Comparative Study of the Impact of Stearin-Modified Starches from Maize, Ginger, and Sweet Potato on the Physicochemical Properties of Low-Fat Mayonnaise †

Abstract

:1. Introduction

2. Material and Methods

2.1. Starch Extraction

2.2. Determination of Amylose Content

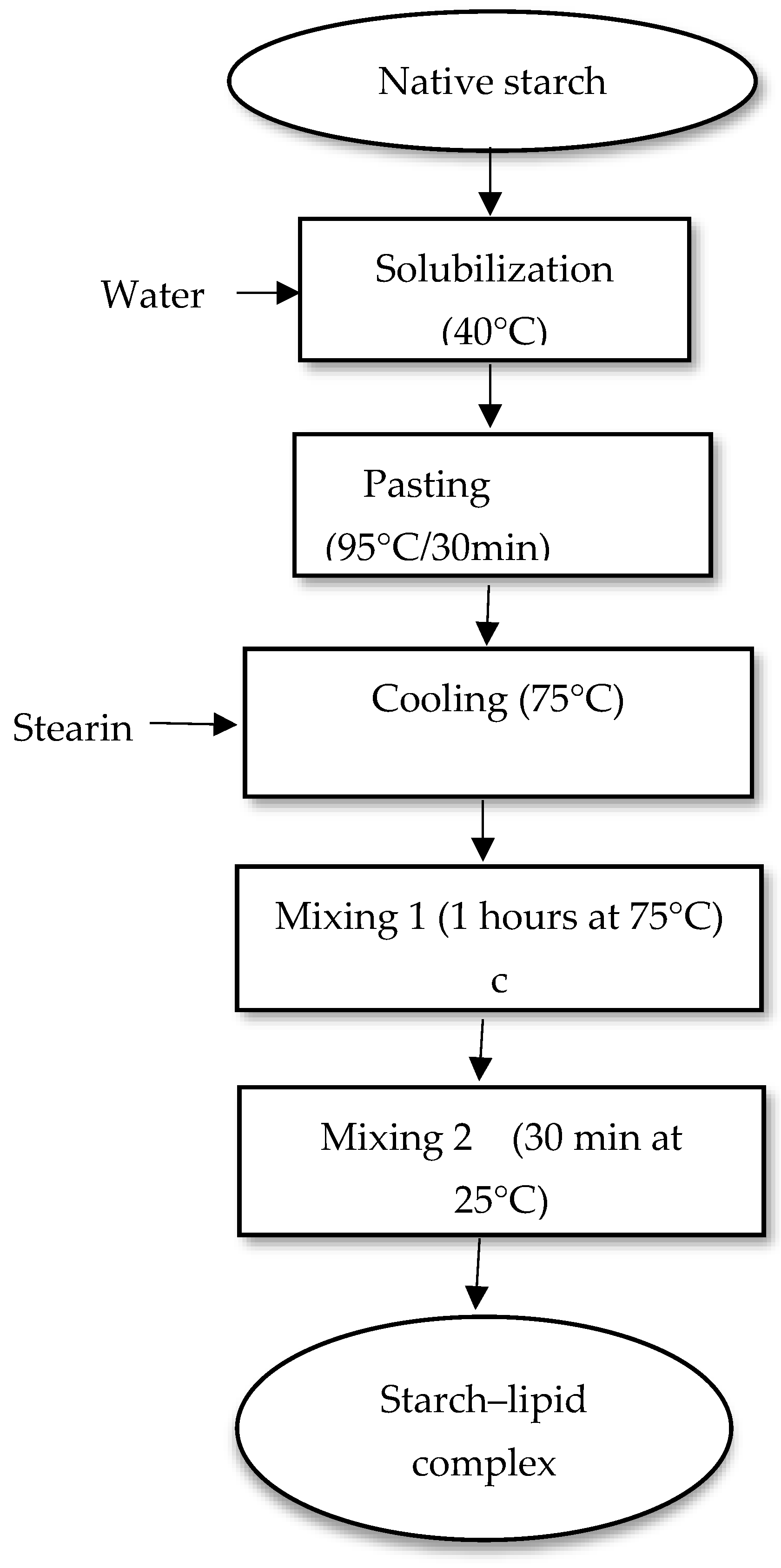

2.3. Production of Starch–Lipid Complexes

