Enhancing Food Security and Nutrition Through Indigenous Agro-Product-Based Functional Foods: A Case Study on Composite Flour Development †

Abstract

1. Introduction

2. Methods

2.1. Sample Collection and Authentication

2.2. Sample Processing and Fermentation

2.3. Experimental Design

2.4. Production of Baked Products

2.5. Physicochemical Property Determination

2.5.1. Proximate Composition

2.5.2. Techno-Functional Composition of the Flours

2.5.3. Mineral Analysis

2.5.4. Antioxidant Activities

2.5.5. Anti-Nutritional Composition

2.6. The Determination of the Color

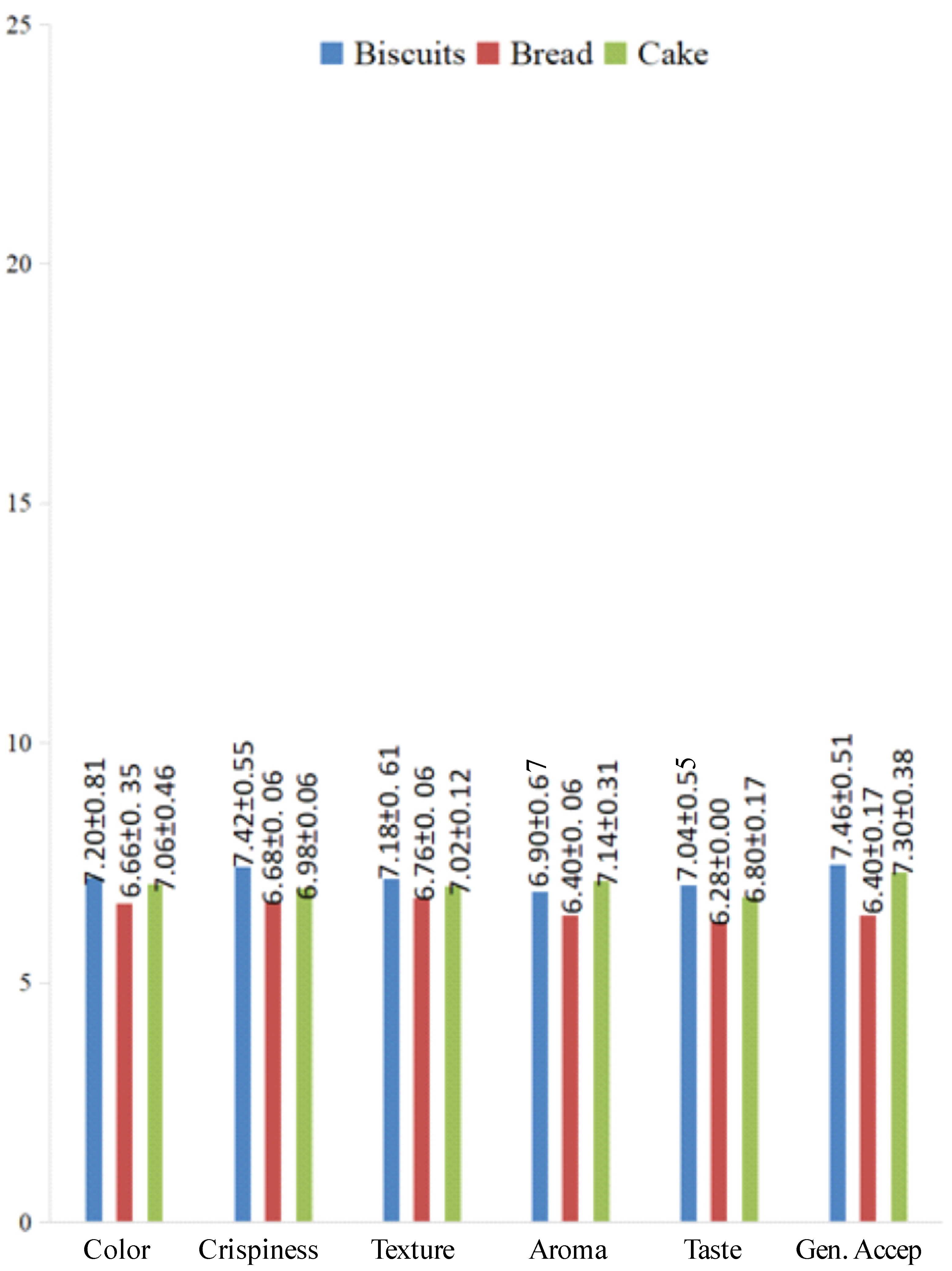

2.7. Sensory Evaluation

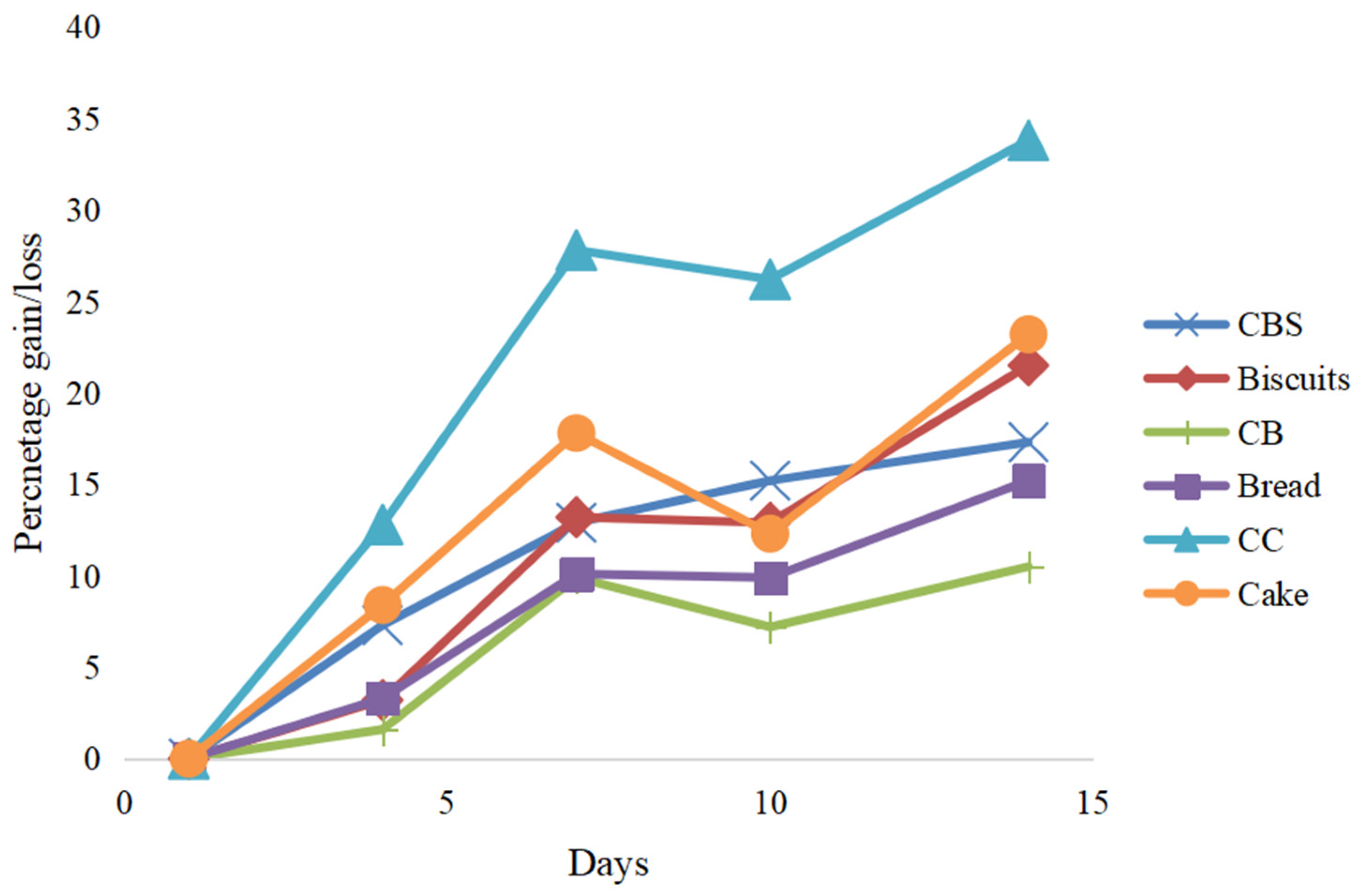

2.8. In Vivo Animal Experiment

2.9. Analysis of Data

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Food and Agriculture Organization (FAO). The State of Food Security and Nutrition in the World 2022. Repurposing Food and Agricultural Policies to Make Healthy Diets More Affordable; FAO: Rome, Italy, 2022; ISBN 978-92-5-136499-4. ISSN 2663-807X. [Google Scholar] [CrossRef]

