Model Studies of Flow through a Packed Bed of Liquids of Various Viscosities †

1. Introduction

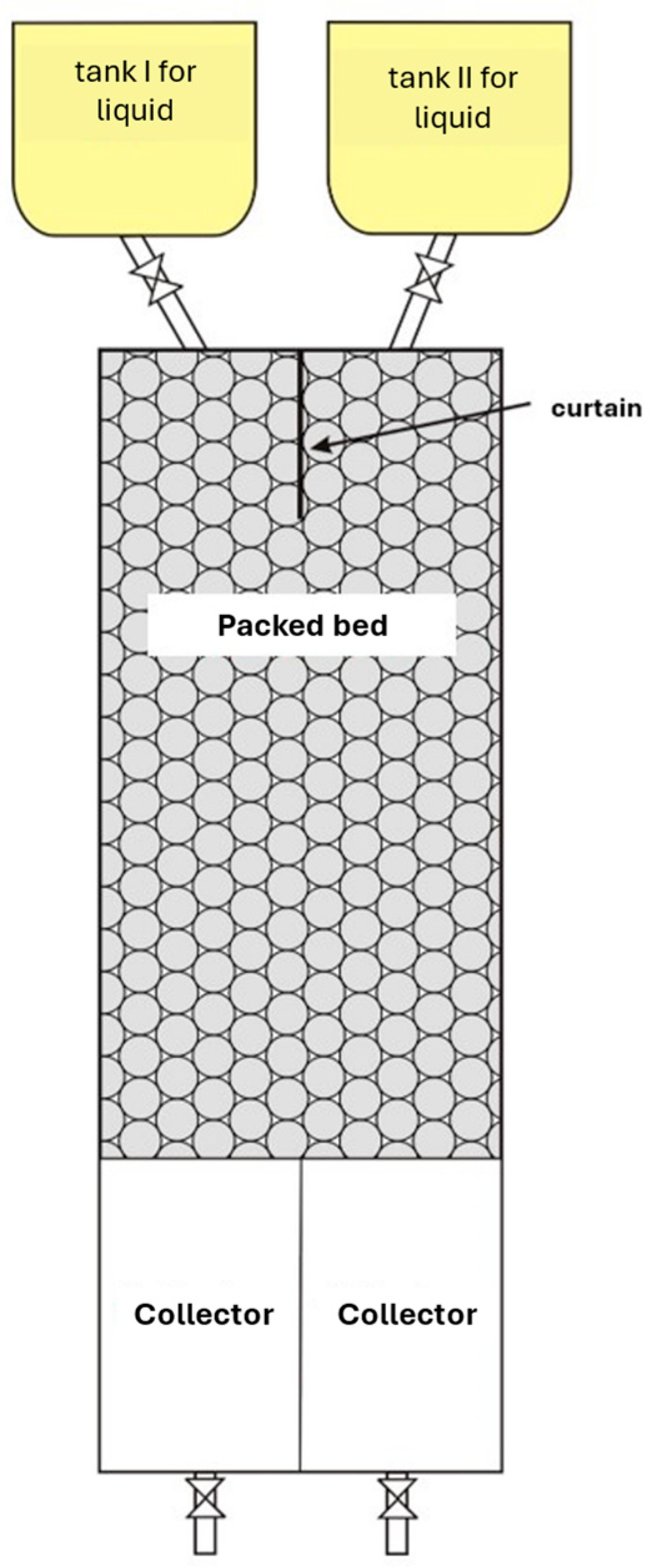

2. Research Installation and Research Methodology

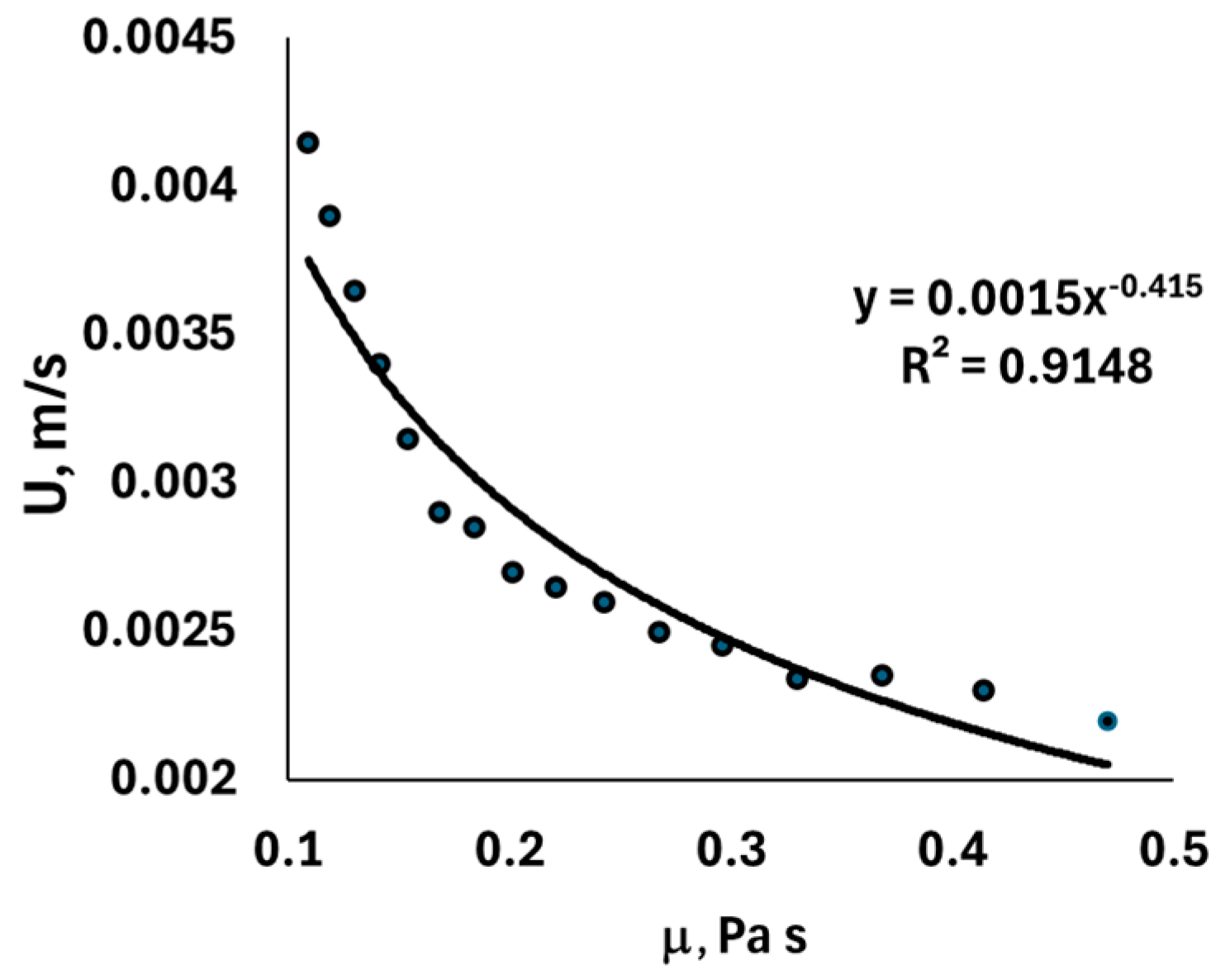

3. Research Results and Discussion

4. Conclusions

- When two streams of liquids with different viscosities flow through the packed bed (at different speeds), an interaction occurs that causes the stream of the higher viscosity liquid to deflect towards the stream of the lower viscosity liquid.

- The test results may indicate that, in the operating conditions of the blast furnace, lateral movement of the flowing streams of liquid metal and slag can be expected, but this would require industrial verification.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lakshminarasimha, S.; Bosco, F.S.; Gadi, V.A.; Gupta, G.S. Quantitative Measurement and Analysis of Powder Holdups in a Packed Bed in the Presence of Internal Blocks and Raceway. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2023, 54, 2694–2711. [Google Scholar] [CrossRef]

- Natsui, S.; Hirai, A.; Terui, K.; Miki, Y.; Nogami, H. Method for simulating gas permeability of a coke bed including fines based on 3d imaging on the coke particle morphology. ISIJ Int. 2021, 61, 1814–1825. [Google Scholar] [CrossRef]