2.4. Complexation Indexes (CIs) of Amylose–Lipid Complexes

2.5. Texture

2.6. Syneresis

2.7. Paste Viscosity (RVA)

2.8. Viscosity

2.9. Sensory Analysis

2.10. Statistical Analysis

3. Result and Discussion

3.1. Sweet Potato, Maize, and Ginger Starch Production Yields

3.2. Amylose Content of Native Starches

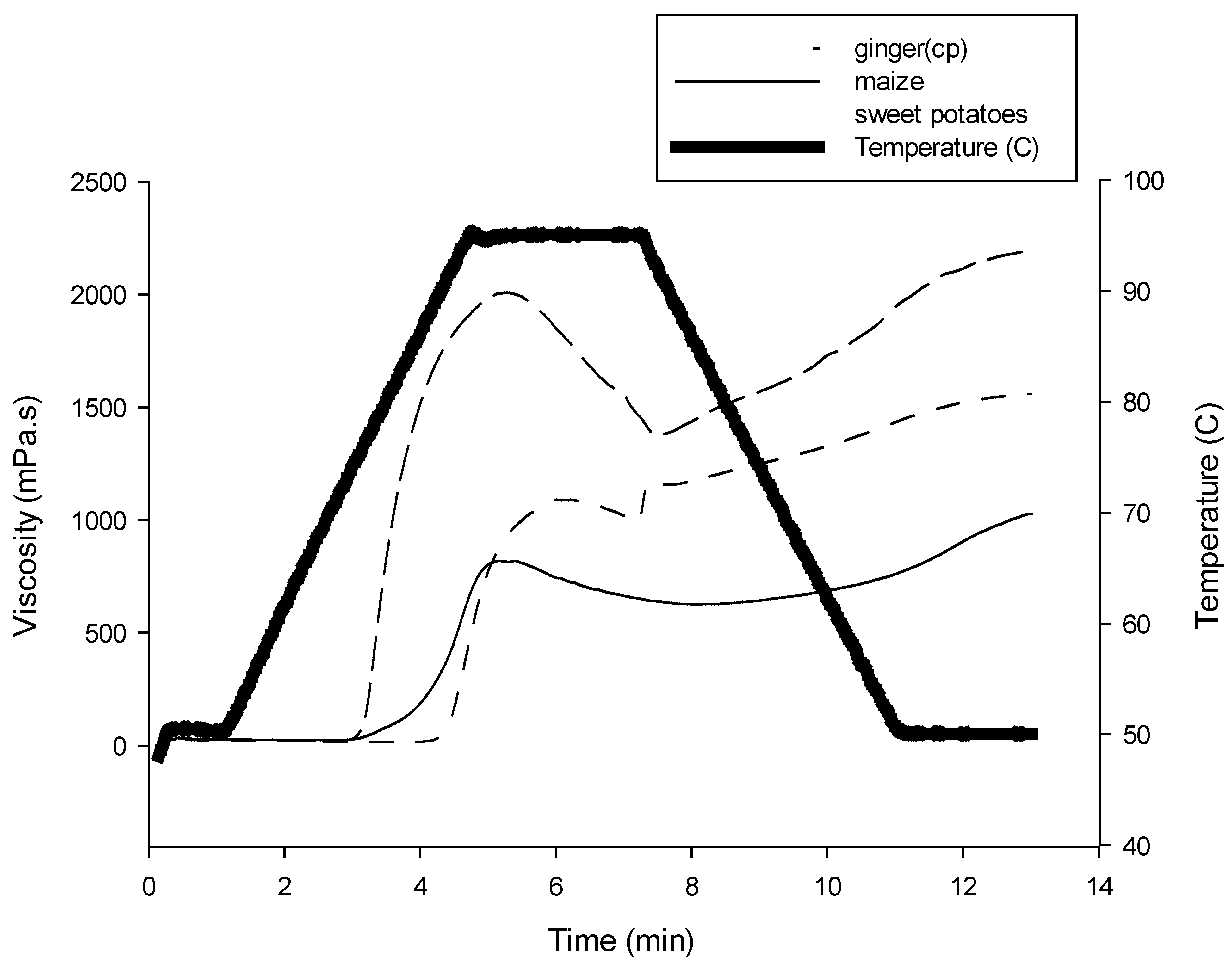

