Abstract

This work presents an innovative approach on aerobic activated sludge (AS) wastewater treatment plants’ (WWTP) design and operation towards more efficient wastewater treatment, minimization of sludge accumulation and significant reduction of excess sludge, with relatively low specific energy consumption. This approach, which is called complete solids retention activated sludge (CRAS) process, was applied on a slaughterhouse’s WWTP and on a fruit processing industry’s WWTP, characterized by high organic and volumetric load respectively, as well as on a municipal WWTP located in Paralimni, Cyprus. The results showed without using sophisticated technologies and processes a more sustainable WWTP operation can be achieved.

1. Introduction

Activated sludge (AS) wastewater treatment plants (WWTPs) offer high treatment efficiency but with a significant cost that renders them, in many cases, far from sustainable technological applications. This cost can be translated to (a) operating cost (waste sludge management, energy consumption, equipment maintenance, operating staff cost), (b) environmental cost (impacts on air, soil, water, flora, fauna and human health) and (c) social issues. The most sustainable approach in AS WWTP design and operation is the one that best balances these three considerations, which is referred as the triple bottom line (TBL) concept [1,2].

Activated sludge processes can offer the potential for increased sustainability, mainly by means of microbial manipulation, i.e., the guided growth of desired microbial species through controlling an AS treatment system’s operational conditions [2,3]. The successful microbial manipulation, which is the principle idea of all biological treatment technologies, alongside with the adaptation of innovative WWTP design and operational approaches can lead to sustainable wastewater treatment [4]. New innovative approaches in AS WWTPs design and operation have to be developed and adapted, since the goal of sustainability is to decrease per-capita resource consumption. The characteristics of sustainable wastewater treatment systems can be identified and then used to develop individual technologies that can be part of such systems [2]. Efficient wastewater treatment (water recovery), reduced resources consumption (energy, chemicals etc.) and minimized processes wastes, such as excess sludge, are the key aspects for sustainable AS WWTPs design and operation.

An innovative approach towards more sustainable AS wastewater treatment is well described by the complete solids retention activated sludge (CRAS) process, which has been successfully applied to full-scale industrial WWTP of high organic load. CRAS process is based on the following operating parameters: (a) the longer possible solids retention time (SRT) up to complete retention; (b) the maintenance of highly aerobic conditions in the aerobic bioreactors; (c) the successful microbial manipulation; (d) the efficient solids/liquid separation [5]. By this approach, efficient wastewater treatment, minimization of sludge accumulation in the WWTP and significant reduction of excess sludge is achieved, with relatively low specific energy consumption [4].

CRAS process surpasses bibliographic limitations concerning solids retention time (SRT), MLSS concentration, dissolved oxygen concentration, sedimentation tank design and return activated sludge rates. The result of previous studies have shown that in CRAS systems having SRT over 120 days, all particulate organic matter (readily and slowly biodegradable particulate COD) can be degraded, thus does not accumulate in the WWTP [6,7,8]. Furthermore, it appears that the considered unbiodegradable fractions of particulate organic matter, such as cell debris from cellular lysis, can be slowly degraded in complete solids retention AS processes [7,8]. An actual complete retention of solids cannot be achieved by any AS process, because in full scale applications a fraction of influent suspended matter is non-biodegradable (non-volatile suspended solids, NVSS), thus accumulating in the WWTP. However, in CRAS applications only a small amount of sludge has to be removed from the system, which depends on wastewater fractionation (NVSS in influent). In cases of low NVSS content in influent, a waste sludge reduction over 90% (compared to conventional aerobic AS processes) can be achieved [4].

Worth mentioning that operation and maintenance costs of a secondary wastewater treatment plant, including the cost of sludge treatment and disposal, can be divided into four major categories: personnel, energy, chemicals and maintenance. Personnel and energy costs account for about 85% of the total cost, 36% of the total plant operating cost is the energy consumption for aeration and pumping systems (wastewater and sludge included). Sludge treatment alone, accounts for more than 32% of the total plant energy consumption [9]. If sludge handling, transportation and final disposal are added then the total cost for sludge treatment and disposal may be up to 40–65% of the total operating cost. The ideal solution to alleviate both cost and space availability problems would be the direct reduction of sludge within the activated sludge process [10].