- Oleghe, P.O.; Akharaiyi, F.C.; Ehis-Eriakha, C.B. Harnessing indigenous agro-processed flour blends as composite bioresources in functional food development. Food Res. 2024, 8, 235–249. [Google Scholar] [CrossRef] [PubMed]

- Dyvik, E.H. Number of Undernourished/Hungry People Worldwide 2000–2022. Available online: https://www.statista.com/statistics/264900/number. (accessed on 25 January 2024).

- Countrymeters. Nigeria Population (2024) Live. Available online: https://countrymeters.info/en/Nigeria (accessed on 25 January 2024).

- Sasu, D.D. Undernourishment and Food Insecurity in the Nigerian Population 2004–2022. Available online: https://www.statista.com/statistics/1262212/undernourishment (accessed on 18 January 2024).

- National Bureau of Statistics. Multidimensional Poverty Index (MPI). Available online: www.nigerianstat.gov.ng (accessed on 25 September 2024).

- Butnariu, M.; Sarac, I. Functional Food (Review). Int. J. Nutr. 2019, 3, 7–16. [Google Scholar] [CrossRef]

- Galanakis, C.M.; Aldawoud, T.M.S.; Rizou, M.; Rowan, N.; Ibrahim, S. Food ingredients and active compounds against the coronavirus disease (COVID-19) pandemic: A comprehensive review. Foods 2020, 9, 1701. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Li, Y.; Li, X.; Zhou, D.; Wang, Y.; Wen, X.; Wang, C.; Liu, X.; Feng, Y.; Li, B.; et al. Functional foods and intestinal homeostasis: The perspective of in-vivo evidence. Trends Food Sci. Technol. 2021, 111, 475–482. [Google Scholar] [CrossRef]

- Oleghe, P.O.; Akharaiyi, F.C.; Ehis-Eriakha, C.B. Compositions nutrient and antinutrients of biscuits prepared from fermentedand unfermented ternary mixture flours. J. Food Qty. Haz. Control 2024, 11, 13–25. [Google Scholar] [CrossRef]

- Su, W.H.; He, H.J.; Sun, D.W. Non-Destructive and rapid evaluation of staple foods quality by using spectroscopic techniques: A review. Crit. Rev. Food Sci. Nutr. 2016, 57, 1039–1051. [Google Scholar] [CrossRef]

- John, R.; Singla, A. Functional foods: Components, health benefits, challenges, and major projects. DRC Sustain. Future J. Environ. Agric. Energy 2021, 2, 61–72. [Google Scholar] [CrossRef]

- Shah, A.M.; Tarfeen, N.; Mohamed, H.; Song, Y. Fermented foods: Their health-promoting components and potential effects on gut microbiota. Fermentation 2023, 9, 118. [Google Scholar] [CrossRef]

- Cámara, M.; Sánchez-Mata, M.C.; Fernández-Ruiz, V.; Cámara, R.M.; Cebadera, E.; Domínguez, L. A review of the role of micronutrients and bioactive compounds on immune system supporting to fight against the COVID-19 disease. Foods 2021, 10, 1088. [Google Scholar] [CrossRef]

- Oleghe, P.O.; Akharaiyi, F.C.; Ehis-Eriakha, C.B.; Oboh, E.J. Microbiological and Physiochemical Properties of Fermented and Unfermented Sweet Potato Flour. Eur. Food Sci. Eng. 2023, 4, 1–9. [Google Scholar] [CrossRef]

- Olorunfemi, M.A.; Awolu, O.O.; Enujiugha, V.N. Evaluation of the chemical, antinutritional and antioxidant properties of composite flour comprising native and modified acha (Digitaria exilis stapf) flour supplemented with mango kernel seed and soy cake flours. Food Sci. Technol. Int. 2021, 28, 40–49. [Google Scholar] [CrossRef] [PubMed]

- Adeyanju, A.A.; Bamidele, O.P. Nutritional composition, in-vitro starch digestibility and antioxidant activities of composite flour made from wheat and mature, unripe pawpaw (Carica papaya) fruit flour. Nutrients 2022, 14, 4821. [Google Scholar] [CrossRef] [PubMed]

- Observatory Economic Complexity. Wheat in Nigeria. OEC Report. Available online: https://oec.world/en/profile/bilateral-product/wheat/reporter/nga (accessed on 15 April 2023).

