1. Introduction

Fibre Bragg Grating is a periodic perturbation of refracting index created along the core of a photosensitive fibre that would result in a single wavelength reflected back (so called the Bragg wavelength), when the fibre is connected to a laser source. The operating mechanism of the sensor is to detect wavelength reflected back to the source due to a stretching/shrinking of the fibre given by a mechanical force applied on the sensitive element [

1].This type of fibre is becoming increasingly attractive in many applications because of its small size, light-weight, chemically inertness, immunity to electromagnetic interferences and low cost. They can be used for measuring strain, force, pressure, displacement, temperature, humidity [

2] and pH [

3]. They are actually used in aeronautic, automotive, civil engineering, undersea oil [

2].

FBGs fibre optic sensors are not extensively used in the application, where the rheological properties are important. In the food industry, for example, the measurement of rheological behaviour of chemical components used as thickeners, emulsifiers or stabilising agents is extremely important to design optimised product and ensure stable flows of these additives during production process. Specifically, measuring the flow behaviour is essential to indicate the product stability and to adapt the food texture. The rheological characteristics also correlate the textural attributes of the final product influencing the sensory characteristics and consumer acceptability. At the moment, those properties are measured by a rheometer [

4].

In this work, we present how FBGs could be used to measure the viscoelasticity of sodium alginate (SA), biocompatible, non-toxic and biodegradable polymer used as gelling, thickening, stabilising and emulsifying agent [

5]. The linear viscoelasticity was measured at different concentration of SA. Comparing to the conventional rheometer, the proposed technique is easier to operate and uses less amount of tested material.

2. Material

The alginic acid sodium salt from brown algae (sodium alginate) (C6H9NaO7, ≥ 2,000 cP, 2 % (25°C) lit.), with no other chemical modifications, was purchased from Sigma Aldrich UK. Different concentration (1.0, 1.5, 2.0, 2.5, and 3.0 w/w%) were prepared by dissolving the right quantity of SA in deionised water. In order to dissolve the SA powder, it has been mixed, using a magnetic stirrer, at room temperature for three hours. The system was then allowed to stand at room temperature for 24 h to remove baubles. The fibre used in this work was a photosensitive fibre (PS 1250/1500) with the coating diameter of 247.5 μm and the fibre diameter of 125.1μm. The numerical aperture was of 0.12 and operating wavelength of 1550 nm. The fibre was stripped of its polymeric jacket (1.00 ± 0.01 cm) and subjected to a 248 nm KrF laser exposure through a phase-mask to have the periodic perturbation of the refractive index. The FBG was then annealed at 100 °C for 3 hours in order to have its optical properties stabilised.

3. Method

The mechanical model (Maxwell model) is one of the most used models that consists of a spring (Hooke’s law) connected in series with a dashpot (Newton’s law of viscosity) to measure the linear viscoelasticity of a liquid.

When broadband light encounters an FBG, it reflects a particular wavelength back to the source and this wavelength is sensitive to the magnitude of the applied stress or compression on the FBG. The principle of operation of this sensor is based on monitoring the shift in the resonance wavelength, known as Bragg wavelength, which alters due to the stretching of fibre resulting from varying strain and temperature, according to Equation 1:

Λ is the grating pitch; neff is the refractive index of the fibre.

Therefore, FBGs have the particular advantage of being used as probe sensors. If we consider the FBG sensitive element that stretches/compresses if a force is applied onto it, the fibre will go back to the same position as before when the force is removed from the fibre. After the force applied on it is removed, the resonance wavelength should resume back to the same position as before. This, however, is true only if the fibre is stressed in the linear range before the breaking point.