Scope of this work is to evaluate treatment efficiency, treatment cost and excess sludge production at three WWTPs operating towards complete solids retention activated sludge (CRAS) process. Due to the fact that the wastewater composition and loads (volumetric and substrate) significantly differ between the three studied WWTPs, this work provides the opportunity to assess the benefits of applying CRAS process on existing or under design WWTPs treating a variety of wastewaters. This assessment can indicate the most significant operating parameters in CRAS process that can be fully or partially imposed on WWTPs for achieving high treatment efficiency, low excess sludge production, while having low operational cost (low specific energy consumption).

2. Material and Methods

Each of the three studied WWTPs has significantly different design and influent characteristics, as well as different operating conditions limitations that depend on the WWTP design and the installed electromechanical equipment. WWTP-1 (slaughterhouse’s) design and operation is based on CRAS process. WWTP-2 (fruit processing industry’s) was initially designed and operated as a conventional aerobic activated sludge system that was later modified, both in design and operation, in order to achieve as high solids retention time (SRT) as possible. WWTP-3 (municipal) was designed and operated as a conventional municipal wastewater treatment plant. WWTP-3 operational characteristics were modified in order to achieve as high SRT as possible without modifying its design or installing additional electromechanical equipment (recirculation pumps, aeration system etc.). The increase of SRT is limited in each WWTP by its design and the installed electromechanical equipment. Additional sedimentation tanks, aeration system and sludge recirculation pumps are the most common modifications needed for applying CRAS process in an existing WWTP [4].

WWTP-1, WWTP-2 and WWTP-3 were monitored for 371 days (12 January 2016 to 17 January 2017), 57 days (11 July 2017 to 6 September 2017) and 127 days (29 May 2017 to 3 October 2017) respectively. Influent characteristics, mixed liquor suspended solids (MLSS) and mixed liquor volatile suspended solids (MLVSS), biomass characteristics and operating parameters were monitored. Samples analysis from WWTP-1 and WWTP-2 were conducted at the accredited according to ISO 17025 “Environmental Chemistry and Wastewater Treatment Laboratory”, Department of Environmental Engineering and Pollution Control, Western Macedonia University of Applied Sciences, Greece, while samples analysis from WWTP-3 were conducted at the laboratory of the facility. All analyzes were conducted by applying standard methods [11] and by using calibrated instruments.

The theoretical solids retention time (SRT) of the each WWTP was calculated by dividing the total mass of biomass in the bioreactors by the amount of biomass wasted at the unit of time (Equation (1)). The time, expressed in days, is the duration of WWTP monitoring. The resulting retention time is an expression of the theoretical time for biomass renewal.

where: SRT is the solids retention time of the WWTP; XV is the total mass of biomass (MLVSS) in the bioreactors; XW is the annual mass of waste sludge; t is the time (days) of WWTP monitoring

