Development and Performance Evaluation of Self-Healing PVA-PAA-Coated PES Membrane for Water Pollution Mitigation †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Self-Healing Membrane

2.3. Characterization of the Self-Healing Membrane

3. Results and Discussion

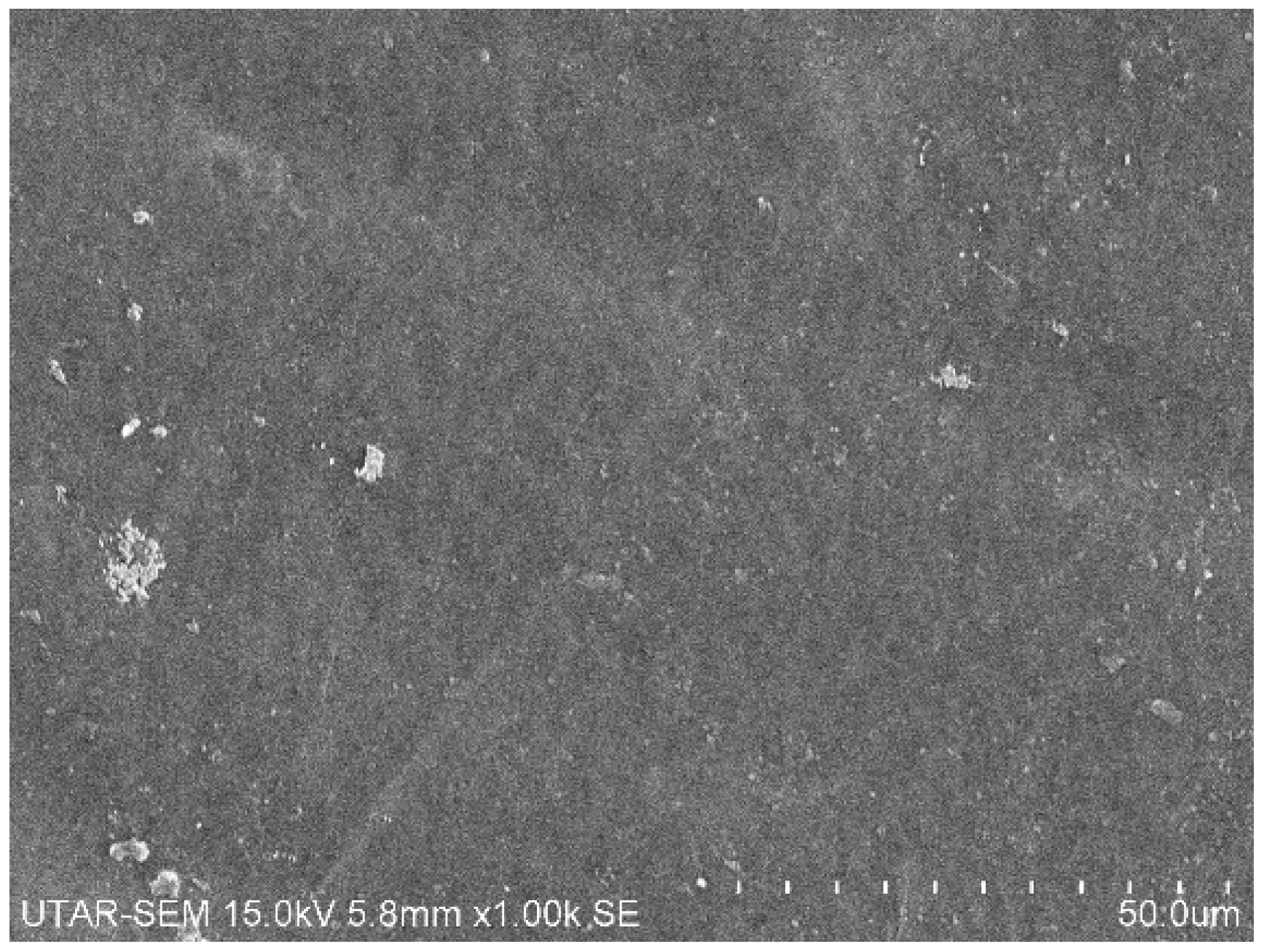

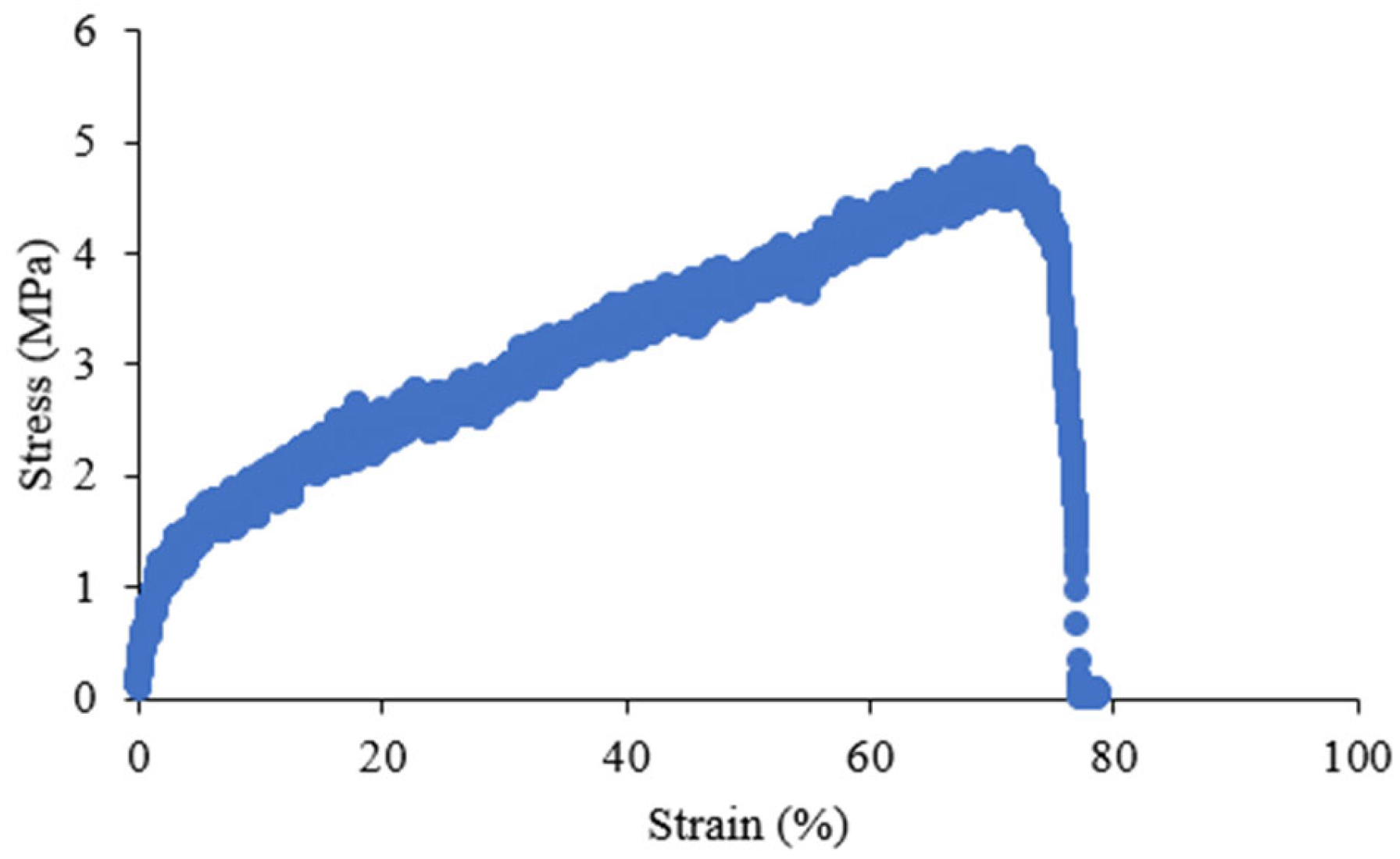

3.1. Membrane Characteristics

3.2. Membrane Flux Performance and Self-Healing Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PVA | Polyvinyl Alcohol |

| PAA | Polyacrylic Acid |

| PES | Polyethersulfone |

| SEM | Scanning Electron Microscopy |

References

- Kononova, S.V.; Kremnev, R.V.; Gubanova, G.N.; Vlasova, E.N.; Popova, E.N.; Vylegzhanina, M.E.; Volkov, A.Y. Effect of Phase Heterogeneity on the Properties of Poly(vinyl alcohol)-Based Composite Pervaporation Membranes. Membranes 2022, 12, 1185. [Google Scholar] [CrossRef] [PubMed]

- Shehata, N.; Egirani, D.; Olabi, A.G.; Inayat, A.; Abdelkareem, M.A.; Chae, K.-J.; Sayed, E.T. Membrane-based water and wastewater treatment technologies: Issues, current trends, challenges, and role in achieving sustainable development goals, and circular economy. Chemosphere 2023, 320, 137993. [Google Scholar] [CrossRef] [PubMed]

- Shemer, H.; Wald, S.; Semiat, R. Challenges and Solutions for Global Water Scarcity. Membranes 2023, 13, 612. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.-H.; Liu, Y.-L. Self-healing polymeric materials for membrane separation: An example of a polybenzimidazole-based membrane for pervaporation dehydration on isopropanol aqueous solution. RSC Adv. 2017, 7, 38360–38366. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Firoozi, A.A. Emerging Trends in Damage Tolerance Assessment: A Review of Smart Materials and Self-Repairable Structures. Struct. Durab. Health Monit. 2024, 18, 1–18. [Google Scholar] [CrossRef]

