Development of an Intelligent Cooling Stave as Part of the Cooling System of a Blast Furnace †

1. Introduction

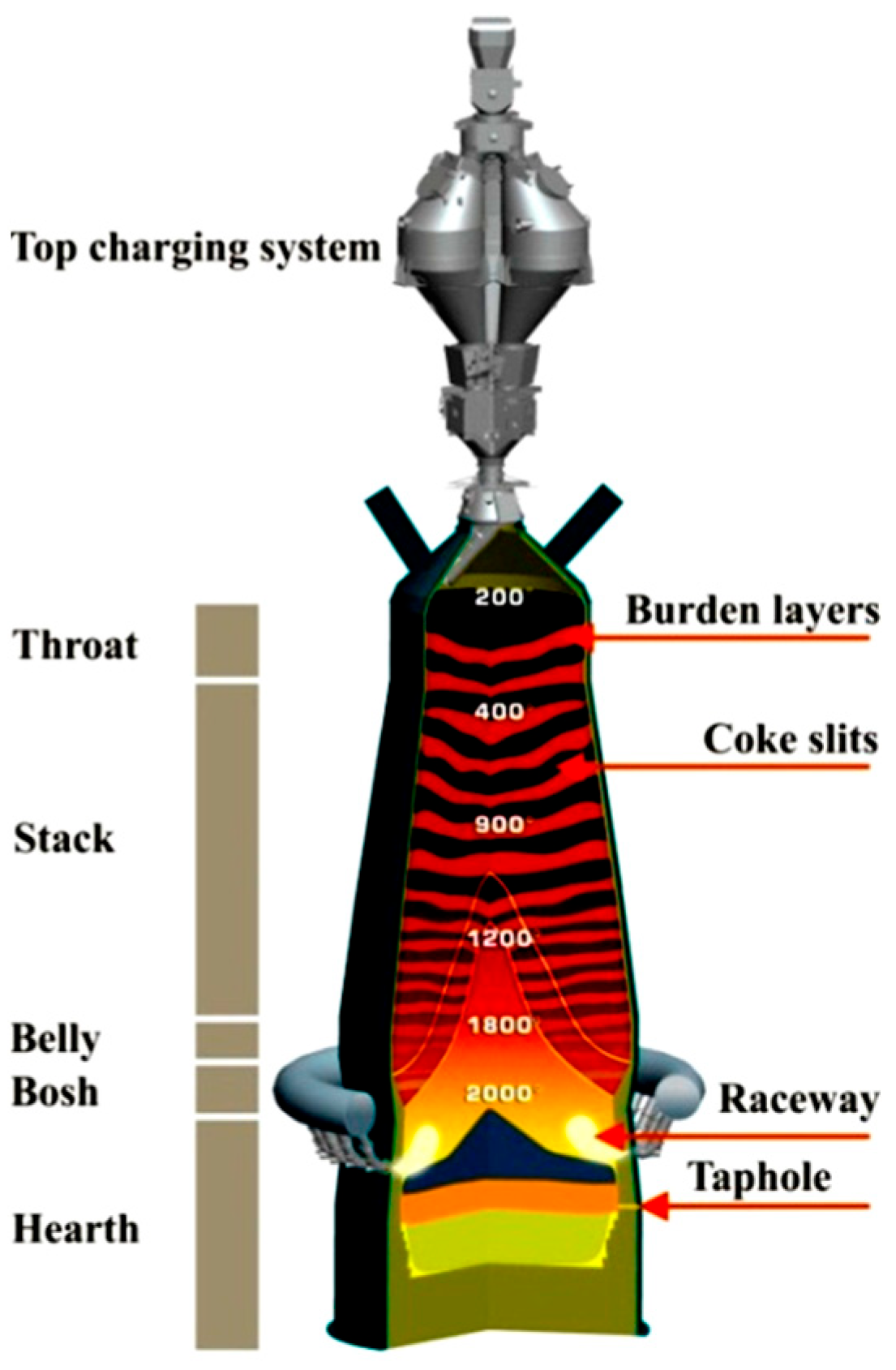

2. Process Description

3. Methodology

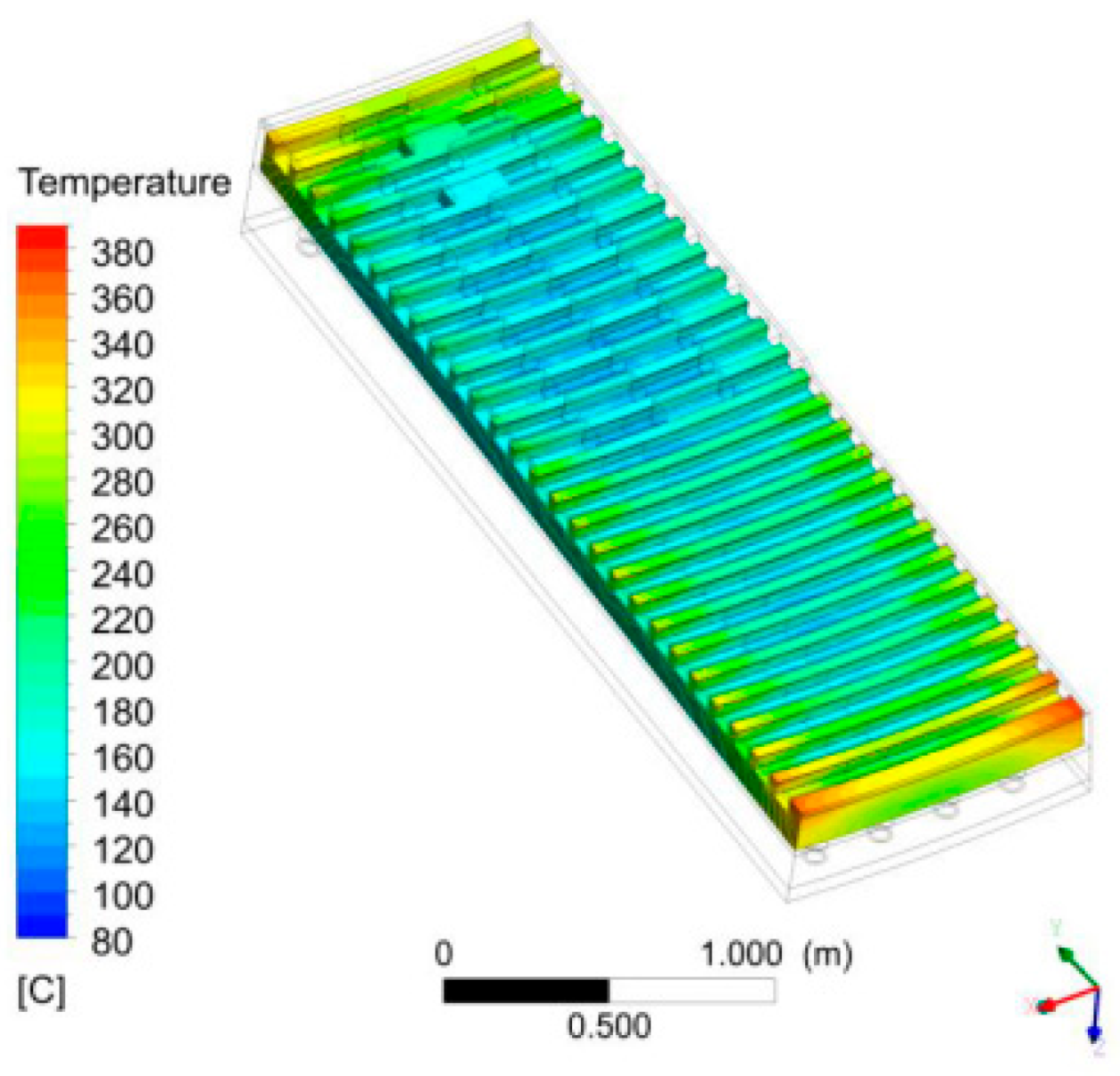

- Identification of the existing state of affairs and development of conceptual assumptions for a new cooling technology for the metallurgical unit: An inventory of the blast furnace cooling system was carried out and historical data on furnace operation were collected. The interconnection topology of the cooling staves was prepared for further computer simulations. Additional sensors were placed on one of the staves to provide verifiable measurement data. A thermal-fluid and strength model of the metallurgical unit cooling stave was also developed.