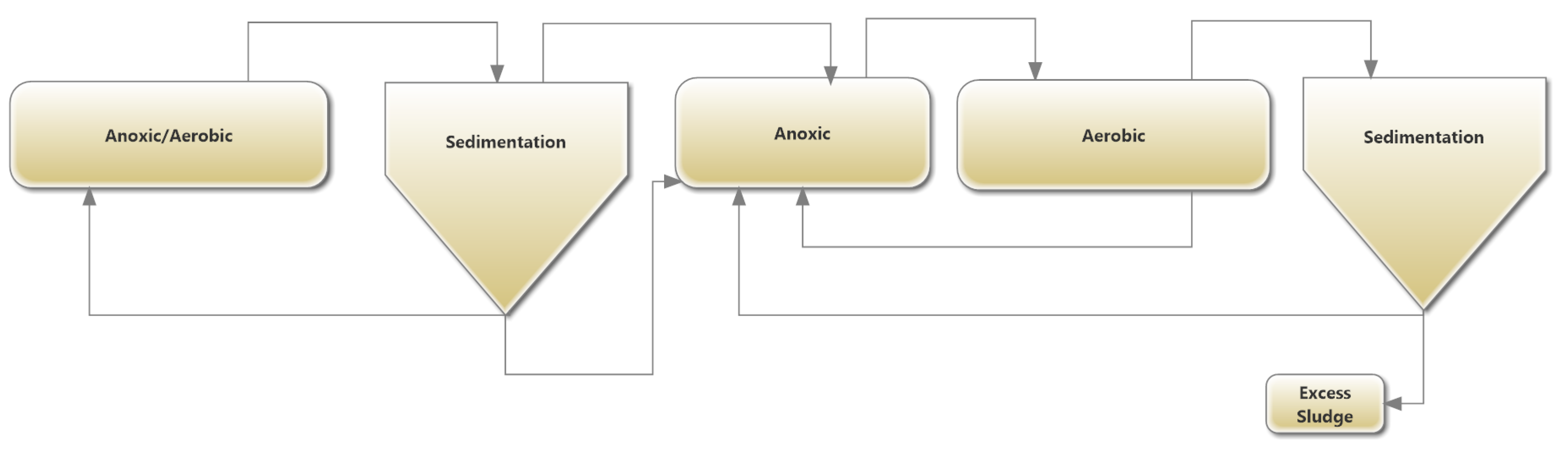

Almopia Slaughterhouses SA’s WWTP (WWTP-1) is located in Alompia municipality of Pella Prefecture, Central Macedonia, Greece. WWTP-1’s innovative design [12] and operation is based on CRAS process and consists of a preliminary, simultaneous nitrification/denitrification treatment stage and a pre-anoxic denitrification, complete mix, extended aeration AS treatment stage with complete retention of solids. The effluent of the preliminary system, which acts as a microbial selector by utilizing readily biodegradable COD [13,14,15], overflows in the extended aeration system, while excess sludge is transferred periodically from preliminary stage into the extended aeration stage (Figure 1).

Figure 1.

Slaughterhouse wastewater treatment plant (WWTP-1) flowchart.

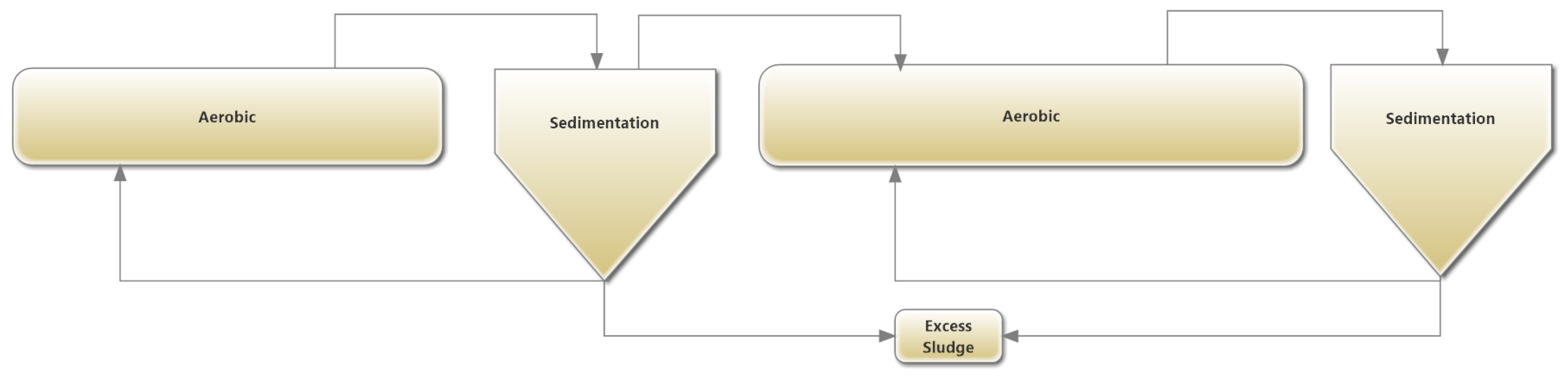

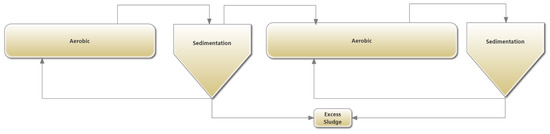

Prodromos Pavlides SA’s WWTP (WWTP-2) is located in Giannitsa Province of Pella Prefecture, Central Macedonia, Greece. The industry produces apricot and peaches composts and is one of the largest industries in its field, both nationally and globally. The industry operates for approximately 2 months annually (mid-July to mid-September), as is the period when apricots and peaches are harvested. Due to the nature of the wastewater, WWTP-2 is designed for organic compounds removal only (COD, BOD etc.), thus it consists only of aeration and sedimentation compartments and does not have any anoxic or anaerobic compartment for denitrification or phosphorus removal. The initial design of WWTP-2 was based on the conventional aerobic activated sludge process. This design was modified, in order to achieve as high SRT as possible based on the constraints defined by the WWTP-2 design and the installed equipment (Figure 2). The influent stream is divided into two parallel treatment lines, which follow the same treatment sequence (Figure 2). Each treatment line consists of (a) an aerobic treatment stage followed by sedimentation (preliminary treatment stage) and (b) secondary aerobic treatment stage followed again by sedimentation (secondary treatment stage). The preliminary treatment stage offers an initial COD removal, especially of the readily biodegradable substrate, thus it acts as a microbial selector [13,14,15]. The effluent from the preliminary stage’s sedimentation tank inflows to the secondary treatment stage in order to further reduce it COD content.

