Exploiting Several Buffer Layers in SPR D-Shaped POF Sensors Based on Gold Film for Different Applications †

Abstract

:1. Introduction

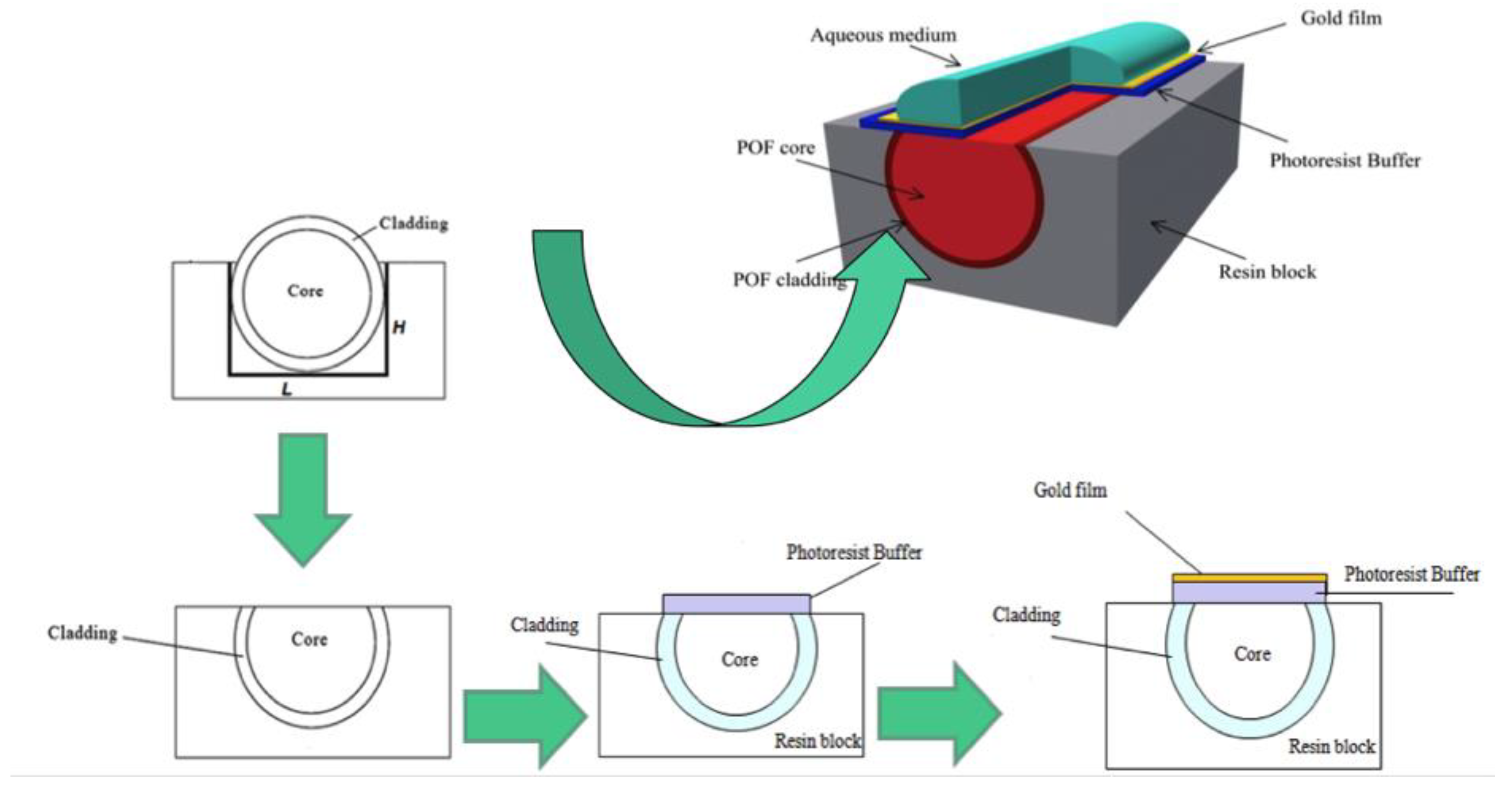

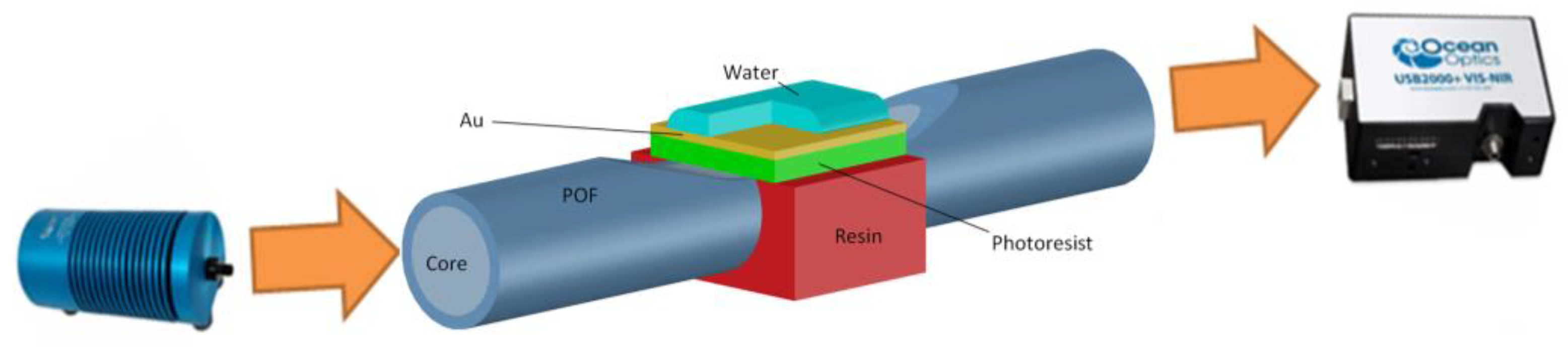

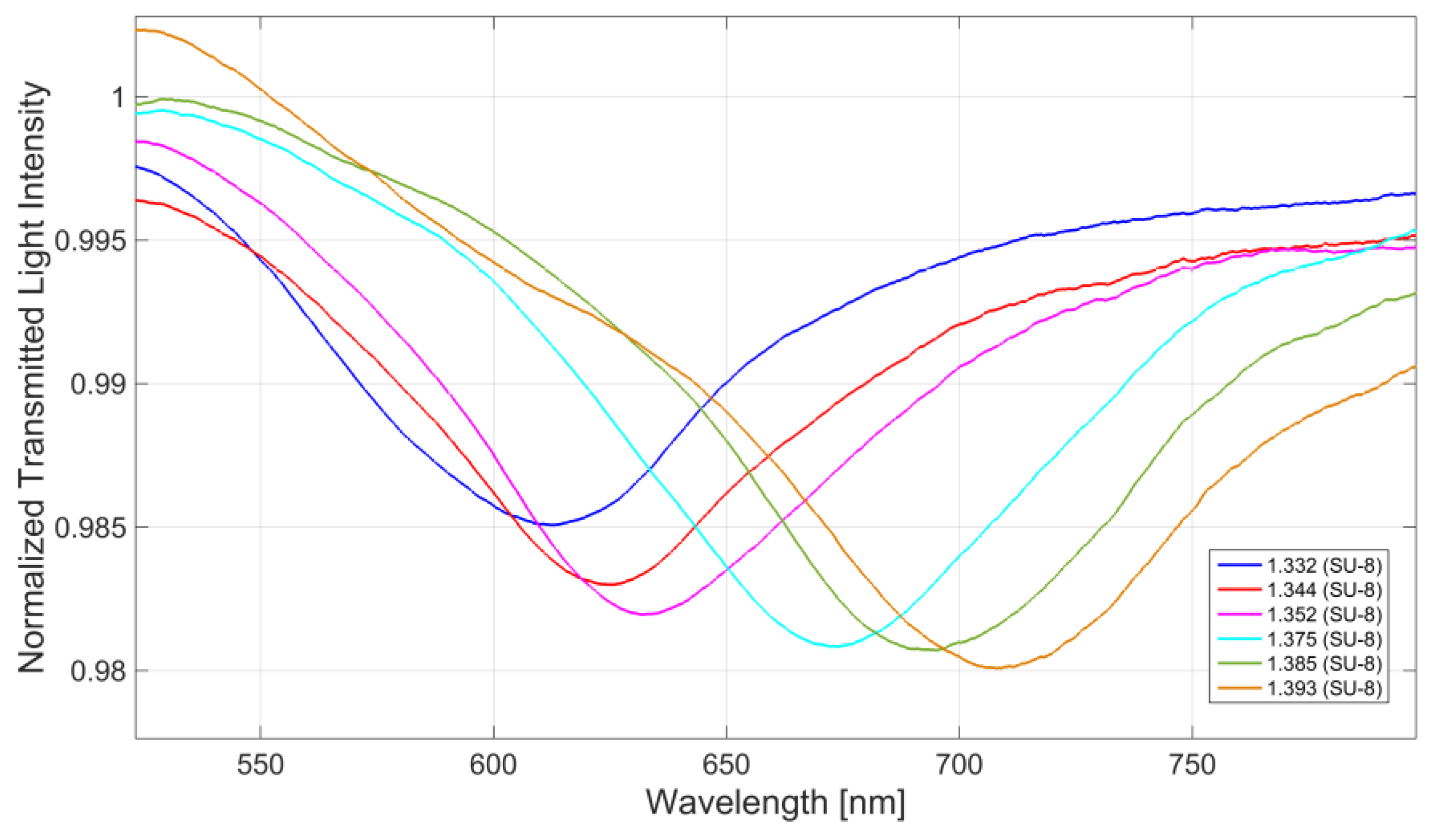