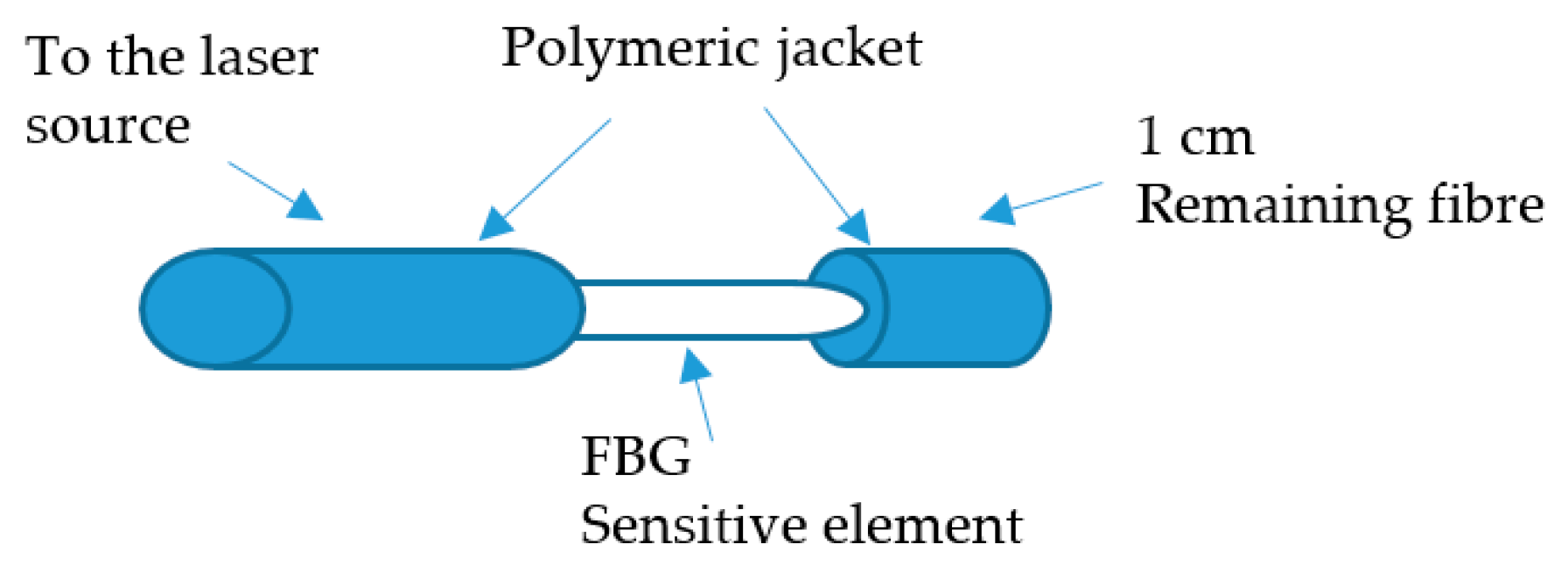

Thus the FBG’s sensitive element can be considered like a spring and the remaining fibre in the free end, of approximately (1.00 ± 0.01) cm, with the polymeric jacket, is free to be immersed into the solution, as can be seen from

Figure 1. The polymeric jacket in the remaining fibre can be considered as the viscous element, and both the spring and the viscous element build the Maxwell model for viscoelasticity. Thus, the mechanical model can be transformed into an opto-mechanic model. The fibre in this study was pulled out from each SA solution of (15.0 ± 0.1) ml for different concentrations at a speed of 1 mm/s and the measurement was taken three times at room temperature.