Figure 2.

Fruit processing industry’s wastewater treatment plant (WWTP-2) flowchart.

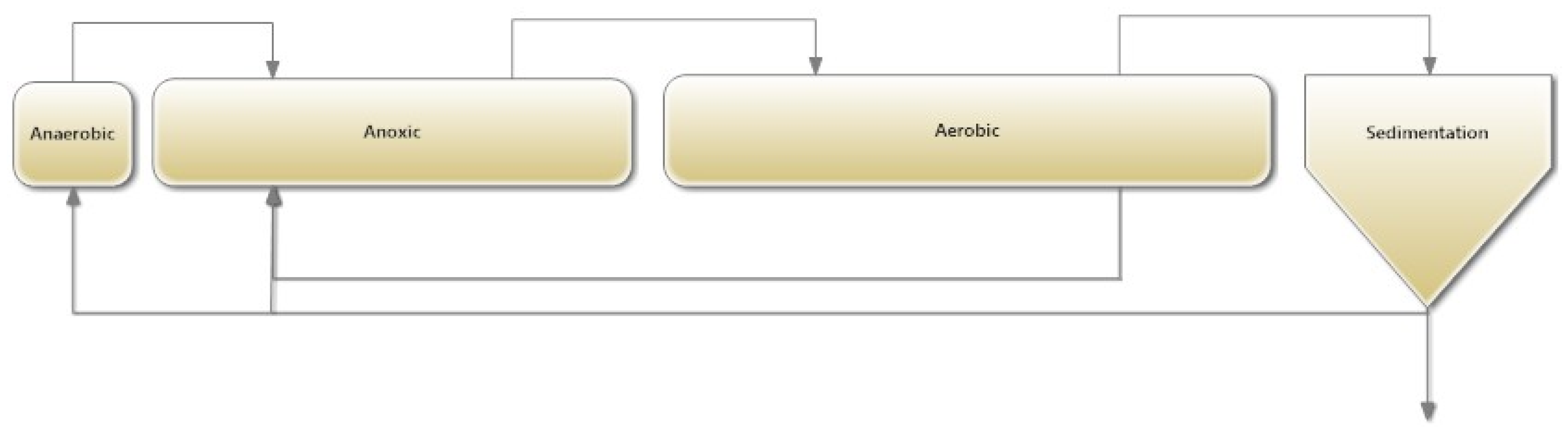

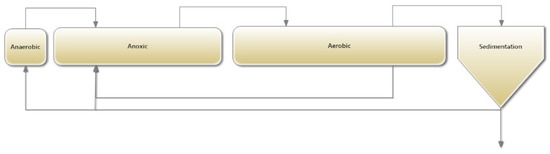

WWTP-3 is designed for treating municipal wastewater from a semi-combined sewer system and is located in Paralimni municipality, Cyprus. Wastewater from the two neighboring municipalities of Paralimni and Ayia Napa inflow into WWTP-3. This biological treatment system is designed for the removal of organic compounds, nitrogen, phosphorus and suspended solids. It incorporates anaerobic, anoxic and aerobic biological treatment stages in a pre-anoxic denitrification configuration with preliminary biological phosphorus removal (Figure 3). There are four identically designed parallel treatment lines that are operating depending on WWTP’s volumetric load. Paralimni and Ayia Napa municipalities are famous Mediterranean summer resorts, thus the volumetric load of WWTP-3 significantly increases (approximately 5 times higher) during the summer, a period when all four parallel treatment lines are operating. WWTP-3 design and operation was based on conventional aerobic activated sludge process. Its operational parameters, mainly MLSS concentration and sludge recirculation (RAS) rates were modified in order to achieve as high SRT as possible based again on the constraints defined by the WWTP-3 design and the installed equipment.

Figure 3.

Municipal wastewater treatment plant (WWTP-3) flowchart.

3. Results and Discussion

Alternative biological treatment applications are essential for reducing waste sludge in aerobic AS WWTPs and lowering their energy demands. A comparison of the specific operational parameters and the results obtained regarding sludge and energy cost minimization between the three studied WWTPs helps on evaluating the benefits of adapting to an extent the innovative CRAS process. Influent composition, influent flowrates and operational conditions are significantly different between the three WWTPs (Table 1).