3.3. Rapid Viscosity Analysis (RVA)

3.4. Syneresis

3.5. Gel Hardness

3.6. Complexation Indexes of the Amylose–Lipid Complexes

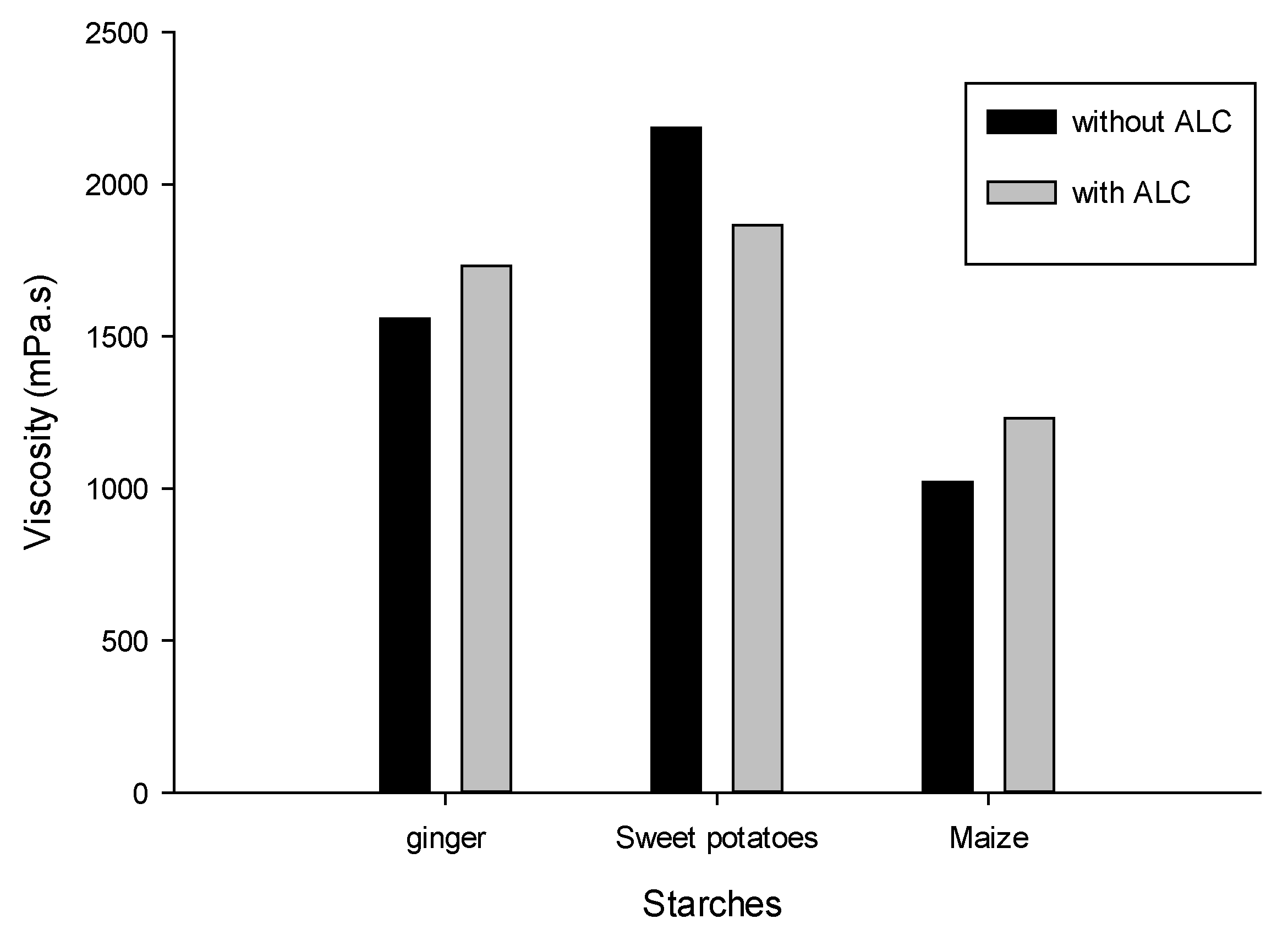

3.7. Viscosity of the Modified Starches with Lipids and Without Lipids

3.8. Texture of the Amylose–Lipid Complex (ALC)

3.9. Influence of Modified Starch Substitution on Mayonnaise Viscosity