- Oleghe, P.O.; Akharaiyi, F.C.; Ehis-Eriakha, C.B. Phylogenetic identification of microbes from fermented botanicals used in gluten-free composite flour mixes. Foods Raw. Mater. 2025, 13, 82–93. [Google Scholar] [CrossRef]

- Squeo, G.; De Angelis, D.; Leardi, R.; Summo, C.; Caponio, F. Background, Applications and Issues of the Experimental Designs for Mixture in the Food Sector. Foods 2021, 10, 1128. [Google Scholar] [CrossRef]

- Chinma, C.E.; James, S.; Imam, H.; Ocheme, O.B.; Anuonye, J.C.; Yakubu, C.M. Physicochemical and sensory properties and in-vitro digestibility of biscuits made from blends of tigernut (Cyperus esculentus) and pigeon pea (Cajanus cajan). Niger. J. Nutr. Sci. 2011, 32, 55–62. [Google Scholar] [CrossRef]

- Begum, R.; Uddin, M.J.; Rahman, M.A.; Islam, M.S. Comparative study on the development of maize flour based composite bread. J. Bangladesh Agric. Univ. 2013, 11, 133–139. [Google Scholar] [CrossRef]

- Asimah, V.K.; Kpodo, F.M.; Adzinyo, O.A.; Dzah, C.S. Utilisation of brown rice flour and peanut paste in cake production. Am J. Food Sci. Technol. 2016, 4, 129–134. [Google Scholar] [CrossRef]

- Association of Analytical Chemist (AOAC). Official Methods of Analysis, 19th ed.; Association of Analytical Chemist: Washington, DC, USA, 2012; Volume 2, pp. 121–130. [Google Scholar]

- Sodipo, M.; Oluwagbenga, A.; Jolayemi, O.; Lawal, O. Development and nutritional evaluation of a complementary diet from fermented provitamin-a-biofortified maize (Zea mays L.) and germinated lentil seeds (Lens culinaris). Croat. J. Food Sci. Technol. 2020, 12, 90–100. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, H.; Wang, Z.; Lan, G.; Zhang, L. Comparative studies on antioxidant activities of extracts and fractions from the leaves and stem of Epimedium koreanum Nakai. J. Food Sci. Technol. 2013, 50, 1122–1129. [Google Scholar] [CrossRef]

- Iombor, T.T.; Olaitan, I.N.; Ede, R.A. Proximate composition, antinutrient content and functional properties of soursop flour as influenced by oven and freeze drying methods. Curr. Res. Nutr. Food Sci. 2014, 2, 106–110. [Google Scholar] [CrossRef]

- Bakker, J.; Arnold, G.M. Analysis of sensory and chemical data for a range of red port wines. Am. J. Enol. Vitic. 1993, 44, 27–34. [Google Scholar] [CrossRef]

- Iwe, M.O. Handbook of Sensory Method and Analysis; Rejoint Communication Service Ltd.: Enugu, Nigeria, 2002; pp. 1–56. [Google Scholar]

- Novelli, E.L.B.; Diniz, Y.S.; Galhardi, C.M.; Ebaid, G.M.X.; Rodrigues, H.G.; Mani, F.; Fernandes, A.A.H.; Cicogna, A.C.; Novelli-Filho, J.L.V.B. Anthropometrical parameters and markers of obesity in rats. Lab. Anim. 2007, 41, 111–119. [Google Scholar] [CrossRef] [PubMed]

- Altunkaynak, B.Z.; Özbek, E. Overweight and structural alterations of the liver in female rats fed a high-fat diet: A serological and histological study. Turk. J. Gastroenterol. 2019, 20, 93–103. [Google Scholar]

- Akubor, P.I. Proximate composition and selected functional properties of African breadfruit and sweet potato flour blends. Plant Foods Hum. Nutr. 1997, 51, 53–60. [Google Scholar] [CrossRef]

