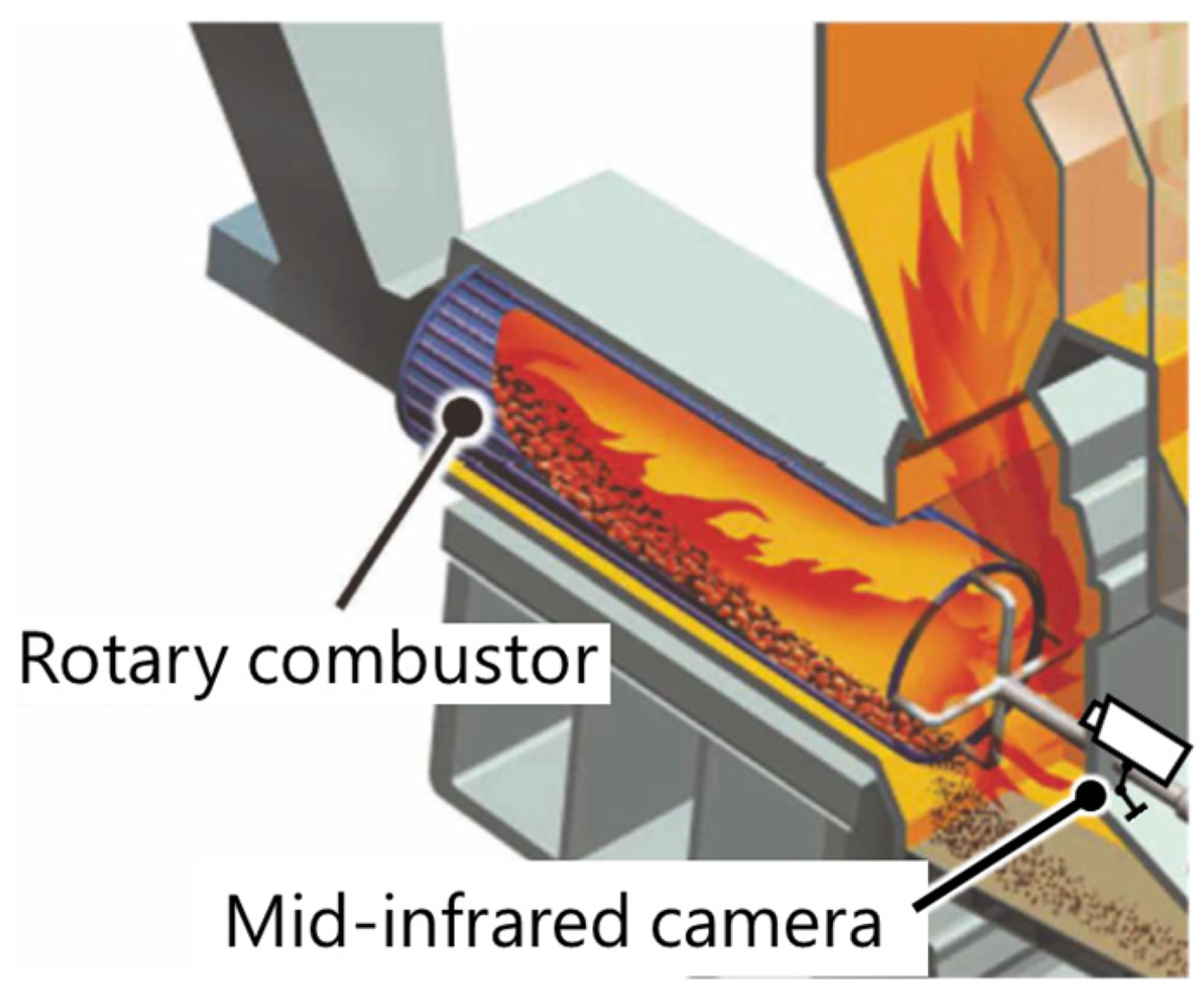

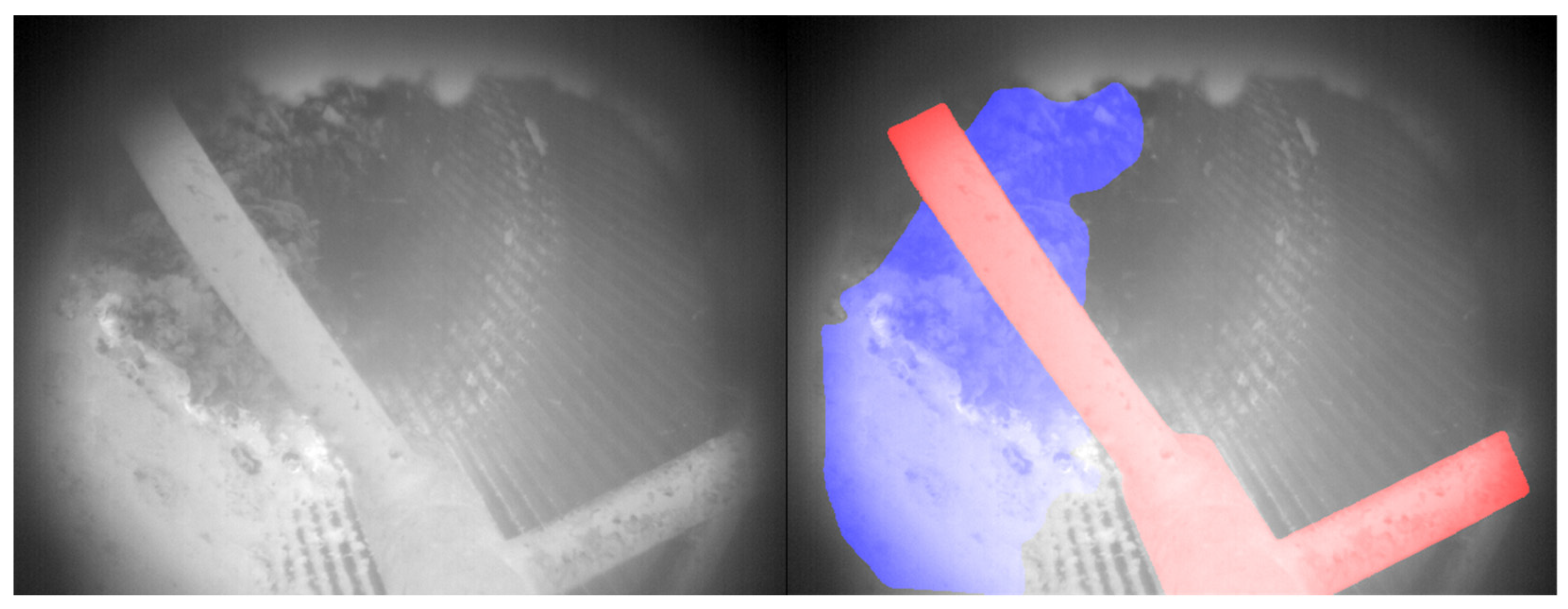

Mid-Infrared Monitoring and Image Processing in a Rotary Combustor †

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Reference

- Cheng, B.; Misra, I.; Schwing, A.G.; Kirillov, A.; Girdhar, R. Masked-attention Mask Transformer for Universal Image Segmentation. In Proceedings of the 2022 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), New Orleans, LA, USA, 18–24 June 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozaki, K.; Kudo, T.; Kajihara, Y.; Tanida, K. Mid-Infrared Monitoring and Image Processing in a Rotary Combustor. Proceedings 2025, 129, 75. https://doi.org/10.3390/proceedings2025129075

Ozaki K, Kudo T, Kajihara Y, Tanida K. Mid-Infrared Monitoring and Image Processing in a Rotary Combustor. Proceedings. 2025; 129(1):75. https://doi.org/10.3390/proceedings2025129075

Chicago/Turabian StyleOzaki, Keita, Takahiro Kudo, Yoshio Kajihara, and Katsuyoshi Tanida. 2025. "Mid-Infrared Monitoring and Image Processing in a Rotary Combustor" Proceedings 129, no. 1: 75. https://doi.org/10.3390/proceedings2025129075

APA StyleOzaki, K., Kudo, T., Kajihara, Y., & Tanida, K. (2025). Mid-Infrared Monitoring and Image Processing in a Rotary Combustor. Proceedings, 129(1), 75. https://doi.org/10.3390/proceedings2025129075