BaTiO3 Based Nanostructures for Humidity Sensing Applications †

Abstract

:1. Introduction

2. Materials and Methods

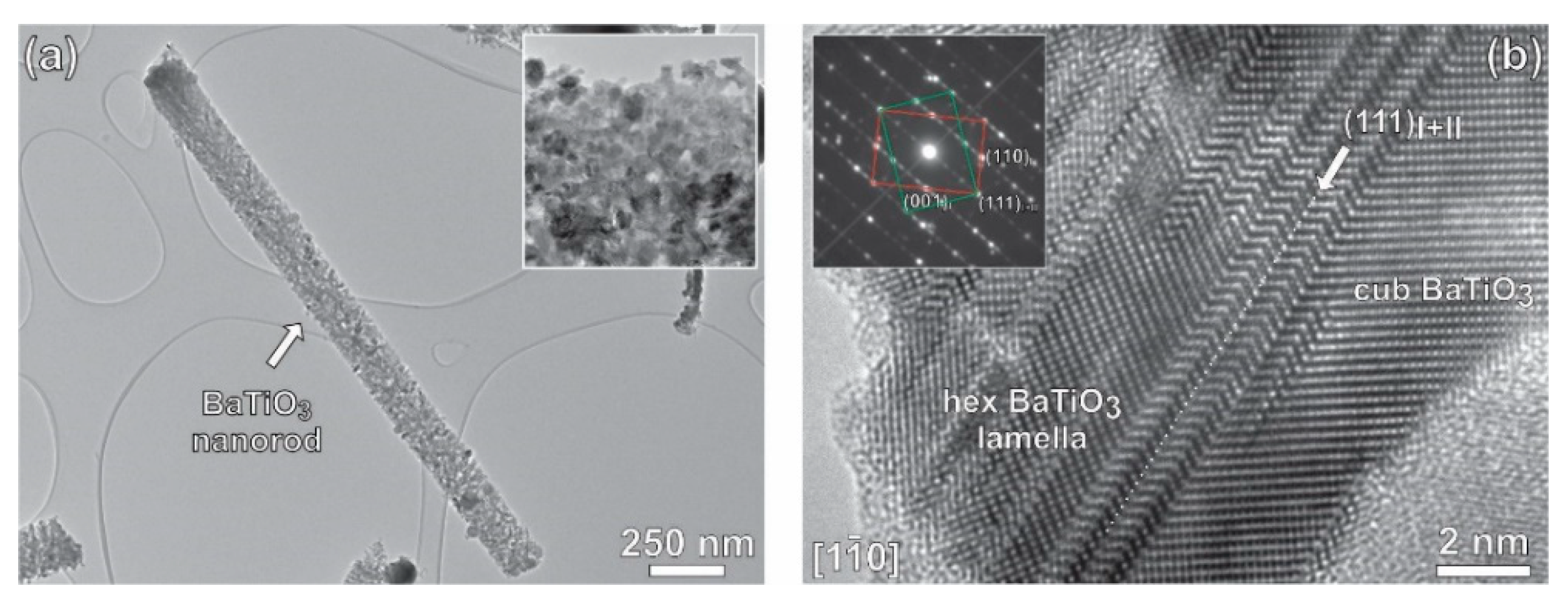

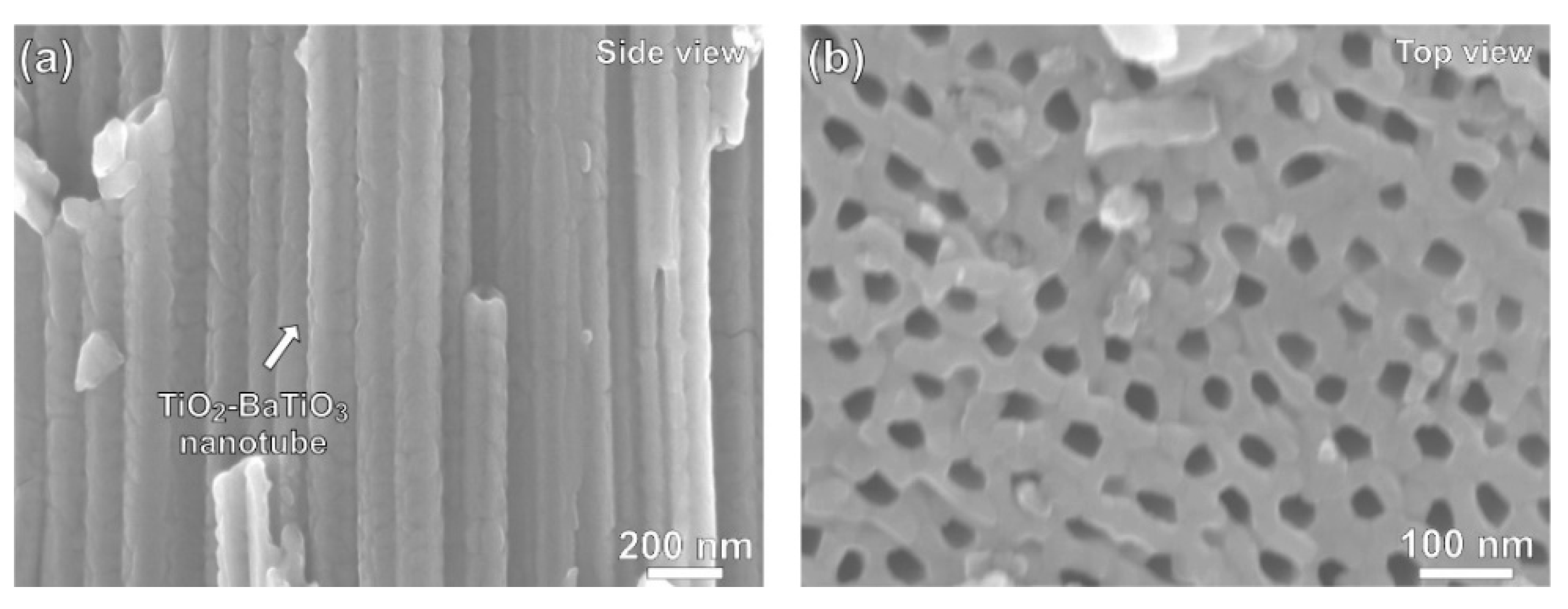

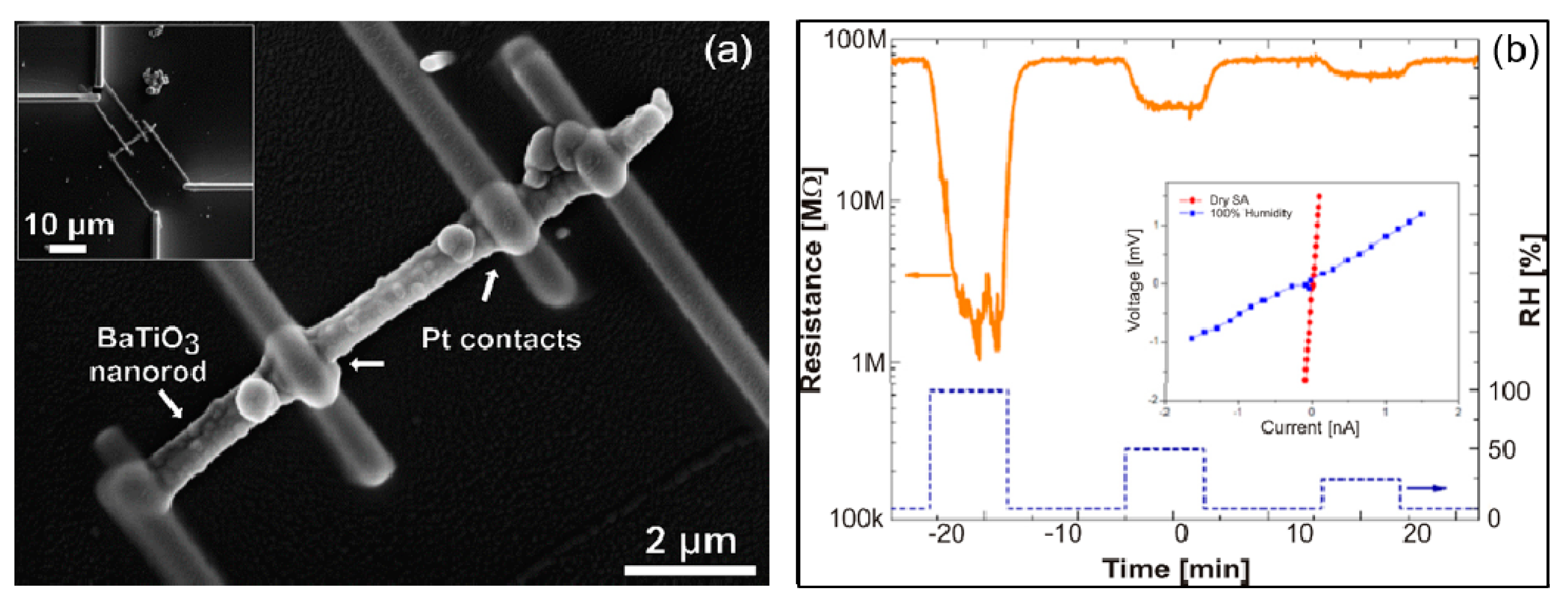

3. Results and Discussion

4. Conclusions

Funding

References

- Xia, Y.; Yang, P.; Sun, Y.; Wu, Y.; Mayers, B.; Gates, B.; Yin, Y.; Kim, F.; Yan, H. One-Dimensional Nanostructures: Synthesis, Characterization, and Applications. Adv. Mater. 2003, 15, 353–389. [Google Scholar] [CrossRef]