Table 1.

Influent characteristics and operational parameters of the three studied WWTPs.

3.1. WWTP-1

The slaughterhouse’s wastewater composition was similar to that of similar size slaughterhouses [16,17]. Relative small deviations in influent measured characteristics were observed due to the use of an influent equalization tank (Table 1). The mean COD:N:P ratio in influent was 150:9.8:1.8 (sufficient nutrient content), while the BOD20/COD and BODultimate/COD ratios were 0.91 and 0.98 respectively (highly biodegradable) [15,18].

The preliminary, simultaneous nitrification/denitrification system operated at a relative constant MLSS concentration of approximately 5000 mg/L and at relatively low DO concentration (0.2 mg/L–0.8 mg/L), high SRT (approximately 36 days), high HRT (2.57 days) and RAS rate approximately 150%. The pre-anoxic denitrification, complete mix, extended aeration AS system operated under complete solids retention, high RAS rate (over 600%), highly aerobic conditions in aeration basin (DO > 4 mg/L) and under high HRT of 4.63 days.

WWTP-1 reached overall COD and Total Nitrogen (TN) removal efficiencies of 98% and 90% respectively. The preliminary system achieved average COD and TN reduction of approximately 32%, while the average COD and TN removal efficiency at the extended aeration stage reached the values of 95% and 85% respectively. These removal rates are representative of high MLSS concentration processes, such as membrane AS processes [19,20]. Furthermore, high MLVSS concentration processes can better handle increases of organic load in influent and can improve nitrogen removal by enhancing nitrifying bacteria growth [20].

The biomass of WWTP-1 is characterized by (a) the growth of metazoan such as rotifers, especially after reaching stabilization phase, (b) small biomass flocs and (c) good settling characteristics (SVI < 100) [21]. Filamentous species have never been observed in WWTP-1, probably due to the higher than 4 mg/L DO concentration in the aerobic stages and the use of the preliminary stage that acts as a microbial selector [13,14,15].

3.2. WWTP-2

The fruit processing industry’s WWTP (WWTP-2) influent is characterized by high organic and volumetric load. Based on its organic load, the equivalent population of WWTP-2 is approximately 400.000 persons. Relative small deviations in influent measured characteristics were observed due to the fixed production process followed by the industry and the use of an influent equalization tank (Table 1). The mean COD:N:P ratio in influent is approximately 150:0.33:0.2 is considered inadequate for developing a healthy biomass, since both nitrogen and phosphorus compounds are almost absent in the wastewater. Consequently, nitrogen (urea) and phosphorus (triple superphosphate fertilizer) compounds were periodically added to the influent in order to maintain a COD:N:P ratio of at least 150:3.7:0.2, which has been proved to be sufficient for healthy biomass growth with good sludge characteristics (sludge volume index—SVI < 120 mL/g) in fruit processing industries’ WWTPs [15]. Due to the composition of the wastewater (low molecular weight organic compounds), its COD content is considered biodegradable [2,21]. This also derives from the conducted biodegradability measurements, in which a high BOD20/COD ratio of 0.93 was obtained (Table 1).

In order for WWTP-2 to be able to operate at high MLSS concentration without compromising sedimentation efficiency, an additional sedimentation tank was constructed and the RAS rate capabilities of the system were increased by adding more recirculation pumps in each sedimentation tank. Furthermore, additional air diffusers and blowers were installed for increasing aeration capabilities. The influent hydraulic retention time (HRT) was approximately 1.4 days, while the theoretical solids retention time (SRT) was approximately 169 days, since the WWTP-2 operated adapting to a great extent the CRAS process. RAS rates and aeration levels were set as high as possible, which is essential for efficient solids/liquid separation and microbial manipulation in CRAS process [18]. RAS rates were approximately 150% and the oxygen concentration (dissolved oxygen—DO) in aeration tanks was maintained at concentrations higher than 2 mg/L in both preliminary and secondary treatment stages. The WWTP-2 influent does not contain considerable quantities of nitrogen, thus the DO concentration in the bioreactors is more than sufficient for organic compounds oxidation [21].

The overall, mean COD removal efficiency in WWTP-2 was approximately 98%, having a mean effluent COD value of 55 mg/L. Approximately 80% of COD removal occurs in the preliminary treatment stage thus almost all readily biodegradable COD is consumed, thus helping microbial manipulation in secondary treatment stage. The biomass of WWTP-2 is characterized by (a) the growth of metazoan species, such as nematodes (sludge reducing microorganisms), especially after reaching stabilization phase, (b) limited presence of filamentous bacteria associated with nitrogen and phosphorus deficiency (morphotypes M. Parvicella, Types 021N, 0041, 0675, 0092 and 0581), (c) good settling characteristics (SVI < 120).

