1. Introduction

Not only is structural safety a concern for many historical buildings, but the ageing deterioration of materials is also an important issue. To preserve them for future generations, it is essential first to investigate, diagnose, and then repair or reinforce them as necessary. Infrared thermography is one of the most commonly used non-invasive methods to investigate the surface layers of historical buildings.

This paper discusses the results of applying infrared thermography during academic investigations of two Italian treasures [

1]. Imaging was performed to evaluate the condition of the exterior finishes and interior frescoes in the Sanctuary [

2] and to detect cracks that were difficult to observe using visible-light imaging in the airship hangar [

3].

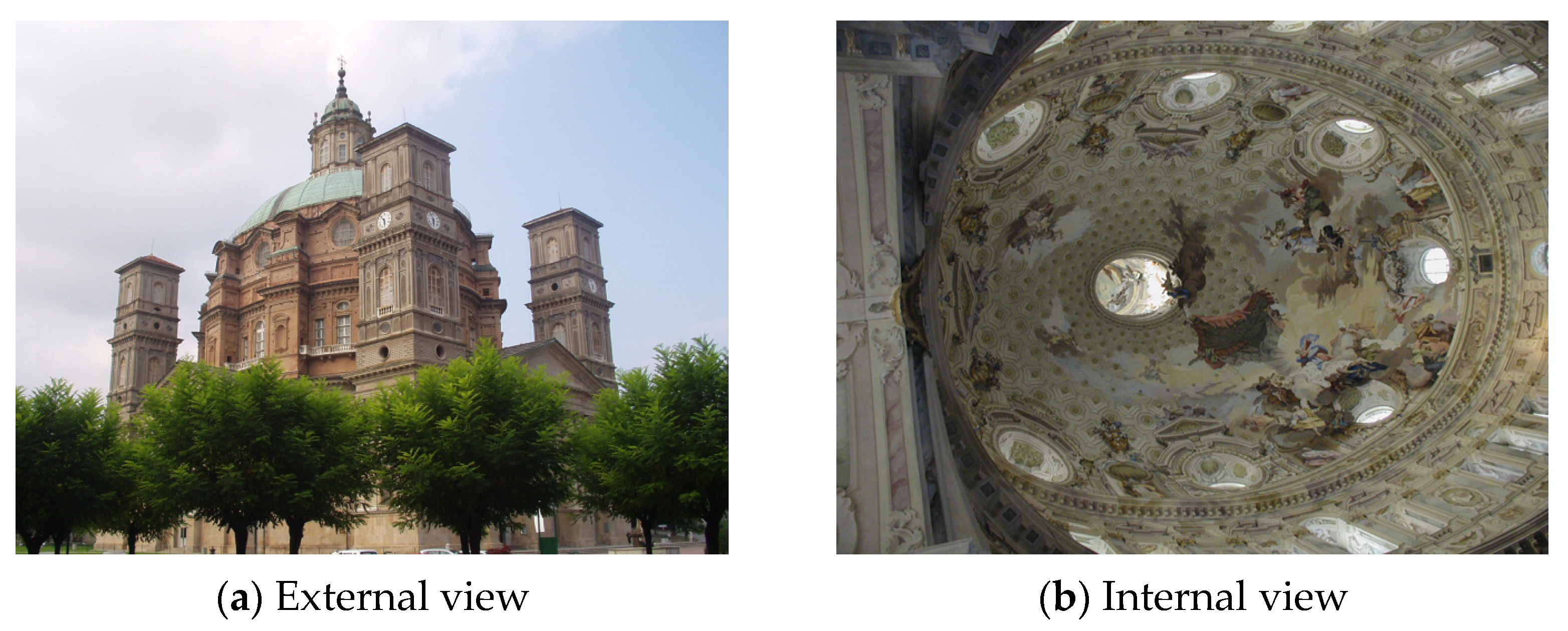

2. Sanctuary of Vicoforte in Piedmont

2.1. Outline of Sanctuary of Vicoforte

The Sanctuary of Vicoforte, located in Mondovì, Piedmont, Italy (construction began in 1596, dome erected in 1731, lantern completed in 1733;

Figure 1), features the world’s largest elliptical masonry dome, with a major axis of approximately 37.15 m, a minor axis of about 24.80 m, and a height of approximately 16.60 m. The height from the ground to the top of the lantern is around 84 m. The church follows an elliptical centralized plan, with an altar room to the north and four bell towers added later. The church’s drum exposes the masonry. The lower external walls are finished with stone cladding, while the bell towers have brick structures with mortar finishes.

