1. Introduction

Resin materials with high functionality and light weight are drawing the attention of the industrial field to realize carbon neutrality, especially in recent years. However, resin materials are susceptible to degradation due to external factors such as heat, water, and ultraviolet (UV) radiation, depending on their environment. These degradations significantly affect the fatigue strength of the materials. To rapidly and quantitatively evaluate the decrease in fatigue strength of the materials caused by environmental degradation, this study proposes an evaluation method of fatigue damage by infrared measurement. Shiozawa, et al. [

1,

2] proposed an estimation method of the fatigue limit of materials based on the change in dissipated energy using infrared thermography. Dissipated energy is the heat generation caused by plastic deformation in the material. In the case of metallic materials, it has been clarified that the second harmonic component included in actual temperature variations corresponds to dissipated energy of the materials. However, it remains unclear whether resin materials exhibit the same heat generation mechanisms as metallic materials.

Therefore, this study aims to propose an infrared measurement method to evaluate the effect of UV-induced degradation on the fatigue strength of epoxy resin. By extracting the second harmonic component from actual temperature variations, similar to the approach used for metallic materials, we investigated whether evaluation of fatigue damage is feasible for epoxy resin itself and for UV degradation.

2. Experimental Methodology

The material used in this study was a general-purpose epoxy resin, SikaBiresin® TD150 (Sika Japan Ltd., Tokyo, Japan). The specimens were fabricated into a dumbbell-shaped specimen according to JIS K6251 No.8. To clarify the effect of ultraviolet degradation of epoxy resin on fatigue strength, the specimens were irradiated with ultraviolet light using a weathering tester (Suga Test Instruments Co., Ltd., Tokyo, Japan, SX75-2D). The test conditions were xenon lamp wavelengths of 300 to 400 nm, an irradiance of 180 W/m2, a black panel temperature of 63 °C, humidity of 50%, and an irradiation period of 2 months. Hereafter, specimens not irradiated with ultraviolet light are referred to as Virgin, and those irradiated with ultraviolet light are referred to as UV.

Fatigue testing was performed with an electro-hydraulic servo pulser. Fatigue tests were conducted at room temperature with a stress ratio of 0.1 and a frequency of 3 Hz and 5 Hz, and the number of unbroken test cycles was 2 × 106. Infrared measurement during fatigue tests of epoxy resins was conducted in a staircase stress amplitude increase test. In a staircase stress amplitude increase test, stress amplitude is increased in a staircase-like manner every Nstep, and infrared measurements are conducted for each stress amplitude every Nmeasure (<Nstep) cycles. Fourier analysis is performed on the actual temperature variation of the material obtained from the infrared measurement, and the second harmonic components are extracted and plotted as representative values for each stress amplitude. In the case of metallic materials, the second harmonic components increase rapidly after a certain stress amplitude. This certain stress amplitude is used as the estimated fatigue limit. The estimated fatigue limit is roughly consistent with the actual fatigue limit of the materials. In this study, similar experiments were conducted with epoxy resin to evaluate fatigue damage. The staircase stress amplitude increase test was conducted by increasing the stress amplitude by 1 MPa until the specimen fractured. The Nstep and Nmeasure of the staircase stress amplitude increase test were 1000 and 600 cycles, respectively. The conditions of fatigue testing in the staircase stress amplitude increase test were a stress ratio of 0.1 and frequency of 3 Hz. Temperature variations at each stress amplitude in the staircase stress amplitude increase test were measured using infPared thermography, Noxant NoxCam 640 HSi. (Noxant, Palaiseau, France) The measurement conditions were a pixel count of 640 pixels × 512 pixels, a frame rate of 100 Hz, and a shooting time of 10 s.

