As emissions limits are tightened, both in relation to transportation and domestic/local heat/power production, and their fulfilment also under real-world conditions (not only for type approval) being enforced, close control of both the combustion process as such and the exhaust/flue gas after-treatment systems is required. In order to ensure efficient combustion and after-treatment system control under different conditions as well as its proper function over time, accurate and reliable monitoring of ever smaller concentrations of exhaust/flue gas components such as nitrogen oxides (NOx), hydrocarbons (HCs), carbon monoxide (CO), oxygen (O2) and ammonia (NH3) is required. Generally being fairly small-scale but large-volume applications the means, besides exhibiting accuracy and long-term reliable performance, also have to be cost-efficient, thereby rendering in-situ positioned solid-state sensors one of the currently most attractive options.

In addition to solid electrolyte based gas sensors, such as the lambda-, wide band oxygen- and NO

x-sensors [

1] in commercial use today, and the resistive-type metal oxide semiconductor sensors (e.g., the TiO

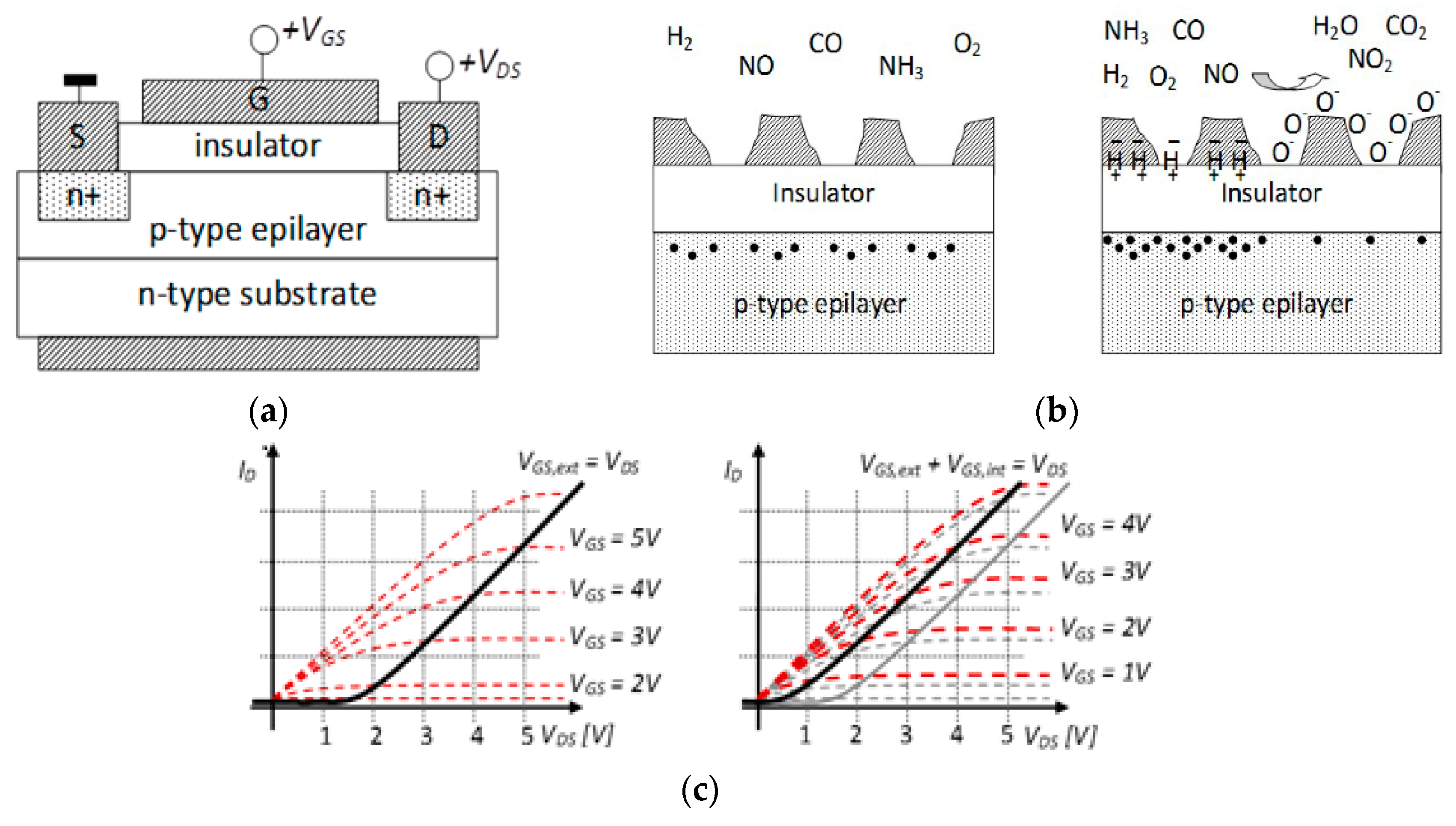

2 based MOS sensor applied as lambda-probe in automotive engine control) also Field Effect Transistor (FET) based sensors employing the wide band gap semiconductor Silicon Carbide (SiC), see