The Vicoforte dome is one of the largest elliptical domes in the world. Due to its construction history and architectural features, it was designated an Italian national monument in 1880, attracting numerous visitors for worship and tourism.

Historical buildings are important assets not only for the structures themselves but also for the historically significant decorations, such as murals, found on both the exterior and interior spaces. As many of these historic buildings serve as tourist resources, even non-destructive investigations face challenges:

Setting up temporary scaffolding is challenging.

Hammer-sounding tests, which can damage surface finishing materials, are often prohibited due to cultural property protection.

Under these conditions, infrared thermography and visible images taken with a digital camera have been considered practical non-contact techniques for historical buildings.

At Vicoforte, measurement of deterioration of the interior and exterior finishing materials was conducted. The results are reported in

Section 2.2 and

Section 2.3.

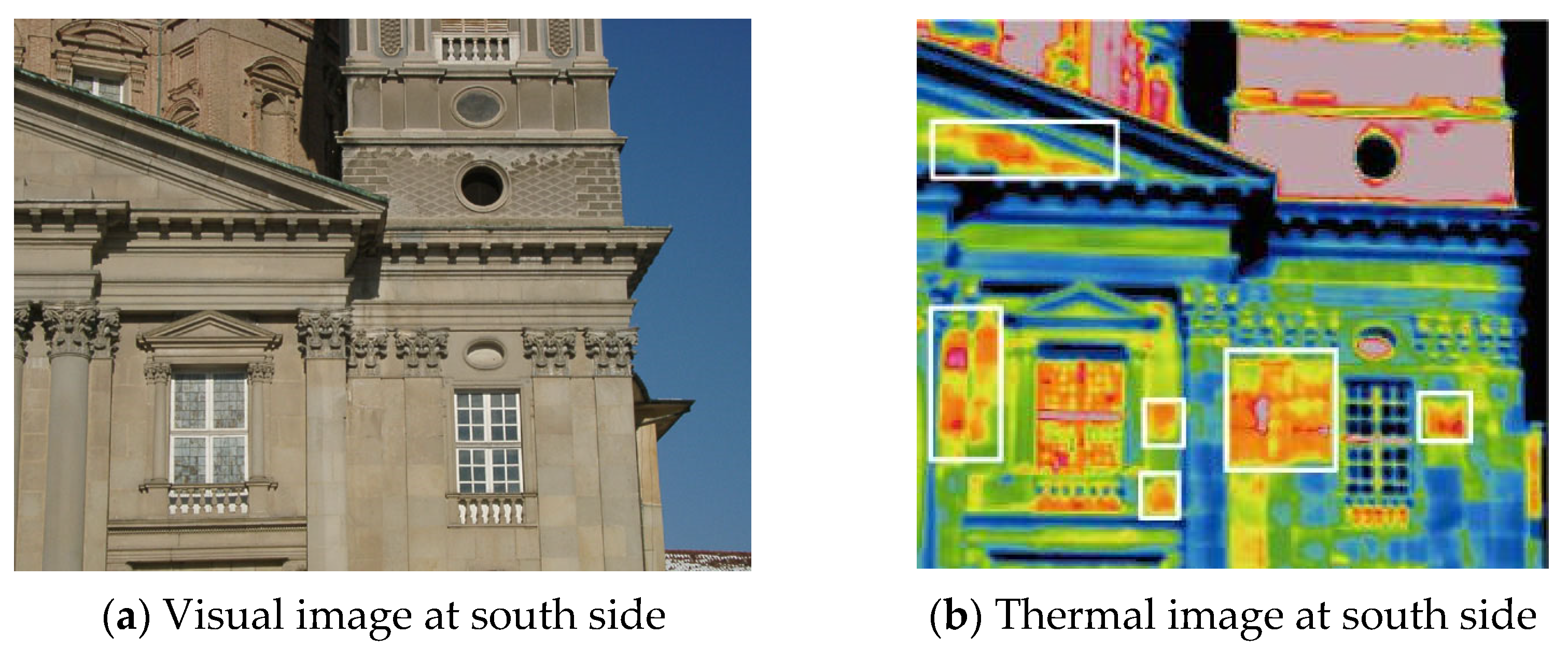

2.2. Measurement Results of Outer Wall

The results, as thermal images, are shown in

Figure 2. According to the principle of defect detection using infrared thermography, when heated by solar radiation, spalling areas of the stone cladding are clearly detected as high temperature zones.

It was confirmed that defects in stone finishing could be detected using infrared thermography. Based on these results, reinforcement work was carried out.