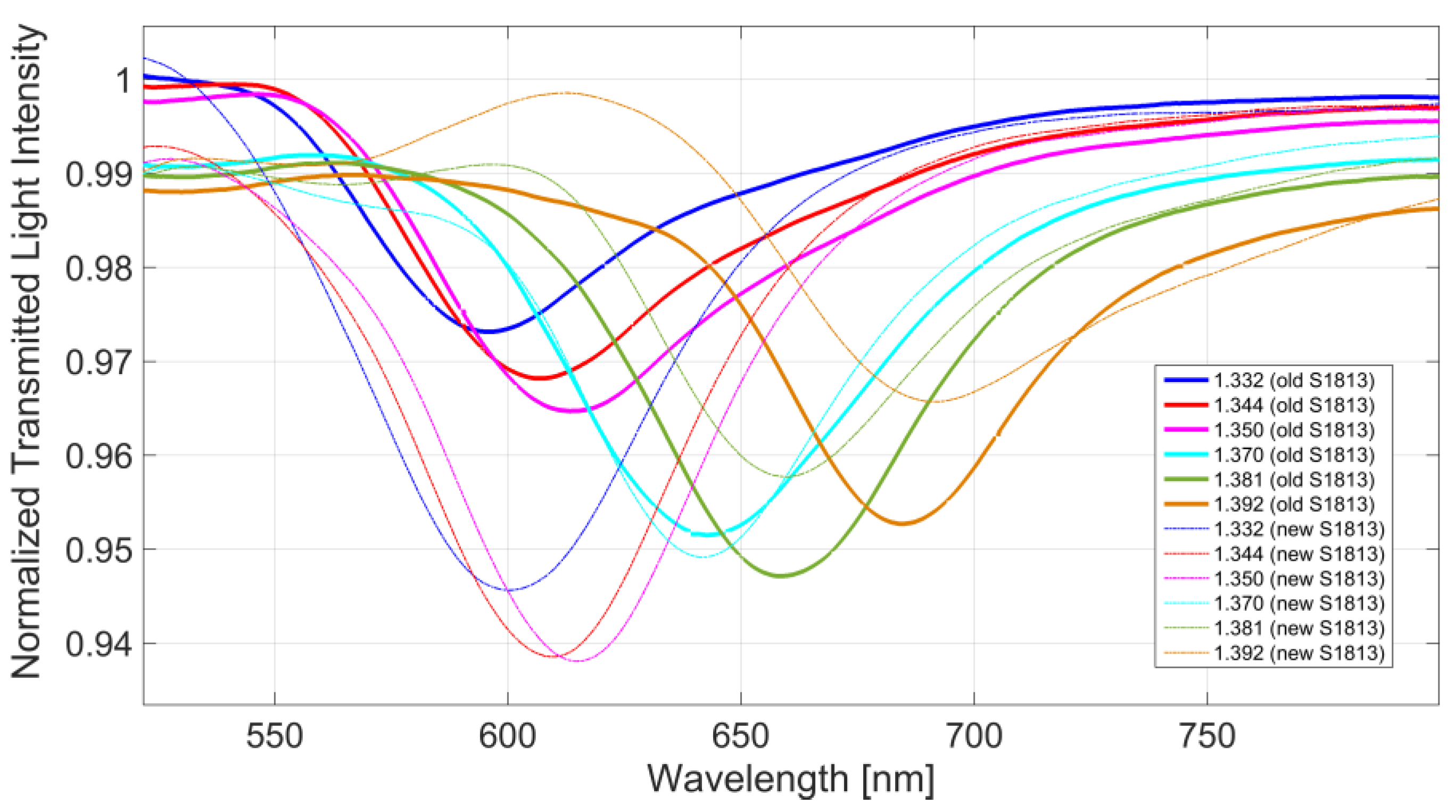

2. Plasmonic POF Sensors

3. Results

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Wang, X.D.; Wolfbeis, O.S. Fiber-Optic Chemical Sensors and Biosensors (2013–2015). Anal. Chem. 2016, 88, 203–227. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.K.; Jha, R.; Gupta, B.D. Fiber-optic sensors based on surface Plasmon resonance: a comprehensive review. IEEE Sens. J. 2007, 7, 1118–1129. [Google Scholar] [CrossRef]

