Economic Evaluation of Novel C-Zero Processes for the Efficient Production of Energy, Chemicals, and Fuels †

Abstract

1. Introduction

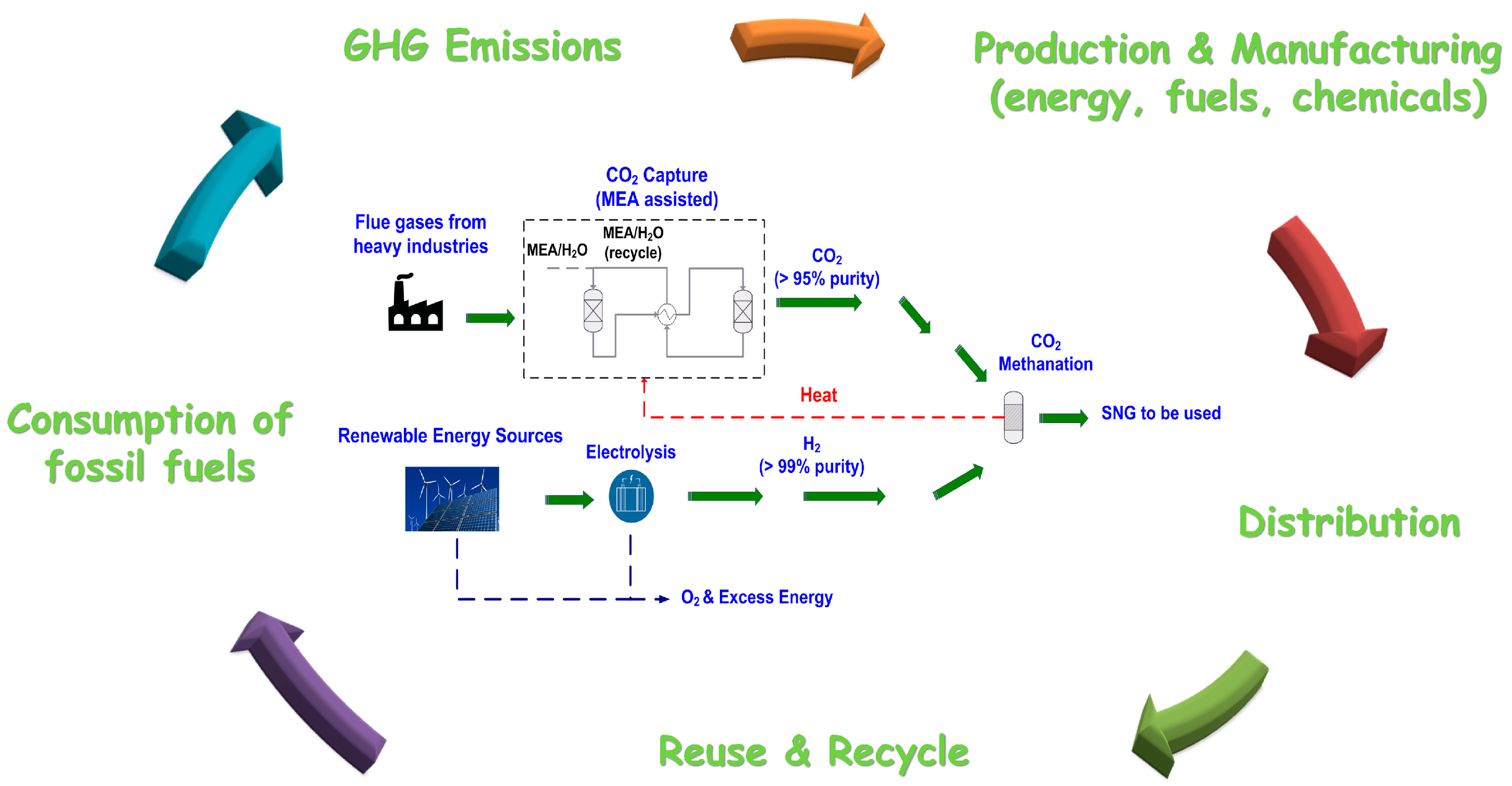

2. Steps Followed Towards the Economic Evaluation of C-Zero Processes

3. Process Description and Scaled-Up Simulation

3.1. SNG Production Through Captured CO2 and RES-H2

3.2. Electricity and Crude Biofuel Production Through Olive Kernel Valorization

4. Economic Analysis of the Novel C-Zero Processes

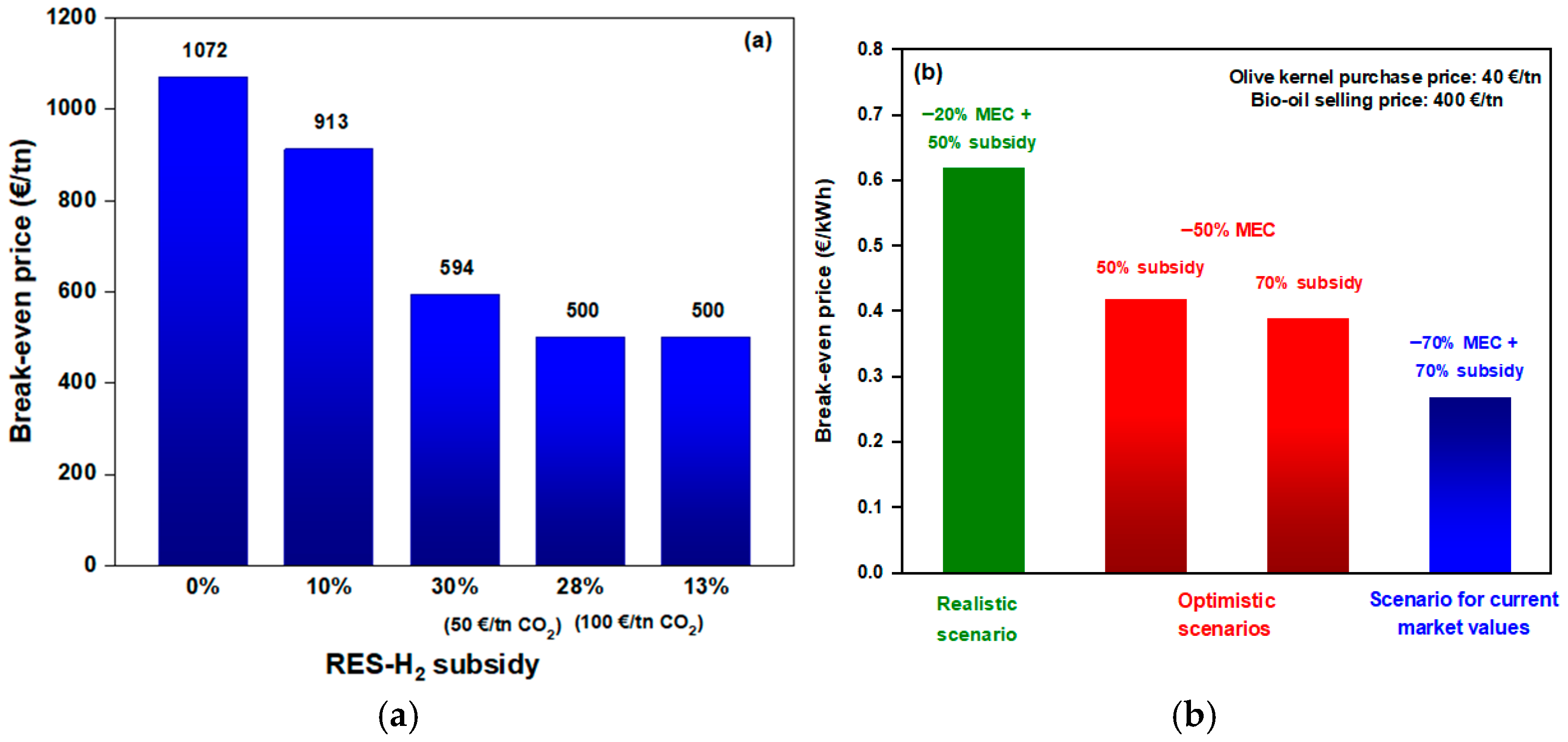

4.1. SNG Production Through Captured CO2 and RES-H2

4.2. Electricity and Crude Biofuel Production Through Olive Kernel Valorization

4.3. Critical Analysis and a Future Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ipsakis, D.; Varvoutis, G.; Lampropoulos, A.; Papaefthimiou, S.; Marnellos, G.E. Τechno-economic assessment of industrially-captured CO2 upgrade to synthetic natural gas by means of renewable hydrogen. Renew. Energy 2021, 179, 1884–1896. [Google Scholar] [CrossRef]