Figure 1, have, at least among economically viable solid-state sensors, been considered for emissions monitoring in automotive applications (SiC FET sensors for combustion control are commercially available for certain applications) [

2]. An example of a basic SiC FET gas sensor is displayed in

Figure 1a. By applying as gate contact in the MOSFET (Metal Oxide Semiconductor Field Effect Transistor) device a material which upon interaction with one or more gaseous substances can give rise to a modulation of the gate to substrate electric field, FET based gas sensors can be fabricated. When, for example, a MOSFET device employing a platinum (Pt) gate is exposed to a hydrogen-containing substance, atomic hydrogen may be generated through dissociative adsorption on the catalytic metal surface and subsequently diffuse through the thin Pt film to adsorb on top of oxygen atoms in the surface of the oxide, see

Figure 1b.The resulting hydroxide groups give rise to a change in polarization of the metal/oxide interface, affecting the gate-to-semiconductor electric field. This hydrogen-mediated direct detection of hydrogen-containing substances, such as hydrocarbons and ammonia, is an attractive feature as the field-effect sensors, in contrast to sensors based on oxygen-mediated indirect detection of these substances (through red-ox reactions consuming oxygen anions), can be easily rendered insensitive to changes in e.g., exhaust and flue gas O

2- and NO

x-levels and so exhibit better selectivity to e.g., ammonia (facilitating better separation between ammonia and NOx than the solid electrolyte-based NO

x sensor in widespread use today). As for the mechanisms behind the detection of CO employing FE sensors, see [

2]. The change in gate-to-semiconductor electric field in turn modulates the number of charge carriers in the top part of the semiconductor and thus the Ids/Vds-characteristics of the device (

Figure 1c). Either the change in drain current upon gas exposure when supplying a constant voltage or vice versa is measured.

Following developments over the last few years in improving the sensor device materials’ stability at elevated temperatures [