3.3. WWTP-3

The studied municipal WWTP (WWTP-3) has relatively high hydraulic retention time in the preliminary biological phosphorus removal stage, where a significant reduction of readily biodegradable COD occurs (35% COD reduction), thus acting as an anaerobic microbial selector [13]. The influent hydraulic retention time (HRT) was approximately 1 day, while the theoretical solids retention time (SRT) was approximately 31 days, since the WWTP-2 operated adapting to a great extent the CRAS process. RAS rates and aeration levels were set as high as possible, which is essential for efficient solids/liquid separation and microbial manipulation in CRAS process (Amanatidou Sedimentation). RAS rates were approximately 70% to 85% and the oxygen concentration (dissolved oxygen—DO) in aeration tanks was maintained at concentrations higher than 4 mg/L in aerobic treatment stages. The overall, mean COD removal efficiency in WWTP-3 was approximately 98%, having a mean effluent COD value of 25 mg/L.

The semi-combined sewer system of Paralimni—Ayia Napa municipality results in significant variations of influent composition between dry and rainy seasons, due to the dilution of wastewater with precipitation runoffs (Table 1). The seasonal variations of influent composition has an impact on COD:N:P ratio. Lower nitrogen and phosphorus concentration are measured during the rainy season (150:3.2:0.75) resulting in slightly nutrient deficient conditions. Although nitrogen and phosphorus ratio falls below the COD:N:P ratio of 150:5:1 and slightly below the 150:3.7:0.2 (concerning nitrogen content), a value found to be sufficient in previous studies [15], there was a limited presence of filamentous bacteria associated with nutrient deficiency. The sludge volume index of WWTP-3 ranged between 75 to 110 mL/g, values that indicated good biomass sedimentation characteristics [21].

Even in periods of consecutive rainfalls (more than a week), when the lowest nitrogen and phosphorus content in influent is observed, filamentous growth remained limited thus sludge maintained its good settling characteristics (SVI < 100 g/mL). This observation is contrary to previous observations of previous years, when consecutive rainfalls resulted in excessive growth of filamentous species that deteriorated WWTP-3 effluent quality (Amanatidou Influence). This can be attributed to the significantly higher SRT and MLVSS concentration of WWTP-3 than of previous years, as these are the operational parameters that significantly changed after the attempt to mimic CRAS process. It appears that high SRT sludge (stabilized) requires fewer nutrients than the requirements during the high growth (startup) and low-growth phases [15].

3.4. Evaluation of Waste Sludge Minimization

In AS processes, the net biomass accumulation (observed biomass yield, Yobs) corresponds to the amount of excess sludge discharged from a WWTP. Yobs accounts the influent particulate solids accumulation, biomass growth, bacterial cell lysis (death) and predation of bacteria by protozoan and metazoan species. It is expressed as the ratio between the produced biomass (MLVSS) and the mass of removed substrate (e.g., kgMLVSS/kgCOD). In conventional activated sludge aerobic systems, Yobs usually ranges between 0.12 and 0.45 kgMLVSS/kgCOD removed [4,21]. Recent studies demonstrated that at high SRT and high D.O. concentration Yobs is significantly lower (up to two orders of magnitude) even than the extended aeration processes [22]. A review conducted by WEF [23] concerning typical operational parameters in various activated sludge processes and the resulting Yobs is presented in Table 2, alongside with the operational parameters and the obtained Yobs in the three studied WWTPs.

Table 2.

Typical operational parameters in various activated sludge processes [23] and corresponding experimental values at the three WWTPs studied.

In the three WWTPs studied, the obtained Yobs values ranged between 0.003 kgSS/kgCOD to 0.15 kgSS/kgCOD, resulting significantly lower sludge accumulation and therefore less waste sludge. WWTP-1 had the lowest Yobs values, followed by WWTP-2 and WWTP-3. It is evident that the sludge minimization rate in the studied WWTPs is dictated by the degree of CRAS process operational parameters adaptation. Consequently, longer the SRT, HRT and higher DO concentration in aerobic basins result in significant sludge minimization. Furthermore, the implementation of a preliminary biological treatment stage, which acts as a microbial selector, also results in sludge minimization by creating substrate limiting condition in the secondary (main) treatment stage as well as good biomass characteristics by limiting filamentous bacteria growth.

