Defect Size Estimation of Building’s Exterior Wall Using Thermal Decay Gradient Approach †

1. Introduction

2. Materials and Methods

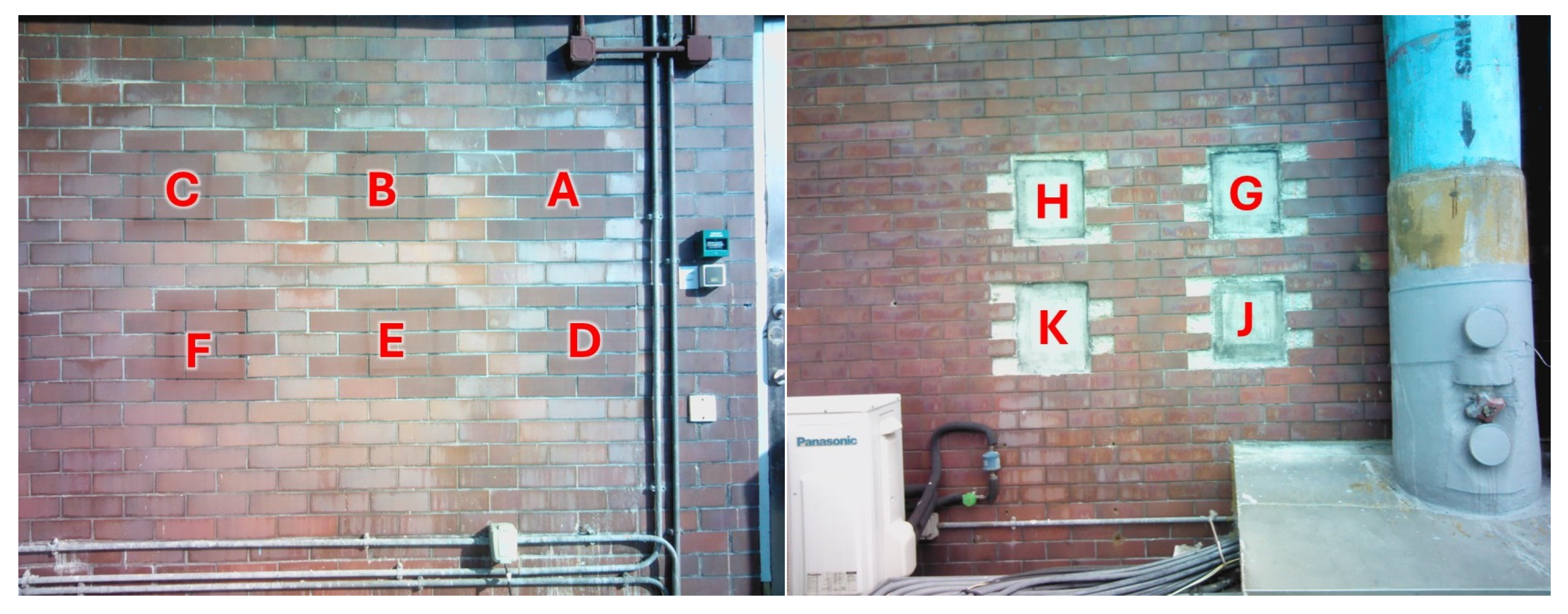

2.1. Experimental Setup

2.2. Methodology

3. Results and Discussion

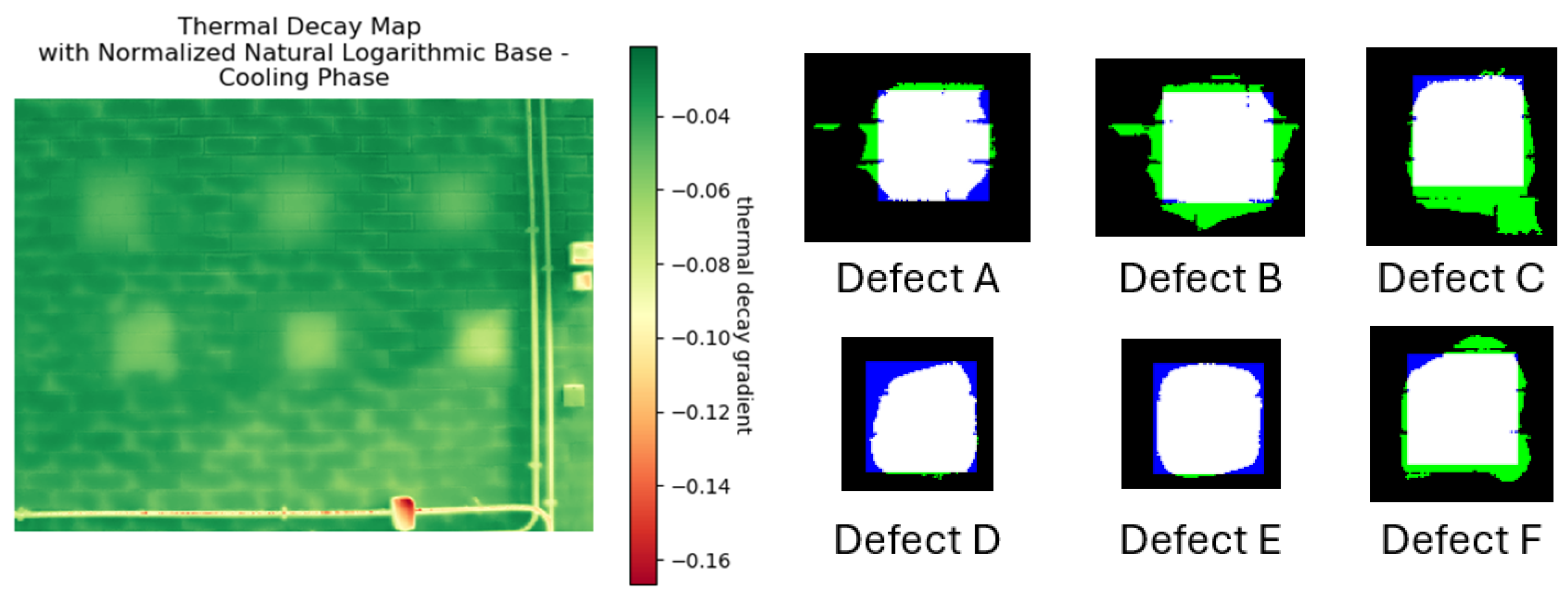

3.1. Resulting Thermal Decay Map

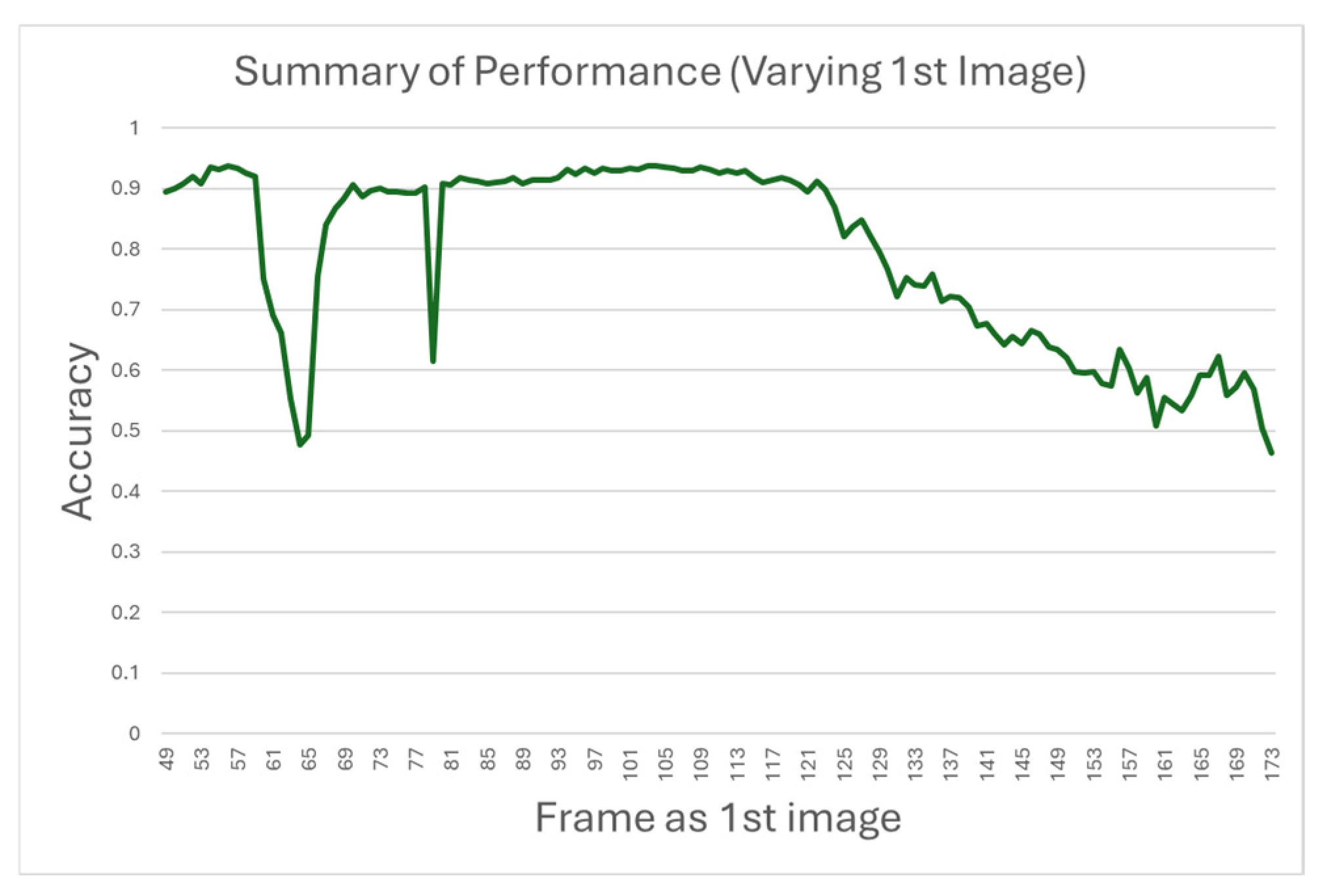

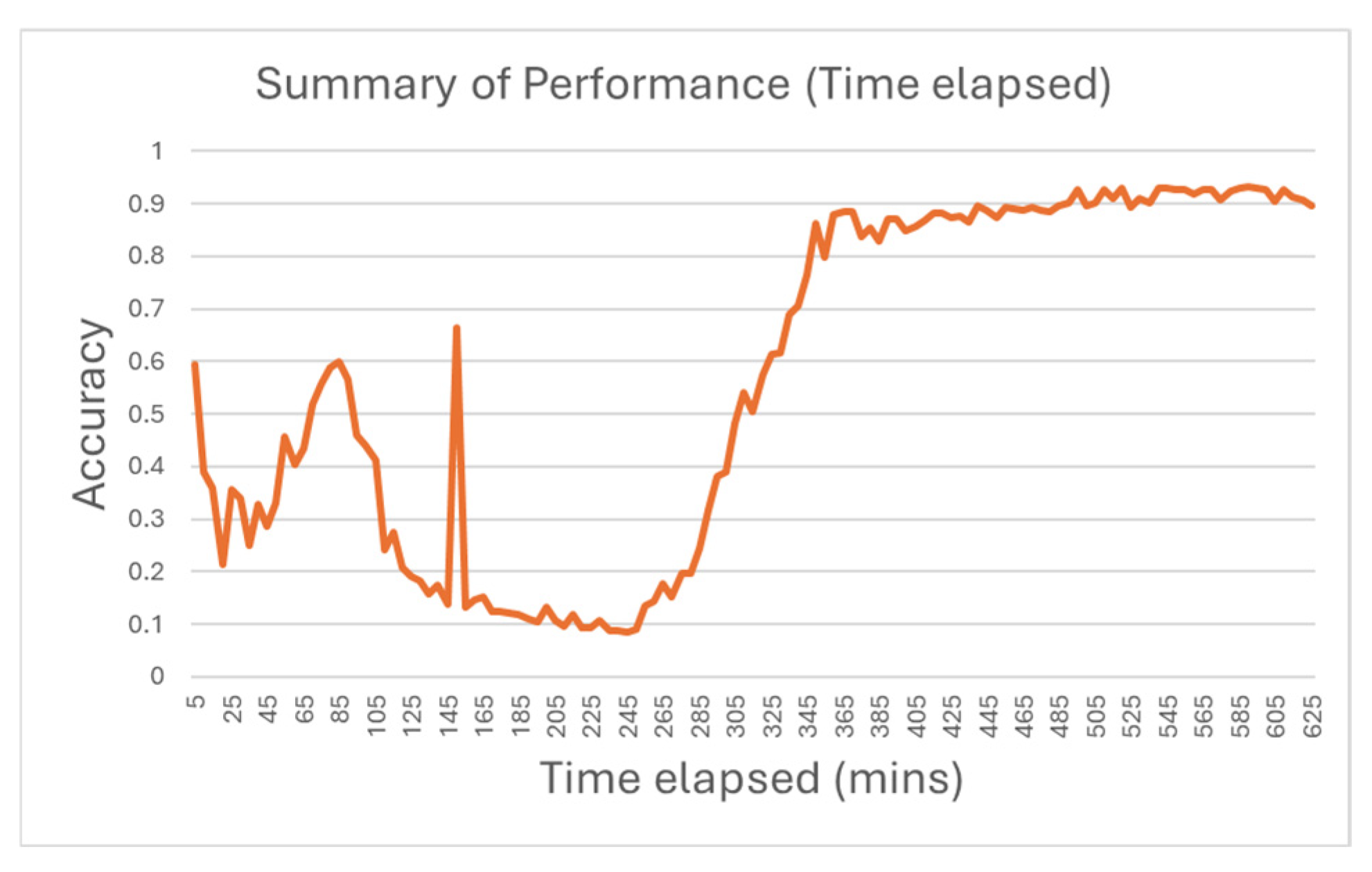

3.2. Selection of Thermal Images for Creating a Thermal Decay Map

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al Gharawi, M.; Adu-Gyamfi, Y.; Washer, G. A framework for automated time-lapse thermography data processing. Constr. Build. Mater. 2019, 227, 116507. [Google Scholar] [CrossRef]