- Nwakanma, C.I.; Obinwa, E.P.; Umeh-Idika, A.S. Proximate and functional properties of pigeon pea (Cajanus cajan) and sorghum (Sorghum bicolor) flour blends. J. Home Econ. Res. 2024, 31, 104–113. [Google Scholar]

- Ihemeje, A.; Uneanya, G.C.; Odimegwu, N.E.; Echefu, E.O. Quality evaluation of cassava-pigeon pea composite flour and the cookies. J. Agric. Food Sci. 2017, 15, 43–53. [Google Scholar] [CrossRef]

- Chiedu, U.C.; Malomo, S.A.; Ijarotimi, O.S.; Emojorho, E.E.; Arogundade, T.J. Physicochemical, nutritional and functional properties of composite flour blends from whole wheat, sweet potato, defatted peanut, and rice bran. Eur. J. Nutr. Food Saf. 2023, 15, 41–55. [Google Scholar] [CrossRef]

- Peter-Ikechukwu, A.I.; Ogazi, C.G.; Uzoukwu, A.E.; Kabuo, N.O.; Chukwu, M.N. Proximate and functional properties of composite flour produced with date fruit pulp, toasted watermelon seed, and wheat. J. Food Chem. Nanotechnol. 2020, 6, 159–166. [Google Scholar] [CrossRef]

- Bukuni, S.J.; Ikya, J.K.; Dinnah, A.; Bongjo, N.B. Chemical and functional properties of composite flours made from fermented yellow maize, Bambara groundnut, and mango fruit for ‘ogi’ production. Asian Food Sci. J. 2022, 21, 22–33. [Google Scholar] [CrossRef]

- Onwuka, C.F.; Ameh, A.; Aliyu, M. Effect of baking time and composite flour blends on the physical, nutritional and sensory properties of bread. J. Food Sci. Technol. 2018, 55, 1973–1983. [Google Scholar]

- Lei, V.; Amoaful, E.; Akonor, P.T. Changes in nutritional composition of fermented foods: An updated review. Trends Food Sci. Technol. 2019, 88, 1–10. [Google Scholar]

- Verni, M.; Verardo, V.; Rizzello, C.G. How fermentation affects the antioxidant properties of cereals and legumes. Foods 2019, 8, 362. [Google Scholar] [CrossRef] [PubMed]

- Oyarekua, M.A.; Adeoye, A.O.; Ojo, O. Comparable vitamin and mineral contents of co-fermented maize/carrot/pigeon pea and co-fermented maize/sweet potato/pigeon pea as infant complementary food. Tropical. J. Nat. Prod. Res. 2022, 6, 1331–1335. [Google Scholar] [CrossRef]

- Kennedy, D.O.B. Vitamins and the Brain: Mechanisms, Dose and Efficacy—A Review. Nutrients 2016, 8, 68. [Google Scholar] [CrossRef]

- Sharma, R.; Garg, P.; Kumar, P.; Bhatia, S.K.; Kulshrestha, S. Microbial fermentation and its role in quality improvement of fermented foods. Fermentation 2020, 6, 106. [Google Scholar] [CrossRef]

- Rashwan, A.K.; Yones, H.A.; Karim, N.; Taha, E.M.; Chen, W. Potential processing technologies for developing sorghum-based food products: An update and comprehensive review. Trends Food Sci. Technol. 2021, 110, 168–182. [Google Scholar] [CrossRef]

- Oghbaei, M.; Prakash, J. Effect of primary processing of cereals and legumes on its nutritional quality: A comprehensive review. Cogent Food Agric. 2016, 2, 1136015. [Google Scholar] [CrossRef]

- Adebo, J.A.; Njobeh, P.B.; Gbashi, S.; Oyedeji, A.B.; Ogundele, O.M.; Oyeyinka, S.A.; Adebo, O.A. Fermentation of cereals and legumes: Impact on nutritional constituents and nutrient bioavailability. Fermentation 2022, 8, 63. [Google Scholar] [CrossRef]

- Kim, J.; Yun, H.; Park, H.; Kim, M.; Chun, J. Effects of fermentation on the antioxidant activity of soy sauce. J. Food Nutr. Res. 2019, 7, 158–163. [Google Scholar]