Energy consumption in a WWTP can be expressed in relation to its population equivalent (PE), its volumetric feed, its COD or BOD removal, as well as to its TKN removal (when separate electromechanical equipment are used) [4,21]. In the cases of WWTP-1 (slaughterhouse) and WWTP-3 (municipal), the energy consumption is referred to both carbon and nitrogen elimination because carbon oxidation and nitrification processes are performed by common electromechanical equipment. Worth mentioning that approximately half the aeration needs of WWTP-1 and a 10% of WWTP-2 are due to the oxygen requirements for nitrification. Energy consumption in WWTP-2 corresponds only for organics (COD, BOD, etc.) removal, since influent wastewater has very low nitrogen content (Table 1).

3.5. Evaluation of Energy Consumption

In this study, the specific loading rate value of 120 gCOD/PE*d (following Directive 91/271/EEC) was used in order to express specific energy consumption in relation to each WWTP’s PE as kWh/PE*year, while the specific energy consumption in relation to organic compounds removal was expressed as kWh/kgCODremoved. The studied WWTPs’ specific energy consumptions can be compared with the results obtained from other studies [24] in Table 3. It is evident that the specific energy consumptions in CRAS applications correspond to the lowest specific energy consumptions of the presented treatment technologies (Table 3).

Table 3.

Energy consumption respect to treatment technology [24]—Comparison with energy consumption of the studied WWTPs.

4. Conclusions

The adaptation of CRAS process can offer process stability, minimized waste sludge yields and excellent treatment efficiency, with low energy consumptions. Furthermore, the implementation of a preliminary biological treatment stage, which acts as a microbial selector, can help on controlling filamentous growth in the bioreactors of an AS WWTP. The increase of SRT over the literature limits for extended aeration AS processes, up to almost complete retention of solids, results in a biomass with good settling characteristics (SVI values < 120 mL/g), characterized by increased presence of protozoan and metazoan species (mainly ciliates and rotifers) and therefore minimizing sludge accumulation through predation phenomena. CRAS process offers the possibility to operate a WWTP under high MLSS concentration, nutrient limiting conditions without filamentous bacteria growth. Consequently, new design and operational concepts can be adopted towards more sustainable biological wastewater treatment.

References

- Wallace, B. Becoming Part of the Solution: The Engineer’s Guide to Sustainable Development, 1st ed.; American Council of Engineering Companies: Washington, DC, USA, 2005; pp. 97–110. [Google Scholar]

- Grady, C.P.L.; Daigger, G.T.; Love, N.G.; Filipe, C.D.M. Biological Wastewater Treatment, 3rd ed.; IWA Publishing: London, UK, 2011; pp. 3–318. [Google Scholar]

- Amanatidou, E.; Samiotis, G.; Trikoilidou, E.; Pekridis, G.; Tsikritzis, L. Complete Solids Retention Activated Sludge Process. Water Sci. Technol. 2016, 73, 1364–1369. [Google Scholar] [CrossRef] [PubMed]

- Trikoilidou, E.; Samiotis, G.; Pekridis, G.; Tsikritzis, L.; Amanatidou, E. Sustainable operation of a biological wastewater treatment plant. IOP Conf. Ser. Mater. Sci. Eng. 2016, 161, 012093. [Google Scholar] [CrossRef]

- Amanatidou, E.; Samiotis, G.; Bellos, D.; Pekridis, G.; Trikoilidou, E. Net biomass production under complete solids retention in high organic load activated sludge process. Bioresour. Technol. 2015, 182, 193–199. [Google Scholar] [CrossRef] [PubMed]

- Sperandio, M.; Labelle, M.A.; Ramdani, A.; Gadbois, A.; Paul, E.; Comeau, Y.; Dold, P.L. Modelling the degradation of endogenous residue and unbiodegradable influent organic suspended solids to predict sludge production. Water Sci. Technol. 2013, 67, 789–796. [Google Scholar] [CrossRef] [PubMed]

- Lubello, C.; Caffaz, S.; Gori, R.; Munz, G. A modified activated sludge model to estimate solids production at low and high solids retention time. Water Res. 2009, 43, 4539–4548. [Google Scholar] [CrossRef] [PubMed]

- Amanatidou, E.; Samiotis, G.; Trikoilidou, E.; Tsikritzis, L. Particulate organics degradation and sludge minimization in aerobic, complete SRT bioreactors. Water Res. 2016, 94, 288–295. [Google Scholar] [CrossRef] [PubMed]

