1. Introduction

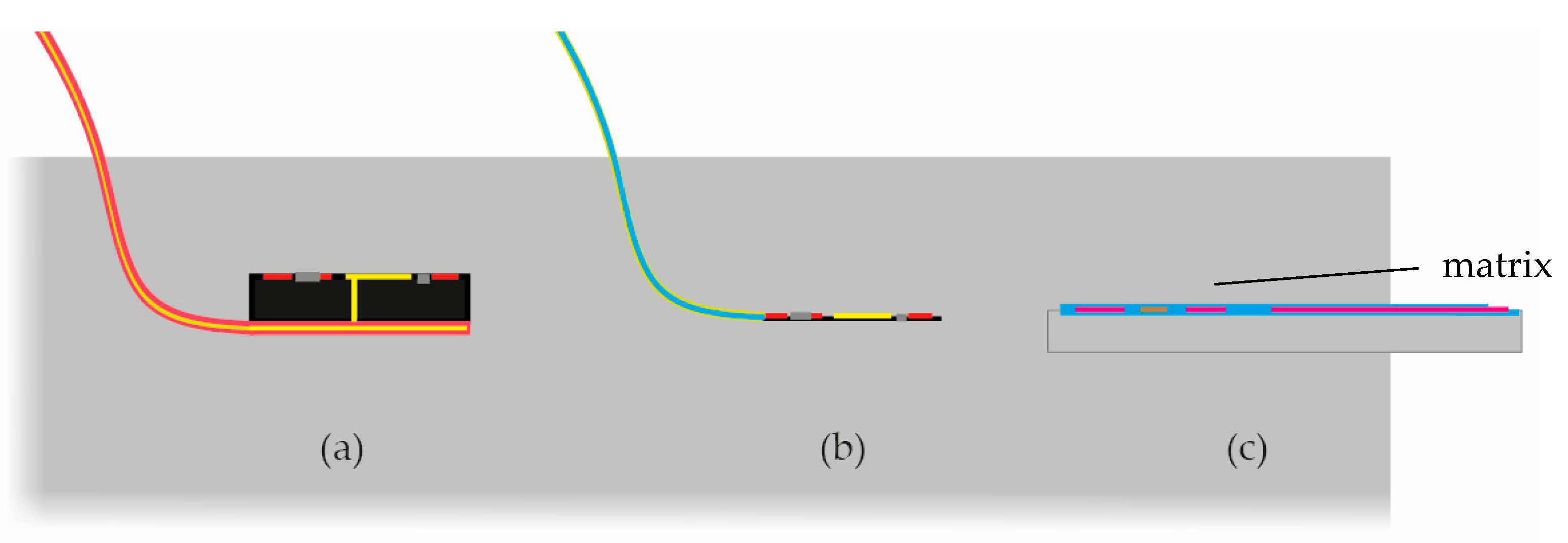

There is strong trend in getting physical measurement quantities, like strain or temperature, out of a material. This data is used to characterize production processes for example, or they are the basis for structural health monitoring systems. Most of the sensors are based on simple and well-known measurement principles like strain gauges, thermocouples, thermoresistive structures or piezoelectric ceramics. So far two different technology approaches have been used to integrate sensors in a material: PCB (Printed Circuit Board) technology and thin film technology. Both are exemplarily shown in

Figure 1a,b where a sensor is brought into a matrix (material). In case of PCB technology, a sensor chip is mounted on a flexible or rigid board. To power the sensor and to send data out of the material, a cable or the flex board itself is leading out of the material. The characteristic size of such systems is a few hundred microns up to a few millimeters. One example is a sensor integrated in concrete [

1,

2], another example is piezoelectric transducer integrated in aluminum [

3,

4]. With this technology approach, sensors can be integrated in materials. The parts are relatively large and a relatively large amount of different materials are brought into the matrix. Regardless of whether the sensor material and the materials for the interconnections are either more flexible or more rigid than the matrix, it will affect the structural behavior of the matrix. This has been discussed by the authors in [

5] and is called the foreign body effect. In addition to a mechanical foreign body effect, a mismatch in the coefficient of thermal expansion or a mismatch in the thermal conductivity can have a huge impact on the matrix, especially when relatively large sensor and interconnects are used.

