Technical and Practical Valuation of Hydrokinetic Turbine Integration into Existing Canal Infrastructure in South Africa: A Case Study †

Abstract

1. Introduction

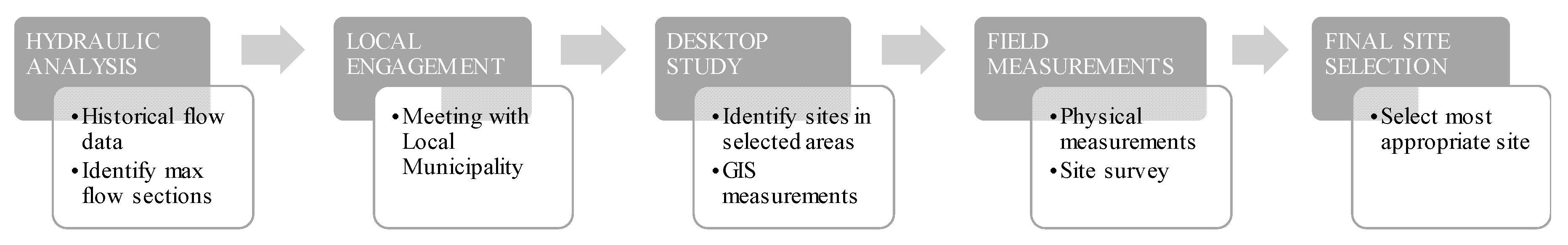

2. Site Description

- Electro-mechanical Components.

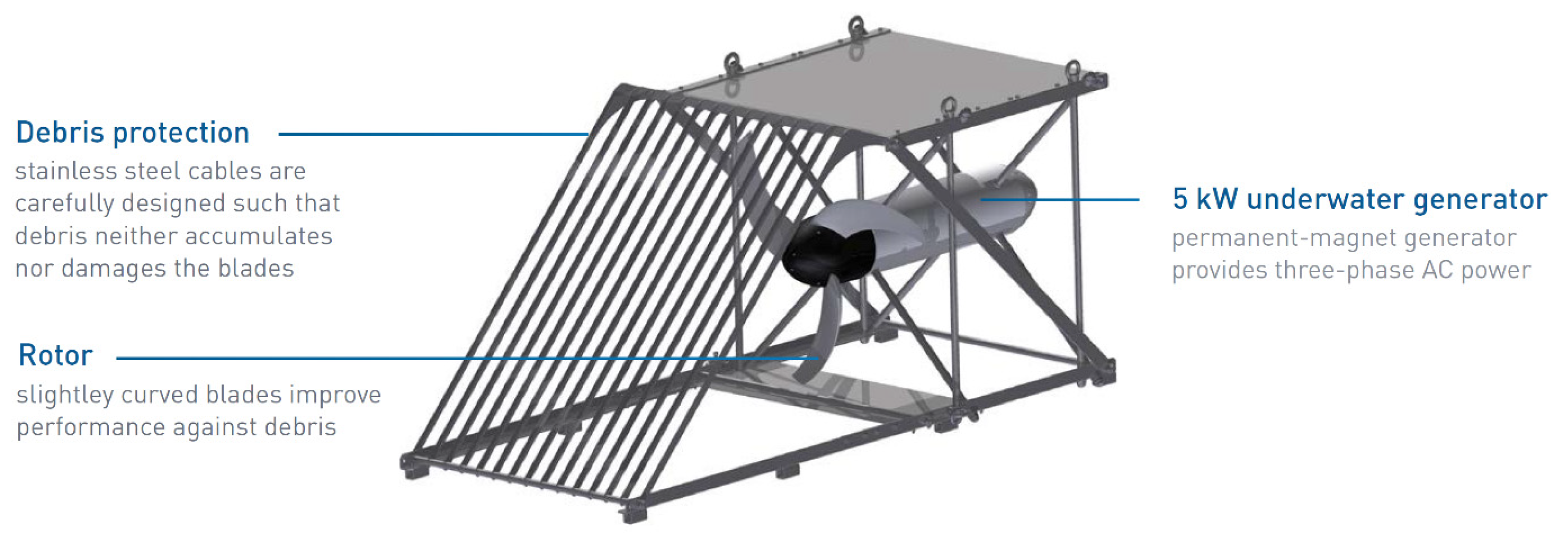

- Smart Hydro Power GmbH (SHP) free stream turbine (Equipped with a 5 kW generator).

