Full-Field Imaging for Evaluating Mode-II Fracture Toughness in CFRP Laminates †

Abstract

1. Introduction

2. Materials and Methods

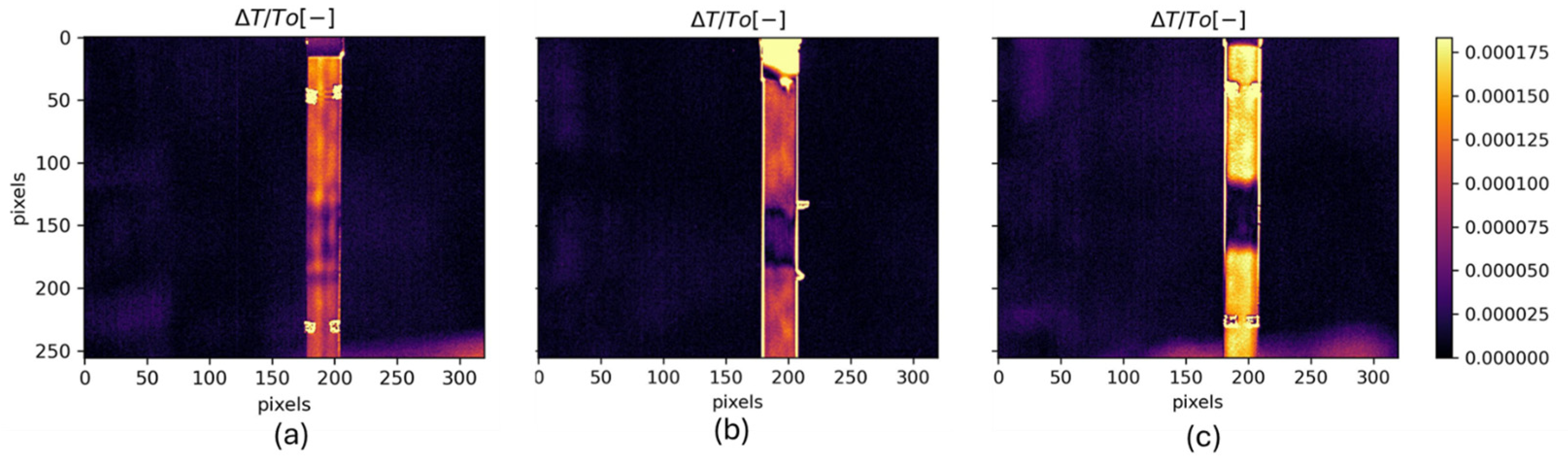

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Wisnom, M.R. On the Increase in Fracture Energy with Thickness in Delamination of Unidirectional Glass Fibre-Epoxy with Cut Central Plies. J. Reinf. Plast. Compos. 1992, 11, 897–909. [Google Scholar] [CrossRef]

- Le Cahain, Y.M.; Noden, J.; Hallett, S.R. Effect of insert material on artificial delamination performance in composite laminates. J. Compos. Mater. 2015, 49, 2589–2597. [Google Scholar] [CrossRef]

- Scalici, T.; Pitarresi, G.; Catalanotti, G.; van der Meer, F.P.; Valenza, A. The Transverse Crack Tension test revisited: An experimental and numerical study. Compos. Struct 2016, 158, 144–159. [Google Scholar] [CrossRef]

- Allegri, G.; Jones, M.I.; Wisnom, M.R.; Hallett, S.R. A new semi-empirical model for stress ratio effect on mode II fatigue delamination growth. Compos. Part A Appl. Sci. Manuf. 2011, 42, 733–740. [Google Scholar] [CrossRef]

- Jiménez-Fortunato, I.; Bull, D.J.; Thomsen, O.T.; Dulieu-Barton, J.M. On the source of the thermoelastic response from orthotropic fibre reinforced composite laminates. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106515. [Google Scholar] [CrossRef]

- Pitarresi, G.; Scalici, T.; Catalanotti, G. Infrared Thermography assisted evaluation of static and fatigue Mode II fracture toughness in FRP composites. Compos. Struct 2019, 226, 111220. [Google Scholar] [CrossRef]

- Cappello, R.; Pitarresi, G.; Catalanotti, G. Thermoelastic Stress Analysis for composite laminates: A numerical investigation. Compos. Sci. Technol. 2023, 241, 110103. [Google Scholar] [CrossRef]

- Wong, T.A.K. A non-adiabatic thermoelastic theory for composite laminates. Phys. Chem. Solids 1991, 52, 483–494. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cappello, R.; Ruiz-Iglesias, R.; Spyridonidis, S.; Chandarana, N.; Dulieu-Barton, J.M. Full-Field Imaging for Evaluating Mode-II Fracture Toughness in CFRP Laminates. Proceedings 2025, 129, 70. https://doi.org/10.3390/proceedings2025129070

Cappello R, Ruiz-Iglesias R, Spyridonidis S, Chandarana N, Dulieu-Barton JM. Full-Field Imaging for Evaluating Mode-II Fracture Toughness in CFRP Laminates. Proceedings. 2025; 129(1):70. https://doi.org/10.3390/proceedings2025129070

Chicago/Turabian StyleCappello, Riccardo, Rafael Ruiz-Iglesias, Spyros Spyridonidis, Neha Chandarana, and Janice M. Dulieu-Barton. 2025. "Full-Field Imaging for Evaluating Mode-II Fracture Toughness in CFRP Laminates" Proceedings 129, no. 1: 70. https://doi.org/10.3390/proceedings2025129070

APA StyleCappello, R., Ruiz-Iglesias, R., Spyridonidis, S., Chandarana, N., & Dulieu-Barton, J. M. (2025). Full-Field Imaging for Evaluating Mode-II Fracture Toughness in CFRP Laminates. Proceedings, 129(1), 70. https://doi.org/10.3390/proceedings2025129070