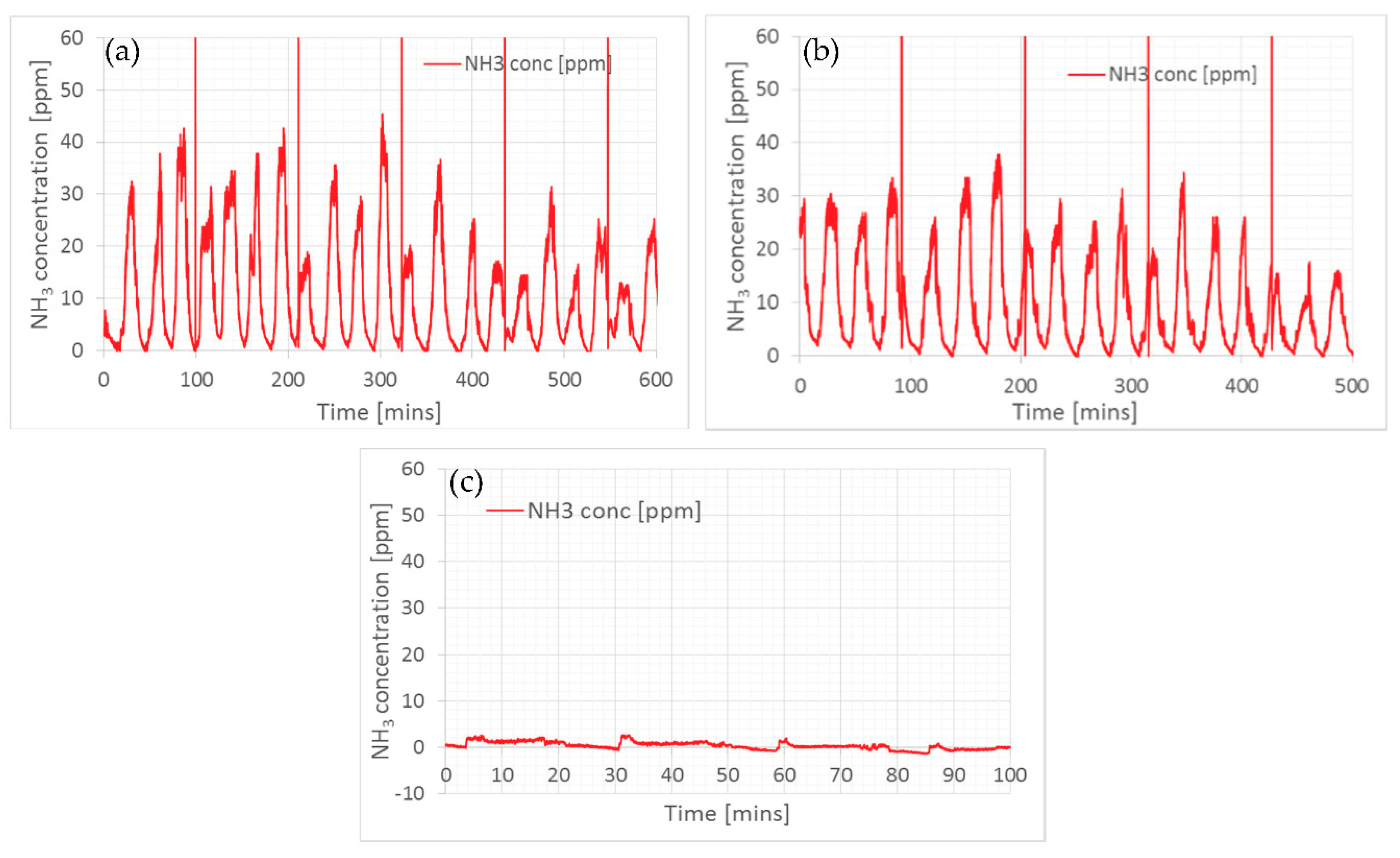

3], the recent improvements in ammonia detection performance also at temperatures above 450 °C, and specifically a growing interest in selective ammonia monitoring for fine-tuning the control of the seemingly most viable NO

x reduction measure—urea-SCR (Selective Catalytic Reduction), see

Figure 2—currently implemented in both automotive, marine, and stationary applications, it has been of interest to explore the long-term performance/applicability of these SiC FET based NH

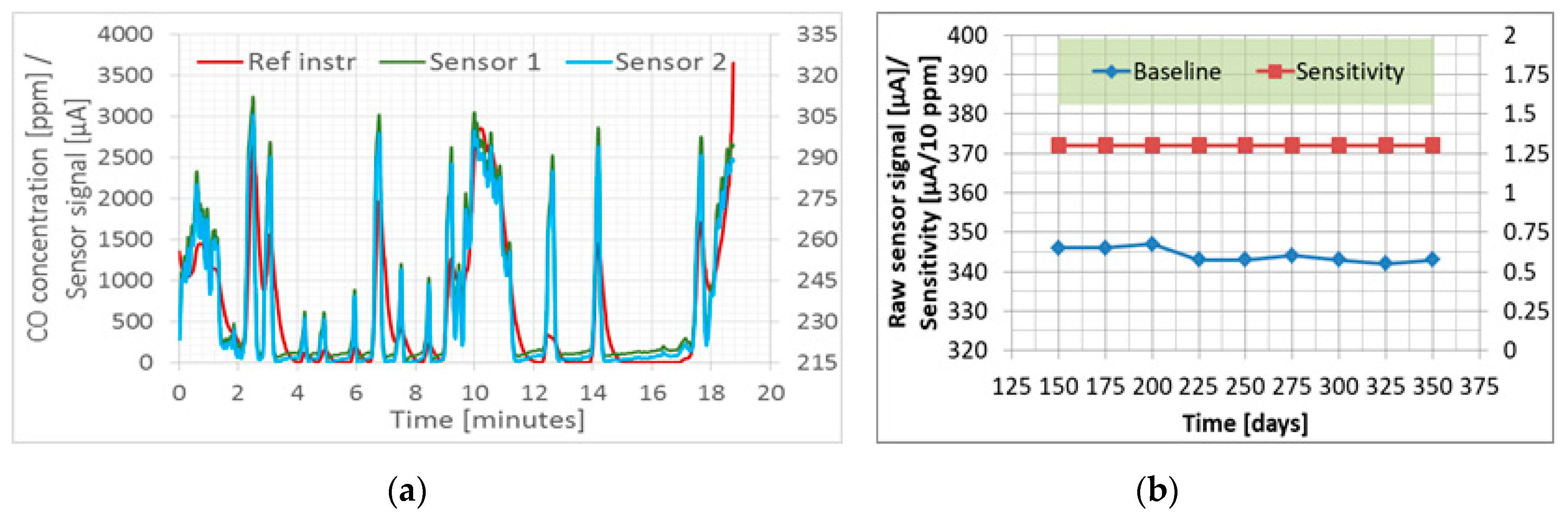

3 sensors in ammonia slip monitoring (downstream the SCR catalyst). Analogously, with the increased interest in sensor-based combustion control in small-scale boilers (/stoves) in local/domestic heating as well as the production of power/process-heat in small- to medium-scale systems for improved efficiency and reduced emissions, the long-term performance of the low-cost SiC FET-based CO sensor in the real environment of these applications has also been of interest to evaluate. This short report therefore aims at giving an overview of the long-term performance of the respective SiC FET NH

3 and CO sensors when evaluated in the real applications (the real environments) over periods of 6 months or more.