- Rectifiers.

- Dump loads.

- Civil Components.

- Concrete block foundation and cable anchors.

- Turbine lifting system.

- Electrical Components.

- Electrical infrastructure.

- Inverters.

- Flow meter.

- Level sensors.

3. Discussion

- No fish life deterioration, due to the canal inlet grid blocking most of the riverine fish population, except for smaller species, which generally are not affected by the spinning blades.

- No habitat destruction caused through the use of man-made canal systems (artificial water ways) rather than riverine applications.

- No sediment disruption of the surrounding area from installation as the canal is concrete lined and the canal sides were used for fastening.

- No altering, impeding or diverting of waterways was done during installation and no major damming caused (which could have resulted in flooding).

- No toxic release of any chemicals (no anti-biofouling, hydraulic fluids etc. used)

- No loud noise from the turbines (no noise pollution) during operation.

- Procedures and costs involved in the legislative process (factoring in delays) should not be underestimated and considered strongly in the prefeasibility study.

- The appropriate selection of a technology for implementations remains a crucial aspect of consideration, the cross-sectional area and dominant flow conditions should be ascertained and HK technology selected accordingly.

- Theft, vandalism and maintenance proves to be major social issues of consideration in South Africa, and these matters should be dealt with during each development phase and premeditated during the implementation design.

4. Conclusions

Acknowledgments

References

- MEAAI. Energy Report 2011; Ministry of Economic Affairs, Agriculture and Innovation: Den Haag, The Netherlands, 2011. [Google Scholar]

- Koko, P.S.; Kusakana, K. Techno-Economic Analysis of an Off-Grid Micro-Hydrokinetic River System as a Remote Rural Electrification Option; Free State CUT: Bloemfontein, South Africa, 2014. [Google Scholar]

- White, J. Viability of Small Scale Hydropower in South Africa; University of Cape Town: Cape Town, South Africa, 2011. [Google Scholar]

- Van Vuuren, S.J.; Blersch, C.L.; van Dijk, M. Modelling the feasibility of retrofitting hydropower to existing South African dams. Water SA 2011, 37, 679–692. [Google Scholar] [CrossRef][Green Version]

- Kartezhnikova, M.; Ravens, T.M. Hydraulic impacts of hydrokinetic devices. Renew. Energy 2014, 66, 425–432. [Google Scholar] [CrossRef]

- SHP. Installer Training Manual; Smart Hydropower GmbH: Feldafing, Germany, 2017. [Google Scholar]

- Reader-Harris, M.J.; Brunton, W.C.; Gibson, J.J.; Hodges, D.; Nicholson, I.G. Discharge coefficients of Venturi tubes with standard and non-standard convergent angles. Flow Meas. Instrum. 2001, 12, 135–145. [Google Scholar] [CrossRef]

- Elbatran, A.H.; Yaakob, O.B.; Yasser, M.A.; Shabara, H.M. Operation, performance and economic analysis of low head micro-hydropower turbines for rural and remote areas: A review. Renew. Sustain. Energy Rev. 2015, 43, 40–50. [Google Scholar] [CrossRef]

| Component | Design Options | Design Considerations | Final Design | |

|---|---|---|---|---|

| Electro-mechanical | Turbine selection | SHP Floating axial flow turbine. | SHP was chosen as the turbine supplier. The freestream was designed specifically for canal application and fits the operating range. It is less prone to debris build-up (due to most debris floating, and grid deflection device) and better for the specific application. | SHP Freestream turbine. |