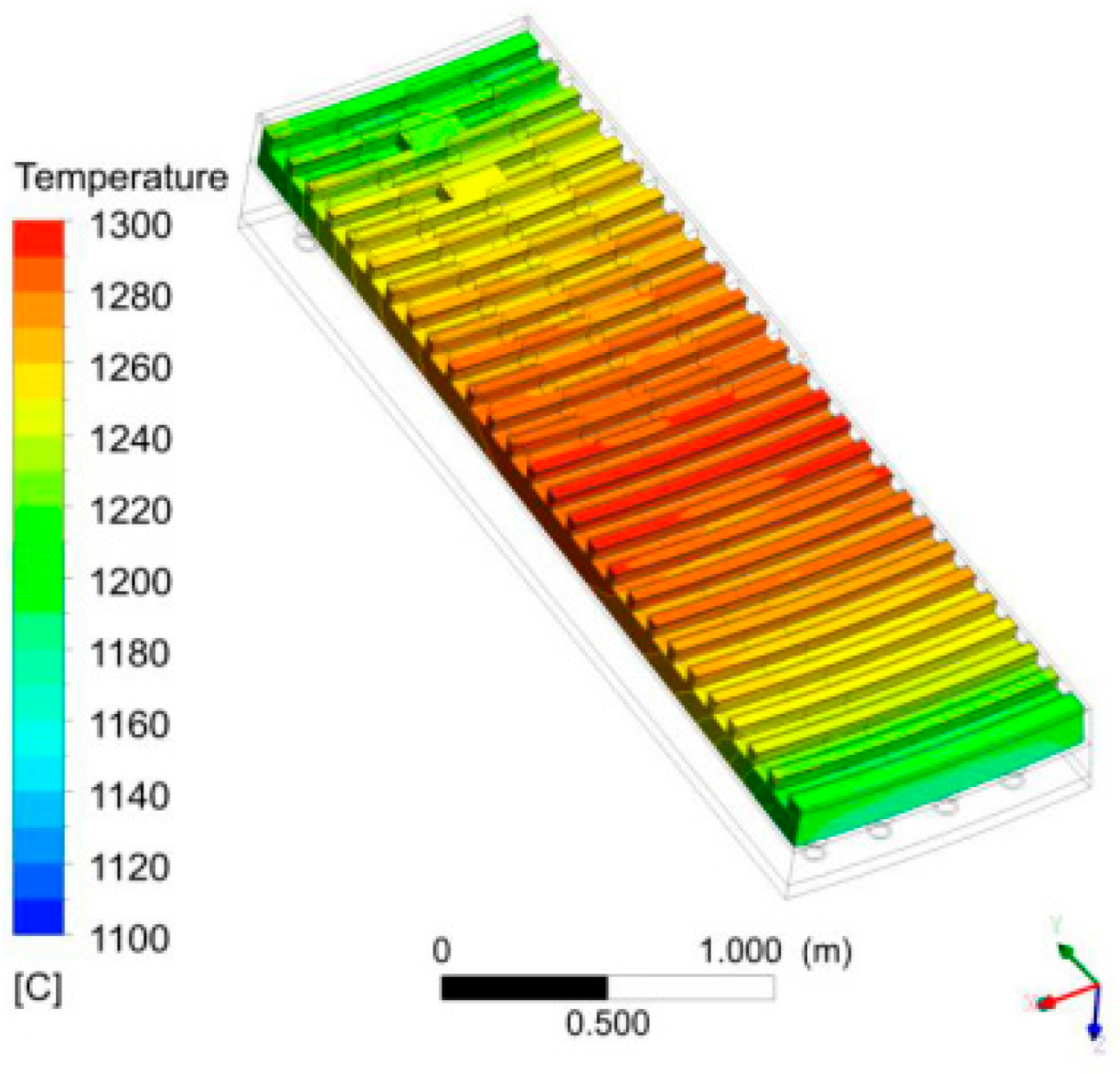

- Development of new technology for the metallurgical unit cooling system: The effect of changing the diameter of the channels in the cooling staves and the cooling water flow rate was investigated. The effect of stopping the flow of cooling water in selected channels on the temperature distribution in the stave and the change in heat flux density was also investigated. In addition, a ‘virtual second layer’ was modelled in the case of a copper stave to check the effect of adding an additional layer behind the main cooling channels on the temperature distribution in the stave. A numerical coupled thermal-strength model was developed for a copper cooling stave to estimate the stress levels resulting from the resulting temperature distributions.

- Preparation of the technological design, verification, construction, and commissioning of the demonstration plant: As part of this phase, recommendations and design guidelines were developed for the design of the cooling staves. The design of the individual cooling staves was verified in terms of the achieved quality parameters of the cooling system. Various solutions for connecting the cooling system using individual cooling staves were analyzed.

- Demonstration plant testing and optimization: Phase 4 analyzed data from the operation of the blast furnace cooling system. The data analyzed were the temperatures and flow rates of the cooling water and the temperatures of the staves. The averaged values of the measured data were compared with the simulation results for the new cooling system. Analyses were also carried out to establish correlations between the technical parameters. Current and proposed furnace operating points were analyzed. As a result of the analyses, new process guidelines were prepared.