3. Results and Discussion

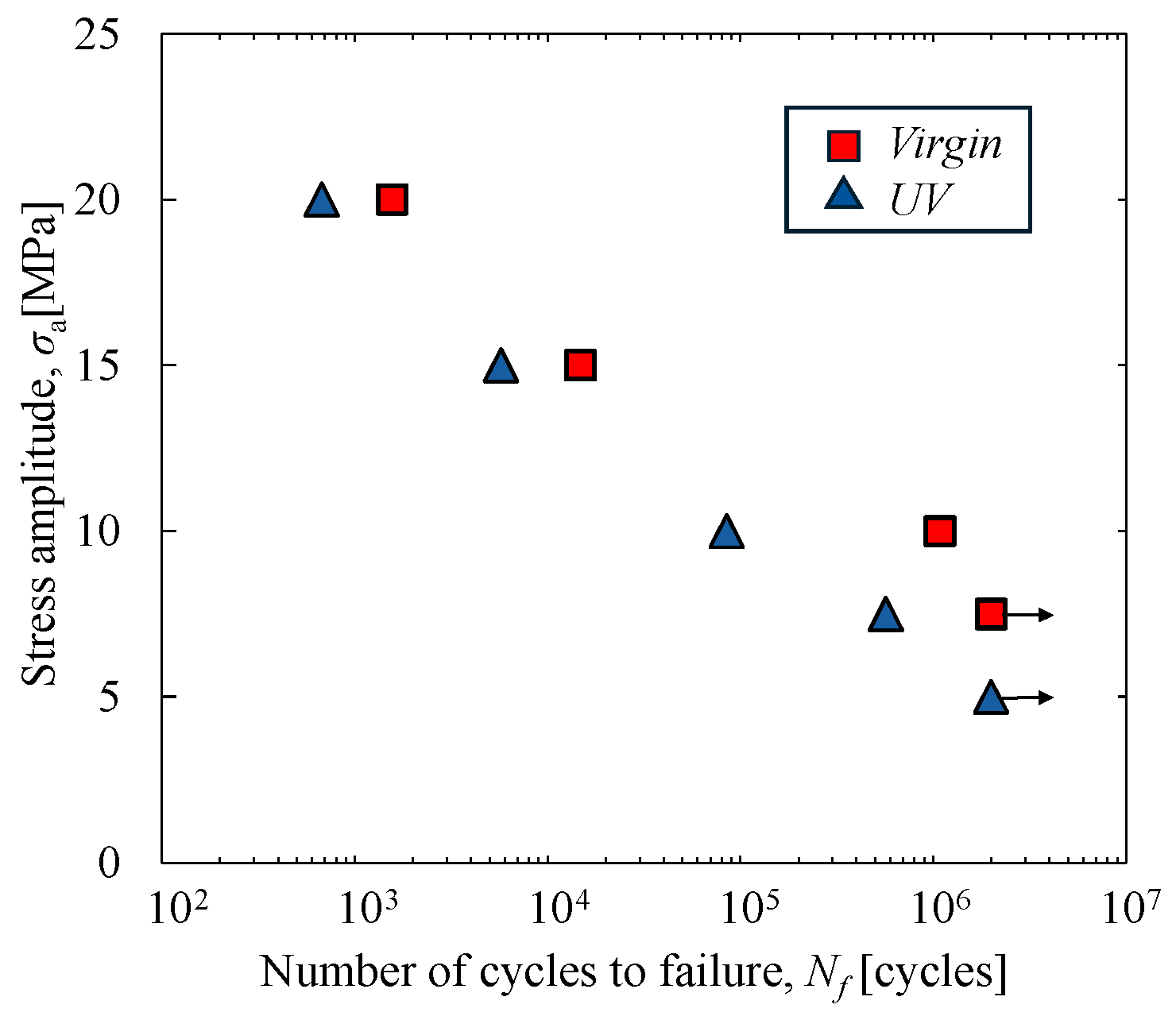

Figure 1 shows the fatigue test results for

Virgin and

UV. The fatigue strength of the

UV was lower than that of

Virgin.