To reduce this foreign body effect and integrate sensors in minimal invasive way, a second approach is the use of thin film technology. Sensor structures are fabricated on thin foils on wafer level. One example is an interdigital structure on 5 µm thick polyimide foil to monitor the curing of carbon fiber reinforced plastics [

6]. The characteristic size of such systems is less than 10 µm. The goal is to make sensors as tiny as possible, to bring them down to size of natural material inhomogeneity such as fiber bundles or trapped air. Since those tiny minimal invasive foil sensors work very well, the problem of a simple and minimal invasive interconnection technology has not been focused yet.

Our paper focuses on a new approach: Printed sensors for material integrated sensing. Sensors and the electrical interconnects are printed on semi-finished parts. Those functionalized parts are further processed to get smart components as shown in

Figure 1c. In this case, interconnection is relatively simply done by printing technology. However, other challenges occur which are discussed in the next section.

2. Printed Sensors for Material Integrated Sensing

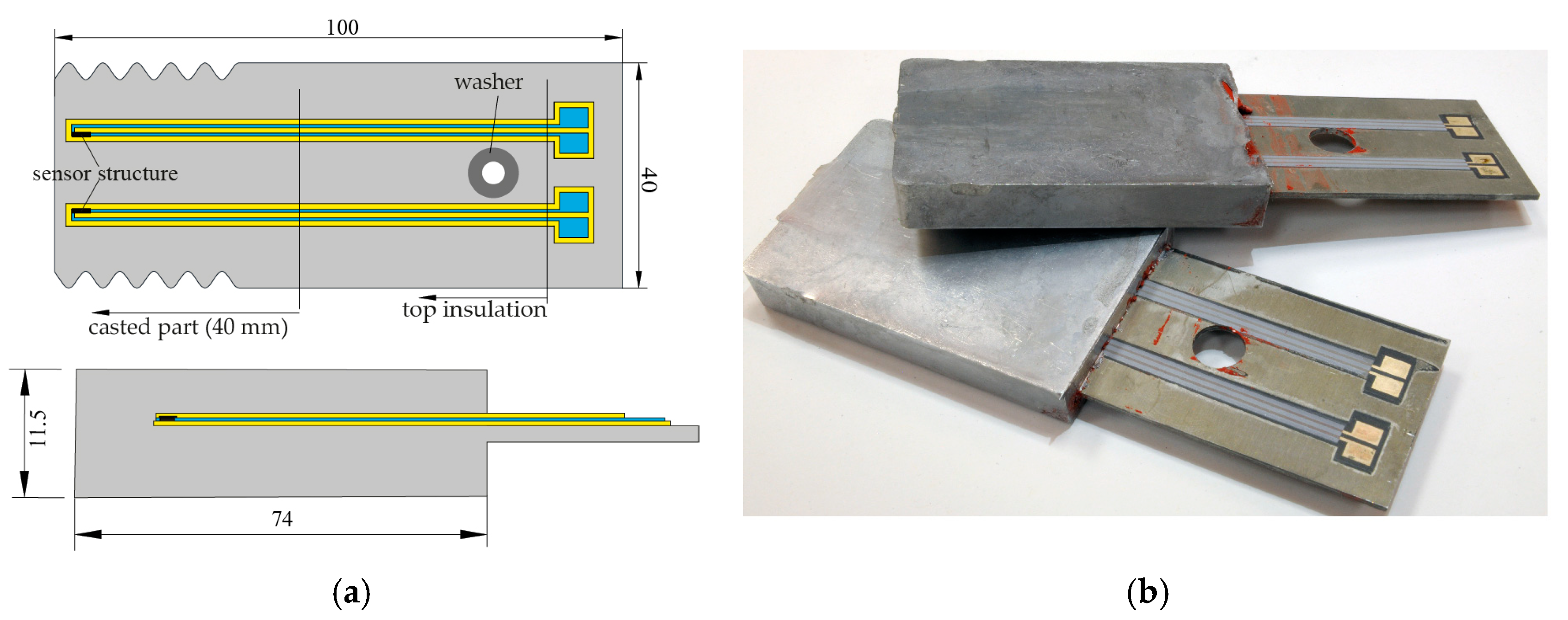

The idea to functionalize semi-finished parts by printing sensors on them, is shown in