- Li, X.; Chen, H.; Liu, J.; Chen, X. Effect of fermentation on the antioxidant activity and phenolic compounds of tartary buckwheat flour. J. Food Process Preserv. 2019, 43, e13857. [Google Scholar]

- Khalid, N.; Muhammad, A.I.; Siddiqui, M.T.H.; Hussain, M.A. Nutritional and antioxidant potential of maize flour fermented with Saccharomyces cerevisiae and Lactobacillus plantarum. Food Sci. Nutr. 2020, 8, 415–422. [Google Scholar]

- Wilson, D.W.; Nash, P.; Buttar, H.S.; Griffiths, K.; Singh, R.; De Meester, F.; Horiuchi, R.; Takahashi, T. The role of food antioxidants, benefits of functional foods, and influence of feeding habits on the health of the older person: An overview. Antioxidants 2017, 6, 81. [Google Scholar] [CrossRef] [PubMed]

- Pham-Huy, L.A.; He, H.; Pham-Huy, C. Free radicals, antioxidants in disease and health. Int. J. Biomed. Sci. IJBS 2008, 4, 89–96. [Google Scholar] [CrossRef] [PubMed]

- Mueen-Ahmed, K.K. The Science of Antioxidants: Balancing the Pros and Cons for Our Health. J. Pharmacol. Pharmacother. 2023, 14, 160–162. [Google Scholar] [CrossRef]

- Ullah, A.; Munir, S.; Badshah, S.L.; Khan, N.; Ghani, L.; Poulson, B.G.; Emwas, A.H.; Jaremko, M. Important flavonoids and their role as a therapeutic agent. Molecules 2020, 25, 5243. [Google Scholar] [CrossRef]

- Şanlier, N.; Gökcen, B.B.; Sezgin, A.C. Health benefits of fermented foods. Crit. Rev. Food Sci. Nutr. 2019, 59, 506–527. [Google Scholar] [CrossRef]

- Adiamo, O.Q.; Babajide, J.M.; Bamgbose, A.M.; Afolayan, A.O. Nutrient and anti-nutrient contents of maize/cassava/sweet potato/soybean flour blends extruded at different temperatures. J. Food Sci. Technol. 2016, 53, 3574–3582. [Google Scholar]

- Ojokoh, A.O.; Onasanya, T.T. Effect of fermentation and extrusion on the nutrient and anti-nutrient composition of Soy beans (Glycine max, L) and Acha (Digitaria exilis Stapf). Microbiol. Res. J. Int. 2017, 21, 1–21. [Google Scholar] [CrossRef]

- Kaur, A.; Singh, N.; Ezekiel, R. Effect of incorporation of legume flours on the quality characteristics of composite breads: A review. J. Food Sci. Technol. 2018, 55, 385–396. [Google Scholar]

- Delgado-Pando, G.; Cofrades, S.; Ruiz-Capillas, C.; Jimenez-Colmenero, F. Healthier meat and meat products: Their role as functional foods. Meat Sci. 2013, 93, 28–36. [Google Scholar]

- Sachanarula, S.; Chantarasinlapin, P.; Adisakwattana, S. Substituting whole wheat flour with Pigeon pea (Cajanus cajan) flour in Chapati: Effect on nutritional characteristics, color profiles, and In Vitro starch and protein digestion. Foods 2022, 11, 3157. [Google Scholar] [CrossRef]

- Idowu, M.A.; Adebowale, A.A.; Adegunwa, M.O. Quality characteristics of biscuits produced from wheat, cocoyam and soybean flour blends. J. Food Process Preserv. 2018, 42, e13320. [Google Scholar] [CrossRef]

| Parameter | Sweet Potato | Pigeon Pea | Maize | Composite Flour Mixture 5 |

|---|---|---|---|---|

| Moisture content (%) | 6.666 ± 0.05 a | 4.105 ± 0.04 c | 4.190 ± 0.02 c | 5.869 ± 0.35 b |

| Fat (%) | 2.535 ± 0.08 d | 5.645 ± 0.02 b | 6.095 ± 0.08 a | 4.477 ± 0.16 c |

| Crude fiber (%) | 4.675 ± 0.21 c | 7.665 ± 0.06 a | 7.225 ± 0.15 b | 4.866 ± 0.63 c |