- Kamble, S.; Lakshminarasimha, S.; Maurya, A.; Gupta, G.S. Validation of Pressure Drop in Gas–Fine Flow in a Packed Bed with Various Types of Injection System (Lateral and Bottom). Trans. Indian Inst. Met. 2020, 73, 2081–2087. [Google Scholar] [CrossRef]

- Panic, B. 3D model studies on the effect of bed and powder type upon radial static pressure and powder distribution in metallurgical shaft furnaces. Arch. Metall. Mater. 2017, 62, 1449–1452. [Google Scholar] [CrossRef][Green Version]

- Panic, B. Influence of the bed type on the flow resistance change during the two-phase (gas + powder) flow through the descending packed bed. Arch. Metall. Mater. 2014, 59, 795–800. [Google Scholar] [CrossRef]

- Ghosh, S.; Viswanathan, N.N.; Ballal, B. Flow Phenomena in the Dripping Zone of Blast Furnace—A Review. Steel Res. Int. 2017, 88, 1–25. [Google Scholar] [CrossRef]

- Panic, B. 3D model study of radial distribution of powder holdup in the descending packed bed of metallurgical shaft furnaces. Arch. Metall. Mater. 2018, 63, 999–1002. [Google Scholar] [CrossRef]

- Dong, X.F.; Jayasekara, A.; Sert, D.; Pinson, D.; Zulli, P. Numerical Investigation of Slag Flow Through a Coke Funnel Analog and Packed Bed. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2021, 52, 2926–2938. [Google Scholar] [CrossRef]

