1. Introduction

The basic secondary processing procedure is the process of blowing liquid steel with inert gasses. Despite the simple technique involved, the hydrodynamic phenomena occurring in liquid metal are very complex in nature. Therefore, they have been the subject of many studies, as evidenced by the literature [,,]. The purpose of the process is to accelerate the outflow of non-metallic inclusions from the volume of liquid steel and promote their effective transport to the slag phase. Liquid steel is also blown with inert gasses to homogenize it, both in terms of chemical composition and temperature [,]. The effectiveness of the process mainly depends on the conditions present for the formation of a hydrodynamic structure in the volume of liquid steel as a result of the influence of the injected gas stream, the design of the porous plug shape, the materials used for its construction, and the location of the shape at the bottom of the steel ladle [,,]. The above-mentioned factors directly affect the formation and nature of the gas column and, consequently, the movement of liquid steel in the steel ladle [,]. It is assumed that, in order to obtain the required effectiveness of the process, gas bubbles flowing from the surface of the porous gas should be as fragmented as possible. The gas column should, therefore, contain as many gas bubbles of very small sizes as possible. This is also important from the point of view of the impact of the gas column on the metal–slag interface and the formation of the slag eye [,].

Modern solutions designed for porous plugs are characterized by a high complexity to meet the above functionalities [,]. Many years of practice and continuous advancements in fields such as materials engineering, materials shaping technologies, fluid mechanics research methodology, etc., have resulted in achieving such a high level of advancement that further increasing their effectiveness in its current form is difficult and ineffective [,,]. Most often, this concerns certain details resulting from the needs of specific producers of high-quality and special-purpose steel. The solution to this problem may be to change the design of the porous plug so that it occupies a larger area of the bottom of the steel ladle (active surface of the plug) than before and, consequently, is a source of a larger number of very small inert gas bubbles while the degree of its consumption is maintained. One such innovative solution is the proposed design of a slot-type module (KS diffuser) [,]. The design concept of the module is fundamentally different from the one used so far. In principle, it is easy to install in the bottom of the ladle due to its cube-like shape. It does not require replacement during the ladle campaign, has a large active surface with a series of slots of specified width, and generates a large number of finely divided gas bubbles, which are conducive to achieving a high degree of dispersion in liquid steel [,]. The presented test results are intended to confirm the functionality of the proposed design solution of the KS diffuser compared to the previously used slot-type porous plug [,]. The confirmation of the validity of the adopted assumptions in new technological solutions not previously used in production conditions is most often obtained through model tests. Physical and numerical modeling are commonly used research tools in a very wide range of metallurgical processes, from the blast furnace [,,,,], through steelmaking processes [,,], and to continuous steel casting [,,,].

The research carried out was a part of the ongoing project “Development of a new technology for deep refining of steel in the process of secondary treatment and casting in a tundish enabling an increase in the degree of steel purity”—no. 1/POIR/08/2018 beneficiary Cognor SA Ferrostal Łabędy Gliwice.

A commonly used research tool to solve similar problems is water-based physical modeling, which allows for the identification of the mechanism of formation and the evolution of the hydrodynamic conditions that prevail in liquid steel as a result of the impact of the blown gas stream.

2. Subject of the Research and the Research Methodology

Laboratory tests were carried out using a water model of a steel ladle made in accordance with the requirements of the similarity theory on a linear reducing scale of SL = 1:3.4. To build the model, an industrial steel ladle with a nominal capacity of 65 t was used as a real object [].

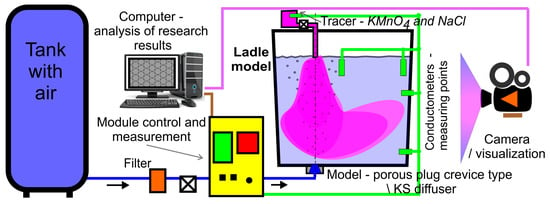

The steel ladle model was equipped with appropriately prepared models of the porous plug and the KS diffuser, also made on a linear scale of SL = 1:3.4. These models were placed on the radius of the bottom of the ladle at a distance of 2/3 of its length from its axis. The gas flow was regulated using a precise regulator system equipped with an additional rotameter. A special system was designed to inject the required portion of the tracer. The system has been designed in such a way that it is possible to introduce the tracer into the model liquid along with the stream of injected gas. Figure 1 shows a diagram of the test stand.

Figure 1.

Schematic diagram of the test stand—water model of the ladle, → means the flow of air.

The modified Froude criterion [,] was adopted as the dominant criterion of dynamic similarity. The research analyzed two of inert gas flow rates—3.7 dm3/min (in the industry this value is 200 dm3/min) and 4.2 dm3/min (in the industry this value is 225 dm3/min).