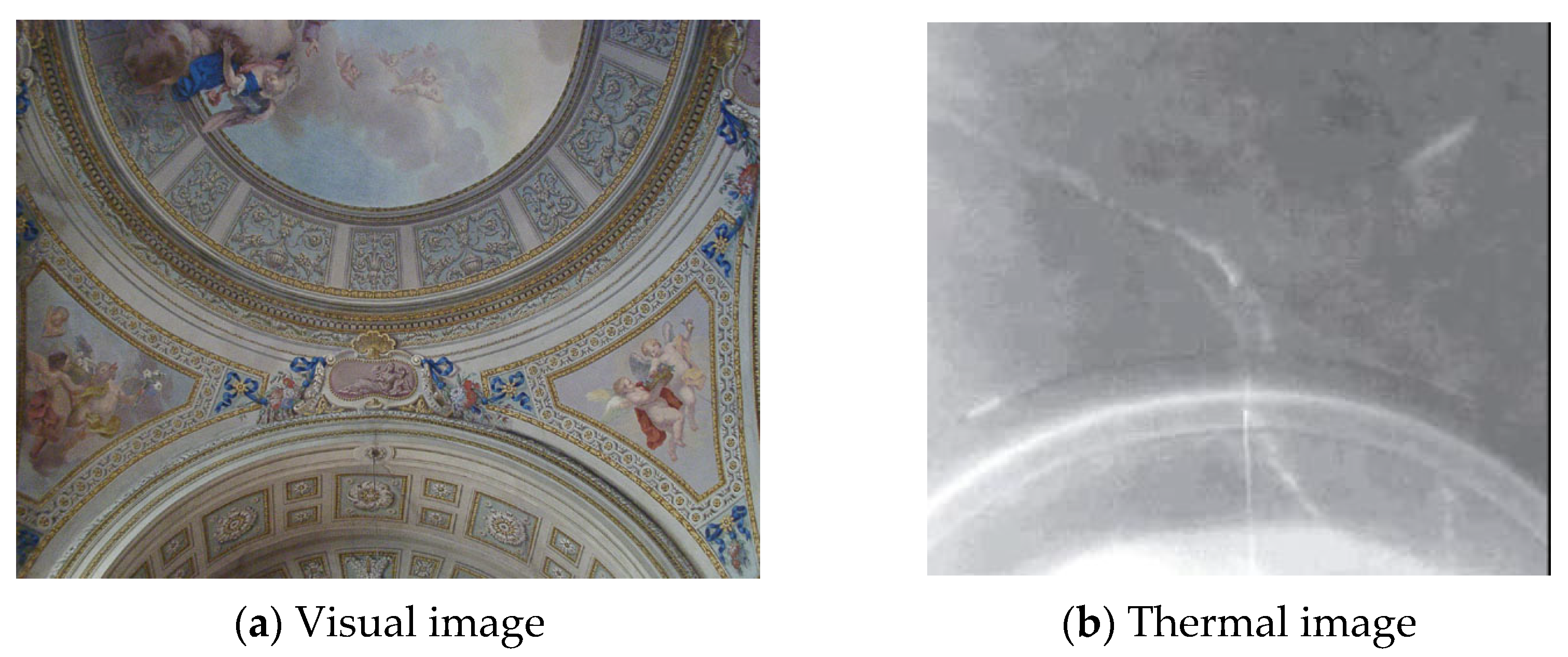

2.3. Measurement Results of the Interior Frescoes

The measurement results for the first-floor chapel are shown in

Figure 3. Areas showing delamination in the frescoes, which pose a risk of falling, were clearly detected as high-temperature zones.