| Ash (%) | 2.365 ± 0.06 c | 3.230 ± 0.13 a | 2.435 ± 0.05 c | 2.553 ±0.13 b |

| Protein (%) | 7.265 ± 0.22 c | 11.665 ± 0.32 a | 3.610 ± 0.20 d | 9.000 ± 1.82 b |

| Carbohydrate (%) | 76.494 ± 0.05 a,b | 75.745 ± 0.41 b,c | 77.805 ± 0.23 a | 72.25 ± 1.60 d |

| pH | 5.770 ± 0.72 b | 5.770 ± 0.72 b | 6.030 ± 0.01 a | 5.253 ± 0.01 c |

| Parameter | Sweet Potato | Pigeon Pea | Maize | Composite Flour Mixture 5 |

|---|---|---|---|---|

| WAC (%) | 21.01 ± 0.14 d | 23.03 ± 0.04 b | 22.16 ± 0.01 c | 25.00 ± 0.00 a |

| OAC (%) | 17.45 ± 0.07 b | 16.06 ± 0.08 c | 15.99 ± 0.07 d | 19.00 ± 0.00 a |

| EMULSION CAPACITY (%) | 40.50 ± 0.00 c | 41.67 ± 0.01 a | 41.85 ± 0.03 a | 41.06 ± 0.01 b |

| SWELLING CAPACITY (%) | 426.60 ± 0.01 d | 427.48 ± 1.43 c | 448.45 ± 0.06 b | 471.93 ± 0.00 a |

| FOAM CAPACITY (%) | 2.01 ± 0.07 d | 4.0 ± 0.00 c | 5.0 ± 0.01 b | 8.05 ± 0.07 a |

| LEAST GEL CONC. (mg/cm3) | 0.2 ± 0.00 b | 0.2 ± 0.00 b | 0.25 ± 0.00 a | 0.21 ± 0.01 b |

| BULK DENSITY (gm/ cm3) | 0.69 ± 0.00 a | 0.69 ± 0.00 a | 0.70 ± 0.00 a | 0.73 ± 0.00 a |

| Sample | Ash Content (%) | Moisture Content(%) | Fat Content (%) | Crude Fiber Content (%) | Protein Content (%) | Carbohydrate (By Difference) Content (%) |

|---|---|---|---|---|---|---|

| CB | 1.011 ± 0.02 c | 10.324 ± 0.05 b | 18.934 ± 0.0 b | 4.140 ± 0.02 c | 13.222 ± 0.01 a | 52.370 ± 0.13 b |

| 5FB | 1.495 ± 0.14 b | 8.875 ± 0.68 c | 17.592 ± 0.07 c | 5.752 ± 0.04 a | 10.450 ± 0.04 b | 55.835 ± 0.75 a |

| CA | 3.163 ± 0.03 b | 5.982 ± 0.01 b | 21.161 ± 0.08 a | 1.271 ± 0.04 b | 12.805 ± 0.25 a | 55.622 ± 0.12 c |

| 5FA | 3.711 ± 0.11 a | 3.639 ± 0.05 c | 17.339 ± 0.03 c | 3.485 ± 0.01 b | 11.918 ± 0.08 b | 58.491 ± 0.70 b |

| CC | 1.808 ± 0.12 c | 13.918 ± 0.38 a | 25.508 ± 0.11 c | 7.116 ± 0.91 a | 14.586 ± 0.06 a | 36.780 ± 0.67 b |

| 5FC | 3.197 ± 0.00 b | 11.859 ± 0.19 b | 24.179 ± 0.12 b | 7.401 ± 0.12 a | 12.813 ± 0.13 b | 40.838 ± 0.58 a |

| Samples | Sodium (Na) (ppm) | Potassium (K) (ppm) | Calcium (Ca) (ppm) | Magnesium (Mg) (ppm) |