- Meola, C.; Di Maio, R.; Roberti, N.; Carlomgano, G.M. Application of infrared thermography and geophysical methods for defect detection in architectural structures. Eng. Fail. Anal. 2005, 12, 875–892. [Google Scholar] [CrossRef]

- Lai, W.L.; Lee, K.K.; Kou, S.C.; Poon, C.S.; Tsang, W.F. A study of full-field debond behaviour and durability of CFRP-concrete composite beams by pulsed infrared thermography (IRT). NDT E Int. 2012, 52, 112–121. [Google Scholar] [CrossRef]

- Lai, W.L.; Lee, K.K.; Poon, C.S. Validation of size estimation of debonds in external wall’s composite finishes via passive infrared thermography and a gradient algorithm. Constr. Build. Mater. 2015, 87, 113–124. [Google Scholar] [CrossRef]

- Chiu, L.S.Y.; Lai, W.W.L.; Santos-Assunção, S.; Sandhu, S.S.; Sham, J.F.C.; Chan, N.F.S.; Wong, J.C.F.; Leung, W.K. A Feasibility Study of Thermal Infrared Imaging for Monitoring Natural Terrain—A Case Study in Hong Kong. Remote Sens. 2023, 15, 5787. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiu, L.S.-Y.; Lai, W.W.-L. Defect Size Estimation of Building’s Exterior Wall Using Thermal Decay Gradient Approach. Proceedings 2025, 129, 3. https://doi.org/10.3390/proceedings2025129003

Chiu LS-Y, Lai WW-L. Defect Size Estimation of Building’s Exterior Wall Using Thermal Decay Gradient Approach. Proceedings. 2025; 129(1):3. https://doi.org/10.3390/proceedings2025129003

Chicago/Turabian StyleChiu, Lydia Sin-Yau, and Wallace Wai-Lok Lai. 2025. "Defect Size Estimation of Building’s Exterior Wall Using Thermal Decay Gradient Approach" Proceedings 129, no. 1: 3. https://doi.org/10.3390/proceedings2025129003

APA StyleChiu, L. S.-Y., & Lai, W. W.-L. (2025). Defect Size Estimation of Building’s Exterior Wall Using Thermal Decay Gradient Approach. Proceedings, 129(1), 3. https://doi.org/10.3390/proceedings2025129003