- Lim, Y.H.; Wong, E.C.; Chong, W.C.; Mohammad, A.W.; Koo, C.H.; Lau, W.J. Introducing self-healing properties to polyethersulfone (PES) membrane via poly(vinyl alcohol)/polyacrylic acid (PVA/PAA) surface coating. Chemosphere 2024, 349, 140772. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wu, H.; Shi, L.; Wu, Z.; Zhang, S.; Wang, S.; Sun, H. Photocatalysis coupling with membrane technology for sustainable and continuous purification of wastewater. Sep. Purif. Technol. 2024, 329, 125225. [Google Scholar] [CrossRef]

- Yu, S.; Pang, H.; Huang, S.; Tang, H.; Wang, S.; Qiu, M.; Chen, Z.; Yang, H.; Song, G.; Fu, D.; et al. Recent advances in metal-organic framework membranes for water treatment: A review. Sci. Total Environ. 2021, 800, 149662. [Google Scholar] [CrossRef] [PubMed]

- Chuah, J.Y.; Chong, K.C.; Lai, S.O.; Lau, W.J.; Lee, S.S.; Ong, H.M. Industrial Nickel Wastewater Rejection by Polyimide Membrane. Chem. Eng. Trans. 2018, 63, 697. [Google Scholar] [CrossRef]

- Deng, W.; Fan, T.; Li, Y. In Situ Biomineralization-Constructed Superhydrophilic and Underwater Superoleophobic PVDF-TiO2 Membranes for Superior Antifouling Separation of Oil-in-Water Emulsions. J. Membr. Sci. 2021, 622, 119030. [Google Scholar] [CrossRef]

- Tan, Y.J.; Tee, B.C.K. Recent Trends in Self-Healing Soft Electronic Materials and Devices. Sigma-Aldrich. Available online: https://www.sigmaaldrich.com/MY/en/technical-documents/technical-article/materials-science-and-engineering/microelectronics-and-nanoelectronics/recent-trends-self-healing-soft-electronic-materials-devices (accessed on 25 August 2024).

- Wang, P.; Cheng, W.; Zhang, X.; Li, J.; Ma, J.; Zhang, T. Engineering a Protective Surface Layer to Resist Membrane Scaling and Scale-Induced Wetting in Membrane Distillation for the Treatment of Hypersaline Wastewater. Chem. Eng. J. 2023, 452, 139167. [Google Scholar] [CrossRef]

- Chin, A.S.; Yin, K.Y.; Cheng, M.J.; Chang, C.Y.; Leggett, G. Poly(allylamine)–based amine blends for separation of carbon dioxide in the indoor environment. Optik 2023, 284, 170973. [Google Scholar] [CrossRef]

- Liu, S.; Jiang, H.; Li, Y.; Shen, X. Construction of tight ultrafiltration membrane for efficient dye/salt separation with physical and chemical self-healing property. Chem. Eng. J. 2023, 467, 143456. [Google Scholar] [CrossRef]

| Pristine Membrane | Damaged Membrane | Healed Membrane |

|---|---|---|

| 36.16 ± 2.73 | 65.21 ± 1.64 | 35.13 ± 0.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chong, K.C.; Chong, W.C.; Pang, Y.L.; Shuit, S.H.; Wong, E.C.; Koh, Y.X.; Von Lim, G.Q. Development and Performance Evaluation of Self-Healing PVA-PAA-Coated PES Membrane for Water Pollution Mitigation. Proceedings 2025, 117, 23. https://doi.org/10.3390/proceedings2025117023

Chong KC, Chong WC, Pang YL, Shuit SH, Wong EC, Koh YX, Von Lim GQ. Development and Performance Evaluation of Self-Healing PVA-PAA-Coated PES Membrane for Water Pollution Mitigation. Proceedings. 2025; 117(1):23. https://doi.org/10.3390/proceedings2025117023

Chicago/Turabian StyleChong, Kok Chung, Woon Chan Chong, Yean Ling Pang, Siew Hoong Shuit, Eng Cheong Wong, Yung Xin Koh, and Grace Qian Von Lim. 2025. "Development and Performance Evaluation of Self-Healing PVA-PAA-Coated PES Membrane for Water Pollution Mitigation" Proceedings 117, no. 1: 23. https://doi.org/10.3390/proceedings2025117023

APA StyleChong, K. C., Chong, W. C., Pang, Y. L., Shuit, S. H., Wong, E. C., Koh, Y. X., & Von Lim, G. Q. (2025). Development and Performance Evaluation of Self-Healing PVA-PAA-Coated PES Membrane for Water Pollution Mitigation. Proceedings, 117(1), 23. https://doi.org/10.3390/proceedings2025117023