- Gupta, B.D.; Verma, R.K. Surface plasmon resonance-based fiber optic sensors: Principle, probe designs, and some applications. J. Sens. 2009, 2009. [Google Scholar] [CrossRef]

- Trouillet, A.; Ronot-Trioli, C.; Veillas, C.; Gagnaire, H. Chemical sensing by surface plasmon resonance in a multimode optical fibre. Pure Appl. Opt. 1996, 5, 227–237. [Google Scholar] [CrossRef]

- Leung, A.; Shankar, P.M.; Mutharasan, R. A review of fiber-optic biosensors. Sens. Actuators B Chem. 2007, 125, 688–703. [Google Scholar] [CrossRef]

- Kanso, M.; Cuenot, S.; Louarn, G. Sensitivity of optical fiber sensor based on surface plasmon resonance: Modeling and experiments. Plasmonics 2008, 3, 49–57. [Google Scholar] [CrossRef]

- Dwivedi, Y.S.; Sharma, A.K.; Gupta, B.D. Influence of design parameters on the performance of a surface plasmon sensor based fiber optic sensor. Plasmonics 2008, 3, 79–86. [Google Scholar] [CrossRef]

- Iga, M.; Seki, A.; Watanabe, K. Gold thickness dependence of SPR-based hetero-core structured optical fiber sensor. Sens. Actuators B Chem. 2005, 106, 363–368. [Google Scholar] [CrossRef]

- Sharma, A.K.; Gupta, B.D. On the sensitivity and signal to noise ratio of a step-index fiber optic surface plasmon resonance sensor with bimetallic layers. Opt. Commun. 2005, 245, 159–169. [Google Scholar] [CrossRef]

- Jin, Y.; Granville, A.M. Polymer Fiber Optic Sensors-A Mini Review of their Synthesis and Applications. J. Biosens. Bioelectron. 2016, 7, 1–11. [Google Scholar] [CrossRef]

- Cennamo, N.; Pesavento, M.; De Maria, L.; Galatus, R.; Mattiello, F.; Zeni, L. Comparison of different photoresist buffer layers in SPR sensors based on D-shaped POF and gold film. In Proceedings of the 25th International Conference on Optical Fiber Sensors, Jeju, Korea, 24–28 April 2017. [Google Scholar]

- Cennamo, N.; D'Agostino, G.; Pesavento, M.; Zeni, L. High selectivity and sensitivity sensor based on MIP and SPR in tapered plastic optical fibers for the detection of L-nicotine. Sens. Actuators B Chem. 2014, 191, 529–536. [Google Scholar] [CrossRef]

- Cennamo, N.; Varriale, A.; Pennacchio, A.; Staiano, M.; Massarotti, D.; Zeni, L.; D’Auria, S. An innovative plastic optical fiber-based biosensor for new bio/applications. The case of celiac disease. Sens. Actuators B Chem. 2013, 176, 1008–1014. [Google Scholar] [CrossRef]

- Sequeira, F.; Duarte, D.; Bilro, L.; Rudnitskaya, A.; Pesavento, M.; Zeni, L.; Cennamo, N. Refractive Index Sensing with D-Shaped Plastic Optical Fibers for Chemical and Biochemical Applications. Sensors 2016, 16, 2119. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cennamo, N.; Zuppella, P.; Arcadio, F.; Zeni, L. Exploiting Several Buffer Layers in SPR D-Shaped POF Sensors Based on Gold Film for Different Applications. Proceedings 2019, 15, 47. https://doi.org/10.3390/proceedings2019015047

Cennamo N, Zuppella P, Arcadio F, Zeni L. Exploiting Several Buffer Layers in SPR D-Shaped POF Sensors Based on Gold Film for Different Applications. Proceedings. 2019; 15(1):47. https://doi.org/10.3390/proceedings2019015047

Chicago/Turabian StyleCennamo, Nunzio, Paola Zuppella, Francesco Arcadio, and Luigi Zeni. 2019. "Exploiting Several Buffer Layers in SPR D-Shaped POF Sensors Based on Gold Film for Different Applications" Proceedings 15, no. 1: 47. https://doi.org/10.3390/proceedings2019015047

APA StyleCennamo, N., Zuppella, P., Arcadio, F., & Zeni, L. (2019). Exploiting Several Buffer Layers in SPR D-Shaped POF Sensors Based on Gold Film for Different Applications. Proceedings, 15(1), 47. https://doi.org/10.3390/proceedings2019015047