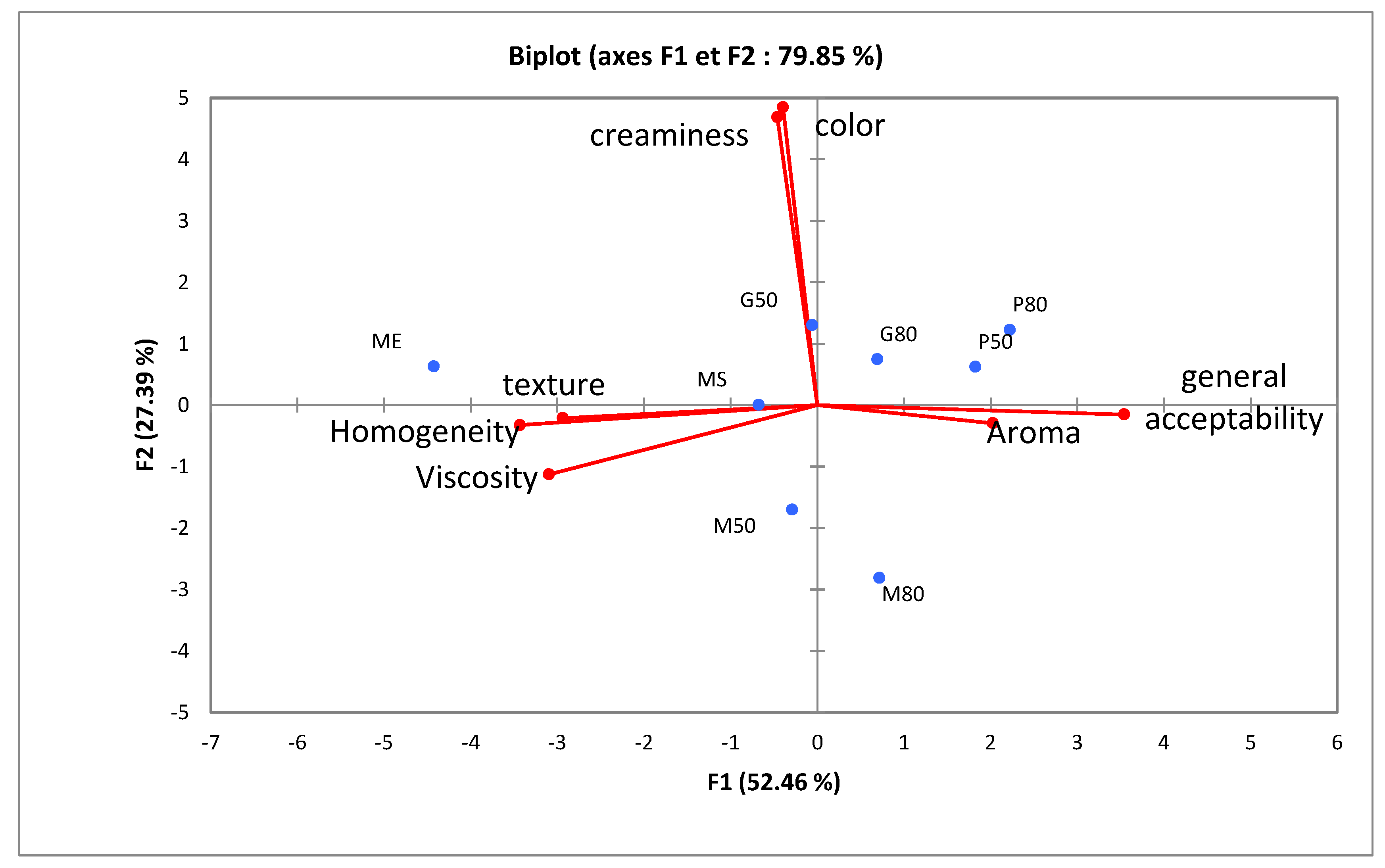

3.10. Influence of Substitution on Sensory Analysis of Mayonnaises

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Souza, C.J.F.D.; Rojas, E.E.G. Emulsion of systems containing egg yolk, polysaccharides and vegetable oil. Cienc. Agrotec 2012, 36, 543–550. [Google Scholar] [CrossRef]