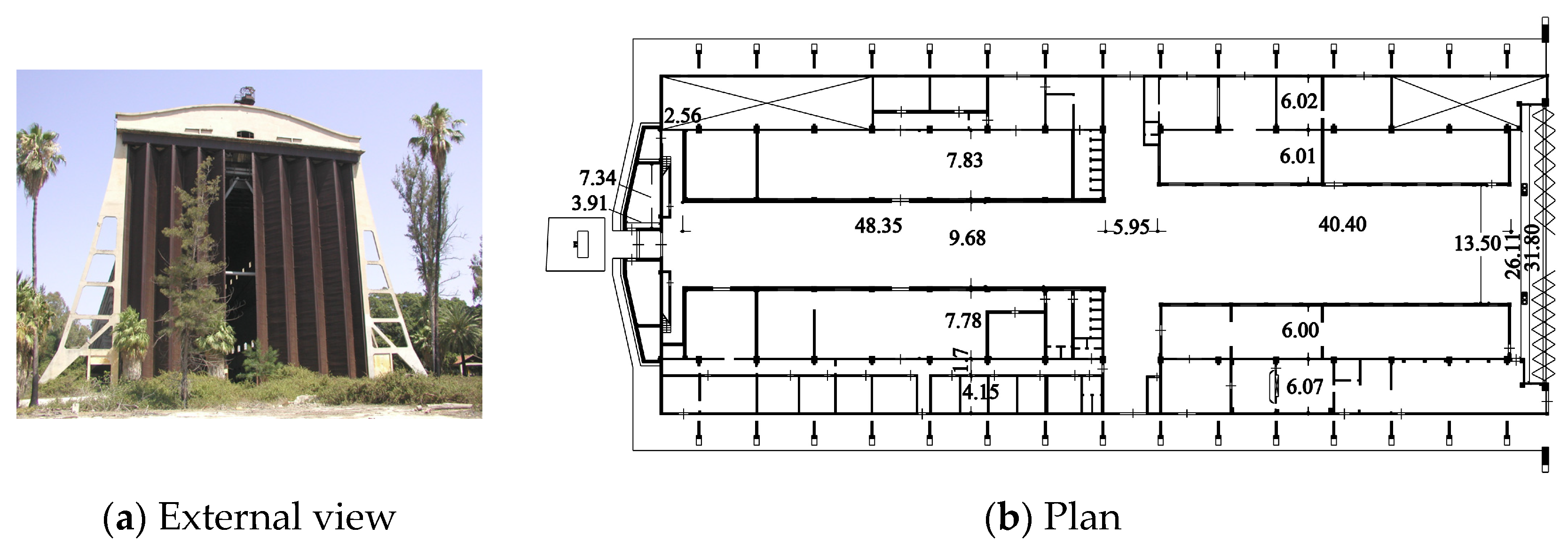

3. Airship Hangar in Augusta

3.1. Outline of Airship Hangar

Construction of the airship hangar in Augusta began in 1917. It is located atop a hill 32 m above sea level, between the Pastandrea and Costa dei Conti districts, overlooking the Megarese harbor.

The hangar, capable of housing an airship of 12,000 m

3, is regarded as the only remaining example in the world built of reinforced concrete. The structure consists of 16 reinforced concrete buttresses, horizontal connecting beams, and walls. Its dimensions are approximately 105.5 m in length, 45.2 m in width, and 37.0 m in height, with internal dimensions of 100.0 m (length), 26.0 m (width), and 31.0 m (height) (

Figure 4).

Though designated a national monument on 24 December 1987, the hangar had suffered extensive damage from frequent hooligan activity at the time of the survey. The weight of the iron doors caused differential settlement, resulting in large cracks in the roof and wall surfaces and raising serious concerns over structural stability.

Although the hangar is surrounded by dense forest, making exterior wall measurements difficult, the walls are thin (about 10 cm). Thus, heat from sunlight easily penetrated the interior, and we attempted to detect deterioration of the walls and roof slab primarily by internal measurements.