- Patzke, G.R.; Krumeich, F.; Nesper, R. Oxidic nanotubes and nanorods—anisotropic modules for a future nanotechnology. Angrew. Chem. Int. Ed. Engl. 2002, 41, 2446–2461. [Google Scholar] [CrossRef]

- Spanier, J.E.; Kolpak, A.M.; Urban, J.J.; Grinberg, I.; Ouyang, L.; Yun, W.S.; Rappe, A.M.; Park, H. Ferroelectric phase transition in individual single-crystalline BaTiO3Nanowires. Nano Lett. 2006, 6, 735–739. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Szafraniak, I.; Zakharov, N.D.; Nagarajan, V.; Steinhart, M.; Wehrspohn, R.B.; Wendorff, J.H.; Ramesh, R.; Alexe, M. Nanoshell tubes of ferroelectric lead zirconate titanate and barium titanate. Appl. Phys. Lett. 2003, 83, 440–442. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, J.; Suryavanshi, A.P.; Yum, K.; Yu, M.-F. Voltage Generation from Individual BaTiO3Nanowires under Periodic Tensile Mechanical Load. Nano Lett. 2007, 7, 2966–2969. [Google Scholar] [CrossRef] [PubMed]

- Yuk, J.; Troczynski, T. Sol–gel BaTiO3 thin film for humidity sensors. Sensors Actuators B: Chem. 2003, 94, 290–293. [Google Scholar] [CrossRef]

- Koka, A.; Zhou, Z.; Tang, H.; A Sodano, H. Controlled synthesis of ultra-long vertically aligned BaTiO 3 nanowire arrays for sensing and energy harvesting applications. Nanotechnol. 2014, 25, 375603. [Google Scholar] [CrossRef] [PubMed]

- Žagar, K.; Hernández-Ramírez, F.; Prades, J.D.; Morante, J.R.; Rečnik, A.; Čeh, M. Characterization of individual barium titanate nanorods and their assessment as building blocks of new circuit architectures. Nanotechnol. 2011, 22, 385501. [Google Scholar] [CrossRef] [PubMed]

- Žagar, K.; Rečnik, A.; Sturm, S.; Gajović, A.; Ceh, M. Structural and chemical characterization of BaTiO3 nanorods. Mater. Res. Bull. 2011, 46, 366–371. [Google Scholar] [CrossRef]

- Hernández-Ramírez, F.; Prades, J.D.; Jimenez-Diaz, R.; Fischer, T.; Romano-Rodriguez, A.; Mathur, S.; Morante, J.R. On the role of individual metal oxide nanowires in the scaling down of chemical sensors. Phys. Chem. Chem. Phys. 2009, 11, 7105. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Zhang, T.; Wang, R.; Liu, X.; Xia, Y.; Zhao, J. Humidity sensing properties of BaTiO3 nanosfiber prepared via electrospinning. Sensors Actuat. B: Chem. 2010, 146, 98–102. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soderznik, K.Z.; Fabrega, C.; Hernandez-Ramirez, F.; Prades, J.D.; Čeh, M. BaTiO3 Based Nanostructures for Humidity Sensing Applications. Proceedings 2019, 15, 9. https://doi.org/10.3390/proceedings2019015009

Soderznik KZ, Fabrega C, Hernandez-Ramirez F, Prades JD, Čeh M. BaTiO3 Based Nanostructures for Humidity Sensing Applications. Proceedings. 2019; 15(1):9. https://doi.org/10.3390/proceedings2019015009

Chicago/Turabian StyleSoderznik, Kristina Zagar, Cristian Fabrega, Francisco Hernandez-Ramirez, Joan Daniel Prades, and Miran Čeh. 2019. "BaTiO3 Based Nanostructures for Humidity Sensing Applications" Proceedings 15, no. 1: 9. https://doi.org/10.3390/proceedings2019015009

APA StyleSoderznik, K. Z., Fabrega, C., Hernandez-Ramirez, F., Prades, J. D., & Čeh, M. (2019). BaTiO3 Based Nanostructures for Humidity Sensing Applications. Proceedings, 15(1), 9. https://doi.org/10.3390/proceedings2019015009