- Mirzanajafi-Zanjani, M.; Yousefi, M.; Ehsani, A. Challenges and approaches for production of a healthy and functional mayonnaise sauce. Food Sci. Nutr. 2019, 7, 2471–2484. [Google Scholar] [CrossRef] [PubMed]

- Panchal, S.K.; Poudyal, H.; Iyer, A.; Nazer, R.; Alam, A.; Diwan, V.; Kauter, K.; Sernia, C.; Campbell, F.; Ward, L.; et al. High-carbohydrate, High-fat Diet–induced Metabolic Syndrome and Cardiovascular Remodeling in Rats. J. Cardiovasc. Pharmacol. 2011, 57, 611–624. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, N.K.; Ragavan, H.; Ahmad, N.H.; Hussin, A.S.M. Egg-free low-fat mayonnaise from virgin coconut oil. Foods Raw Mater. 2022, 10, 76–85. [Google Scholar] [CrossRef]

- Schädle, C.N.; Sanahuja, S.; Bader-Mittermaier, S. Influence of Fat Replacers on the Rheological, Tribological, and Aroma Release Properties of Reduced-Fat Emulsions. Foods 2022, 11, 820. [Google Scholar] [CrossRef]

- Yu, X.X.; Chi, S.X.; Wang, X.H.; Liu, B.H.; Wang, Y.; Zhang, Y.H. Preparation of fat substitute based on maize starch hydrolysates and application in reduced-fat acidified milk gel. Int. J. Biol. Macromol. 2023, 244, 125479. [Google Scholar] [CrossRef]

- Emmambux, M.N.; Taylor, J.R.N. Morphology, physical, chemical, and functional properties of starches from cereals, legumes, and tubers cultivated in Africa: A review. Starch—Stärke 2013, 65, 715–729. [Google Scholar] [CrossRef]

- Teklehaimanot, W.H.; Duodu, K.G.; Emmambux, M.N. Maize and teff starches modified with stearic acid as potential fat replacer in low calorie mayonnaise-type emulsions. Starch—Stärke 2013, 65, 773–781. [Google Scholar] [CrossRef]

- Ren, S. Comparative analysis of some physicochemical properties of 19 kinds of native starches. Starch—Stärke 2017, 69, 1600367. [Google Scholar] [CrossRef]

- Simanavičiūtė, D. Physical and chemical modification of the starch. A review. Chem. Technol. 2015, 66, 45–54. [Google Scholar] [CrossRef]

- Mapengo, C.R.; Ray, S.; Emmambux, M.N. Pasting properties of hydrothermally treated maize starch with added stearic acid. Food Chem. 2019, 289, 396–403. [Google Scholar] [CrossRef] [PubMed]

- D’Silva, T.V.; Taylor, J.R.; Emmambux, M.N. Enhancement of the pasting properties of teff and maize starches through wet–heat processing with added stearic acid. J. Cereal Sci. 2011, 53, 192–197. [Google Scholar] [CrossRef]

- Martins, S.H.F.; Pontes, K.V.; Fialho, R.L.; Fakhouri, F.M. Extraction and characterization of the starch present in the avocado seed (Persea americana mill) for future applications. J. Agric. Food Res 2022, 8, 100303. [Google Scholar] [CrossRef]

- Kaufman, R.; Wilson, J.; Bean, S.; Herald, T.; Shi, Y.C. Development of a 96-well plate iodine binding assay for amylose content determination. Carbohydr. Polym. 2015, 115, 444–447. [Google Scholar] [CrossRef]

- Adewuni, A.O.; Robertson, M.D.; Grassby, T. The use of complexing index methods to examine the production of amylose-lipid complexes from potato starch. Proc. Nutr. Soc. 2023, 82, E4. [Google Scholar] [CrossRef]

- González, L.C.; Loubes, M.A.; Bertotto, M.M.; Baeza, R.I.; Tolaba, M.P. Flow behavior and syneresis of ball milled rice starch and their correlations with starch structure. Carbohydr. Polym. Technol. Appl. 2021, 2, 100168. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Q.; Ferdinand, U.; Gong, X.; Qu, Y.; Gao, W.; Ivanistau, A.; Feng, B.; Liu, M. Isolation and characterization of starch from light yellow, orange, and purple sweet potatoes. Int. J. Biol. Macromol. 2020, 160, 660–668. [Google Scholar] [CrossRef] [PubMed]

