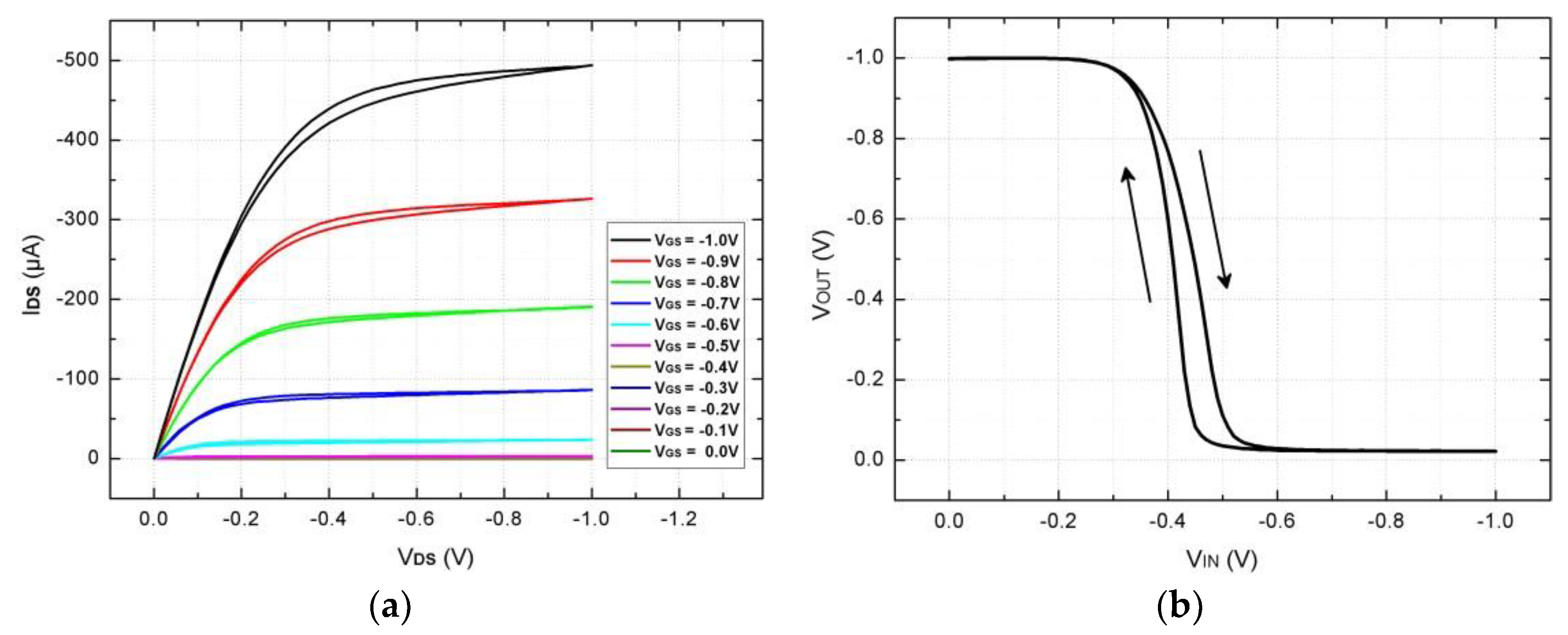

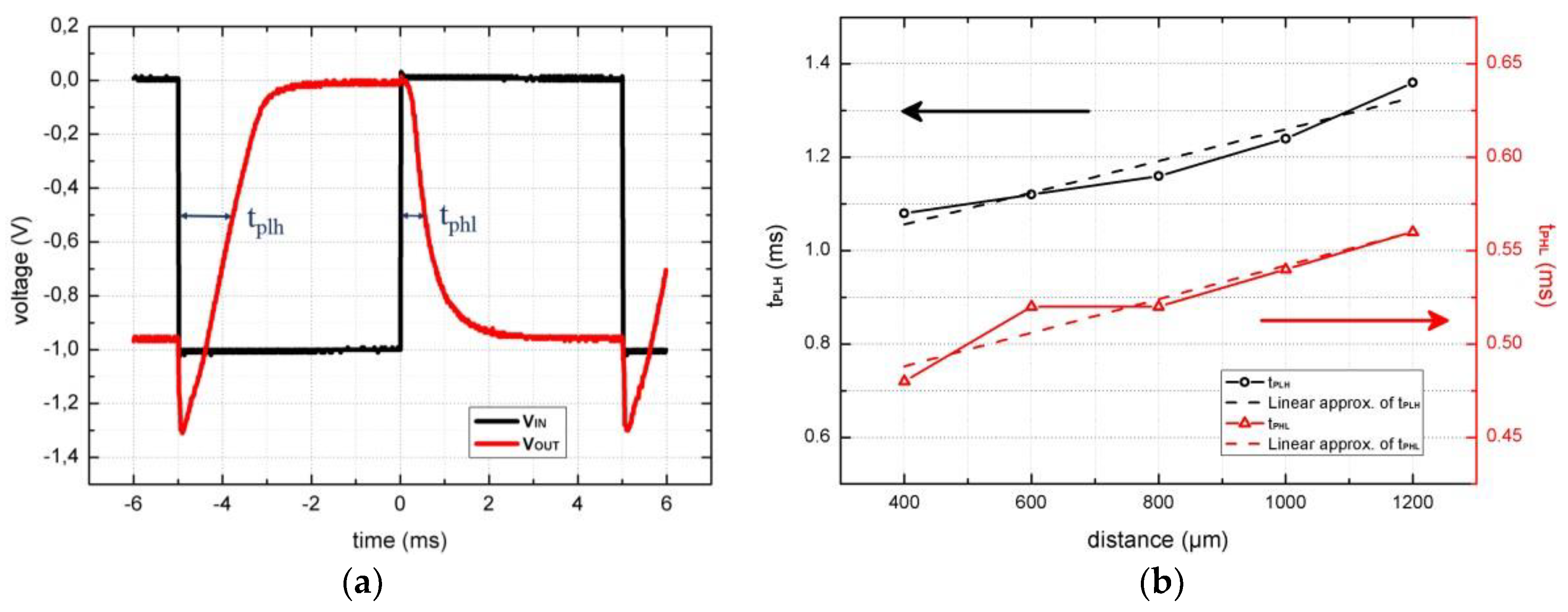

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Ertop, O.; Sonmez, B.G.; Mutlu, S. Realization of planar water-gated field effect transistor (WG-FET) using 16-nm-thick single crystalline Si film. Procedia Eng. 2014, 87, 76–79. [Google Scholar] [CrossRef]

- Sonmez, B.G.; Ertop, O.; Mutlu, S. Improved repeatability in planar water-gated field effect transistor (WG-FET) with 16-nm-thick single crystalline Si film. Procedia Eng. 2016, 168, 1739–1742. [Google Scholar] [CrossRef]

- Ertop, O.; Sonmez, B.G.; Mutlu, S. Investigation of the salt concentration dependence of water-gated field effect transistors (WG-FET) using 16-nm-thick single crystalline Si film. Proceedings 2017, 1, 486. [Google Scholar] [CrossRef]

- Sonmez, B.G.; Ertop, O.; Mutlu, S. Modelling and realization of a water-gated field effect transistor (WG-FET) using 16-nm-thick mono-Si film. Sci. Rep. 2017, 7, 12190. [Google Scholar] [CrossRef] [PubMed]

- Chossat, J.; Park, Y.; Wood, R.J.; Duchaine, V. A soft strain sensor based on ionic and metal liquids. IEEE Sens. J. 2013, 13, 3405–3414. [Google Scholar] [CrossRef]

