Abstract

We report an energy-autonomous Radio Frequency IDentification (RFID) tag system which is powered by an electrostatic MEMS-based Vibration Energy Harvester (e-VEH). The VEH is designed specifically for the vibrations of low frequency around 10 Hz. An energy of 80 nJ/cycle can be delivered when the VEH is loaded with an optimal resistor and a bias of 20 V. An RFID chip is powered by the current released from a 1-μF capacitor, which is charged by the VEH through a diode rectifier. The read range of the tag is increased from 2.5 m (under batteryless mode) to 15 m when powered by the VEH working with an acceleration of 2 grms and 10 Hz. The energy of the VEH stored in the capacitor within 40 s can sustain up to 3 tag readings.

1. Introduction

Low frequency vibration energy widely exists in the environment, thus VEHs are probable energy sources for powering RFID tags. However, the power available in these vibrations are confined by their frequency, thus it is still challenging to extract sufficient power for practical applications. In order to maximize the efficiency of power transition, a variety of techniques regarding both the mechanical and electrical behaviors are introduced in the VEHs, including frequency up-conversion technique [1], impedance matching [2], and adaptive conditioning technique [3].

In this paper, we propose a full semi-passive RFID system assisted by a MEMS-based capacitive VEH, providing a communication distance larger than that of passive RFID tags [4]. The VEH has a frequency up-conversion mechanism and a wideband feature, and the scavenged energy are stored temporarily in a reservoir capacitor through a passive AC-DC conditioning circuit and powers RFID communications through a switch module. The system is thus self-sustainable as long as the environmental vibrations are available.

2. System Description

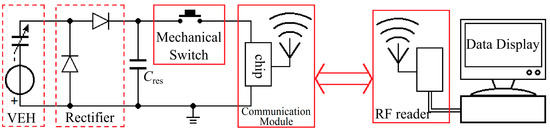

The schematic of the RFID system is shown in Figure 1, where a VEH delivers energy to the reservoir capacitor Cres through a half-wave diode rectifier. The energy stored in Cres is released by manually pressing a tact switch each time when Vres reaches 3.3 V. Then the communication module is ready to be read by a remote RF reader. Each RFID communication is conducted within about 40 ms [5]. After a couple of tag readings, Vres drops to 1.1 V, after which the RFID chip is unavailable for further communications. Then the switch is turned off and the charging of Cres is restarted. The mechanical switch can also be replaced by automatic switches that where switching events are triggered by its input voltage as shown in [6].

Figure 1.

Schematic of the proposed VEH-assisted RFID system read by a distant RF reader (up to 15 m apart).

3. Functional Modules

3.1. Power Supply Module

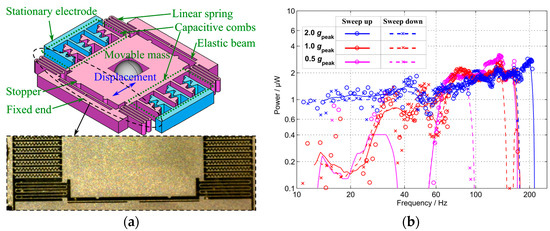

The schematic of the VEH is shown in Figure 2a. It is developed from a previous MEMS design with a frequency up-conversion structure [7]. The VEH is based on a single layer silicon, containing 3 electrodes. Among them, two electrodes are stationary, while the central electrode contains a movable mass with linear springs connecting to fixed ends. Along the sides of the VEH, the stationary electrodes and the central electrode form interdigited variable capacitors. Here a comb-teeth hierarchical comb structure is introduced so as to obtain less significant thin-film air damping effect during vibration than that of a classical gap-closing comb structure [8]. The new comb geometry is advantageous in reducing air damping probably due to a reduced approaching and separating velocity of electrode surfaces. The movable mass holds a tungsten ball in the center, which enables the oscillation of the movable electrode through impact. The excitation frequency of the VEH is thus expanded towards low frequency down to 10 Hz.

Figure 2.

The power supply module: (a) Simplified schematic and microscopic photograph of the MEMS-based VEH working as the power supply; (b) Transduced power of the VEH with frequency sweeps in air, working with the optimal load resistor R = 6.6 MΩ and a bias voltage of 20 V.

The output power of the VEH vs. frequency with the optimal load of 6.6 MΩ is shown in Figure 2b, where the bias voltage across the VEH is 20 V [7]. The energy conversion capability is greatly improved by the ball especially in low-frequency range. A frequency up-conversion behavior can be clearly observed. The transduced power reaches about 0.8 μW with the acceleration of 2 gpeak at 10 Hz, corresponding to an energy of 80 nJ per period of excitation.

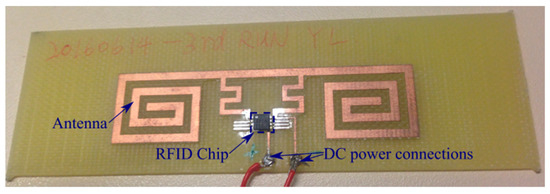

3.2. RFID Communication Module

The RFID communication module consists of a RFID chip and a dedicated wideband antenna. The RFID chip used is EM4324 provided by EM Microelectronic. The wideband antenna is based on a dipole with matching structures, and is designed through FEM analysis so as to reach the resonance around 868 MHz and to achieve a preferable impedance matching. The photograph of the communication module is shown in Figure 3. The RFID chip is biased by the DC voltage across the capacitor Cres, under the control of the mechanic switch.

Figure 3.

Photograph of the RFID communication module.