The porous plug used in the existing technology was characterized by 12 slots, while the KS diffuser has 8 of them.

The active surface of the diffuser resembles a traditional slotted shape, but the slots are arranged in a rectangular shape, not as in traditional circular shapes. Additionally, it does not have steel armor and does not require shell fitting for installation. The module is covered by patent no. PL 229475 [].

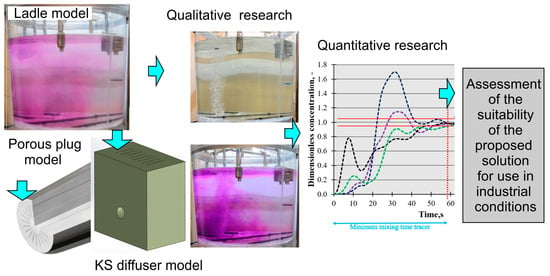

Due to the results obtained, the research was carried out using a water model of a steel ladle was of a double nature—qualitative and quantitative. The result of the qualitative research was the visualization of the process of mixing the model liquid and, based on it, the assessment of the mechanism of formation of a cone of gas bubbles (gas column). During these tests, the degree of gas dispersion in the model liquid was also determined. As a result of quantitative tests, RTD mixing curves and, based on them, the minimum values for the mixing time were determined. The minimum mixing time was adopted as a criterion for assessing the ability of the tested system to homogenize the model liquid. Figure 2 shows a schematic diagram of the research program.

Figure 2.

Schematic diagram of the test stand—water model of the ladle.

3. Preliminary Results and Discussion

Based on the results of the model tests, it was found that the newly designed solution for the KS diffuser meets the assumed requirements. During the visualization of the gas column formation process, we observed a favorable phenomenon: a large number of small gas bubbles detached from the diffuser surface and flowed steadily towards the model liquid mirror. The growth of bubbles along their flow path was relatively small. This mechanism of gas column formation predicts an increased refining capacity when using the KS diffuser compared to the previous solution, where bubbles tended to merge into larger conglomerates and flow out in a swirling manner.

When using the KS diffuser, an increase in the degree of gas dispersion in the model liquid was also observed compared to a classic porous plug. The consequence of this phenomenon is a larger volume of the mixed gas–liquid phase in the steel ladle model, which favors the process of homogenization of the model liquid in its entire volume. Moreover, this structure of hydrodynamic conditions significantly reduces the possibility of creating dead zones. The increase in the system’s ability to effectively homogenize the model liquid when using the KS diffuser compared to the classic solution was also confirmed by the results of the analysis of the obtained RTD curves. The minimum mixing times determined on their basis were significantly shorter for the KS diffuser than for the porous plug.

To sum up, it should be stated that, based on research conducted using a physical water model of a steel ladle, the proposed innovative design solution for the KS diffuser meets the assumed expectations and may constitute an effective alternative to the previously used solution.

Author Contributions

Conceptualization, T.M., J.P., R.W. and J.W.; methodology, J.P. and T.M.; research T.M., J.P., R.W. and J.W.; validation, J.P. and T.M.; formal analysis, T.M. and M.S.; investigation, T.M., J.P., R.W. and J.W.; resources, R.W., T.M. and J.P.; data curation, R.W. and J.W.; writing—original draft preparation, T.M., J.P. and M.S.; writing—review and editing, T.M., M.S. and J.P.; visualization, J.P. and T.M.; project administration, R.W. and J.P.; funding acquisition, R.W., J.P., J.W. and T.M. All authors have read and agreed to the published version of the manuscript.

Funding

The presented research results are the result of research and development work funded by the National Center for Research and Development, grant number 1/POIR/08/2018 beneficiary Cognor SA Ferrostal Łabędy Gliwice Branch. The article was also supported by funds from work 11/020/BK_24/0129 (Silesian University of Technology).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

Author Robert Wende was and currently is employed by the company Cognor SA Ferrostal Łabędy Gliwice. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The research was funded by the National Center for Research and Develop, while Cognor SA Ferrostal Łabędy Gliwice was the beneficiary.