4. Results and Discussion

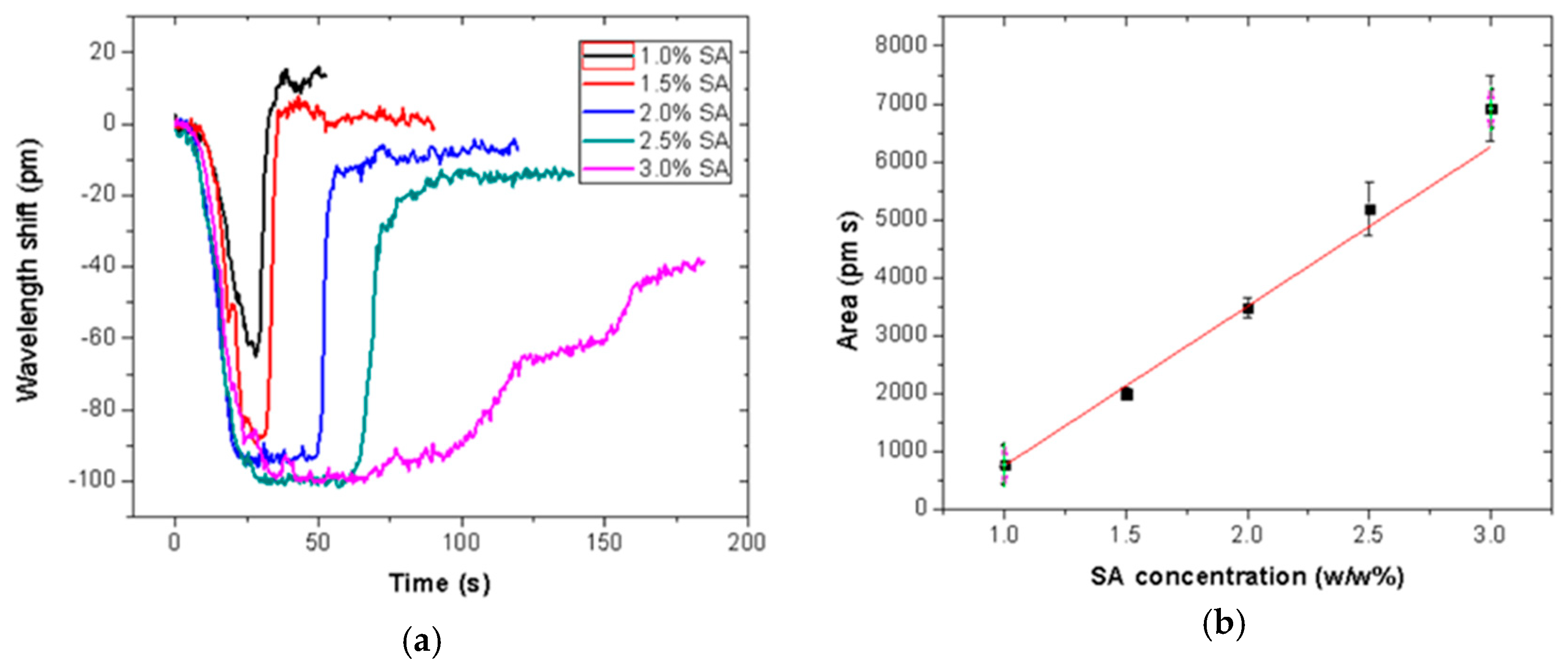

The fibre was immersed into the solution for one minute before pulling it out from the solutions with different concentration of SA. The graph depicted in

Figure 2a shows the analogy to the Maxwell model. It shows, as well, that the wavelength shift, in terms of pm, varies both in terms of peak height and in terms of time to reach the first plateau of the waveform. The fibre, while returning to the same position as before, encounters the increase in weight and viscosity of the polymer on its sensitive element, i.e. the FBG, and eventually reaches the initial point. The higher the concentration of the solution, the longer it takes for the FBG to resume to its initial position. In the case of SA 3.0 w/w% it is clearly demonstrated where several plateaus are distinctly visible while the fibre is attempting to resume to its original position. Taking this aspect into account, the area under the peak can be used as a measurement to evaluate different viscoelasticity. For this measurement, area is calculated within the time it takes for the sensor to reach the first plateau.

Figure 2b represent the area with respect to the increase in SA w/w%. This shows a good linearity, where the R

2 is of 0.992 and the sensitivity is (2.7 ± 0.1) (nm·s)/(w/w%). The error is negligible, suggesting an acceptable and good precision of the technique.