- Madeneni, M.N.; Faiza, S.; Ramaswamy, R.; Guha, M.; Pullabhatla, S. Physico-chemical and functional properties of starch isolated from ginger spent. Starch—Stärke 2011, 63, 570–578. [Google Scholar] [CrossRef]

- Abegunde, O.K.; Mu, T.H.; Chen, J.W.; Deng, F.M. Physicochemical characterization of sweet potato starches popularly used in Chinese starch industry. Food Hydrocoll. 2013, 33, 169–177. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, X.; Xu, Y.; Xu, Z.; Li, H.; Sui, Z.; Corke, H. Gel texture and rheological properties of normal amylose and waxy potato starch blends with rice starches differing in amylose content. Int. J. Food Sci. 2020, 56, 1946–1958. [Google Scholar] [CrossRef]

- Nhan, M.T.; Copeland, L. Effect of variety and growing environment on pasting and thermal properties of wheat starch. Starch—Stärke 2015, 68, 436–445. [Google Scholar] [CrossRef]

- Bajaj, R.; Singh, N.; Kaur, A.; Inouchi, N. Structural, morphological, functional and digestibility properties of starches from cereals, tubers and legumes: A comparative study. J. Food Sci. Technol. 2018, 55, 3799–3808. [Google Scholar] [CrossRef] [PubMed]

- Amani, N.G.; Tetchi, F.A.; Dufour, D.; Kamenan, A. A Comparative Study of the Syneresis of Yam Starches and other Modified Starches. J. Food Technol. Afr. 2002, 7, 4–8. [Google Scholar] [CrossRef]

- Vamadevan, V.; Bertoft, E. Structure-function relationships of starch components. Starch—Stärke 2014, 67, 55–68. [Google Scholar] [CrossRef]

- Panyoo, A.E.; Emmambux, M.N. Amylose–lipid complex production and potential health benefits: A mini-review. Starch—Stärke 2017, 69, 1600203. [Google Scholar] [CrossRef]

- Chung, H.J.; Liu, Q. Impact of molecular structure of amylopectin and amylose on amylose chain association during cooling. Carbohydr. Polym. 2009, 77, 807–815. [Google Scholar] [CrossRef]

| Starch | Amylose Content | Volume of Syneresis (mL) | Gel Hardness (N) |

|---|---|---|---|

| Maize | 29.45 ± 0.38 b | 17.15 ± 0.21 b | 0.10 ± 0.03 a |

| Sweet potato | 21.35 ± 1.91 a | 1.3 ± 0.14 a | 0.07 ± 0.03 a |

| Ginger | 28.91 ± 0.38 b | 36.25 ± 0.35 c | 1.27 ± 0.54 b |

| Sample | Hardness (N) | IC (%) |

|---|---|---|

| ALC ginger | 0.097 ± 0.001 b | 69.13 ± 1.41 c |

| ALC sweet potato | 0.081 ± 0.002 a | 43.98 ± 1.55 a |

| ALC maize | 0.101 ± 0.002 a | 61.92 ± 0.28 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akdowa, E.P.; Didi, A.; Clergé, T. Comparative Study of the Impact of Stearin-Modified Starches from Maize, Ginger, and Sweet Potato on the Physicochemical Properties of Low-Fat Mayonnaise. Proceedings 2025, 118, 12. https://doi.org/10.3390/proceedings2025118012

Akdowa EP, Didi A, Clergé T. Comparative Study of the Impact of Stearin-Modified Starches from Maize, Ginger, and Sweet Potato on the Physicochemical Properties of Low-Fat Mayonnaise. Proceedings. 2025; 118(1):12. https://doi.org/10.3390/proceedings2025118012

Chicago/Turabian StyleAkdowa, Emmanuel Panyoo, Astaharam Didi, and Tchiégang Clergé. 2025. "Comparative Study of the Impact of Stearin-Modified Starches from Maize, Ginger, and Sweet Potato on the Physicochemical Properties of Low-Fat Mayonnaise" Proceedings 118, no. 1: 12. https://doi.org/10.3390/proceedings2025118012

APA StyleAkdowa, E. P., Didi, A., & Clergé, T. (2025). Comparative Study of the Impact of Stearin-Modified Starches from Maize, Ginger, and Sweet Potato on the Physicochemical Properties of Low-Fat Mayonnaise. Proceedings, 118(1), 12. https://doi.org/10.3390/proceedings2025118012