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dobrzański, L.A.; Gawron, M.; Berliński, M. The use of artificial neural networks for the prediction of a chemical composition of hot metal produced in blast furnace. J. Achiev. Mater. Manuf. Eng. 2014, 67, 32–38. [Google Scholar]

- Burgo, J.A. The Manufacture of Pig Iron in the Blast Furnace. In The Making, Shaping and Treating of Steel, 11th ed.; Wakelin, D.H., Ed.; AIST: Warrendale, PA, USA, 1999; pp. 699–740. [Google Scholar]

- Geerdes, M.; Toxopeus, H.; van der Vliet, C. Modern Blast Furnace Ironmaking; IOS Press: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Król, L. Blast Furnace, Onstruction and Equipment; Silesian University of Technology Press: Gliwice, Poland, 1989. [Google Scholar]

| No | Stave Operating Conditions | Heat Flux Density | Thermocouple Temperature | ∆T Water Temperature in Channel |

|---|---|---|---|---|

| 1 | 2/4 working cooling channel | 62 kW/m2 | 167.6 °C | 9.98 °C |

| 2 | 2/4 working cooling channel + second cooling layer | 65 kW/m2 | 120.8 °C | 5.76 °C |

| 3 | 0/4 working channel | 7 kW/m2 | 1277.3 °C | - |

| 4 | 0/4 working channel + second cooling layer | 61 kW/m2 | 164.3 °C | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berlinski, M.; Grzybowska, A. Development of an Intelligent Cooling Stave as Part of the Cooling System of a Blast Furnace. Proceedings 2024, 108, 13. https://doi.org/10.3390/proceedings2024108013

Berlinski M, Grzybowska A. Development of an Intelligent Cooling Stave as Part of the Cooling System of a Blast Furnace. Proceedings. 2024; 108(1):13. https://doi.org/10.3390/proceedings2024108013

Chicago/Turabian StyleBerlinski, Marek, and Agata Grzybowska. 2024. "Development of an Intelligent Cooling Stave as Part of the Cooling System of a Blast Furnace" Proceedings 108, no. 1: 13. https://doi.org/10.3390/proceedings2024108013

APA StyleBerlinski, M., & Grzybowska, A. (2024). Development of an Intelligent Cooling Stave as Part of the Cooling System of a Blast Furnace. Proceedings, 108(1), 13. https://doi.org/10.3390/proceedings2024108013