- Yeo, C.Y.; Yu, J.; Shang, M.; Loh, K.P.; Lim, C.T. Highly Flexible Graphene Oxide Nanosuspension Liquid-Based Microfluidic Tactile Sensor. Small 2016, 12, 1593–1604. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ertop, O.; Sonmez, B.G.; Mutlu, S. Displacement Sensor with Inherent Read-Out Circuit Using Water-Gated Field Effect Transistor (WG-FET). Proceedings 2018, 2, 926. https://doi.org/10.3390/proceedings2130926

Ertop O, Sonmez BG, Mutlu S. Displacement Sensor with Inherent Read-Out Circuit Using Water-Gated Field Effect Transistor (WG-FET). Proceedings. 2018; 2(13):926. https://doi.org/10.3390/proceedings2130926

Chicago/Turabian StyleErtop, Ozan, Bedri Gurkan Sonmez, and Senol Mutlu. 2018. "Displacement Sensor with Inherent Read-Out Circuit Using Water-Gated Field Effect Transistor (WG-FET)" Proceedings 2, no. 13: 926. https://doi.org/10.3390/proceedings2130926

APA StyleErtop, O., Sonmez, B. G., & Mutlu, S. (2018). Displacement Sensor with Inherent Read-Out Circuit Using Water-Gated Field Effect Transistor (WG-FET). Proceedings, 2(13), 926. https://doi.org/10.3390/proceedings2130926