- Lampropoulos, A.; Varvoutis, G.; Mandela, E.; Konsolakis, M.; Marnellos, G.E. Techno-economic assessment of an autothermal poly generation process involving pyrolysis, gasification and SOFC for olive kernel valorization. Int. J. Hydrogen Energy 2023, 48, 39463–39483. [Google Scholar] [CrossRef]

- European Commission. Europe’s 2030 Climate and Energy Targets. Research & Innovation Actions. Available online: https://op.europa.eu/en/publication-detail/-/publication/1c8ab88a-e44d-11eb-895a-01aa75ed71a1/language-en/format-PDF/source-219125747 (accessed on 22 July 2025).

- IEA. Net Zero by 2050: A Roadmap for the Global Energy Sector, Int. Energy Agency. Available online: https://iea.blob.core.windows.net/assets/deebef5d-0c34-4539-9d0c-10b13d840027/NetZeroby2050-ARoadmapfortheGlobalEnergySector_CORR.pdf (accessed on 22 July 2025).

- Peters, M.S.; Peters, J.I. Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 1959. [Google Scholar]

- Towler, G.; Sinnott, R.K. Chemical Engineering Design—Principles, Practice and Economics of Plant and Process Design, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Psarros, G.N.; Stavros, P.A. Electricity storage requirements to support the transition towards high renewable penetration levels—Application to the Greek power system. J. Energy Storage 2022, 55, 105748. [Google Scholar] [CrossRef]

- Ruhnau, O.; Qvist, S. Storage requirements in a 100% renewable electricity system: Extreme events and inter-annual variability. Environ. Res. Lett. 2022, 17, 044018. [Google Scholar] [CrossRef]

| Cost Type | MEA-CO2 | RES-H2 | SNG Production (Including Utilities) | Biomass to Power and Biofuels |

|---|---|---|---|---|

| CAPEX, EUR | 159,326,500 | 9,060,667,150 | 487,710,300 | 35,179,298 |

| OPEX, EUR/y | 50,352,200 | 39,811,900 | 55,315,000 | 8,283,850 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ipsakis, D.; Varvoutis, G.; Lampropoulos, A.; Athanasiou, C.; Lykaki, M.; Mandela, E.; Damartzis, T.; Papaefthimiou, S.; Konsolakis, M.; Marnellos, G.E. Economic Evaluation of Novel C-Zero Processes for the Efficient Production of Energy, Chemicals, and Fuels. Proceedings 2025, 121, 13. https://doi.org/10.3390/proceedings2025121013

Ipsakis D, Varvoutis G, Lampropoulos A, Athanasiou C, Lykaki M, Mandela E, Damartzis T, Papaefthimiou S, Konsolakis M, Marnellos GE. Economic Evaluation of Novel C-Zero Processes for the Efficient Production of Energy, Chemicals, and Fuels. Proceedings. 2025; 121(1):13. https://doi.org/10.3390/proceedings2025121013

Chicago/Turabian StyleIpsakis, Dimitris, Georgios Varvoutis, Athanasios Lampropoulos, Costas Athanasiou, Maria Lykaki, Evridiki Mandela, Theodoros Damartzis, Spiros Papaefthimiou, Michalis Konsolakis, and George E. Marnellos. 2025. "Economic Evaluation of Novel C-Zero Processes for the Efficient Production of Energy, Chemicals, and Fuels" Proceedings 121, no. 1: 13. https://doi.org/10.3390/proceedings2025121013

APA StyleIpsakis, D., Varvoutis, G., Lampropoulos, A., Athanasiou, C., Lykaki, M., Mandela, E., Damartzis, T., Papaefthimiou, S., Konsolakis, M., & Marnellos, G. E. (2025). Economic Evaluation of Novel C-Zero Processes for the Efficient Production of Energy, Chemicals, and Fuels. Proceedings, 121(1), 13. https://doi.org/10.3390/proceedings2025121013