- Gadi, V.A.A.; Gupta, G.S. Discrete Liquid Flow Behavior in a 2D Random Packed Bed. ISIJ Int. 2023, 63, 810–821. [Google Scholar] [CrossRef]

- Chaitanya, G.V.A.; Gupta, G.S. Gas-Liquid-Particle Interaction in the Lower Part of the Blast Furnace. Trans. Indian Inst. Met. 2023. [Google Scholar] [CrossRef]

- Dong, X.F.; Jayasekara, A.; Sert, D.; Monaghan, B.J.; Zulli, P. Numerical Investigation of Gas and Slag Flow in the Packed Bed. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2024, 55, 1303–1317. [Google Scholar] [CrossRef]

- Lakshminarasimha, S.; Bosco, F.S.; Gupta, G.S. Quantification of powder phase transient accumulation behaviour in gas-powder-liquid flow through a packed bed with the cohesive zone of a blast furnace. Chem. Eng. Res. Des. 2024, 202, 49–59. [Google Scholar] [CrossRef]

- Tan, F.; He, Z.; Jin, S.; Pan, L.; Li, Y.; Li, B. Physical Modeling Evaluation on Refining Effects of Ladle with Different Purging Plug Designs. Steel Res. Int. 2020, 91, 1900606. [Google Scholar] [CrossRef]

- Jardón-Pérez, L.E.; González-Rivera, C.; Ramirez-Argaez, M.A.; Dutta, A. Numerical Modeling of Equal and Dierentiated Gas Injection in Ladles: Effect on Mixing Time and Slag Eye. Processes 2020, 8, 917. [Google Scholar] [CrossRef]

- Lakkum, S.; Kowitwarangkul, P. Numerical Investigations on the Effect of Gas Flow Rate in the Gas Stirred Ladle with Dual Plugs. Mater. Sci. Eng. 2019, 526, 012028. [Google Scholar] [CrossRef]

- Lakkum, S.; Ninpetch, P.; Phophichit, N.; Kowitwarangkul, P. Numerical and Physical Investigations of the Mixing Process in Gas Stirred Lade System. Appl. Sci. Eng. Prog. 2021, 14, 447–459. [Google Scholar]

- Luz, A.P.; Tomba Martinez, A.G.; López, F.; Bonadia, P.; Pandolfelli, V.C. Slag foaming practice in the steelmaking process. Ceram. Int. 2018, 44, 8727–8741. [Google Scholar] [CrossRef]

- Michalek, K.; Gryc, K.; Socha, L.; Tkadlecková, M.; Saternus, M.; Pieprzyca, J.; Merder, T.; Pindor, L. Study of tundish slag entrainment using physical modelling. Arch. Metall. Mater. 2016, 61, 257–260. [Google Scholar] [CrossRef]

- Merder, T. Effect of casting flow rate on steel flow phenomena in tundish. Metalurgija 2013, 52, 161–164. [Google Scholar]

- Wang, X.-Y.; Zhao, D.-T.; Qio, S.T.; Zou, Z.-S. Effect of tunnel filters on flow characteristics in an eight-strand tundish. ISIJ Int. 2017, 57, 1990. [Google Scholar] [CrossRef]

- Gupta, V.K.; Jha, P.K.; Jain, P.K. Numerical investigation on gas bubbling assisted inclusion transport and removal in multistrand tundish. Metal. Mater. Int. 2022, 28, 2146–2165. [Google Scholar] [CrossRef]

| Modeling Fluid | Slag (Blast Furnace) 1500–1800 °C, [6] | |

|---|---|---|

| , m | 0.008 | 0.03–0.04 |

| , m/s | 0.002–0.004 | 0.008–0.012 |

| , kg/m3 | 1400–1490 | 2300–2600 |

| , Pa·s | 0.1–0.47 | 0.8–1.2 |

| , N/m | 0.0322–0.0393 | 0.43–0.47 |

| Shape coef. of the bed particles −φ, - | 1 | 0.5–0.6 |

| Coef. of free space of bed −ε, - | 0.38 | 0.4 |

| Reynolds number , - | 0.047–0.47 | 0.23–0.936 |

| Capillary number , - | 22–29 | 10–34 |

| Galileo number , - | 44–1115 | 121–1432 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panic, B. Model Studies of Flow through a Packed Bed of Liquids of Various Viscosities. Proceedings 2024, 108, 7. https://doi.org/10.3390/proceedings2024108007

Panic B. Model Studies of Flow through a Packed Bed of Liquids of Various Viscosities. Proceedings. 2024; 108(1):7. https://doi.org/10.3390/proceedings2024108007

Chicago/Turabian StylePanic, Bogdan. 2024. "Model Studies of Flow through a Packed Bed of Liquids of Various Viscosities" Proceedings 108, no. 1: 7. https://doi.org/10.3390/proceedings2024108007

APA StylePanic, B. (2024). Model Studies of Flow through a Packed Bed of Liquids of Various Viscosities. Proceedings, 108(1), 7. https://doi.org/10.3390/proceedings2024108007