| SHP freestream axial flow. | ||||

| Civil | Anchoring structure | Bottom anchoring onto canal bed. | Initially the Boegoeberg WUA 1 requested no alterations be done on the canal itself. In addition, an anchoring system outside of the flow would be simpler for accessibility purposes. | Side Anchoring. |

| Side anchoring with concrete anchor blocks. | ||||

| Lifting system | Gantry permanent structure. | Extremely large cost due to large width of canal. | Portable crane. | |

| Gantry on rails over all turbines. | Extremely expensive and would require only straight level sections (existing site has a bend). | |||

| Portable crane. | Second hand crawler crane available at low cost, single crane can be used for all turbines (for future installations). | |||

| Turbine placement (multiple turbines) | Centre placement (one behind the other at specific spacing). | Fastest velocity in center section of canal. | Center placement with adjacent turbines (depending on upstream effect). | |

| Staggered placement (staggered behind each other). | Staggered placement could result in less interference between turbines and could allow closer placement. | |||

| Adjacent placement (multiple turbine in single cross-section). | Recommended by supplier, increasing the Betz limit. | |||

| Electrical | Flow meter | Doppler velocity sensor and ultra-sonic level sensor. | Velocity sensor is placed on the canal bed, with level sensor over the canal wall. | Due to theft resistance the doppler sensor was selected. |

| “Microflow” radar sensor. | Placed over the canal wall, resulting in large device sensitive to movement. | |||

| Electrical distribution | Stand-alone system. | Require back-up storage and self-synchronization. Also a change over switch from micro-grid mode to municipal grid mode required when supply is insufficient. | For the purpose of simplicity, a grid-tied system was selected. | |

| Grid-tied system. | Allows possible integration of the HK plant with the existing grid and synchronized with the solar plant when the grid is off. | |||

| Output (W) | 250–5000 | |

| Dimensions | length (mm) | 2640 |

| width (mm) | 1120 | |

| height (mm) | 1120 | |

| Rotational speed (rpm) | 90–230 | |

| Weight (kg) | 300 | |

| Number of rotor blades | 3 | |

| Rotor diameter (mm) | 1000 | |

| Positive Factors | Negative Factors |

|---|---|

| The use of local labour for project development allowed an income for unemployed locals and also a sense of pride and protectiveness of the installation from the locals in the small community. The system usually requires little maintenance and allows a constant supply of electricity through the majority of the year, aiding the poor municipality financially. The project functions as a pilot of possible renewable electricity technologies which could promote the market for HK systems in South Africa. Benefits to the !Kheis Municipality would include reducing their reliance on the national power grid, as well as reducing their electricity costs and thus mitigating their risk of not being able to supply water to their communities. | The HK devices are a risk to children swimming in the canals (sharp fast flowing propeller blades could result in injury). The largely poor area results in potential theft of components during canal maintenance periods. Higher maintenance may be required due to debris. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niebuhr, C.; Dijk, M.v.; Bhagwan, J. Technical and Practical Valuation of Hydrokinetic Turbine Integration into Existing Canal Infrastructure in South Africa: A Case Study. Proceedings 2018, 2, 595. https://doi.org/10.3390/proceedings2110595

Niebuhr C, Dijk Mv, Bhagwan J. Technical and Practical Valuation of Hydrokinetic Turbine Integration into Existing Canal Infrastructure in South Africa: A Case Study. Proceedings. 2018; 2(11):595. https://doi.org/10.3390/proceedings2110595

Chicago/Turabian StyleNiebuhr, Chantel, Marco van Dijk, and Jay Bhagwan. 2018. "Technical and Practical Valuation of Hydrokinetic Turbine Integration into Existing Canal Infrastructure in South Africa: A Case Study" Proceedings 2, no. 11: 595. https://doi.org/10.3390/proceedings2110595

APA StyleNiebuhr, C., Dijk, M. v., & Bhagwan, J. (2018). Technical and Practical Valuation of Hydrokinetic Turbine Integration into Existing Canal Infrastructure in South Africa: A Case Study. Proceedings, 2(11), 595. https://doi.org/10.3390/proceedings2110595