|---|---|---|---|---|

| CB | 18.701 ± 0.00 d | 24.100 ± 0.00 b | 12.702 ± 0.00 a | 17.499 ± 0.00 a |

| 5FB | 18.011 ± 0.02 d | 20.007 ± 0.01 c | 10.706 ± 0.01 c | 14.298 ± 0.00 c |

| CA | 27.501 ± 0.00 a | 20.601 ± 0.00 d | 14.099 ± 0.00 a | 9.200 ± 0.00 e |

| 5FA | 17.105 ± 0.01 e | 19.803 ± 0.00 e | 10.505 ± 0.01 d | 15.160 ± 0.06 a |

| CC | 20.096 ± 0.01 d | 18.501 ± 0.00 f | 15.001 ± 0.00 a | 7.901 ± 0.00 f |

| 5FC | 15.798 ± 0.00 f | 23.005 ± 0.01 c | 13.901 ± 0.00 b | 11.890 ± 0.01 c |

| Sample | OH (%) | ABTS (mMol/g) | DPPH (%) | Fe2+ Chelation (%) | FRAP (mg/g) |

|---|---|---|---|---|---|

| CB | 42.810 ± 0.61 a | 0.010 ± 0.00 c | 71.345 ± 0.23 b | 7.360 ± 0.36 b | 7.292 ± 0.13 c |

| 5FB | 36.960 ± 0.64 b | 0.019 ± 0.00 b | 72.547 ± 0.41 b | 5.788 ± 0.93 b | 10.500 ± 0.27 b |

| CA | 42.143 ± 0.34 d | 0.025 ± 0.00 a | 52.502 ± 0.82 c | 2.980 ± 0.23 f | 5.842 ± 0.09 f |

| 5FA | 60.000 ± 0.45 a | 0.026 ± 0.00 a | 55.608 ± 0.44 b | 12.848 ± 0.14 d | 26.309 ± 0.76 a |

| CC | 40.22 ± 0.76 d | 0.007 ± 0.00 d | 26.275 ± 0.04 g | 12.747 ± 0.46 e | 8.342 ± 0.10 g |

| 5FC | 43.157 ± 0.25 c | 0.025 ± 0.00 a | 72.657 ± 0.50 c | 16.440 ± 0.21 d | 18.314 ± 0.02 d |

| Sample | Tannins (mg/g) | Oxalates (mg/g) | Phytates (mg/g) | Saponins (%) |

|---|---|---|---|---|

| CB | 1.316 ± 0.00 a | 0.315 ± 0.00 c | 1.650 ± 0.00 d | 14.494 ± 0.03 c |

| 5FB | 0.917 ± 0.01 c | 3.731 ± 0.07 b | 1.728 ± 0.18 c | 21.424 ± 0.01 a |

| CA | 0.720 ± 0.00 d | 0.902 ± 0.00 e | 1.858 ± 0.01 a | 12.497 ± 0.00 e |

| 5FA | 1.461 ± 0.02 b | 2.261 ± 0.01 c | 1.742 ± 0.01 b | 23.495 ± 0.03 a |

| CC | 0.708 ± 0.02 d | 0.241 ± 0.04 g | 0.929 ± 0.00 f | 13.711 ± 0.23 f |

| 5FC | 0.754 ± 0.02 c | 1.791 ± 0.01 d | 1.441 ± 0.00 e | 20.654 ± 0.06 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ehis-Eriakha, C.B.; Oleghe, P.O.; Akharaiyi, F.C. Enhancing Food Security and Nutrition Through Indigenous Agro-Product-Based Functional Foods: A Case Study on Composite Flour Development. Proceedings 2025, 118, 4. https://doi.org/10.3390/proceedings2025118004

Ehis-Eriakha CB, Oleghe PO, Akharaiyi FC. Enhancing Food Security and Nutrition Through Indigenous Agro-Product-Based Functional Foods: A Case Study on Composite Flour Development. Proceedings. 2025; 118(1):4. https://doi.org/10.3390/proceedings2025118004

Chicago/Turabian StyleEhis-Eriakha, Chioma Bertha, Peace Omoikhudu Oleghe, and Fred Coolborn Akharaiyi. 2025. "Enhancing Food Security and Nutrition Through Indigenous Agro-Product-Based Functional Foods: A Case Study on Composite Flour Development" Proceedings 118, no. 1: 4. https://doi.org/10.3390/proceedings2025118004

APA StyleEhis-Eriakha, C. B., Oleghe, P. O., & Akharaiyi, F. C. (2025). Enhancing Food Security and Nutrition Through Indigenous Agro-Product-Based Functional Foods: A Case Study on Composite Flour Development. Proceedings, 118(1), 4. https://doi.org/10.3390/proceedings2025118004