Figure 2. A sensor structure, made of conductive, semi conductive or insulating materials, is printed on a semi-finished part by e.g., screen printing, inkjet or roll to roll process. The semi-finished part could be a woven fabric as shown in

Figure 2a, a metallic sheet (see

Figure 2b) or any other material. After printing process, the semi-finished part is brought into the fabrication process of the final part. In comparison to thin film technology, the sensor structure and the interconnections are built up by printing process. No further cables or any other connection technology, which has to withstand the process of integration, are necessary. The semi-finished part is designed and integrated in a way that the electrical contacts lead to the outer edge of the final part. And since the process of building up the sensor is already adapted to the boundary conditions of the final integration process (e.g., thermal stress or thermal budget), the interconnections are optimized too.

Two different approaches of printed and integrated sensors are shown in

Figure 3 and

Figure 4. The first example is a strain gauge printed on carbon weave and integrated in CFRP (carbon fiber reinforced plastics) [

7] as seen in

Figure 3. Therefore, the carbon weave is partially insulated and the sensor structures are printed on the carbon weave (similar to the process shown in

Figure 2a). The “smart” woven fabric is then handled as a common woven fabric and integrated in a standard CFRP process. A second example is a resistive structure printed on an aluminum sheet [

8], as shown in

Figure 4. The sensor can be used as either a strain gauge or a thermoresistive temperature sensor. The “smart” aluminum sheet is integrated in a casting process. In both cases, aluminum and CFRP, the interconnections are printed. No further materials for packaging or cables are necessary. And in both cases the materials for the interconnections are already adapted to the process of integration.

If we compare printing technology with thin film technology, printing process is cheap, quickly adaptable, and up scaling to large structures is easy. No cleanroom technology is necessary and the sensors can be directly built up on the matrix material. In comparison to PCB technology, printing on semi-finished parts and integrating them is expected to be less invasive, because the characteristic length of such sensors is in the range of a few 10 µm.

However, the mechanical coupling between the semi-finished part, the sensor structures and the matrix is one of the most challenging things. If we get back to the examples shown in

Figure 3, the coupling of the carbon weave is expected to be good. During fabrication of the final part, the fibers of the “smart” carbon weave merge with the resin of the matrix. In case of the “smart” aluminum sheet in

Figure 4, the native oxide prevents a substance-to-substance bond, leading to a friction-locked connection. Getting a substance-to-substance bond between sheet and matrix is, so far, the most challenging thing from the view of the casting technology. Furthermore, there might be a risk of crack formation at the point, where interconnects lead out of the part. During long-term mechanical or thermal load, crack propagation might start from this point, leading to a failure of the part.

There is also a need of new materials like inks and pastes. So far, most inks are based on carbon or silver. Printable metals or metal alloys, especially polymer based pastes/inks for low temperature curing, are rarely found. Furthermore, new materials might be focused to print insulating materials for sensors integrated in casted iron.

3. Conclusions and Outlook

We have presented a new technology approach to integrate sensors in a material. Sensors are printed on semi-finished parts and then further processed to get “smart” components. With printing technology, the problem of interconnection technology is relatively simple, because they are printed in parallel with the sensor structures. Two examples, a smart woven fabric and a smart aluminum sheet, have been presented. We have shown that the approach of printing technology can be used to integrate sensors in a material. Advantages and challenges have been focused. One of the main challenges in the functionalization of semi-finished parts is the mechanical coupling at the interfaces of the semi-finished part and the matrix.

To reach the goal of a broad range of printed sensors for material integrated sensing, there is a need of design rules and material selection. Further investigations must focus on this. Tests on the mechanical coupling at the interfaces should be done. Besides this, new materials for printing conductive sensor structures and insulating materials must be developed.