References

- Lis, T. Metalurgia Stali o Wysokiej Czystości; Silesian University of Technology: Gliwice, Poland, 2009. [Google Scholar]

- Mazumdar, D.; Dhandapani, P.; Sarvanakumar, R. Modeling and optimization of gas stirred ladle systems. ISIJ Int. 2017, 57, 286–295. [Google Scholar] [CrossRef]

- Amaro-Villeda, A.M.; Ramirez-Argaez, M.A.; Conejo, A.N. Effect of slag properties on mixing phenomena in gas-stirred ladles by physical modeling. ISIJ Int. 2014, 54, 1–8. [Google Scholar] [CrossRef]

- Warzecha, M.; Hutny, A.; Warzecha, P.; Kutyła, Z.; Merder, T. Investigations of dual plug argon blowing for efficient mixing at ladle furnace station. Arch. Metall. Mater. 2021, 66, 561–572. [Google Scholar] [CrossRef]

- Chattopadhyay, K.; Sengupta, A.; Ajmani, S.K.; Lenka, S.N.; Singh, V. Optimisation of dual purging location for better mixing in ladle: A water model study. Ironmak. Steelmak. 2009, 36, 537–542. [Google Scholar] [CrossRef]

- Pieprzyca, J.; Merder, T.; Saternus, M.; Gryc, K.; Socha, L. The influence of parameters of argon purging process through ladle on the phenomena occuring in the area of phase distributions: Liquid steel-slag. Arch. Metall. Mater. 2019, 64, 653–685. [Google Scholar] [CrossRef]

- Magnesite Plants ROPCZYCE, S.A. Information Materials (Materials—Iron and Steel Industry) ROPCZYCE S.A. Available online: https://ropczyce.com.pl (accessed on 3 March 2023).

- RHI Magnesita GmbH. Information materials RHI Magnesita GmbH. Available online: https://www.rhimagnesita.com (accessed on 25 March 2023).

- Merder, T.; Warzecha, P.; Pieprzyca, J.; Warzecha, M.; Wende, R.; Hutny, A. Model investigation of argon injection into liquid steel at ladle furnace station with using of innovative module. Materials 2023, 16, 7698. [Google Scholar] [CrossRef] [PubMed]

- Barchuk, Y.; Shcherbak, M. Moduł do Dennego Przedmuchiwania Wytopu Gazami Szlachetnymi. PL Patent 229475, 31 July 2018. [Google Scholar]

- Panic, B. 3D model studies on the effect of bed and powder type upon radial static pressure and powder distribution in metallurgical shaft furnaces. Arch. Metall. Mater. 2017, 62, 1449–1452. [Google Scholar] [CrossRef][Green Version]

- Dong, X.F.; Jayasekara, A.; Sert, D.; Monaghan, B.J.; Zulli, P. Numerical investigation of gas and slag flow in the packed bed. Metall. Mater. Trans. B 2024, 55, 1303–1317. [Google Scholar] [CrossRef]

- Panic, B. 3D model study of radial distribution of powder holdup in the descending packed bed of metallurgical shaft furnaces. Arch. Metall. Mater. 2018, 63, 999–1002. [Google Scholar] [CrossRef]

- Gadi, V.A.; Gupta, G.S. Discrete liquid flow behavior in a 2D random packed bed. ISIJ Int. 2023, 63, 810–821. [Google Scholar] [CrossRef]

- Li, L.; Li, M.; Shao, L.; Li, Q.; Zou, Z. Physical and mathematical modeling of swirling gas jets impinging on a liquid bath using a novel nozzles-twisted lance. Steel Res. Int. 2020, 91, 207–250. [Google Scholar] [CrossRef]

- Tan, F.; He, Z.; Jin, S.; Pan, L.; Li, Y.; Li, B. Physical modeling evaluation on refining effects of ladle with different purging plug designs. Steel Res. Int. 2020, 91, 1900606. [Google Scholar] [CrossRef]

- Peranandhanthan, M.; Mazumdar, D. Modeling of slag eye area in argon stirred ladles. ISIJ Int. 2010, 50, 1622–1631. [Google Scholar] [CrossRef]

- Wang, X.; Wang, S.; Hu, H.; Xie, X.; Wu, C.; Chen, D.; Long, M. Flow behavior of liquid steel in fewer strands casting of six-strand bloom tundish. Metals 2023, 13, 706. [Google Scholar] [CrossRef]

- Michalek, K.; Gryc, K.; Socha, L.; Tkadlecková, M.; Saternus, M.; Pieprzyca, J.; Merder, T.; Pindor, L. Study of tundish slag entrainment using physical modelling. Arch. Metall. Mater. 2016, 61, 257–260. [Google Scholar] [CrossRef]

- Bulko, B.; Molnár, M.; Demeter, P.; Baricová, D.; Pribulová, A.; Futáš, P. Study of the influence of intermix conditions on steel cleanliness. Metals 2018, 8, 852. [Google Scholar] [CrossRef]

- Bulko, B.; Molnár, M.; Demeter, P. Physical modeling of different configurations of a tundish for casting grades of steel that must satisfy stringent requirements on quality. Metallurgist 2014, 57, 976–980. [Google Scholar] [CrossRef]

- Michalek, K. The Use of Physical Modeling and Numerical Optimization for Metallurgical Processes; Publishing of the VSB: Ostrawa, Czech Republic, 2001. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).