- Tsagarakis, K.P.; Mara, D.D.; Angelakis, A.N. Application of cost criteria for selection of municipal wastewater treatment systems. Water Air Soil Pollut. 2003, 142, 187–210. [Google Scholar] [CrossRef]

- Odegaard, H. Sludge minimization technologies—An overview. Water Sci. Technol. 2004, 49, 31–40. [Google Scholar] [CrossRef] [PubMed]

- American Public Health Association (APHA); American Water Works Association (AWWA); Water Environmental Federation (WEF). Standard Methods for the Examination of Water and Wastewater, 22nd ed.; American Public Health Association: Washington, DC, USA, 2012. [Google Scholar]

- Bellos, D. Special Compact Activated Sludge Wastewater Treatment Plant for Large and Medium Size Applications. U.S. Patent 1,007,711, April 2012. [Google Scholar]

- Martins, A.M.P.; Heijnen, J.J.; van Loosdrecht, M.C.M. Effect of dissolved oxygen concentration on sludge settleability. Appl. Microbiol. Biotechnol. 2003, 62, 586–593. [Google Scholar] [CrossRef] [PubMed]

- Henze, M.; van Loosdrecht, M.C.M.; Ekama, G.A.; Brdjanovic, D. Biological Wastewater Treatment: Principles, Modelling and Design, 1st ed.; IWA Publishing: London, UK, 2008. [Google Scholar]

- Amanatidou, E.; Samiotis, G.; Trikoilidou, E.; Michailidis, A. Influence of Wastewater Treatment Plants’ Operational Conditions on Activated Sludge Microbiological and Morphological Characteristics. Environ. Technol. 2016, 37, 265–278. [Google Scholar] [CrossRef] [PubMed]

- Massé, D.I.; Masse, L. Characterization of wastewater from hog slaughterhouses in Eastern Canada and evaluation of their in-plant wastewater treatment systems. Can. Agric. Eng. 2000, 42, 139–146. [Google Scholar]

- Pozo, R.; Tas, D.O.; Dulkadiroglu, H.; Orhon, D.; Diez, V. Biodegradability of slaughterhouse wastewater with high blood content under anaerobic and aerobic conditions. J. Chem. Technol. Biotechnol. 2003, 78, 384–391. [Google Scholar] [CrossRef]

- Amanatidou, E.; Samiotis, G.; Trikilidou, E.; Pekridis, G.; Taousanidis, N. Evaluating sedimentation problems in activated sludge treatment plants operating at complete sludge retention time. Water Res. 2015, 69, 20–29. [Google Scholar] [CrossRef] [PubMed]

- Dialynas, E.; Diamantopoulos, E. Integration of a membrane bioreactor coupled with reverse osmosis for advanced treatment of municipal wastewater. Desalination 2009, 238, 302–311. [Google Scholar] [CrossRef]

- Melidis, P.; Ntougias, S.; Vasilatou, V.; Skouteris, G.; Azis, K.; Diamantis, V.; Alexandridis, A. Biofouling Aspects and Critical Flux Evaluation in an Intermittently Aerated and Fed Submerged Membrane Bioreactor Environmental Processes. Environ. Process. 2016, 3, 23–33. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Burton, F.; Stensel, H.D. Wastewater Engineering: Treatment and Reuse, 4th ed.; Metcalf & Eddy Inc.: Boston, MA, USA; McGraw Hill: Boston, MA, USA, 2003. [Google Scholar]

- Foladori, P.; Andreottola, G.; Ziglio, G. Sludge Reduction Technologies in Wastewater Treatment Plants, 1st ed.; IWA Publishing: London, UK, 2010. [Google Scholar]

- Water Environmental Federation. Design of Wastewater Treatment Plants, Manual of Practice, 4th ed.; Water Environmental Federation: Alexandria, VA, USA, 1998. [Google Scholar]

- ENERWATER. Deliverable 2.1: Study of Published Energy Data; Horizon 2020 ENERWATER Project; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Williams, R.; Schuler, P.; Comstock, K.; Pope, R. Large Membrane Bioreactors of Georgia: A Guide and Comparison. In Proceedings of the Membrane Technology Conference, Atlanta, GA, 27–30 January 2008; pp. 548–561. [Google Scholar]

- Malcolm, B.; Middlenton, R.; Wheale, G.; Schulting, F. Energy efficiency in the water industry, a global research project. Water Pract. Technol. 2011, 6. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).