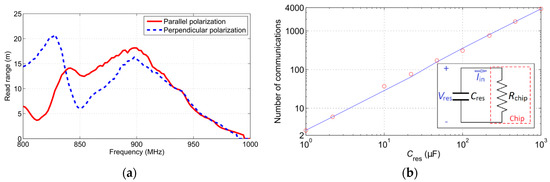

In order to test the communication module separately, we firstly bias the RFID chip with a constant DC voltage of 3.3 V, and the read ranges (maximum reading distances) of the RFID tag with different polarizations are measured with Tagformance reader provided by Voyantic. The result is shown in Figure 4a, where the maximum read range for the parallel polarization of 15 m is reached at 868 MHz.

Figure 4.

Performance of the RFID communication module: (a) Maximum read range of the RFID tag powered by a 3.3 V battery; (b) Number of communications of the RFID module that can be supported by capacitors with different values.

The RFID chip is then powered by pre-charged capacitors Cres of different values, and the number of tag readings supported by different capacitors are measured by an Impinj reader, as shown in Figure 4b. The tag is located beyond the distance where passive tag readings can be proceeded, while the reader is set at a continuous reading mode. The tag communications start right after Cres is charged to the maximum feasible voltage (Vres = 3.3 V), and are proceeded repeatedly until the RFID tag is unavailable to the reader (when Vres is below 1.1 V). The number of communications is proportional to the value of Cres. With a capacitor of 1 μF, up to 3 tag readings can be supported.

4. Systematic Performance

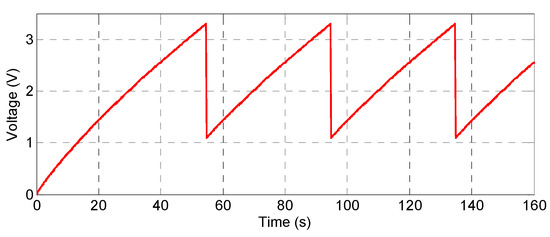

Shown in Figure 5 is the evolution of voltage on Cres = 1 μF during the charging and communication process. The VEH is biased at 20 V, and is excited @10 Hz, 2 gpeak. The initial charging takes 54 s, corresponding to an average energy of 10 nJ/cycle. While each following charging process takes 40 s, the average energy of which is 13.6 nJ/cycle. There is still a large margin of energy available from the VEH if its power with frequency sweeps are considered. The loss of available energy is majorly caused by the impedance and voltage mismatch on the conditioning circuit, and by the voltage drop on the diodes.

Figure 5.

Voltage evolution on the capacitor Cres during charging and communication processes, with the VEH working at 10 Hz, 2 gpeak with an external bias of 20 V.

5. Conclusions

In this paper we have introduced a fully energy-autonomous RFID tag that can be read by a remote reader intermittently. The system consists of a power supply module, an interface circuit, and a communication module. The power supply module contains a low-frequency electrostatic VEH. The VEH is featured with frequency up-conversion behavior, so its energy conversion efficiency is high at low frequency. It offers a power of 0.8 μW to a resistive load when excited at 10 Hz, 2 gpeak. The communication module contains a commercial RFID chip and a dedicated antenna. The read range of the communication module is increased from 2.5 m (under batteryless mode) to 15 m, and the average energy consumption of each communication is measured (about 1.8 μJ). While the interface circuit is composed of a half-wave rectifier loaded by a storage capacitor and a switch. The energy is released from the capacitor when the voltage across it reaches the maximum feasible voltage of the RFID chip 3.3 V. When the VEH is excited by the acceleration of 2 gpeak at 10 Hz, the waiting time between one series of tag readings and another is about 40 s.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kulah, H.; Najafi, K. Energy scavenging from low-frequency vibrations by using frequency up-conversion for wireless sensor applications. IEEE Sens. J. 2008, 8, 261–268. [Google Scholar] [CrossRef]

- Leland, E.S.; Wright, P.K. Resonance tuning of piezoelectric vibration energy scavenging generators using compressive axial preload. Smart Mater. Struct. 2006, 15, 1413–1420. [Google Scholar] [CrossRef]

- Szarka, G.D.; Stark, B.H.; Burrow, S.G. Review of power conditioning for kinetic energy harvesting systems. IEEE Trans. Power Electron. 2012, 27, 803–815. [Google Scholar] [CrossRef]

- Laheurte, J.M. UHF RFID Tags: Design and Technologies; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Lu, Y.; Basset, P.; Laheurte, J.M. Performance Evaluation of a long-range RFID tag powered by a vibration energy harvester. IEEE Antennas Wirel. Prop. Lett. 2017, 16, 1832–1835. [Google Scholar] [CrossRef]

- Lu, Y.; Cottone, F.; Boisseau, S.; Marty, F.; Galayko, D.; Basset, P. Low-frequency and ultra-wideband MEMS electrostatic vibration energy harvester powering an autonomous wireless temperature sensor node. In Proceedings of the 2016 IEEE 29th International Conference on Micro Electro Mechanical Systems (MEMS), Shanghai, China, 24–28 January 2016; pp. 33–36. [Google Scholar]

- Lu, Y.; O’Riordan, E.; Cottone, F.; Boisseau, S.; Galayko, D.; Blokhina, E.; Marty, F.; Basset, P. A batch-fabricated electret-biased wideband MEMS vibration energy harvester with frequency-up conversion behavior powering a UHF wireless sensor node. J. Micromech. Microeng. 2016, 26, 124004. [Google Scholar] [CrossRef]

- Lu, Y.; Marty, F.; Galayko, D.; Basset, P. New comb geometry of capacitive vibration energy harvesters miniaturizing the air damping effect. In Proceedings of the 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems (MEMS), Las Vegas, NV, USA, 22–26 January 2017; pp. 857–860. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).