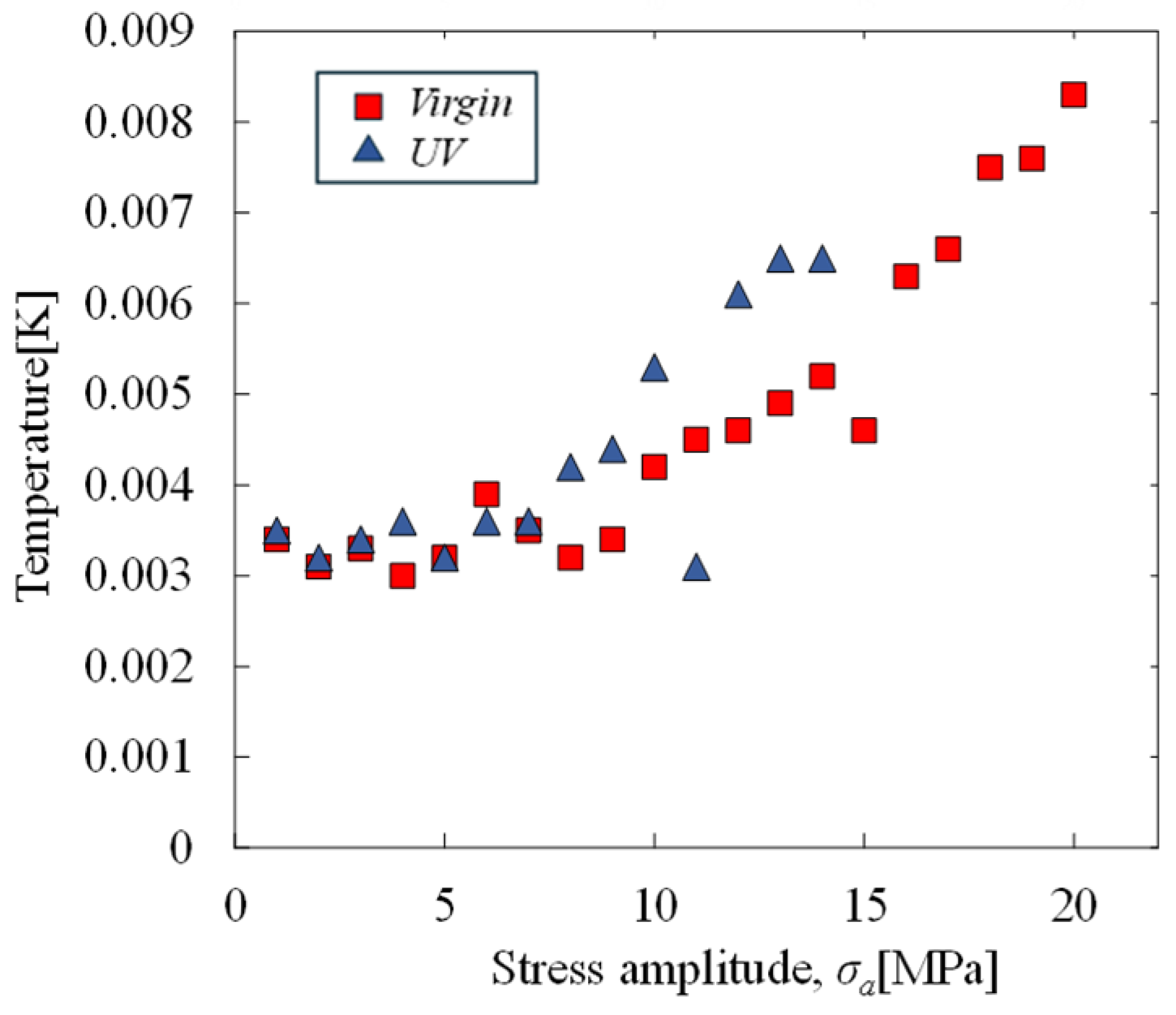

Figure 2 shows the second harmonic component of each stress amplitude for

Virgin and

UV obtained in the staircase stress amplitude increase test. The second harmonic component was evaluated over a 10 × 10-pixel area centered on the fracture origin of the specimens. The second harmonic components of both

Virgin and

UV showed constant values up to a certain stress amplitude; after that, the second harmonic components increased with increasing stress amplitude. This is similar to the tendency of change in the dissipated energy of metallic materials. Therefore, it is inferred that temperature fluctuations due to fatigue damage in epoxy resin appear in the second harmonic component.

UV showed higher values after the stress amplitude that began to increase. Therefore, it is suggested that the second harmonic component of epoxy resin also captures the effect of

UV degradation on fatigue damage and the change in fatigue strength.

4. Conclusions

Comparing the second harmonic components of the resin and UV materials, the UV material shows higher values after the stress amplitude, at which the second harmonic component begins to increase. The effect of the degradation caused by UV irradiation on fatigue damage and the resulting changes in fatigue strength were captured by the second harmonic components.

It is suggested that there is a possibility that the fatigue damage of resin materials can be evaluated by the second harmonic component, as well as that of metal materials.

Author Contributions

Conceptualization, Y.O., H.A. and A.S.; methodology, Y.O. and S.S.; software, M.N.; validation, M.N. and Y.O.; formal analysis, M.N.; investigation, M.N. and Y.O.; resources, Y.O. and S.S.; data curation, M.N.; writing—original draft preparation, M.N., Y.O., H.A., A.S. and S.S.; writing—review and editing, M.N., Y.O., H.A., A.S. and S.S.; visualization, M.N. and Y.O.; supervision, Y.O. and H.A.; project administration, Y.O.; funding acquisition, Y.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no specific grant from any public funding agency.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author S.S. was employed by Mitsubishi Electric Corporation. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Shiozawa, D.; Inagawa, T.; Washio, T.; Sakagami, T. Fatigue limit estimation of stainless steels with new dissipated energy data analysis. Procedia Struct. Integr. 2016, 2, 2091–2096. [Google Scholar]

- Ogawa, Y.; Horita, T.; Iwatani, N.; Kadoi, K.; Shiozawa, D.; Sakagami, T. Evaluation of fatigue strength based on dissipated energy for laser welds. Infrared Phys. Technol. 2022, 125, 104288. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).