3.2. Measurement Results

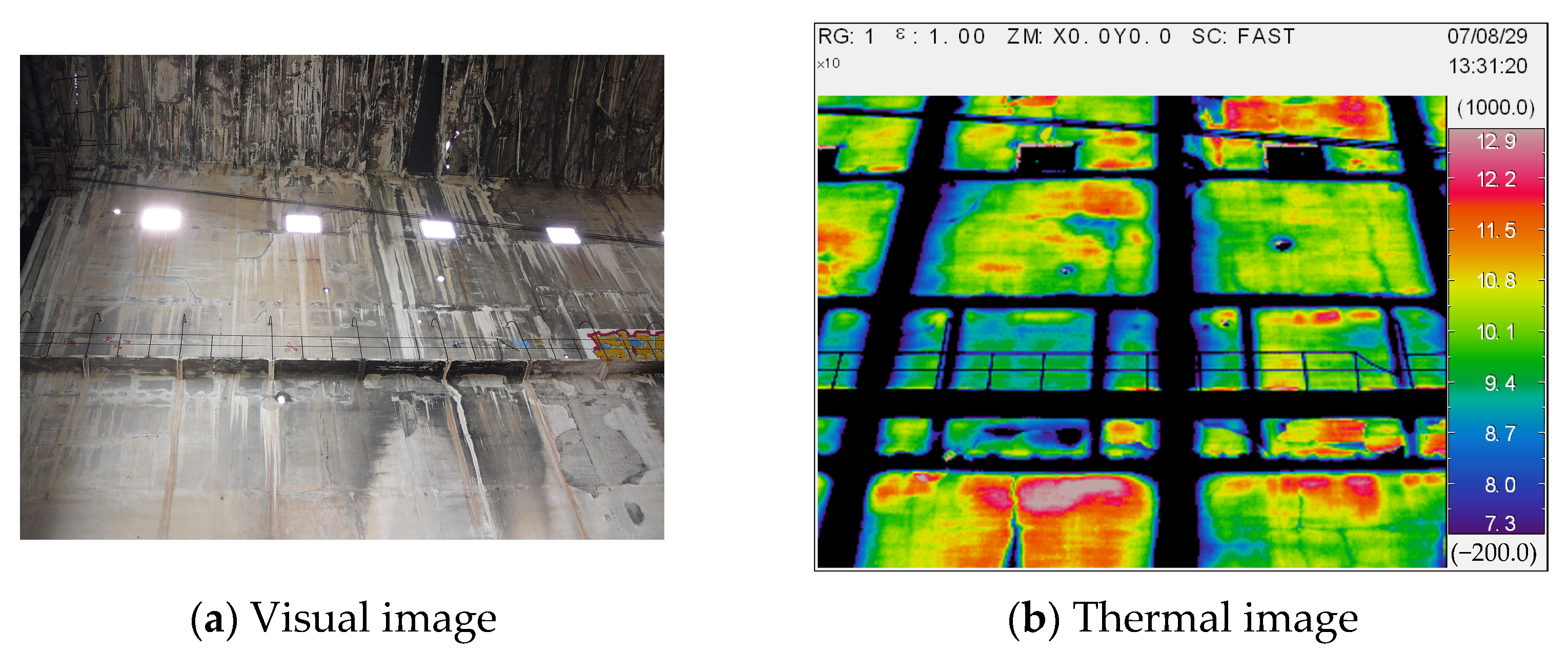

Figure 5 shows the results of measuring the west exterior wall from the inside.

The influence of heat entering from outside through through-cracks in the exterior wall made the cracks detectable as high-temperature regions.

4. Conclusions

This paper has reported case studies of the application of infrared thermography in academic surveys of Italian historical structures—the Sanctuary of Vicoforte and the airship hangar in Augusta.

At the Sanctuary, infrared thermography enabled non-contact, non-destructive measurement for the deterioration of stone cladding and interior frescoes, successfully detecting delamination and areas of damage. For interior fresco diagnosis using artificial heating, large-scale delamination was detected in high-temperature areas, but the detection of small-scale delamination was limited.

At the airship hangar, the survey demonstrated that, for thin exterior walls and roof slabs, a combination of solar heating and internal measurement could enable the detection of through-cracks, concrete spalling, and delaminated zones.

These results demonstrate that infrared thermography is a valuable, non-destructive, non-contact diagnostic tool for the preservation and maintenance management of historical structures.

Author Contributions

Conceptualization, D.S. and T.A.; methodology, D.S.; software, D.S.; validation, D.S. and T.A.; investigation, D.S. and T.A.; data curation, D.S. and T.A.; writing—original draft preparation, D.S. and T.A.; writing—review and editing, D.S. and T.A.; visualization, D.S. and T.A.; supervision, D.S. and T.A.; project administration, T.A.; funding acquisition, T.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by JSPS KAKENHI Grant Numbers 23K25413.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available upon request; to those interested, please contact the corresponding author.

Conflicts of Interest

Author Daisuke Sato is employed by the company Constec Engi, Co. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Aoki, T. Investigation on Structural System, Material and Restoration Strategies of Historical Masonry Structures and RC Structures in Itary, 2008. Available online: https://kaken.nii.ac.jp/en/grant/KAKENHI-PROJECT-18254004/ (accessed on 7 September 2025).

- Aoki, T.; Hamasaki, H.; Komiyama, T.; Yuasa, N.; Tanigawa, Y. Deterioration investigation of airship hanger in Augusta, Italy. AIJ J. Technol. Des. 2006, 23, 53–58. [Google Scholar] [CrossRef]

- Sato, D.; Sakagami, T.; Komiyama, T.; Kubo, S.; Aoki, T. Self-reference lock-in thermography for inspection of historic landmark. In Proceedings of the JSNDI Fall Conference, Sapporo, Japan, 18–19 October 2007; pp. 257–260. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).