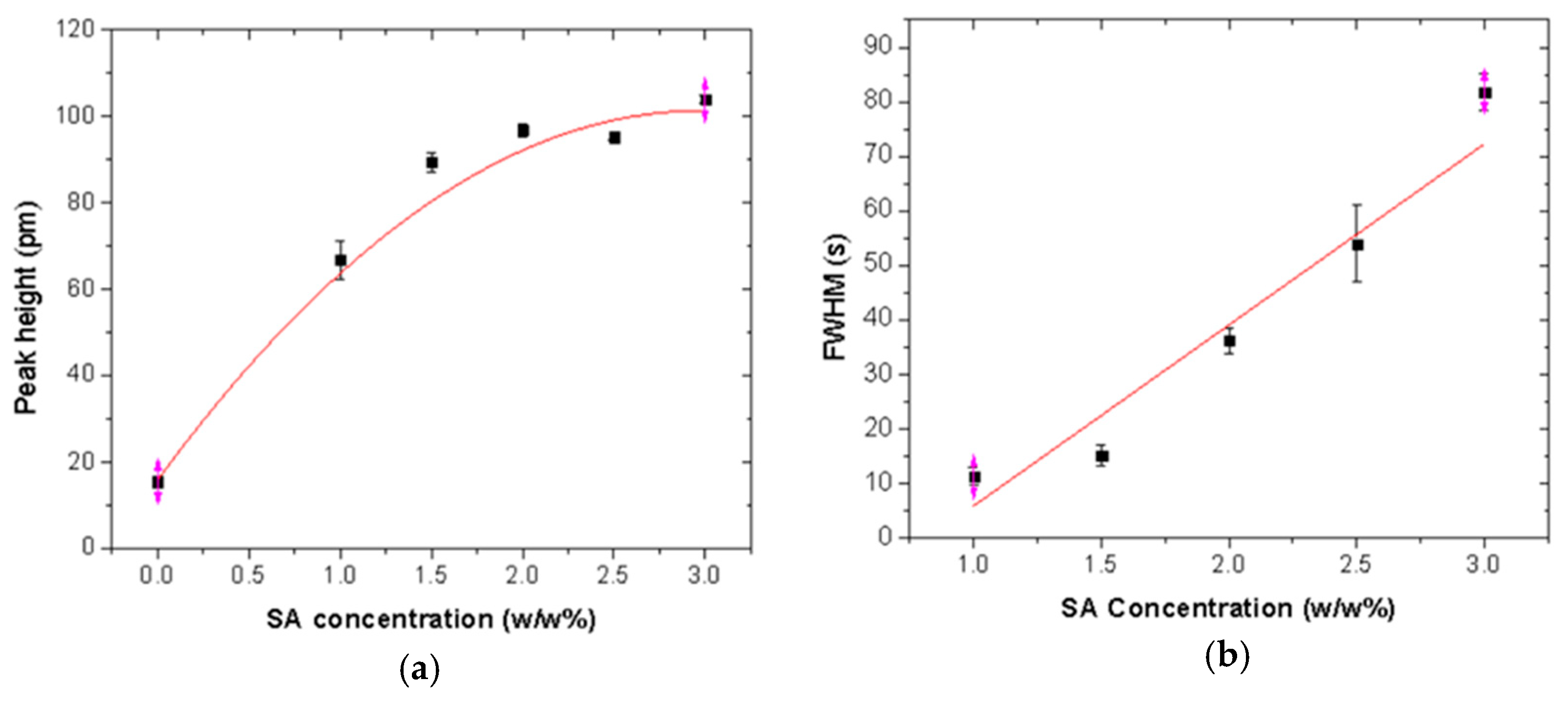

The variation in peak height and FWHM in response to the increase in concentration are shown in

Figure 3a and

Figure 3b respectively.

Figure 3a depicts that the peak height, considering also the level of water where the concentration of SA is of 0.0%, changes as the concentration increases, from 0.0% to 1.5%. This suggests the increase of resistivity offered by the polymer to the fibre, but it has an asymptotic behaviour reaching the plateau at 102 pm in terms of wavelength shift. This aspect can be associated with the fact that SA will offer different resistance to the fibre for different concentrations of SA, stretching from 0.0 to 3.0%. The polynomial fit suggest that it is of second order where the two values are 57.39 ± 1.73 and -9.64 ± 0.61 and R

2 of 0.986.

Figure 3b presents FWHM versus SA w/w% and it shows a good linearity with a slope of (33.2 ± 5.8) (s)/(w/w%) and with a R

2 of 0.886. As seen from

Figure 2(a), the time to reach the first plateau increases as the concentration increases linearly.

5. Conclusions

To sum up, a new sensor for measuring the viscoelastic properties of sodium alginate has been tested. From the tests conducted, it is evident that there is a good linearity in terms of area under the curve and in terms of FWHM as the concentration of the polymer increases from 1.0 to 3.0 w/w%. It can also be concluded that the peak height rapidly increases with the change in concentration. Work is ongoing to evaluate best means to reduce the amount of solution needed for measurement so that optimum usage of material can be realised, reducing waste of material.

Author Contributions

Conceptualization, L.B.; methodology, L.B.; software, L.B.; validation, A.S. and L.A.; formal analysis, L.B.; investigation, L.B.; resources, L.B.; data curation, L.B.; writing—original draft preparation, L.B.; writing—review and editing, A.S. and L.A.; supervision, A.S. and L.A.; project administration, L.A.

Funding

This research received no external funding.

Acknowledgments

We acknowledge any administrative and technical support given by Edinburgh Napier University for materials used for the experiment. We acknowledge the support of City, University of London for providing the FBGs that are used for the experimental work presented here.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cong, J.; Zhang, X.; Chen, K.; Xu, J. Fiber optic Bragg grating sensor based on hydrogels for measuring salinity, Sens. Act., B Chem. 2002, 87, 487–490. [Google Scholar] [CrossRef]

- Al-Fakih, E.A.; Abu Osman, N.A.; Adikan, F.R.M. The Use of Fiber Bragg Grating Sensors in Biomechanics and Rehabilitation Applications: The State-of-the-Art and Ongoing Research Topics. Sensors 2012, 12, 12890–12926. [Google Scholar] [CrossRef] [PubMed]

- Binetti, L.; Stankiewicz, A.; Alwis, L.S.M. Graphene-Oxide and Hydrogel Coated FBG-Based pH Sensor for Biomedical Applications. Proc. 2018, 2, 789. [Google Scholar]

- Ma, J.; Lin, Y.; Chen, X.; Zhao, B.; Zhang, J. Flow behavior, thixotropy and dynamical viscoelasticity of sodium alginate aqueous solutions. Food Hydrocoll. 2014, 38, 119–128. [Google Scholar] [CrossRef]

- de Bruin, C. V. Microbiologische aspecten van de bereiding van hemodialyseconcentraat. Pharm. Weekbl. 1972, 107, 677–686. [Google Scholar] [PubMed]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).